Simulation and Optimization Analysis of Circuit Breaker Operating Mechanism

WU Ji,AI Shijie,CHEN Yingxia

Dazu Power Supply Co.,Ltd.,Chongqing Electric Power CORP,Chongqing 402360,China

The circuit breaker plays an important role in power distribution system,which can be used to distribute electric energy,without needing to start the asynchronous motor.It plays a role in protecting the power circuit and motor.When the failures such as severe overload,short circuit and under voltage occur,it can cut off the related circuit automatically,and its function covers the fuse type switch and overunder thermal relay.The operating mechanism is an important part of circuit breaker,the performance of which may determine the opening and closing performance of the circuit breaker directly.Thus,the simulation and optimization analysis of the circuit breaker operating mechanism is of very important academic value and practical significance[1 -13].

1.Analysis for operating principle of molded case circuit breaker

The main contacts of molded case circuit breaker are closed by manual operation or electrically.After the main contracts are closed,the free tripping mechanism will lock the main contacts at the closing position.The coils of over-current release and the thermal elements of the release are in series with the main circuit,and the coils of the under-voltage release are in parallel with the power.When short circuit or serious overload occur in the circuit,the armature of the over-current release will be closed,to make the free tripping mechanism act,and the main contacts will disconnect the main circuit.When the circuit is overloaded,the thermal elements of the thermal release will be heated to make the bimetallic strip bend upward,and push the free tripping mechanism to act.When the circuit is under voltage,the armature of the under-voltage release will be released,which also can make the free tripping mechanism act.The shunt release will be used as remote distance control.In normal operation,the coils are outage,and when distance control is required,press the start button to make the coils electrify,the armature will bring the free tripping mechanism act and make the main contacts cut off.

2.Building of multi-body dynamics model of circuit breaker

For the complex three-dimension shape modeling,the modeling function of multi-body dynamics analysis software is weaker than the more professional three-dimension software,thus,the common solution is to build the model in the professional three-dimension solid modeling software such as ProE etc.,and then import through ADAMS graphical interface function to perform kinesiology and dynamics analysis.

