微生物燃料电池——新型产能及废水处理技术

黄健盛,李崇明,穆 斌,穆世江,封 丽,张 韵

(1.重庆市环境科学研究院,重庆401147;2.重庆市农业机械鉴定站,重庆402160;3.重庆星河房地产开发有限公司,重庆402260)

通常情况下,微生物燃料电池(microbial fuel cell,MFC)由阳极室、阳极、阴极、阴极室(单室型MFC中无阴极室)、阴阳极分隔材料(多为质子交换膜、离子交换膜或不用)、外电路组成。自Potter于1910年提出MFC的概念以来[1],研究者们设计出结构形式多样的MFC,其目的是为了从MFC中得到更高的产电效率,提高MFC处理废水的能力,降低造价并改善其实际应用能力。现从构造、原理、影响因素、应用及尚需解决的问题等方面对微生物燃料电池技术进行阐述。

1 MFC结构形式

从微生物燃料电池极室构造上,把其分为双室微生物燃料电池(double chambers microbial fuel cell,DCMFC)、单室微生物燃料电池(single chamber microbial fuel cell,SCMFC)和电池组微生物燃料电池(multiple chambers microbial fuel cell,MCMFC)以及其他形式的微生物燃料电池。

1.1 双室微生物燃料电池

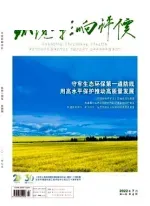

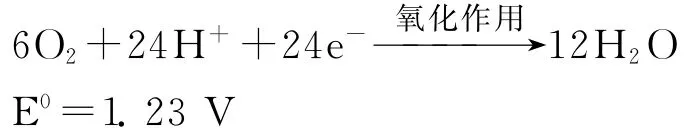

随着MFC的发展,研究者们或从分隔材料、或从阳极液的流向等方面对DCMFC进行了改进,以提高DCMFC产电及废水处理能力,从而提高实际应用能力。相继出现了经典H型DCMFC[2]、盐桥DCMFC[3]、无膜DCMFC[4-5]、平板DCMFC[6]、微型DCMFC[7-9]、升流式DCMFC[10-11]、阴极铁离子氧化DCMFC[12]。各结构形式见图1。

