静电纺Janus纳米纤维膜的研究进展

摘 要:鉴于Janus分离膜特殊的结构与性能,其在众多领域均展现出巨大潜力。通过静电纺丝法制备的Janus纳米纤维膜具有高比表面积、细长纤维结构和可控性等优势,受到广泛关注。为更好了解静电纺Janus纳米纤维膜的发展近况,对近年来静电纺Janus纳米纤维膜的研究进展进行了综述。重点介绍了静电纺Janus纳米纤维膜的制备方法,及其在水处理、空气过滤、生物医用等领域中的应用,讨论了静电纺Janus纳米纤维膜的制备及应用过程中的优势和缺点,并对未来发展进行展望。综述结果可为静电纺Janus纳米纤维膜的发展提供一定参考。

关键词:静电纺丝;Janus纳米纤维膜;制备方法;水处理;空气过滤;生物医用

中图分类号:TQ342

文献标志码:A

文章编号:1009-265X(2024)10-0001-10

近年来,Janus分离膜是膜分离研究领域的一个新兴概念,在不同领域均展示出巨大潜力,受到研究者的广泛关注。Janus分离膜是一种特殊的薄膜材料,因其双面具有不同性质而得名,类似于罗马神话中的两面神Janus。Janus分离膜其中一面具有亲水性(疏油性),而另一面则具有疏水性(亲油性),该特性使其在油水分离、膜蒸馏、催化降解等领域中具有独特的优势[1-3]。

与其他分离膜相比,静电纺纳米纤维膜具有高比表面积、细长纤维结构和可控性等特点[4],在分离、催化和生物医用等领域具有广泛的应用潜力。然而,以单一聚合物为原料制备的纳米纤维膜,存在功能单一、应用领域窄等缺陷,开发功能多样化、性能更为优异的纳米纤维膜迫在眉睫。相较于传统静电纺纳米纤维膜,静电纺Janus纳米纤维膜在众多领域均有更为巨大的潜力。

Janus纳米纤维膜主要利用不对称浸润性产生的协同作用[5],使其在两相或多相体系中实现单向传输,进而实现两相或多相体系的分离。因此,如何实现膜两侧非对称浸润性是其核心问题。鉴于此,本文对近年来发表的相关研究成果进行综述,介绍静电纺丝技术制备纳米纤维膜的原理和影响因素;对静电纺Janus纳米纤维膜的制备方法及其应用进行重点阐述,并对静电纺Janus纳米纤维膜未来发展进行展望,以期为静电纺Janus纳米纤维膜的开发和创新提供参考。

1 静电纺丝

1.1 静电纺丝法简介

目前,制备纳米纤维的方法主要有微相分离法、拉伸法、模板合成法、闪蒸纺丝法、海岛纺丝法及静电纺丝法等[6-9]。其中,静电纺丝法具有设备结构简单、纤维结构可控性高及制备过程连续性高等优点,是制备纳米纤维的主要技术之一。静电纺丝是指在高压电场作用下,聚合物溶液或熔体射流发生形变而形成“泰勒锥”,然后经拉伸、细化及固化过程而制得纳米纤维。静电纺丝纳米纤维具有纤维直径小、孔隙率高、比表面积高等优点,在过滤、催化、能源、生物医药等领域已得到广泛应用[10-14]。

1.2 静电纺丝影响因素

静电纺丝过程中,通过调控不同因素可以实现对纤维形态和性质的控制。影响纤维形态的因素包括以下几个方面:1)聚合物性质:聚合物的分子量、流变性质、表面张力等对静电纺丝过程有重要影响。高分子量的聚合物通常有更高的纺丝稳定性和纤维质量[15]。2)溶液浓度:溶液的浓度会影响纺丝过程中电荷的累积和液滴的形成。较高的溶液浓度通常有助于形成均匀而稳定的纳米纤维。3)溶剂性质:溶剂对聚合物的溶解度、表面张力等有影响。合适的溶剂选择可以改善纺丝过程中的流动性和纤维形态。4)电场参数:电场强度、频率和极性等参数会直接影响纺丝的效果和纤维形态。适当调节电场参数可以控制纤维的直径、排列方式和三维结构。5)距离和喷射速度:纺丝距离和喷射速度会影响纤维的拉伸和固化过程。适当的距离和速度可以得到所需的纤维形态和尺寸。6)环境条件:温度、湿度和空气流动情况等环境条件也可能对纺丝过程产生一定影响[16]。