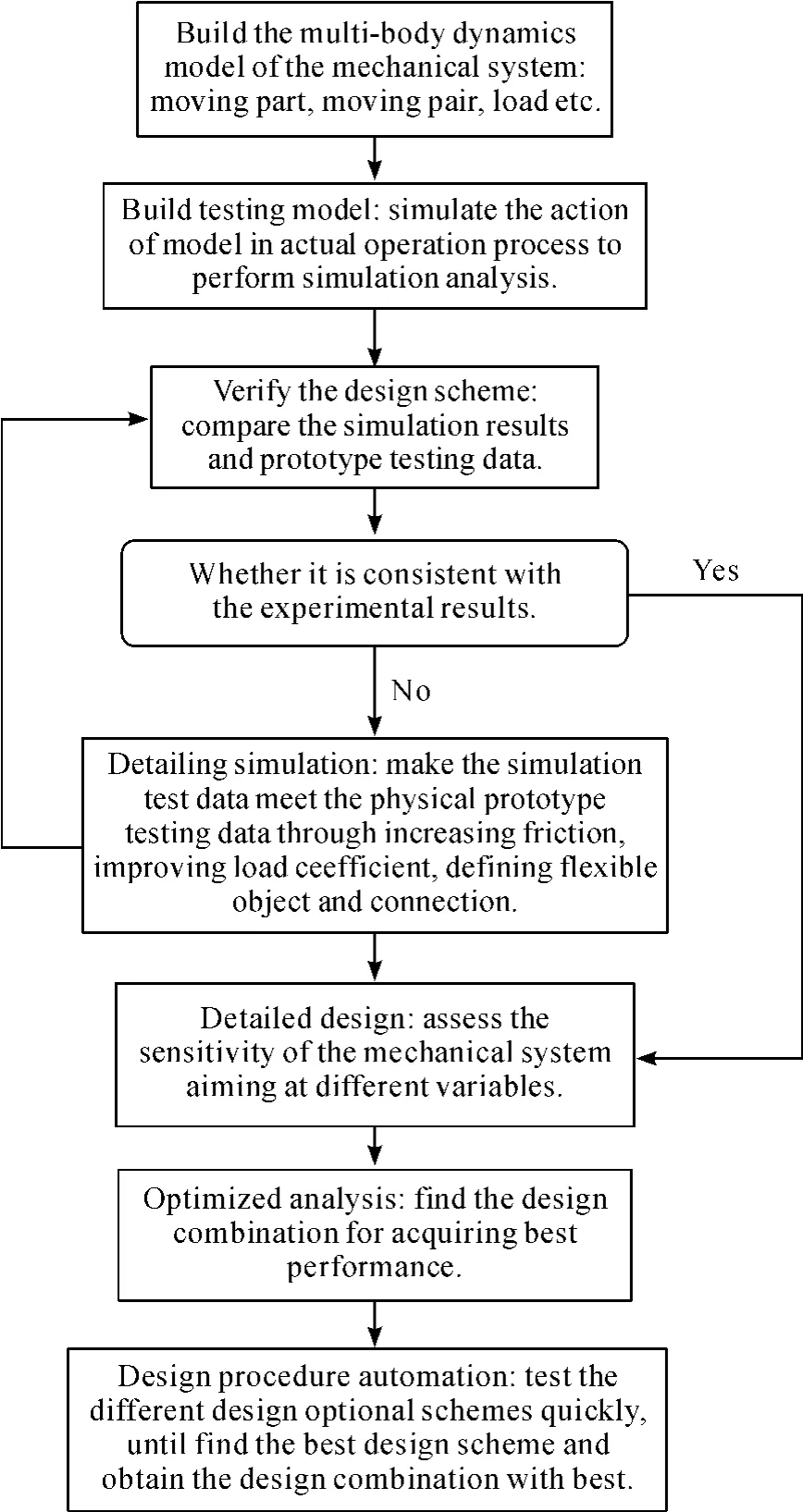

The members that perform simulation analysis in ADAMS are provided with different features,such as point mass, rigid member, flexible member and frame.Where,point mass only has quality but cannot load any moment,the frame only has shape,which always keep the steady state to act as the reference of other members.Each member is provided with a reference coordinate system fixed on it,in order to analyze the relationship between the members better.The simulation and optimization flow of the circuit breaker operating mechanism is shown in Fig.1.