1.2 单室型微生物燃料电池

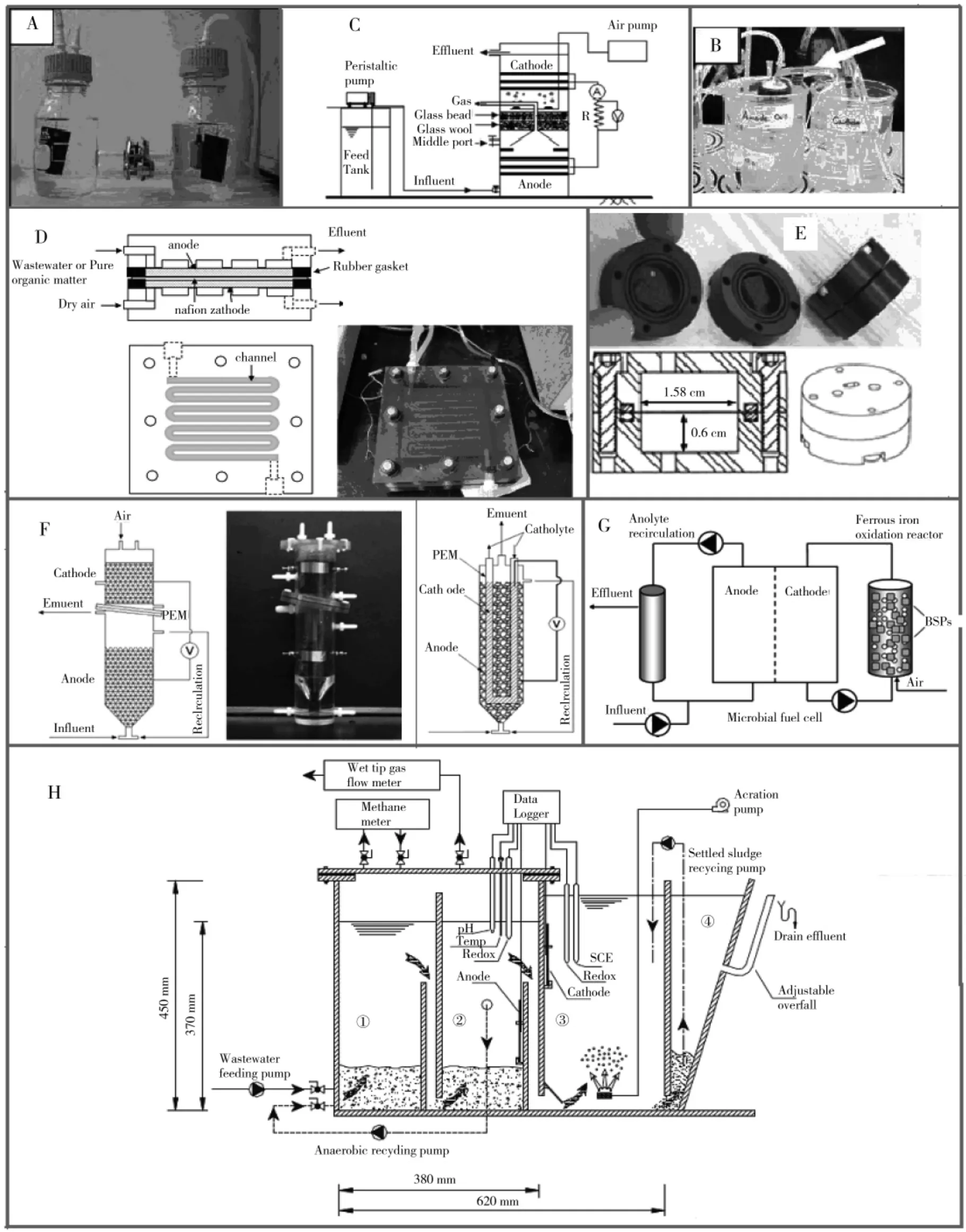

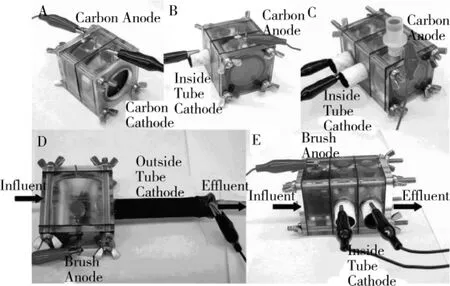

对于DCMFC,因其系统内阻较高,因而DCMFC系统适用于确定一种特殊底物是否能用于产电,或接种后是否能形成微生物群落,但此种MFC系统很难区别不同的微生物或底物是否能提高反应器的性能。为了克服DCMFC系统存在的不足,Liu和Logan等研究人员设计出SCMFC,用于测试影响MFC功率输出的因素。目前出现的SCMFC如图2所示,包括管型SCMFC[13]、典型SCMFC[14]、新管型SCMFC[15-17]、旋转阴极SCMFC[18-19]、石墨纤维刷阳极SCMFC[20]、渗析管SCMFC[21]、折流型SCMFC[22]等。

图1 双室微生物燃料电池结构形式:(A)典型DCMFC[2];(B)盐桥式MFC[3];(C)无膜DCMFC[4];(D)平板型DCMFC[6];(E)微型DCMFC[7];(F)升流式DCMFC[10];(G)亚铁离子氧化型DCMFC[12];(H)厌氧折流板反应器DCMFC[5]。