2 静电纺Janus纳米纤维膜的制备及结构调控

2.1 顺序静电纺丝法

顺序静电纺丝法是基于传统静电纺丝法,按照先后顺序逐层纺丝制得纳米纤维再复合成Janus纳米纤维膜的方法[17]。与传统静电纺丝法相同,顺序静电纺丝法可通过聚合物溶液性质、纺丝参数等调控所得纳米纤维膜结构。除此之外,顺序静电纺丝法也可通过聚合物溶液纺丝顺序及时间对纳米纤维结构与性能进行调控,以制备特定结构与性能的纳米纤维膜[18]。顺序静电纺丝法通常以不同选择润湿性聚合物为原料或添加不同性能添加剂实现Janus纳米纤维膜的非对称浸润性。

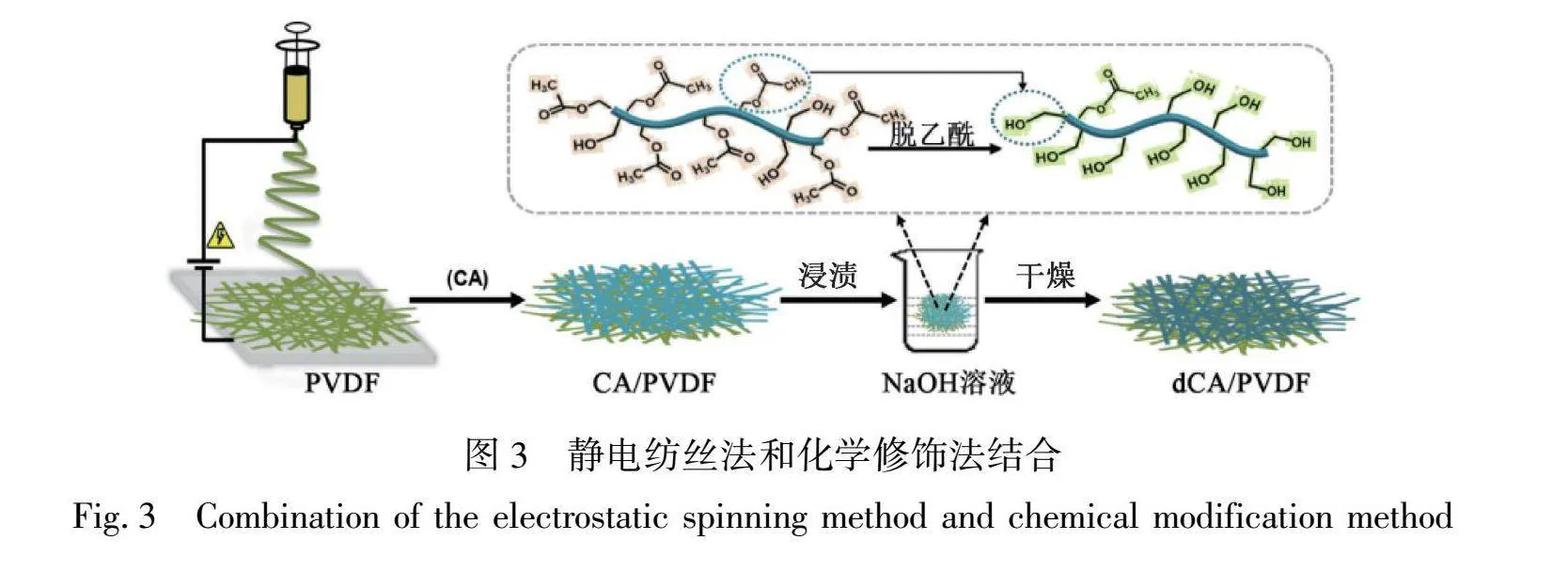

Chen等[19]以聚偏氟乙烯-六氟丙烯(Poly(vinylidene fluoride-co-hexafluoropropylene),PVDF-HFP)为成纤聚合物,以氟化SiO2为添加剂,通过静电纺丝法制得疏水性纳米纤维层;然后以聚丙烯腈(Polyacrylonitrile,PAN)为成纤聚合物,以亲水性SiO2为添加剂,制得亲水性纳米纤维层,并使用化学氧化法在亲水层上包覆聚吡咯材料,最终制得光热Janus纳米纤维膜。该纤维膜在光热膜蒸馏测试中,水通量为44.4 kg/(m2·h),脱盐率达到99.99%,太阳能利用效率为92.20%,表现出优异海水淡化性能。Wu等[20]通过顺序静电纺丝法制得Janus纳米纤维膜,其制备示意图如图1所示。从图1中观察到,首先以PAN为成纤聚合物,以蜡烛烟灰为亲水性添加剂,通过静电纺丝法制得亲水性纳米纤维层;然后以上述纳米纤维层为接收基体,PAN为成纤聚合物,ZIF-8(Zeolitic imidazolate framework-8)为疏水性添加剂,通过静电纺丝法制得疏水性纳米纤维层,最终制得Janus纳米纤维。该纤维膜能有效分离含油废水,分离性能优异。

顺序静电纺丝法具有性能优异、结构易控等特点,是制备Janus纳米纤维膜常用方法之一。然而,顺序静电纺丝法也面临一些挑战,如纺丝顺序或喷丝头参数对纤维结构与性能影响明显,纳米纤维层的结合性需进一步加强。

2.2 静电纺丝法和物理方法结合

