Numerical Simulation Study on the Influence of Arris-edge Fillet of Spool Valve on Flow Characteristics

WANG Dongwei,YE Zhengmao

School of Mechatronics Engineering,Harbin Institute of Technology,Harbin 150001,China

Numerical Simulation Study on the Influence of Arris-edge Fillet of Spool Valve on Flow Characteristics

WANG Dongwei,YE Zhengmao*

School of Mechatronics Engineering,Harbin Institute of Technology,Harbin 150001,China

The flow characteristic of the spoolvalve affects the performance of the servo valve.U-sing Fluent,this paper discusses the follow ing four cases:the idealspoolvalve,the spool valves with arris-edge fillets of5,8 and 10μm.The effects of different fillets on the valve’s flow characteristics are discussed and a correction formula for the flow coefficient of ideal spoolvalve is proposed by polynomial approximation of the simulation results.

flow characteristics,Fluent,the working arris-edge fillet

1.Introduction

A three-stage electro-hydraulic servo valve is the key component of high power electro-hydraulic servo control systems.Because of its outstanding features such as large capacity,high-frequency response,high resolution and high reliability,etc,three-stage electro-hydraulic servo valves have been widely used in many high-performance apparatus including 6-DOF motion simulators,vibrating tables and load simulators,etc[1-2].Generally,the main valve of a three-stage electro-hydraulic servo valve is a spool valve,and its fluid flow rate is controlled by changing the flow area of the valve port by the relative motion of the valve spool and sleeve[3].

The flow characteristic of the spool valve affects the performance of the servo valve.Actually,the working arris-edge fillet is unavoidable in practical manufacture.The presence of the fillet has great influence on the servo valve flow characteristics. Therefore,this study provides insightful guidance for the manufacture and testing of servo valve[4].

The research on the flow characteristics of spool valve is quite difficult for the following two reasons:①It is difficult to detect a opening of only a few microns in the experiment.②The theoretical formula is derived from the simplified model and thus the formula is not effective in certain circumstances[5]. Numerical simulation can overcome these shortcomings,and it is relatively easy to apply,so this paper studies the effect of the working arris-edge fillet of valve spool on the flow characteristics using Fluent.

