行星齿轮变速器和双离合器变速器在前置横驱车辆上的技术竞争

1 前言

横置前驱传动以其最经济的成本和安装空间而成为绝大多数轿车的标准形式。而所谓的标准传动即发动机纵向布置和后轮驱动方式已成例外,但是“标准传动”仍有其优点,主要应用在豪华轿车、SUV和商用车辆中。ZF Friedrichshafen AG作为变速器制造商的领导者之一,已经认识到小型豪华轿车的这种趋势并早已开展横置前驱动力换档变速器的研究。

1.1 全球市场状况

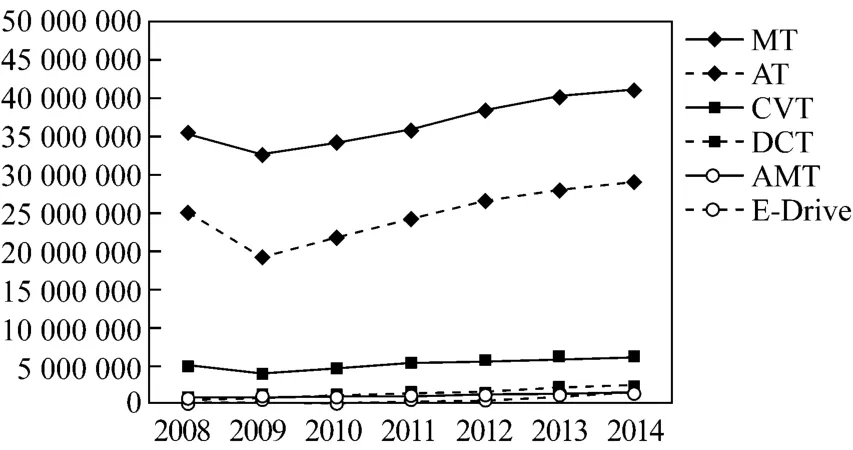

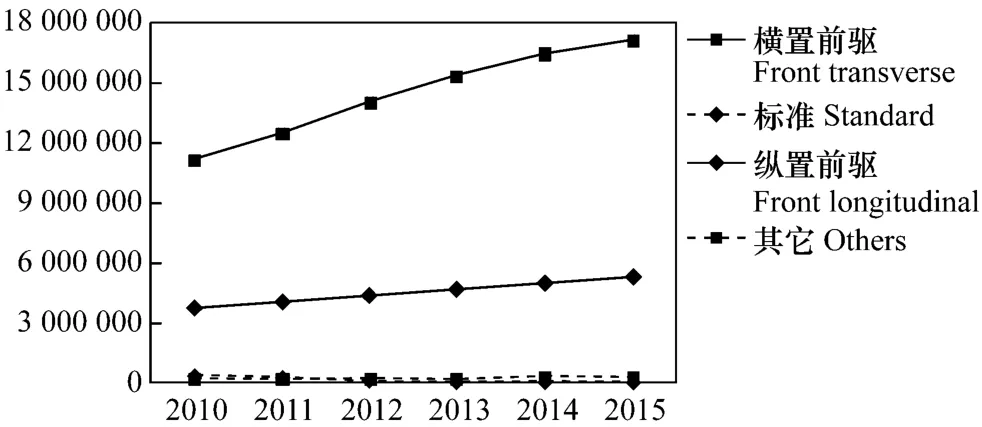

目前轿车和总质量小于6吨的轻型车辆中约80%均采用横置前驱形式(见图1)。考虑到产量方面的持续增长,可以预测其百分比在近几年中仍将提高,这是因为对紧凑型轿车的偏爱,尤其是在新兴市场上。图2是全球各类变速器的统计分析。各种型号变速器的总产量在2008-2015年间仍将继续增加。手动变速器和行星齿轮变速器还占据市场主导地位。从地域方面看,至少迄今为止CVT是亚洲市场上的一个利基现象,而双离合器变速器则是欧洲市场上的一个利基现象。图3则是中国市场上轿车和轻型商用车所采用的各种传动形式的一个详细说明。2010年总产量为15800万辆、到2015年总产量将达到23200万辆的中国市场是一个超过欧洲、美国和日本的最大轿车和轻型商用车市场。在今后5年中将增加740万辆,因此中国也成为全球增速最快的市场。其中横置前驱车辆将从2010年的1100万辆增长到2015年的1700万辆以上。