2.1.Three-dimensional solid modeling of circuit breaker

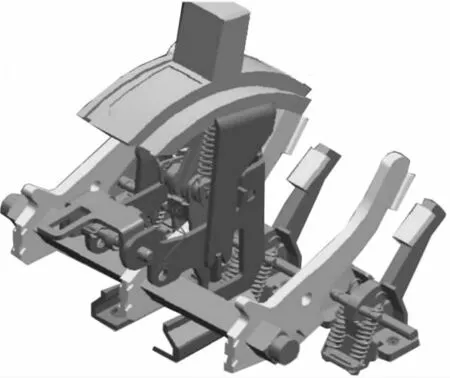

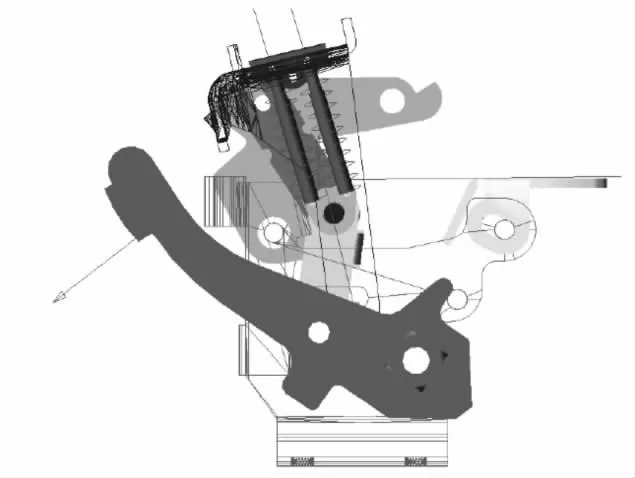

Perform three-dimension modeling for the circuit breaker in Pro/E.In the process of building member three-dimension model,only reserve the members participating in movement directly,and remove the affiliate members that have slight influence on the simulation results,which not only can simplify the building process of three-dimension model to improve the accuracy of simulation process,but also reduce the workload of research to make the simulation result clearer,and improve the work efficiency without affecting the simulation result.The three-dimensional solid model of the circuit breaker operating mechanism built in ProE is shown in Fig.2.

2.2.Building of multi-body dynamics model of circuit breaker

After building the three-dimensional solid model of the circuit breaker operating mechanism,import the model through the graphic interface function of ADAMS,and add the required constraints and elastic load.Based on the analysis to the operating mechanism,adding suitable constraints can assembly various members into an integral whole,and use this whole as a mechanical system to perform kinesiology and dynamics analysis.During the process of adding constraints,the following problems shall be considered:

Fig.1 Simulation and optimization flow of circuit breaker operating mechanism

Fig.2 Three-Dimensional Solid Model of the Circuit Breaker Operating Mechanism

1)Note to consider the direction problem of constraints.Adding constraints can reduce the degree of freedom of the mechanism,but constraints of wrong direction may not reduce the degree of freedom of the mechanism reasonably.Thus,increase the solving difficulty and accuracy.

2)Verify the constraints while adding constraints,to ensure the correctness of constraints,and prevent wrong constraints from causing confusion of movement relationship between members.

3)For every constraint to be added,minimum moving pair shall be used.Excessive moving pair may cause the mechanism be with redundant degree of freedom,which may lead the mechanism fail to operate normally.

4)In case of no load,the correctness and accuracy of constraints can be verified through the dynamics analysis performed to the operating mechanism.

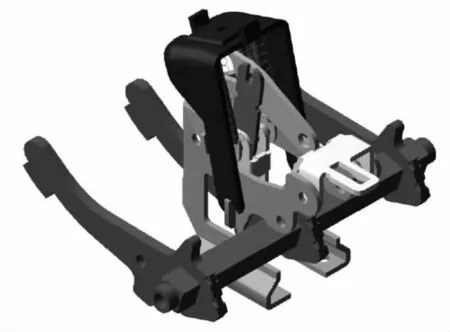

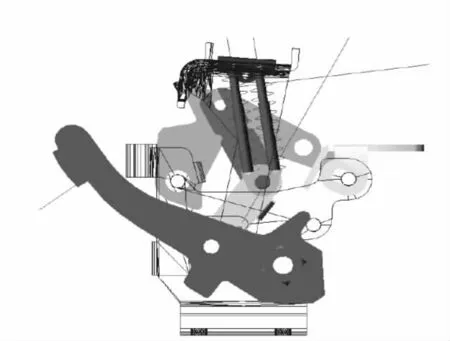

2.3.Simulation analysis of circuit breaker operating mechanism

The three-dimensional solid model through accurate constraints can be used for simulation analysis.Before performing simulation operation,the expected value output by simulation analysis can be specified,and verify the existing three-dimension model and constraints on this basis,and find the reasonable initial condition and the corresponding parameters.These parameters include the analysis method,operating time and expected accuracy etc.After completing these works,ADAMS can seek for the solving methods automatically,and use the set solving method to complete the required kinesiology and dynamics simulation.The following figure is the simulation model of the circuit breaker operating mechanism in ADAMS.

Fig.3 Simulation Model of the Circuit Breaker Operating Mechanism

Through simulation analysis,the basic condition and force condition of each mechanism can be obtained.Meanwhile,analysis for the simulation result and drawing of the corresponding data curve can be performed through separate post processing model,in order to debug and optimize the mechanical system.The simulation initial condition given by the program is usually reasonable,thus,modifying without theoretical and experimental basis may influence the correctness and accuracy of the simulation result.During the simulation analysis process of operating mechanism,the reasonable iterated times shall be selected,to make the iterated analysis result of two times tend to consistent,to guarantee stable and reliable simulation result.