2.Theoretical formula of the slide valve flow characteristics

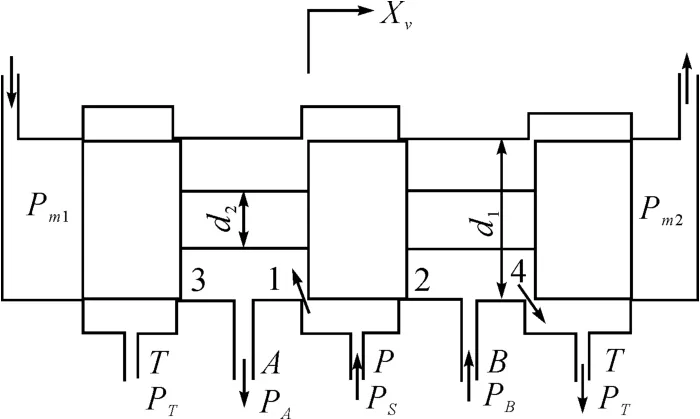

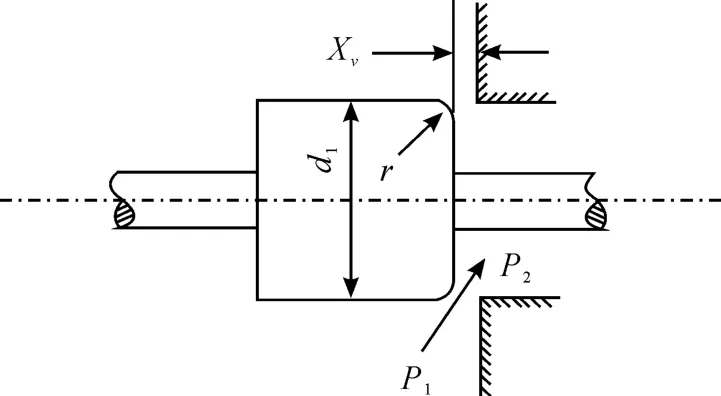

The ideal model of the spool valve is shown in Fig.1,it shows that,aside from the two left and right control channels,the valve has four channels connecting the outside hydraulic circuits,namely port P,port T,port A and port B.Port P connects to the pressure oil source,port A and port B connect to the two load cavities of actuator respectively,and port T connects to the tank.It is often assumed that the positive direction of the spool valve is moving to the right,thus,port 1 and port 4 are open,port 2 and port 3 are closed.In this assumption,port1 and port 4 are working valve ports.

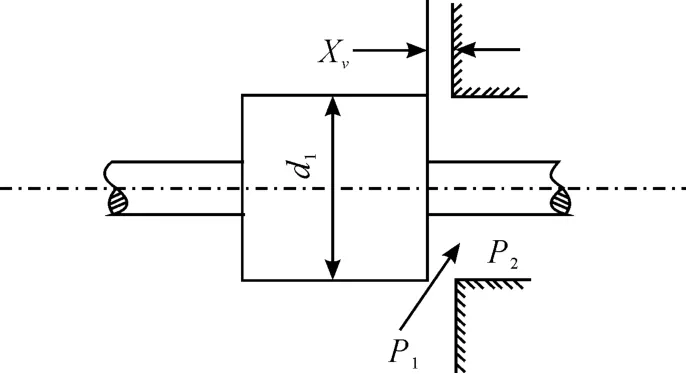

ideal spool valve,the valve port model is shown in Fig.2.

Fig.1 Structure of the ideal spool valve

Fig.2 The valve port model of ideal cylindrical spool valve

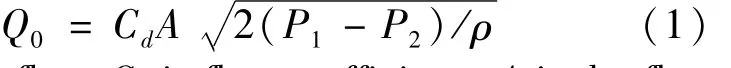

According to the Fluid mechanics,the flow formula is:

Where:Q0is flow,Cdis flow coefficient,A is the flow area of throttling port,Ρis density of hydraulic oil(kg/m3),P1is pressure inlet(Pa),P2is pressure outlet(Pa).

In this paper,the spool valve is made up of four throttling ports,so the flow formula of spool valve is:

However,the radius of the arris-edge fillet for a real spool can not be zero.An actual spool model is shown in Fig.3.

Fig.3 The actual spool valve model

Now the flow formula of the spool valve is:

where B is the width of the throttling port.

The flow characteristics can be analyzed by the formula(2)and(3).If the change of the flow coefficient is ignored,for ideal spool valve,the flow will change with the opening of the valve linearly.

And for the actual spool valve,its flow characteristic curve should be the asymptote based on the flow characteristic curve of the ideal spool valve.The flow characteristic curve is shown in Fig.4.

Fig.4 Flow characteristic curve

3.The geometry model and the simulation method

The simulation model in this paper is shown in Fig.1.The following four spool valve models are established:the ideal spool valve,the spool valves with working arris-edge fillets of 5μm,8μm and 10μm. From Fig.1,the conclusions can be drawn that the valve has two symmetrical valve chambers and both valve chambers are axisymmetrical.To reduce the calculation,only 1/4 model of a single valve chamber needs to be established.