1 Introduction

The front-transverse drive with the frontmounted engine,which is transverse to the direction of travel has firmly established itself in almost all passenger car categories as the most eco-nomical design with respect to costs and installation space.The so-called standard drive with a longitudinal mounted front engine and rear-wheel drive,how ever,has meanwhile become the exception,but the‘standard drive'still has an advantage,particularly for use in luxury passenger cars,SUVs,and commercial vehicles.ZF Friedrichshafen AG,as one of the leading transmission manufacturers,has recognized a trend for small premium-class vehicles and has undertaken a conceptual study involving fronttransverse powershift transmissions

1.1 Global market situation

Currently,almost 80%of all passenger cars and light commercial vehicles less than 6 tons manufactured worldwide have a front-transverse design(see Fig.1).In view of the steady increase in production figures,it is expected that this percentage will increase over the next years,since there is a preference for compact vehicles,particularly in emerging markets.Fig.2 presents a global breakdown for various types of transmissions.The quantities for all transmission types shown will continue to increase during the 2008 to 2015 period.Manual transmissions and planetary transmissions continue to dominate the market.From a regional point of view,it can be seen that at least presently,CVTs are a niche phenomenon on Asian markets while dual clutch transmissions are a niche phenomenon on European markets.A detailed examination of the development of the vehicle production for passenger cars and LCV's in China for different types of drivetrain installation can be seen in Fig.3.With a total production volume of 15,8 mill vehicles in 2010 and a forecast of 23,2 mill in 2015 China is the largest producer of PC and LCV worldwide well ahead of EU,US and Japan.Showing an increase of 7,4 mill units in the next five years,additionally China is the fastest growing production base in the world.The production of FWD vehicles with transverse engine mount is expected to increase strongly starting from approx.11 mill units in 2010 to more than 17 mill vehicles in 2015.

图1 全球各种发动机驱动形式车辆的产量Fig.1 Production volume of various types of engine assemblies on a global scale

图2 全球范围轿车和小于6吨轻型商用车变速器分类Fig.2 Breakdown of transmissions for cars and LCV<6 tons,worldwide

这些增长背后的是那些将其生产能力在中国扩展的国外OEM和那些在过去几年中已明显壮大并将继续发展的本土OEM所持续取得的成功。

与之对比,通常自动变速器占高比例的标准传动的绝对产量在2010至2015年间仅有轻微的增加。

在中国其它动力传动形式仅占汽车总产量很小一部分。

图4表明与2009年相似,2015年中国市场上手动变速器仍将占据主导地位。但是其它类型变速器也将增长,其中适用于前置前驱的自动变速器将独占鳌头。从2013年起,将出现电动汽车,并在2015年稳占总市场的一小部分份额。

包括AT、CVT、DCT和AMT的各种自动变速器将占有31%-38%的份额。随着自动变速器装车率的提高,2010年中国市场的总产量将达到5百万台,在2015年达到9百万台。这将使得中国成为继美国之后的第二大自动变速器市场。到2015年中国市场上横置前驱形式的变速器将达到7百万台。虽然采用行星齿轮的AT仍将继续扩大起市场份额,但是DCT将加速占领市场。因此,问题是哪种形式的变速器更适合中国的前驱传动。以下准则被定义为发展目标:

The driver behind this increase is the continuous success of foreign OEM‘s who are expanding their production capacities in China as well as the significant growth of local OEM's which already could be observed during the last couple of years and which will certainly continue in the future.

In contrast to that the absolute quantities for standard drives which traditionally have a high percentage of automation will increase only slightly during the period from 2010 until 2015.

All other drivetrain configurations only contribute marginal to the total vehicle production volume in China.

Fig.4 shows that manual transmissions will predominate in the Chinese market also in 2015,same as in 2 0 0 9.But the variety of transmission designs is growing and the absolute figures with respect to automation,particularly in FWD vehicles,have an interesting order magnitude.Starting in 2013,vehicles will also be offered with electric drives,which will initially secure a small share of the total market in 2015.

◦ 降低油耗和排放

◦ 有竞争力的生产成本

◦ 满足安装空间的要求

◦ 混合动力的可能性

◦ 先进的驾驶性能

◦ 高舒适性

图3 中国轿车和轻型商用车变速器总产量Fig.3 Absolute production numbers of passenger cars and LCV in China by engine mount

图4 中国2010到2015年间变速器分类Fig.4 Breakdown of the transmission figures in China for 2010 and 2015

2 概念设计

以下概念设计的目的之一是无偏见地探寻一种理想的变速器设计。

2.1 设计调研

目前车辆使用的变速器可细分为有级式和无级式两类。行星齿轮变速器、带副轴的圆柱齿轮变速器和混合动力驱动被认为是有级式变速器。无级变速器具有更多的形式,其动力传递可能是机械、电力或液压式。本文随后的研究中不再涉及无级变速器。其原因部分在于该类变速器需要更大的安装空间、效率过于低下或系统成本过高等。选择下列变速器进行调研。