Through simulation analysis,the closing state,tripping state and re-tripping state of circuit breaker operating mechanism is obtained(Fig.4 ~6).

Fig.4 Closing state of circuit breaker operating mechanism

Fig.5 Tripping state of circuit breaker operating mechanism

Fig.6 Re-tripping state of circuit breaker operating mechanism

Closing,tripping and re-tripping process can be seen in the simulation picture,which is very coincident with the operating process and principle of the operating mechanism in theory,meanwhile,basic analysis for the dynamic inference condition between various members also be performed.Judging from Figure 4,the motor base may generate certain acting force for tripping,which plays a limit role to tripping.Meanwhile,the acting force of the handle to the tripping may also plays a limit role to the relative movement.The whole system recovers to static balance again,and completes all the tripping process.The running torque loading on the handle can make the handle and tripping generate acting force,in order to complete re-tripping process of the operating mechanism.After re-tripping,the tripping mechanism can return to locking state again,at this time,reclosing can be performed through moving the handle.

2.4.Optimization of simulation model

Due to many unknown parameters in the actual operating system,there are some differences between preliminary simulation result and the practical situation.The parameters easily acquired will be drawn a curve and fitted with the curve acquired from experiment,namely,the unknown parameters in the simulation model conforms to the practical situation.

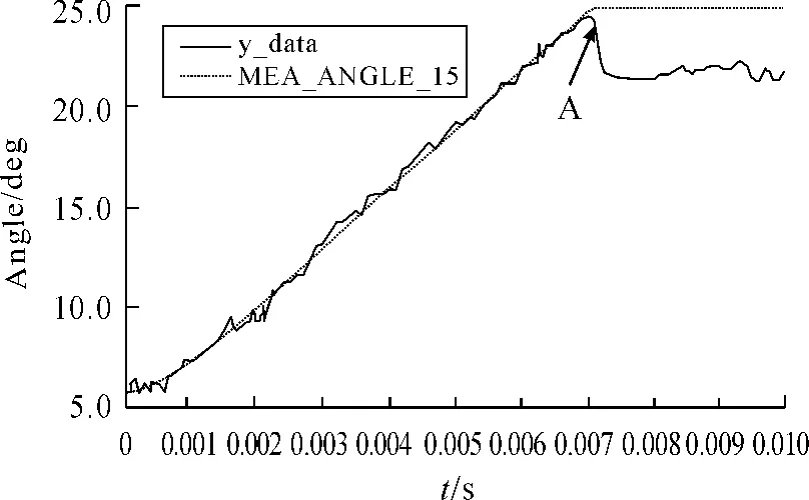

Real experiment is done to the circuit breaker operating mechanism with no load in order to acquire relation curve between angle and time of moving contact.Repeated substitution of experimental data may adjust the unknown parameters in the model in order to acquire simulation data which is closer to the practical data.By comparing the simulation data and experimental data,it concludes the relation chart shown in the Fig.7.

Fig.7 Relation Chart of Simulation Data and Experimental Data

In Fig.7,dotted line and full line respectively indicate the curves of the simulation experiment and the real experiment.With continuous optimization of simulation model,fitting of simulation and experiment is basically realized when the relation curve of angle and time of moving contact is rising.Abnormal change at point A is caused by direct contact of moving contact and stop piece.It is observed that the end of curve is poorly connected,which needs further improvement for the model.Such experiment shows high conjunction of the model and practical situation and therefore it proves that the model is right.

Breaking performance of circuit breaker is an important indicatorforperformance ofoperating mechanism and breaking performance shall be selected for optimized object.Namely,for optimization breaking speed shall be used as major parameter for optimization function.

First step for optimization design is parameterization of the simulation model,the correlation values are parameterized through modifying the performance of the simulation model.There are several parameterization processing methods in ADAMS.For processing parameterization,ADAMS will automatically execute the corresponding simulation analysis through adjusting different parameters.Find out impact on design parameters by observing analysis results.