图2 单室微生物燃料电池结构形式:(A)管型SCMFC[13];(B、D、E)新管型SCMFC[15-17];(C)石墨纤维刷阳极SCMFC[20];(F、G)旋转阴极SCMFC[18-19];(H)渗透管SCMFC[21];(I)典型SCMFC[14];(J)折流型SCMFC[22]。

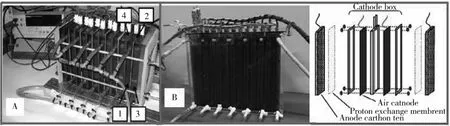

1.3 电池组微生物燃料电池

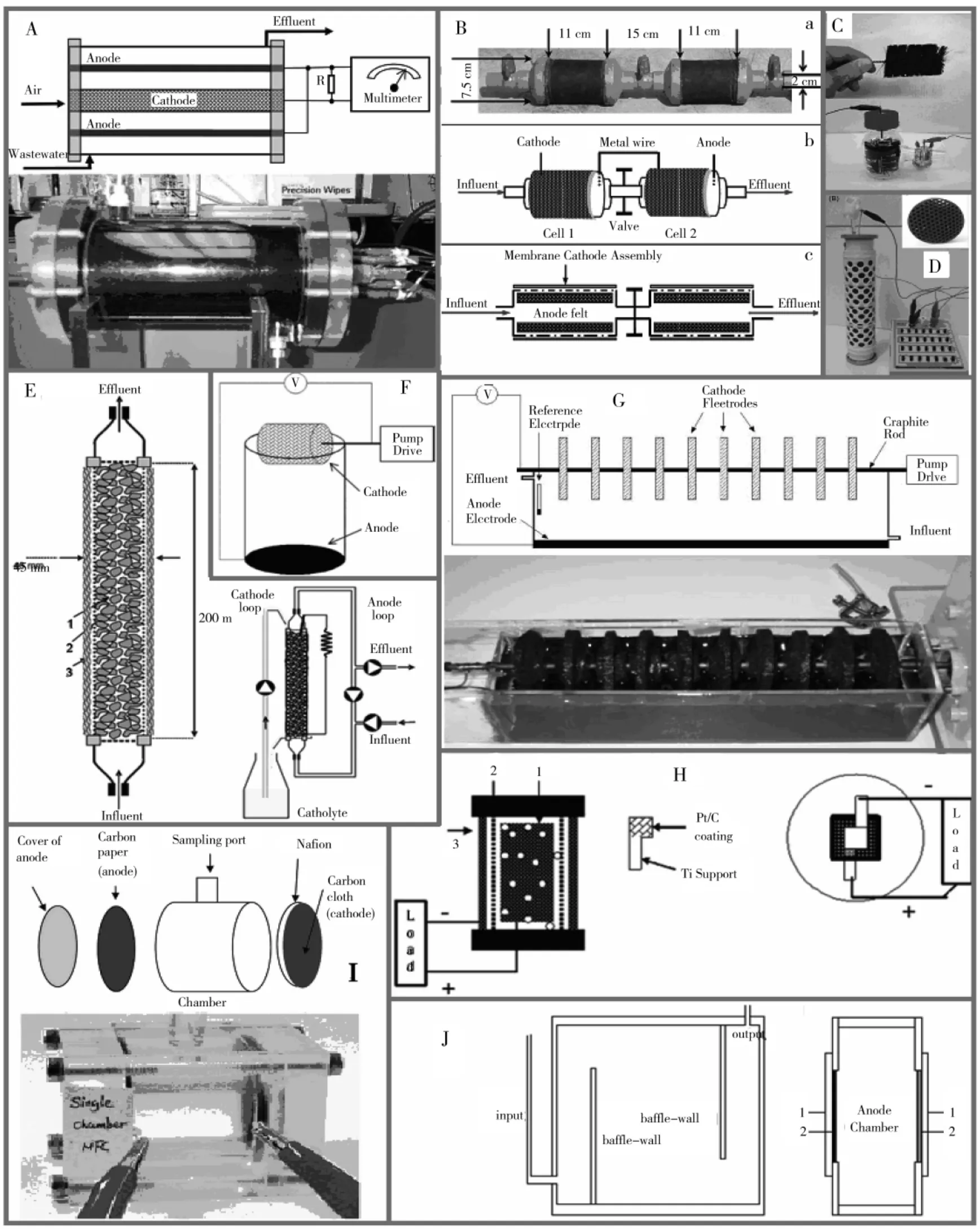

基于提高MFC的产电能力,Aelterman等[23]建造了如图3(A)所示的6-电池组MFC,Shimoyama等[24]设计了如图3(B)所示的12-盒式阴极MFC。

1.4 其他形式微生物燃料电池

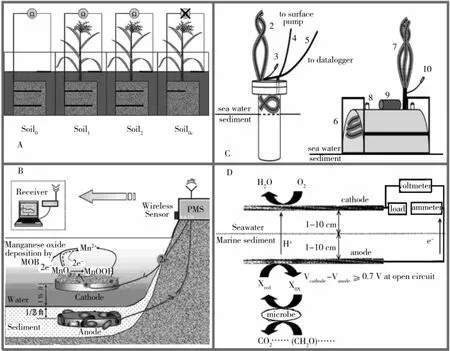

随着MFC技术的发展,其在反应器结构形式上除了前述的双室型MFC、单室型MFC以及多室型MFC外,还出现了其他各种结构形式的MFC(见图4、5),如沉积型MFC[25-28]、管型膜阴极MFC[29]。

图3 电池组MFC:(A)6-电池组MFC[23];(B)12-盒电极电池组MFC[24]