◦ 现代化的常规变矩器行星齿轮变速器

In total the quota of automatic transmissions including AT's,CVT's,DCT's and AMT's will increase from 31%to 38%.With this development of the installation rate of automatic transmission solutions the absolute numbers in China will raise from 5 mill in 2010 to approx.9 mill in 2015.This makes China the second largest automatic transmission market in the world following the US.Frontwheel transverse driveline will account for almost 7 mill units of this huge automatic transmission demand in China in 2015.Although planetary AT's will remain the dominating technology with even increasing market shares,also DCT are expected to gain an increasing portion of the market.For this reason,the question should be asked what type of transmission is ideally suited for front-wheel drives in China.

The following criteria were specified as development goals:

◦ Reduced fuel consumption and emissions

◦ Competitive production costs

◦ Meet the requirements in terms of installation space

◦ Hybrid capability

◦ Advanced driving dynamics

◦ High comfort

2 Concept study

One of the objectives under the scope of this concept study is to find an ideal transmission design,totally unbiased.

2.1 Designs that were investigated

The transmission designs already in use in today's vehicles,can be subdivided into stepped and continuously variable transmissions.Planetary transmissions and spur-gear drives with a countershaft design as well as hybrid forms that arederived therefrom ,are considered as stepped transmis sions.Continuously variable transmissions have significantly more variants,however,in that the pow-

◦ 带综合起步功能的行星齿轮变速器

◦ 带独立起步离合器的行星齿轮变速器

◦ 带动力换档功能的各种多轴式变速器

◦ 现代化的双离合器变速器

2.2 行星齿轮变速器

有一个作为起步元件的液力变矩器和3个行星排5个换档元件的6档行星齿轮变速器代表者目前的先进水平。

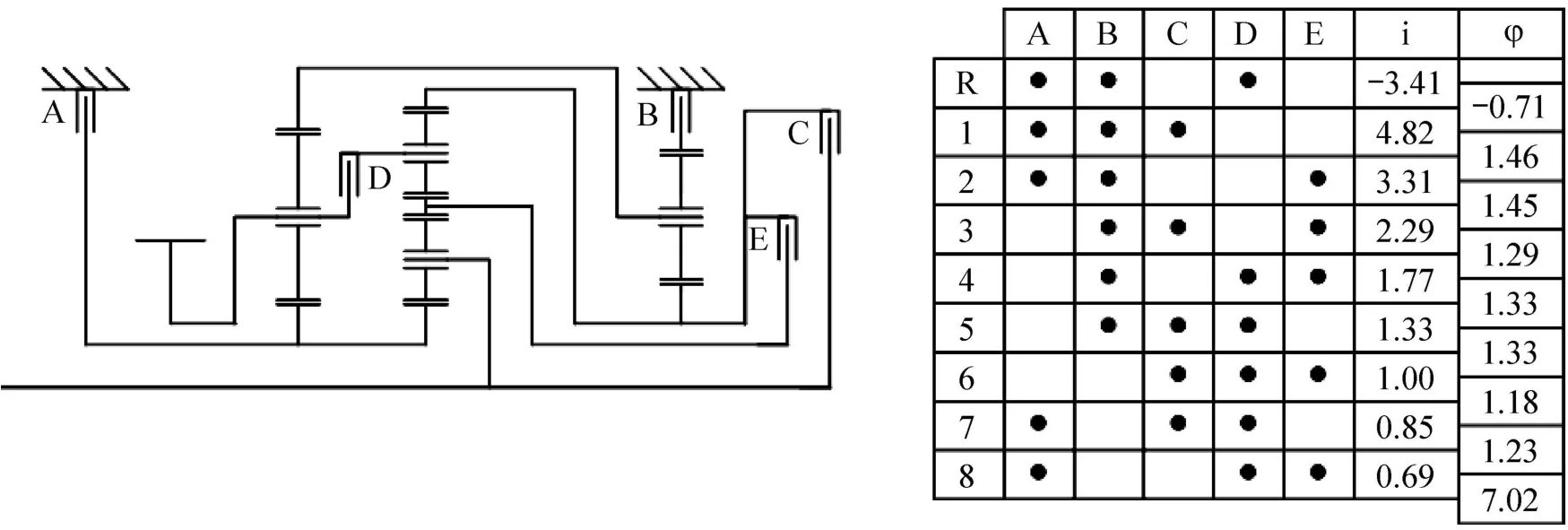

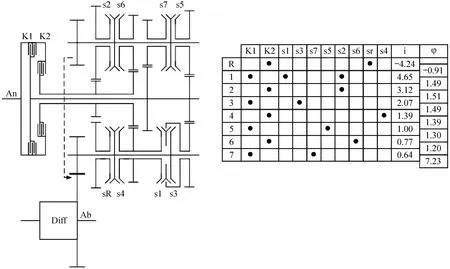

具有更多档位的行星齿轮变速器是本文的研究对象之一。图5给出了一种首选的行星齿轮变速器[1]。其基本概念是将用于标准传动的ZF8HP中的一个行星排[2],通过改变内部联接方式,使其能够径向排列两个行星排。这样变速器的轴向安装长度仅有3个行星排。