In ADAMS,there are mainly parameterization of design point,design variable,movement tools and expression.The parameterization of expression is the most common and effective one among them.

3.Analysis and optimization of simulation results

3.1.Relation of spring stiffness and breaking speed

As core component of circuit breaker operating mechanism,spring drives the tripping movement and therefore optimization of the spring stiffness can significantly influence the breaking performance of circuit breaker operating mechanism.This article researches the spring stiffness and breaking performance of circuit breaker operating mechanism with the method of ADAMS design research.

The design research mainlyresearcheshow changes of a single variable influence performance of the entire mechanical system.During the process of the design research,select several values for a certain parameter in reasonable range,then analyze each value and finally give analysis result in table.Obtain the relation of target variable and performance changes of the entire mechanical system through the design research and on this account,test and verify the best value of the parameter.Additionally,judge the importance of the parameter in the mechanical system.

This article assumes the spring stiffness is the design variable and through analysis,it concludes the positive relationship of angular speed of contact and spring stiffness,which can shorten the breaking time and raise the breaking speed.It can conclude thereby that appropriately increasing the spring stiffness is important for improving the performance of the circuit breaker operating mechanism within the tolerance range.Due to positive relationship of the spring stiffness and the mechanism operating force,excessively increasing the spring stiffness is not appropriate in the view of saving the mechanism operating force.In addition,the excessive spring stiffness can also lead to bounce when the contact closes.Therefore,the above factors must keep balance while the spring stiffness increases.

3.2.Relation of member shape and breaking speed

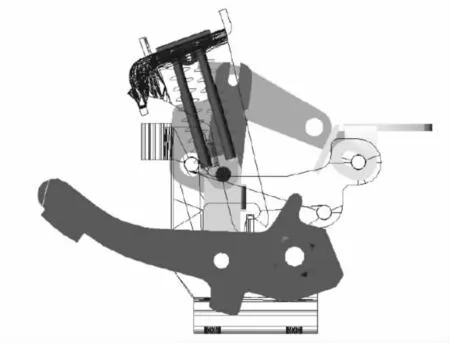

Build mathematical model in the previous analysis and import the model into ADAMS in integrated mode.Since establishment of equation mainly depends on the location of center of mass of rigid body in the computational coordinate system,location changes of center of mass of the rigid body in ADAMS shows the movement condition of the rigid body.

In different circuit breaker,shapes of connecting rods are different to a certain extent and different shapes of connecting rods indicate changes of center of mass and mass of the connecting rods.Therefore,this article respectively parameterizes the center-ofmass coordinate system and member mass and reaches a conclusion as follows:

1)Location of center of mass of the tripping has the maximum impact on the breaking speed of the operating mechanism and mass has less impact on the breaking speed and within the tolerance range of normal movement of the mechanism,the center of mass of the tripper shall be adjusted close to O axle;

2)Center of mass of upper connecting rod has less impact on the breaking speed,the mass has more impact on the breaking speed and therefore the mass of the upper connecting rod shall be decreased to the greatest extent in order to achieve higher breaking speed.

3.3.Analysis and optimization of energy storage spring

As a key member of the operating mechanism,the energy storage spring is usually cylindrical helical spring and it can provide closing energy by tensile or compression deformation during the closing process of the circuit breaker.With shape of a given mechanism,input energy of the closing process has close relation with the parameter and deformation of the energy storage spring itself.Therefore,analysis and optimization of the energy storage spring is important for improving performance of the circuit breaker operating mechanism.

During the closing process,reducing the system stress will reduce the residue energy after the completion of the process so as to prolong life cycle of the circuit breaker operating mechanism and improve reliability of the closing.Parameter and deformation of the energy storage spring directly decides the input value of the energy during the closing process of the circuit breaker operating mechanism.Optimization and analysis of the circuit breaker operating mechanism can omit the process of the practical lift experiment and shorten the design development cycle as result of increasing efficiency of scientific research as well as saving material and energy.