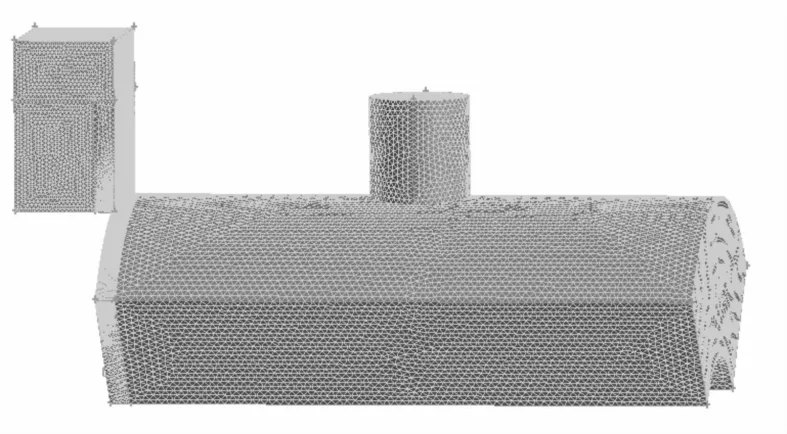

The main purpose of the simulation is to obtain the flow through the throttling port of the valve.The overall length of the model is up to 30 mm.However,the size of the opening is just tens of or even several microns,the proportion of the two sizes is so large that it brings great difficulties to give the model a propermesh.To ensure the accuracy of the calculation and improve computational efficiency,the local mesh refinement method should be adopted[6].The meshed model is shown in Fig.5.

Fig.5 The meshed model

The meshed models are imported into Fluent,a series of parameters should be set[7].After running the simulation,the flows in different openings can beobtained and the flow coefficients in different opening can be calculated accordingly.

4.Simulation results and analysis

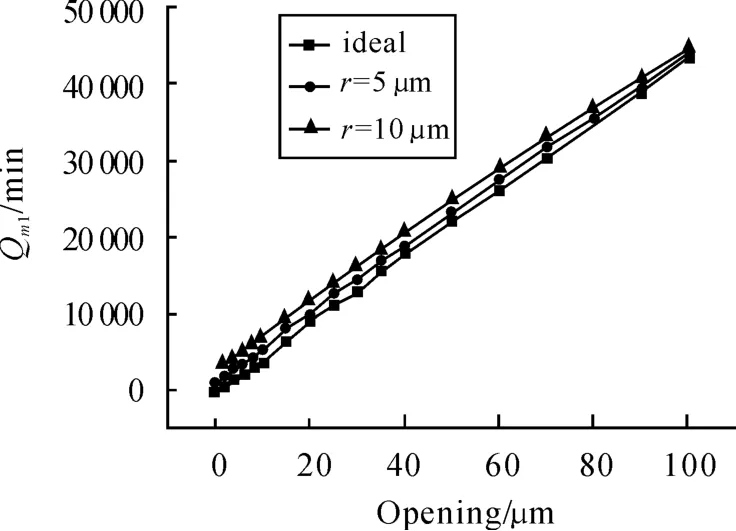

This paper mainly discusses the situation when the opening is less than 100μm,and 17 points are selected for research.The three-dimensional models in these different openings are established,then the models are meshed and simulated,and a series of the flow values can be obtained.From the simulation results,the flow characteristic curves can be drawn as shown in Fig.6 and Fig.7.

Fig.6 The flow characteristic curve

Fig.7 The flow coefficient curve

According to Fig.6,the following conclusions can be drawn:

1)The flow characteristic curve of the ideal spool valve is approximately linear.

2)With the same opening,the flow increases with the arris-edge fillet.

3)If the arris-edge fillet is held constant,with the increase of opening,the influence of the fillet on the flow becomes smaller and smaller.When the opening is large enough,the flow characteristics of the actual spool valve get close to the flow characteristics of the ideal spool valve.

4)Because of the arris-edge fillet,there is flow leakage at the zero position.And larger fillet radius will lead to greater flow leakage.The larger the fillet radius is,the greater the flow leakage will be.

5.Effects on the flow coefficient

The following conclusions can be drawn from Fig.7:

1)For an ideal spool valve,it is generally believed that the flow coefficient is constant.However,the flow coefficient changes along with the opening and this change is particularly obvious in the micro-opening.Then with the opening increasing,the flow coefficient is substantially a constant.

2)If there is a arris-edge fillet on the spool valve,its flow coefficient will be larger than that of the ideal spool valve and will increase with the fillet’s size.This can be explained by the fact that the presence of the fillet leads to the increase of the flow area.