图5 8HP-FQ行星排示意图和换档表Fig.5 8HP-FQ gearset schematic and shifting table

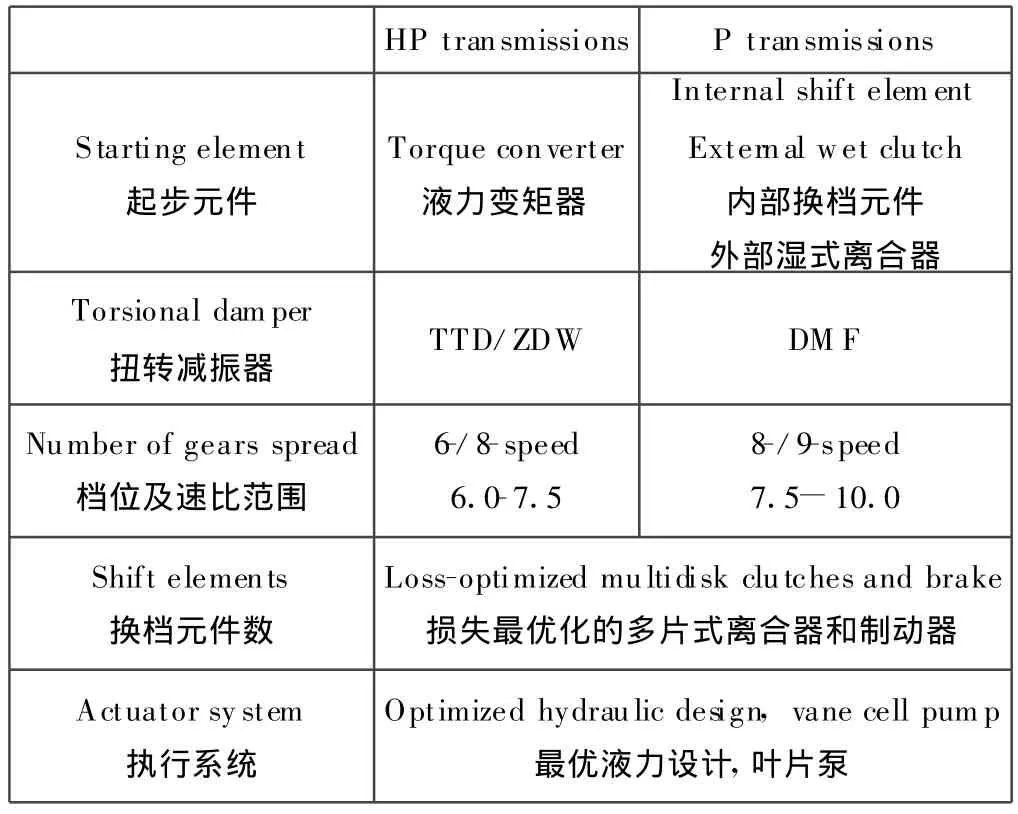

表1是建设性设计行星齿轮变速器时各种可能选择的结构形式。通常选择液力变矩器作为起步元件。其次是采用安装在轴上的综合式起步元件或油冷却的起步离合器。

对于所选轮系而言,变速器的速比范围和速比间隔是用于在经济性和动力性之间找到一个最佳平衡。

根据目前的知识,也能在流体动力方面实现最优化。从油泵的研究可知,通常采用由液力变矩器泵轮带动的常规内啮合齿轮泵或轴向偏置的叶片泵,而叶片泵在安装空间和效率方面更有优势。

2.3 双离合器变速器

在双离合器变速器中,在决定变速器是否合适时双离合器和换档机构扮演着重要角色。对以下各方面详加探讨。

2.3.1 湿式双离合器变速器(N-DKG)

液压式油冷却双离合器变速器和换档系统

采用多片式离合器的双离合器通过液压活塞动作。er transfer can be in the form of mechanical,electrical,or hydraulic means.Within the scope of the study,it w as determined,that continuously variable transmissions will no longer be pursued.The reasons for this are particularly the large amount of required installation space,too low efficiency,or the considerably higher costs of such systems.The following categories of transmissions were selected to be investigated in this study.