图4 沉积型MFC:(A)根瘤沉积型MFC[25];(B)河流沉积型MFC[26];(C、D)海洋沉积型MFC[27-28]

图5 管型膜阴极MFC

2 MFC产电及废水处理原理

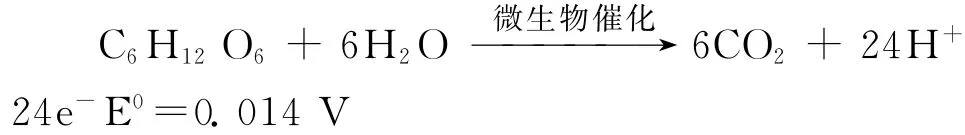

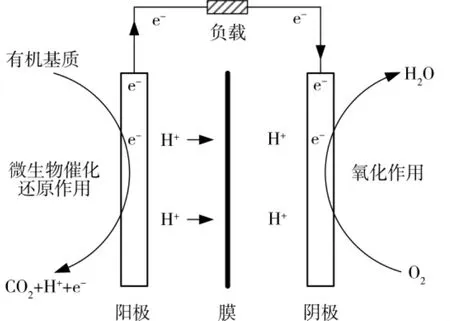

MFC是以微生物作为催化剂降解有机基质并有机基质中蕴含的化学能转化为电能的装置,由阳极区和阴极区组成,中间多用膜分隔。MFC产电及废水处理原理如图6所示,其工作过程分为4步:在阳极区,微生物利用电极材料作为电子受体将有机基质氧化,这个过程要伴随电子和质子的释放;释放的电子在微生物作用下通过电子传递介质转移到电极上;电子通过导线转移到阴极区,同时,由烟酰胺腺嘌呤二核苷磷酸(NADH)释放出来的质子透过质子交换膜也到达阴极区;在阴极区,电子、质子和氧气反应生成水。因此,有机基质在MFC阳极区在微生物的作用下被降解去除,而随着阳极有机基质被不断氧化和阴极反应的持续进行,电子沿外电路持续流动而形成电流,其反应式如下(以葡萄糖基质为例):

阳极反应:

阴极反应:

图6 MFC产电及废水处理原理

3 MFC产电及废水处理的影响因素

到目前为止,实验室研究的MFC的性能低于理想状态。影响MFC性能的因素包括微生物的种类、底物的种类和浓度、离子强度、pH、温度、反应器的结构、电极材料、质子交换系统以及极室的操作条件等[30]。

4 MFC的应用

产电:由于MFC技术可通过微生物的作用把有机废物中的化学能转化为电能,故MFC可用于发电[3,31-34]。废水处理:生活污水、工业废水、养殖废水等含有丰富的有机物[6,13,35-36],可作为MFC底物加以利用达到污水净化的目的。产氢MFC阳极反应产生的电子和质子在阴极结合产生氢气[37],使得MFC技术可改装用于产氢来代替产电。传感器:MFC的产电量与废水中有机污染物浓度之间成比例关系,使得MFC可以BOD传感器的形式用于污染物的分析和原位过程监测与控制[38-42]。生物修复:MFC技术可对被污染的环境进行生物修复,其生物修复的形式包括阴极生物修复和阳极生物修复。其中,阴极生物修复可用于地下水的修复,细菌在阴极使用电子完成硝酸盐[43-45]或 U(Ⅵ)的还原[46]。通常意义的生物修复都是污染物在MFC的阴极被还原,但是,当存在高浓度的可生物降解有机物时,生物诱发的污染物也可在阳极被氧化,这要求阴极有足够的电子受体,此生物修复被称为阳极生物修复[47]。

5 目前MFC技术尚需解决的问题

(1)MFC产电功率密度低,使MFC技术产电与常规能源发电相比实用价值不高。

(2)使用碳纸、载铂碳纸等材料作电极,MFC制造成本昂贵,增加了MFC技术在废水处理领域的应用成本。

(3)目前各国研究报道的MFC多以间歇操作为主,且反应器结构形式多样、容积过小不利于放大,这不利于MFC技术在实际废水处理领域的应用。

(4)现有的MFC技术多为针对产电能力的研究,对高有机物浓度废水处理效率下产电的MFC技术研究较少,这造成针对废水处理的MFC基础研究相对缺乏,进而阻碍了MFC技术在废水处理领域的应用。

(5)低有机物浓度废水在MFC研究中使用较多,而对于高有机物浓度废水研究甚少,这不利于厌氧MFC技术的发展。

(6)MFC技术废水有机基质降解及产电机理的研究不足也是限制MFC技术在废水处理领域应用的一个关键因素。

[1] Du ZW,Li HR,Gu TY.A state of the art review on microbial fuel cells:A promising technology for wastewater treatment and bioenergy[J].Biotechnol Adv,2007,25(5):464-482.

[2] Logan BE,Murano C,Scott K,et al.Electricity generation from cysteine in a microbial fuel cell[J].Water Res,2005,39(5):942-952.

[3] Min B,Cheng S,Logan BE.Electricity generation using membrane and salt bridge microbial fuel cells[J].Water Res,2005,39(9):1675-1686.

[4] Ghangrekar MM,Shinde VB.Performance of membrane-less microbial fuel cell treating wastewater and effect of electrode distance and area on electricity production[J].Bioresour Technol,2007,98(15):2879-2885.

[5] Aldrovandi A,Marsili E,Stante L,et al.Sustainable power production in a membrane-less and mediator-less synthetic wastewater microbial fuel cell[J].Bioresour Technol,2009,100(13):3252-3260.

[6] Min B,Logan BE.Continuous electricity generation from domestic wastewater and organic substrates in a flat plate microbial fuel cell[J].Environ Sci Technol,2004,38(21):5809-5814.

[7] Ringeisen BR,Henderson E,Wu PK,et al.High power density from a miniature microbial fuel cell using Shewanella oneidensis DSP10[J].Environ Sci Technol,2006,40(8):2629-2634.

[8] Biffinger JC,Pietron J,Ray R,et al.A biofilm enhanced miniature microbial fuel cell using Shewanella oneidensis DSP10 and oxygen reduction cathode[J].Biosens Bioelectron,2007,22(8):1672-1679.