Through analyzing the simulating results,it concludes:the minimum energy required for the closing process is 90 351 N·mm and the parameters corresponding to is are the energy storage spring stiffness of 163.46 N/mm and preload of the energy storage spring of 6 043.6 N.

4.Conclusions

This article establishes ADAMS simulation model of molded case circuit breaker and based on the model,it describes addition of constraint and dynamic simulation analysis of three-dimensional model.Good consistency of the experimental data and the practical data shows that the model is scientific and advanced.

The simulation result shows:increasing of the spring stiffness is in favor of raising the breaking speed of the operating mechanism and the spring stiffness and operating force of handle as a result that the breaking spring stiffness must be increased in a reasonable range,otherwise it may reduce the efficiency of the operating mechanism;change of member shape may change its center of mass so as to raise the breaking speed of the circuit breaker;analysis and optimization of the energy storage spring is significant for improving the performance of the operating mechanism and therefore it shall be appropriately selected.

[1] CHEN Degui,LIU Qingjiang,KANG Yan.Effect of Different Factors to the Operating Velocity of Molded Case Circuit Breakers[J].Voltage Apparatus,2005(12):9-12.

[2] ZHANG Jingshu,CHEN Degui,LIU Hongwu.DYNAMIC SIMULATION AND OPTIMUM DESIGN OF LOW-VOLTAGE CIRICUIT BREAKER [J].Proceedings of the Csee,2004,33:102 -107.

[3] LI Zenggang.Threshold and Explains in Detail of ADAMS[M].Beijing: National Defence Industry Press,2006.

[4] ZHENG Jianrong.Introduction and Advancement of Mechanical System Virtual Prototyping[M].Beijing:Machinery Industry Press,2004.

[5] ZHANG Qiyou.Isomax S series moulded case circuit breaker[J].Mechanical and Electrical Equipment,2000(3):24-26.

[6] XU Zhihong,ZHANG Peiming,YAN Yipeng.A New Type of Low Voltage Circuit Breaker[J].LOW VOLTAGE APPARATUS,1999(6):24-26.

[7] HU Xue-sng.DW45 SERIES INTELLIGENT AIR CLRCUIT BREAKERS[J].Mechanical& Electrical Engineering Magazine,2001(6):70 -75.

[8] MA luzhong,SHEN Yu,WU Weiguang.Property A-nalysis and Dynamic Simulation of Vacuum Interrupter[J].China Mechanical Engineering,2001(3):53 -56.

[9] LIAO Lizhi.On the Present Situations of the Low-voltage Circuit Breakers and Their Main Technical Properties[J].Jiangsu Electrical Apparatus,2003(3):5 - 7.

[10] HE Ruihua;YING Tian-wen.State of the Art and Development Trend of Low Voltage Electrical Apparatus in China[J].Low Voltage Apparatus,2004(1):3 - 7.

[11] WAN Shaoyou.Present Situations on LV Intellectualized Circuit Breakers Both at Home and Abroad[J].Jiangsu Electrical Apparatus,2001(3):5 -8.

[12] GU Ming,YANG Xin.Application of Collision Detection in Spacecraft Visual Simulation[J].v,2006(5):30 -32.

[13] CHEN Degui.New Technology of Low Voltage Electrical Apparatus to Face the 21 Century[J].Low Voltage Apparatus,2001(1):3 -8.

- 机床与液压的其它文章

- Reasearch on A/D Conversion with Strong Anti-jamming Ability Using PWM

- Synchronous Motion Servo-control of Biaxial Cross Coupling Based on Intelligence Fusion Strategy

- Decoupling Control Algorithm of Online Self-tuning Based on DRNN

- Experimental Study on Mechanical Properties of Low Carbon Steel with Ultrasonic Vibration Tensile

- Wavelet Analysis Fault Information and Realization in Virtual Instrument

- Precision Measurement of Series Motor Housing Based on CMM