◦ State-of-the-art conventional torque converter planetary transmissions

◦ Planetary transmissions with integrated starting functionality

◦ Planetary transmissions with a separate starting clutch

◦ Variants of countershaft transmissions with full power shift capability

◦ State-of-the-art dual clutch transmissions

◦ Non-conventional hybrid forms

2.2 Planetary transmission

6-speed planetary transmissions with three gearsets and five shift elements and one hydro-dynamic torque converter as starting element are the state-of-the-art.

An extensive search for other planetary transmissions,particularly those with a higher number of gears,was done within the scope of this study.Fig.5 shows one of the preferred planetary transmissions[1].This is based upon the basic idea of selecting a gearset that is suitable for the ZF 8HP standard drive[2].By changing internal connec tions,it is now possible to radially arrange two planetary gearsets.In this way,the achievable axi-al installation length corresponds to a transmission that has only three planetary gearsets.

表1 开发的行星齿轮变速器结构特点Table 1 Applied configurations of the developed planetarytransmissions

2.3.2 干式双离合器变速器(T-DKG)

◦ 电机控制的干式双离合器和换档机构

使用伺服电机作为执行元件,能够进一步改善双离合器变速器的油耗。

双离合器变速器的干式摩擦片仅有极低的牵引转矩。齿轮的冷却和润滑采用飞溅润滑。仅有两台电动机作用在齿轮的滑动环上。另外两个执行机构作用在双离合器的分离轴承上。

2.3.3 “湿式”双离合器变速器(F-DKG)

◦ 电机控制的油冷双离合器和换档机构

该系统将干式双离合器的执行机构和类似于湿式双离合器的油冷多片式离合器组合起来,但是执行机构和干式双离合器相似,采用分离轴承和膜片弹簧。

利用一个低压内啮合齿轮泵冷却双离合器。换档执行机构和双离合器控制与湿式双离合器相同。

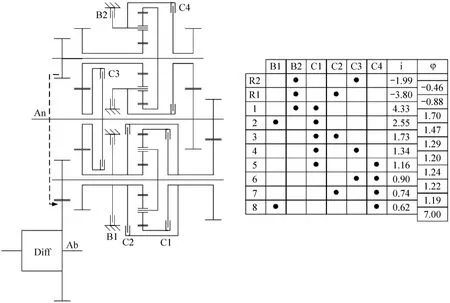

该系统可将双离合器变速器的档位扩展到6-9档,速比范围达到7-7.5。7档变速器见图6,可知它非常适用于常规工况。

该变速器有4个同步器、7对齿轮副和一根多用途的传动轴。1档齿轮被设计成分流传动,这里需要一个简单的机构来减轻重量、降低成本和减少轴承损失。

2.4 混合动力

2.4.1 平行轴式行星齿轮变速器

平行轴式行星齿轮变速器由一套常规行星齿轮变速器和若干根平行轴组成,而先前采用的联轴器则由圆柱齿轮所替代。其优点是轴向尺寸短。

Table 1 is an overview of the various selected configurations for w orking out the constructive designs of planetary transmissions.The first variant uses a conventional torque converter as the starting element.The second variant either has a shift element in the form of an integrated starting element,or a primary oil-cooled starting clutch.

The series of ratios and transmission spacing for each selected gearset was in order to find an optimal compromise in terms of fuel consumption and dynamics.

Based upon current knowledge,the hydraulics were also optimized.Among the pumps in-vestigated w as a conventional internal gear pump on the torque converter impeller hub as well as an axially offset vane cell pump,w here it was found that the vane cell pump has significant advantages in terms of installation space and efficiency.

2.3 Dual clutch transmissions

In dual clutch transmissions,both the dual clutch as well as the gearshift play an important part in determining w hether the transmission is suitable.The following variants were examined in detail.

2.3.1 Wet dual clutch transmission(N-DKG)

◦ Hydraulic actuation of oil-cooled dual clutch and shift system.

The dual clutch as two multidiscclutches is actuated by means of hydraulic pistons.

The conventional hydraulic control,in that it was attempted to find an optimal solution in terms of leakage,installation space,and costs.The types of pumps investigated were an internal gear pump and a vane cell pump,that were each driven with a chain and arranged directly on the control unit.The actuation of the synchronizer for gear selection is performed by means of conventional selector rods which are moved by hydraulic.

2.3.2 Dry dual clutch transmission(T-DKG)

◦ Electromotive actuation of the dry dual clutch and shift system

Using servomotors for actuation,it is possible to accomplish additional improvements in common systems for dual clutch transmissions in terms of fuel consumption.