[9] Ringeisen BR,Ray R,Little B.A miniature microbial fuel cell operating with an aerobic anode chamber[J].J Power Sources,2007,165(2):591-597.

[10] He Z,Minteer SD,Angenent LT.Electricity generation from artificial wastewater using an upflow microbial fuel cell[J].Environ Sci Technol,2005,39(14):5262-5267.

[11] He Z,Wagner N,Minteer SD,et al.An upflow microbial fuel cell with an interior cathode:Assessment of the internal resistance by impedance spectroscopy[J].Environ Sci Technol,2006,40(17):5262-5267.

[12] Heijne AT,Hamelers HVM,Buisman CJN.Microbial fuel cell operation with continuous biological ferrous iron oxidation of the catholyte[J].Environ Sci Technol,2007,41(11):4130-4134.

[13] Liu H,Ramnarayanan R,Logan BE.Production of electricity during wastewater treatment using a single chamber microbial fuel cell[J].Environ Sci Technol,2004,38(7):2281-2285.

[14] Liu H,Logan BE.Electricity generation using an air-cathode single chamber microbial fuel cell in the presence and absence of a proton exchange membrane[J].Environ Sci Technol,2004,38(14):4040-4046.

[15] Rabaey K,Clauwaert P,Aelterman P,et al.Tubular microbial fuel cells for efficient electricity generation[J].Environ Sci Technol,2005,39(20):8077-8082.

[16] Zhuang L,Zhou SG.Substrate cross-conduction effect on the performance of serially connected microbial fuel cell stack[J].Electrochem Commun,2009,11(5):937-940.

[17] Kim JR,Premier GC,Hawkes FR,et al.Development of a tubular microbial fuel cell(MFC)employing a membrane electrode assembly cathode[J].J Power Sources,2009,187(2):393-399.

[18] He Z,Shao HB,Angenent LT.Increased power production from a sediment microbial fuel cell with a rotating cathode[J].Biosens Bioelectron,2007,22(12):3252-3255.

[19] He Z,Kan JJ,Wang YB,et al.Electricity production coupled to ammonium in a microbial fuel cell[J].Environ Sci Technol,2009,43(9):3391-3397.

[20] Logan BE,Cheng S,Watson V,et al.Graphite fiber brush anodes for increased power production in air-cathode microbial fuel cells[J].Environ Sci Technol,2007,41(9):3341-3346.

[21] Biffinger JC,Ray R,Little B,et al.Diversifying biological fuel cell design by use of nanoporous filters[J].Environ Sci Technol,2007,41(4):1444-1449.

[22] Li ZL,Yao L,Kong LC,et al.Electricity generation using a baffled microbial fuel cell convenient for stacking[J].Bioresour Technol,2008,99(6):1650-1655.

[23] Aelterman P,Rabaey K,Pham HT,et al.Continuous electricity generation at high voltage and currents using stacked microbial fuel cells[J].Environ Sci Technol,2006,40(10):3388-3394.

[24] Shimoyama T,Komukai S,Yamazawa A,et al.Electricity generation from model organic wastewater in a cassette-electrode microbial fuel cell[J].Appl Microbiol Biotechnol,2008,80(2):325-330.

[25] Schamphelaire LD,Bossche LVD,Dang HS,et al.Microbial fuel cells generating electricity from rhizodeposits of rice plants[J].Environ Sci Technol,2008,42(8):3053-3058.

[26] Donovan C,Dewan A,Heo D,et al.Batteryless,wireless sensor powered by a sediment microbial fuel cell[J].Environ Sci Technol,2008,42(22):8591-8596.

[27] Reimers CE,Tender LM,Fertig S,et al.Harvesting energy from the marine sediment-water interface[J].Environ Sci Technol,2001,35(1):192-195.