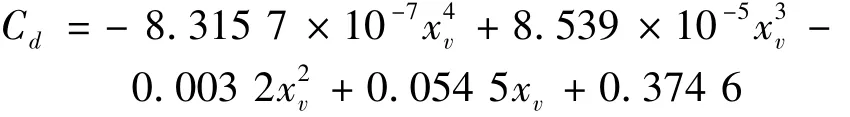

Apply a polynomial approximation to the flow coefficient of the ideal spool valve(when the opening is less than 40μm)and the formula can be expressed as:

this is the correction formula for the flow coefficient and it can be used directly to calculate the flow in later applications without any complex simulations.

6.Conclusions

In this paper,the influence of the arris-edge fillet on the flow characteristics of spool valve is studied.First this paper uses the theory of fluid dynamics to analyze the effect of the arris-edge fillet on the flow characteristics.Then based on Fluent,numerical simulation of the above-mentioned effect is carried out.

The result of simulation indicated that the existence of the arris-edge fillet will increase the flow area of the spool valve,leading to the deterioration of the flow curve linearity.Larger fillet will result in worse linearity and greater leakage at zero position,and this will seriously affect the performance of the servo valve.Therefore,a more reasonable processing technology should be adopted to minimize the arris-edge fillet.

Finally,based on the simulation results,this paper gives the flow coefficient correction formula atthe micro-opening to avoid the complicated simulations.The flow can be directly obtained by the formula,which provides guidance for spool valve’s testing.

[1] HAN Junwei,LIHongren.Application of Fluid Control Technology in the Environment Analogue and Simulation Test Facilities[J].Fluid Power Transmission and Control.2005,3(2):34-38.

[2] FANG Qun,WANG Zeng.Developing Process,Research Actuality and Trend of Electrohydraulic Servovalve[J].Machine Tool and Hydraulics,2007(11):162-165.

[3] PAN Xudong.Study on servovalve spool valve overlap value hydraulicmeasuring system and the key technics of the system[J].Dissertation for the doctoral degree in engineering,2007(9):7-20.

[4] Finnemore E J,Franzini JB.Fluid mechanics and engineering application[M].Beijing:China Machine Press,2005.

[5] Tsukiji T.Discrete-vortex simulation of a two-dimensional flow in oil hydraulic valves[J].Journal of Fluid Control,1991,21(1):43.

[6] Chen Q,Stoffel B.CFD simulation of a hydraulic conical valve with cavitation and poppet movement[C]//4th International Fluid Power Conference.Germany:Dresden,2004:331-339.

[7] Pountney D C,Weston W,Banieghbal M R.A Numerical Study of Turbulent Flow Characteristics of Servo-valve Orifices[C]//Proc Instn Mech Engrs.1991:139-147.

滑阀节流棱边圆角对流量特性影响的三维模型仿真

王东魏,叶正茂*

哈尔滨工业大学机电工程学院,哈尔滨 150001

滑阀的流量特性直接影响伺服阀的性能。使用Fluent软件对滑阀在不存在棱边圆角(理想滑阀),棱边圆角分别为5μm、8μm和10μm等4种情况进行数值仿真研究,得出棱边圆角对滑阀流量特性的影响规律,并对理想滑阀的流量系数进行了修正。

流量特性;Fluent;节流棱边圆角

TH12

10.3969/j.issn.1001-3881.2013.12.002

2013-03-17

National Natural Science Foundation for young(51205077)

*YE Zhengmao,Associate professor.E-mail:yezhm@hit.edu. cn

- 机床与液压的其它文章

- Reasearch on A/D Conversion with Strong Anti-jamming Ability Using PWM

- Simulation and Optimization Analysis of Circuit Breaker Operating Mechanism

- Synchronous Motion Servo-control of Biaxial Cross Coupling Based on Intelligence Fusion Strategy

- Decoupling Control Algorithm of Online Self-tuning Based on DRNN

- Experimental Study on Mechanical Properties of Low Carbon Steel with Ultrasonic Vibration Tensile

- Wavelet Analysis Fault Information and Realization in Virtual Instrument