图7所示的平行轴式变速器有8个齿轮副。组成两套行星齿轮机构并经两平行轴与传动轴相连。液力变矩器和液压控制单元没有变化。

2.4.2 行星齿轮式双离合器变速器

如果将常规双离合器变速器中的圆柱齿轮替换成行星齿轮,这将创造出一种行星齿轮双离合器变速器(图8)。变速器设计上的变化将导致更小的几何尺寸和更低的成本。

图6 7档双离合器变速器的结构示意图和换档表Fig.6 Gearset schematic and shifting table for a 7-speed dual clutch transmission

图7 平行轴式行星齿轮变速器结构示意图和换档表Fig.7 Gearset schematic and shifting table of the axially parallel planetary transmission

The dry friction discs of the dual clutch only have minimal drag torques.Cooling and lubrication of the gearset was realized by means of splash lu-brication.Only tw o electrical actuators actuate all sliding collars of the gearset.Two additional actua tors operate the dual clutches by means of classic release bearings.

图8 行星齿轮双离合器变速器结构示意图及换档表Fig.8 Gearset schematic and shifting table of a planetary dual clutch transmission

研究表明采用副行星齿轮机构的最大档位为7档。而操纵副行星齿轮机构有时将非常复杂。

离合器和执行机构可采用前述常规双离合器变速器。

3 结论

上述各节所给出的变速器的设计转矩可达280Nm。从成本和安装空间角度考虑,除了动力转化元件例如起步单元、齿轮组和输出轴外,设计还包括壳体及必要的附属部件,

3.1 安装空间

首先确定B级轿车相应安装空间的最小公分母。该空间被用来评估所有变速器创新设计和它们的适应性潜力。

3.2 油耗和性能

对不同类型变速器各部件的损失进行计算以获得各自的效率。

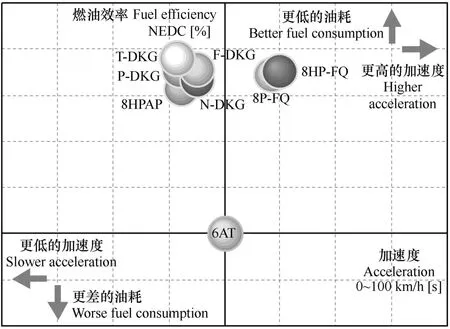

在此基础上,对应不同车辆和发动机系统进行油耗和动力性仿真分析。图9给出了配备85kW汽油机B级车的仿真结论。横坐标是0-100km/h加速时间的差值。纵坐标则是新欧洲行驶工况下的油耗。将一个典型的横置前驱6档自动变速器作为比较的基准。

2.3.3 "Moist"dual clutch transmission(F-DKG)

◦ Electromotive actuation of the oil-cooled dual clutch and shift mechanismThis system is a combination of the actuation of the T-DKG with an oil-cooled multidisk clutch similar to the N-DKG,but that is actuated the same as the dry dual clutch,using release bearings and diaphragm springs.

A Gerotor low-pressure pump is used for cooling the dual clutch.The actuation of the gear-shift system and the dual clutch is identical to that of the T-DKG.

For the selected application,it was attempted to find gearsets for dual clutch transmissions from six to nine gears and transmission spacing betw een 7.0 and 7.5.The 7-speed gearset show n in Fig.6 was found to be extremely suitable for the general conditions required.

Itcomes with four synchronizers, seven gearsand multiple use of the drive shaft.The first gear is designed as a winding path gear,which requires a simpler construction with respect to gears,and thus also means reduced weight,costs and bearing losses.

图9 油耗和行驶动力性比较Fig.9 Comparison between fuel consumption and driving dynamics

正如所预期的那样,干式双离合器变速器的油耗最低。湿式双离合器变速器也具有相当低的油耗,尽管增加了部分牵引损失。值得注意的是液力变矩器行星齿轮变速器(8HP-FQ)与它们的差距很小。 这是由于极小的牵引损失所致,因为开启的换档元件数量很少。另外,在最近的调查中发现,并不能忽略双离合器变速器在轴承和同步器中的损失。集成了起步功能的行星齿轮变速器(8HPFQ)由于将换档元件用作为起步元件使得尺寸较大而稍有缺陷。这导致牵引转矩明显增加。

在起步特性方面的不同主要取决于起步转矩对不同速比和不同转动惯量的适应性。配备液力变矩器的变速器最佳,因为转矩成倍放大。

3.3 系统成本

尽管将注意力集中在油耗方面,但系统成本将最终决定市场的接受程度。为了给出一个公平的成本比较以适用于今后情况,先确定以下前提:

考虑关于特殊系统的所有事实

以车辆年装车20万套变速器为依据

产品生产地:德国

在制造、装配和测试方面的新投资,不计现有设施

投资分配、开发费用和5年中的非经常成本

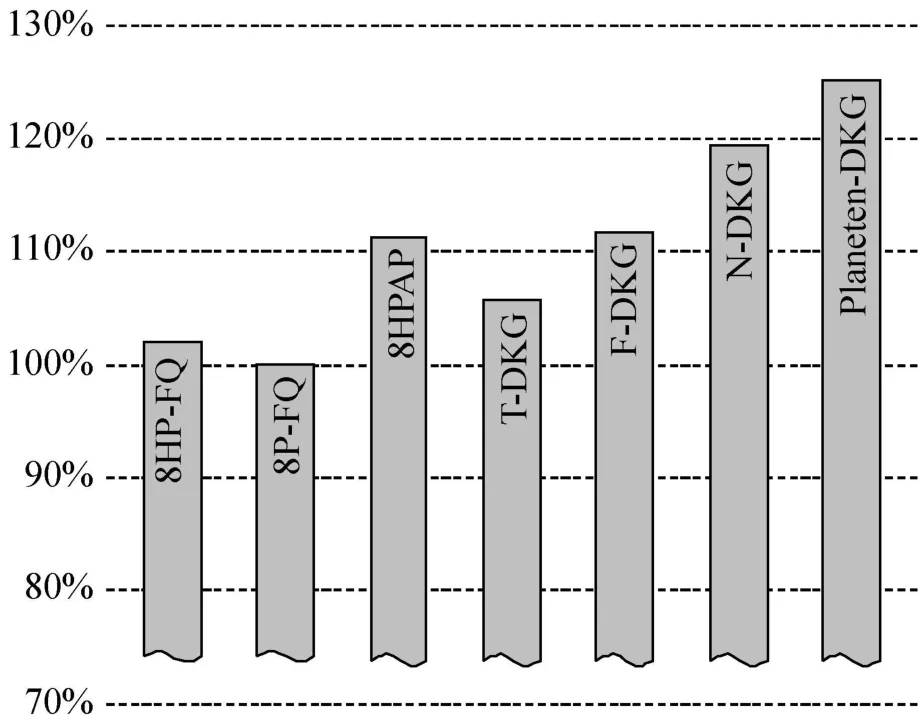

图10是相对成本的比较。配备集成起步功能的行星齿轮变速器(8P-FQ)达到100%的标准。配备液力变矩器的行星齿轮变速器(8HP-FQ)增加了约2%的成本。配备电动执行机构的干式双离合器变速器(T-DKD)约增加了6%的成本。湿式双离合器变速器(F-DKG和N-DKG)约增加了 11%到19%的成本,而行星齿轮双离合器变速器的成本的增加超过了25%。

2.4 Hybrid forms

2.4.1 Axially parallel planetary transmission

The axially parallel planetary transmission is developed by subdividing a conventional plane-tary transmission across several parallel shafts,whereby the shaft couplings used previously are replaced by spur gears.Advantages can be gained in terms of installation length.

The gearset which is an example of an axially parallel planetary transmission with eight gears is shown in Fig.7.This consists only of two planetary gearsets that are arranged on two shafts parallel to the drive shaft.The torque converter and the hydraulic controlunit were incorporated unchanged.

2.4.2 Planetary dual clutch transmission

If the sub-transmission components,which normally consist of spur gears,are replaced by planetary transmissions in a conventionaldual clutch transmission,this will create a planetary dual clutch transmission(see Fig.8).This change in the transmission design was ex-pected to result in a smaller physical size,as well as lower costs.

The search revealed,however,that useful sub-transmission components are available only up to a maximum number of seven gears.The actuation of the sub-transmission components is sometimes also very complex.

The selection of clutches and their actuation can be done again in the same manner as in the conventionally designed dualclutch transmissions shown above.

3 Results

The transmission designs presented in the preceding section were designed for 280 Nm torque by means of 3D CAD.In order to be able to use it for the determination of costs and the installation space,the design also included the housing and necessary attachment parts in addition to the power-transfer elements,such as the starting element,gearset,and the output drive.determine the respective efficiency.