[28] Nielsen ME,Reimers CE,Stecher HA.Enhanced power from chambered benthic microbial fuel cell[J].Environ Sci Technol,2007,41(22):7895-7900.

[29] Zuo Y,Cheng SA,Call D,et al.Tubular membrane cathodes for scalable power generation in microbial fuel cells[J].Environ Sci Technol,2007,41(9):3347-3353.

[30] Liu H,Cheng S,Logan BE.Power generation in fed-batch microbial fuel cells as a function of ionic strength,temperature,and reactor configuration[J].Environ Sci Technol,2005b,39(14):5488-5493.

[31] Moon H,Chang IS,Kim BH.Continuous electricity production from artificial wastewater using a mediator-less microbial fuel cell[J].Bioresour Technol,2006,97(4):621-627.

[32] Chaudhury SK,Lovley DR.Electricity generation by direct oxidation of glucose in mediatorless microbial fuel cells[J].Nat Biotechnol,2003,21(10):1229-1232.

[33] Rosenbaum M,Schroder U,Scholz F.Investigation of the electrocatalytic oxidation of formate and ethanol at platinum black under microbial fuel cell conditions[J].J Solid State Electrochem,2006,10(10):872-878.

[34] Liu H,Cheng SA,Logan BE.Production of electricity from acetate or butyrate using a single-chamber microbial fuel cell[J].Environ Sci Technol,2005,39(2):658-662.

[35] Oh SE,Logan BE.Hydrogen and electricity production from a food processing wastewater using fermentation and microbial fuel cell technology[J].Water Res,2005,39(19):4673- 4682.

[36] Zuo Y,Maness PC,Logan BE.Electricity production from stream-exploded corn stover biomass[J].Energ Fuel,2006,20(4):1716-1721.

[37] Liu H,Grot S,Logan BE.Electrochemically assisted microbial production of hydrogen from acetate[J].Environ Sci Technol,2005,39(11):4317-4320.

[38] Kim BH,Chang IS,Gil GC,et al.Novel BOD(biological oxygen demand)sensor using mediator-less microbial fuel cell[J].Biotechnol Lett,2003,25(7):541-545.

[39] Chang IS,Jang JK,Gil GC,et al.Continuous determination of biochemical oxygen demand using microbial fuel cell type biosensor[J].Biosens Bioelectron,2004,19(6):607-613.

[40] Chang IS,Moon H,Jang JK,et al.Improvement of a microbial fuel cell performance as a BOD sensor using respiratory inhibitors[J].Biosens Bioelectron,2005,20(9):1856-1859.

[41] Moon H,Chang IS,Kang KH,et al.Improving the dynamic response of a mediator-less microbial fuel cell as a biochemical oxygen demand(BOD)sensor[J].Biotechnol Lett,2004, 26(22):1717-1721.

[42] Kang KH,Jang JK,Pham TH,et al.A microbial fuel cell with improved cathode reaction as a low biochemical oxygen demand sensor[J].Biotechnol Lett,2003,25(16):1357-1361.

[43] Gregory KB,Bond DR,Lovley DR.Graphite electrodes as electron donors for anaerobic respiration[J].Environ Microbiol,2004,6(6):596-604

[44] Bond DR,Holmes DE,Tender LM,et al.Electrode-reducing microorganisms that harvest energy from marine sediments[J].Sci,2002,295(5554):483-485.

[45] Bond DR,Lovley DR.Electricity production by Geobacter sulfurreducens attached to electrodes[J].Appl Environ Microbiol,2003,69(3):1548-1555.

[46] Gregory KB,Lovley DR.Remediation and recovery of uranium from contaminated subsurface environments with electrodes[J].Environ Sci Technol,2005,39(22):8943-8947.

[47] Jin S,Morris J.The feasibility of using microbial fuel cell technology in bioremediation of hydrocarbons in groundwater[J].J Environ Sci Health,2008,43(1):18-23.