图10 变速器相对成本比较Fig.10 Relative cost comparison of the transmission designs worked out

3.4 混合动力可能性

本文一开始就提及变速器采用混合动力的可能性,显然双离合器变速器安装电动机存在问题。如果电动机被布置在内燃机和变速器之间,将增加变速器的长度,为安装空间制造了难题。虽然可以将紧邻变速器安装并与两副变速器之一联接作为一个可选择的方案,但工作时仅有一个副变速器会存在很大问题。

配备液力变矩器的变速器,能够将其替换成电动机而无需考虑安装空间问题,因此仅有优势。

4 总结

基于以上研究,不论是现在还是将来,双离合器变速器和配备液力变矩器的行星齿轮变速器都将是横向传动车辆的最佳配置。从安装空间和成本方面考虑,行星齿轮变速器比双离合器变速器更具优势。在油耗方面,它们与安装电动执行机构的双离合器变速器相比略显不足,但能够从起步那些方面加以补偿,因为转矩被变矩器成倍放大。

3.1 Studies with respect to installation space

In a first step,the smallest common denominator of the relevant installation space in B-Segment vehicles was determined.This space was then used to assess all created transmission designs and evaluate them for potential adaptation.

3.2 Fuel consumption and performance

The engineering concepts ofthe different transmissions were also used to precisely calculate the specific losses of individual components and to

On this basis,simulations of fuel consumption and dynamics were performed for various ve-hicles and engine systems.Fig.9 illustrates the results for a B Segment vehicle with an 85 kW gasoline engine.The abscissa represents the difference in time for the acceleration from start to 100 km/h.The ordinate represents a relative comparison for fuel consumption in the New European Driving Cycle(NEDC).A state-of-the-art 6-speed automatic transmission for front-transverse configuration serves as the basis for this comparison.

As was to be expected,the dry dual clutch transmission(T-DKG)was found to be the system with the lowest fuel consumption.The moist dual clutch transmission(F-DKG)also had very low fuel consumption,despite increased drag losses.Noteworthy is the small distance of the torque converter planetary transmission(8HP-FQ),how ever.

This is due to the very small drag losses,because of the small number of open shift ele-ments.In addition,under close examination,it is also apparent that also dual clutch trans-missions have drag losses in bearings and synchronizers that cannot be ignored.The plane-tary transmission with integrated start function(8P-FQ)has a slight disadvantage in that it has a larger sized shift element that also serves for start up.This results in a marked increase of the drag torque.

The differences in startup characteristics are primarily the result of the necessary adaptation on the starting torque ratio to the various spreads and the different moments of inertia.Transmissions with a hydrodynamic torque converter are best,due to the torque multiplica-tion.

3.3 System costs

Despite focusing mainly on fuel consumption,ultimately the system costs are decisive with respect to market acceptance.In order to make a fair cost comparison which can be applied to future circumstances,the following premises were established:

◦ Taking into account all facts with regard to specific systems

◦ One vehicle application based upon an annual quantity of 200,000 transmissions

◦ Location of production facility:Germany

◦ New investment in manufacturing,assembly and testing,without taking existing facilities into consideration

◦ The apportionment of investments,development expenses,and nonrecurring costs over aperiod of five years

Fig.10 represents the result of the relative cost comparison.The planetary transmission with integrated startup function(8P-FQ)w as standardized 100%.The planetary transmission with torque converter(8HP-FQ)with additional costs of approximately 2%,is only marginally more expensive.The dry dual clutch transmission with electrical actuation(T-DKD)has an additional cost of approximately 6%.The moist and the wet dual clutch transmission(F-DKG and N-DKG)are approximately 11%or 19%more expensive,and the planetary dual clutch transmission is over 25%more expensive.

3.4 Hybrid capability

Right from the start,all transmissions were designed for hybrid suitability,and here it was evident that the dual clutch transmissions,in particular,are problematic in terms of placing the electrical engine.If the electrical engine is arranged between the combustion engine and the transmission,its entire length must be added to the length of the transmission,which creates problems in terms of installation space.But even if placed next to the transmission and connecting it to one of the two sub-transmissions as an alternative arrangement,the fact that it operates with only one sub-transmission is also extremely problematic.

Transmissions with torque converters,which can be replaced with an electric engine almost irrespective of the availableinstallation space,have advantages.

4 Summary

Based upon this study,it can be said that dual clutch transmissions and planetary transmis-sions with torque converters are basically suitable for use in vehicles with transverse drive systems,now and in the future.In terms of installation space and particularly with respect to costs,planetary transmissions have distinct advantages compared with dual clutch transmis-sions,however.With respect to fuel consumption,they have only minor drawbacks when compared with electrically actuated dual clutch transmissions,which,however,are compensated by the starting dynamics due to the torque multiplication of the torque converter.

So if we finally count the facts,the planetary transmissions are the better choice for front-transverse applications.

5 Bibliography

Literature

[1]DE 10 2005 014 592 A1 M ehrstufengetriebe[multistage transmissions]

[2]DE 10 2005 002 337 A1 M ehrstufengetriebe[multistage transmissions]

——变矩器的锁止控制