除顺序静电纺丝法外,静电纺丝法常与其他物理方法相结合以制备Janus纳米纤维膜,如旋涂法、浸渍法、真空抽滤法和静电喷涂法等[21-24]。其中,静电喷涂法和静电纺丝法相结合是常用方法之一。静电喷涂法是指在高压电场作用下,液滴产生定向运动,并沉积于接收体表面的方法[25]。使用静电喷涂法,聚合物稀溶液或无机粒子溶液会在高压电场作用下产生雾化现象,在接收体表面形成微纳串珠-纳米纤维结构,从而赋予所得膜特定的选择润湿性。目前,研究者常结合静电纺丝法和静电喷涂法制备Janus纳米纤维膜。

Li等[26]通过静电纺丝法和静电喷涂法结合制备了Janus纳米纤维膜,其制备流程如图2所示。从图2中观察到,首先通过静电纺丝法制得PAN纳米纤维层,经高温热压处理,制得亲水性纳米纤维层;然后以PVDF-HFP溶液为静电纺丝液,以聚苯乙烯/聚二甲基硅氧烷混合溶液为静电喷涂液,制得疏水性纳米纤维层,最终制得Janus纳米纤维膜。该纤维膜在膜蒸馏过程中,水通量为27.7 L/(m2·h),脱盐率达到100%,在连续膜蒸馏测试中表现出优异的性能稳定性。Li等[27]通过仿生改性制得PAN@聚多巴胺(Polydopamine,PDA)亲水性纳米纤维层后,以其为接收基体,以丝素蛋白溶液和聚己内酯/姜黄素溶液为静电纺丝液制得疏水性纳米纤维层,然后将胺化介孔二氧化硅-壳聚糖溶液静电喷涂至疏水纳米纤维层表面,最终制得具有优异载药性和缓释性、抗菌性、抗氧化性及液体单向输送能力的Janus纳米纤维膜。

静电纺丝法和静电喷涂法结合,不仅解决纳米300262e547ca49e128eab1fd4e0da834微球之间相互堆叠不牢固的问题,而且赋予纳米纤维膜独特的3D凹凸表面结构,所得纳米纤维膜具有稳定性高、界面相容性好等特点。然而,静电喷涂法所得纳米微球大小不一,导致膜性能不均一,且静电喷涂法需溶剂挥发快,溶剂种类选择有限,这限制了其在纳米纤维膜改性领域中的广泛应用。

2.3 静电纺丝法和化学方法结合

静电纺丝法和化学方法结合是将纳米纤维膜单侧(双侧)或单侧连续多次进行化学交联,或在溶液内部添加化学物质,使膜的另一侧具有相反的性质,实现两侧非对称浸润性,从而制得Janus纳米纤维膜的方法。常用的化学改性方法有化学沉积法和接枝300262e547ca49e128eab1fd4e0da834改性法(等离子表面处理法、化学修饰法)。

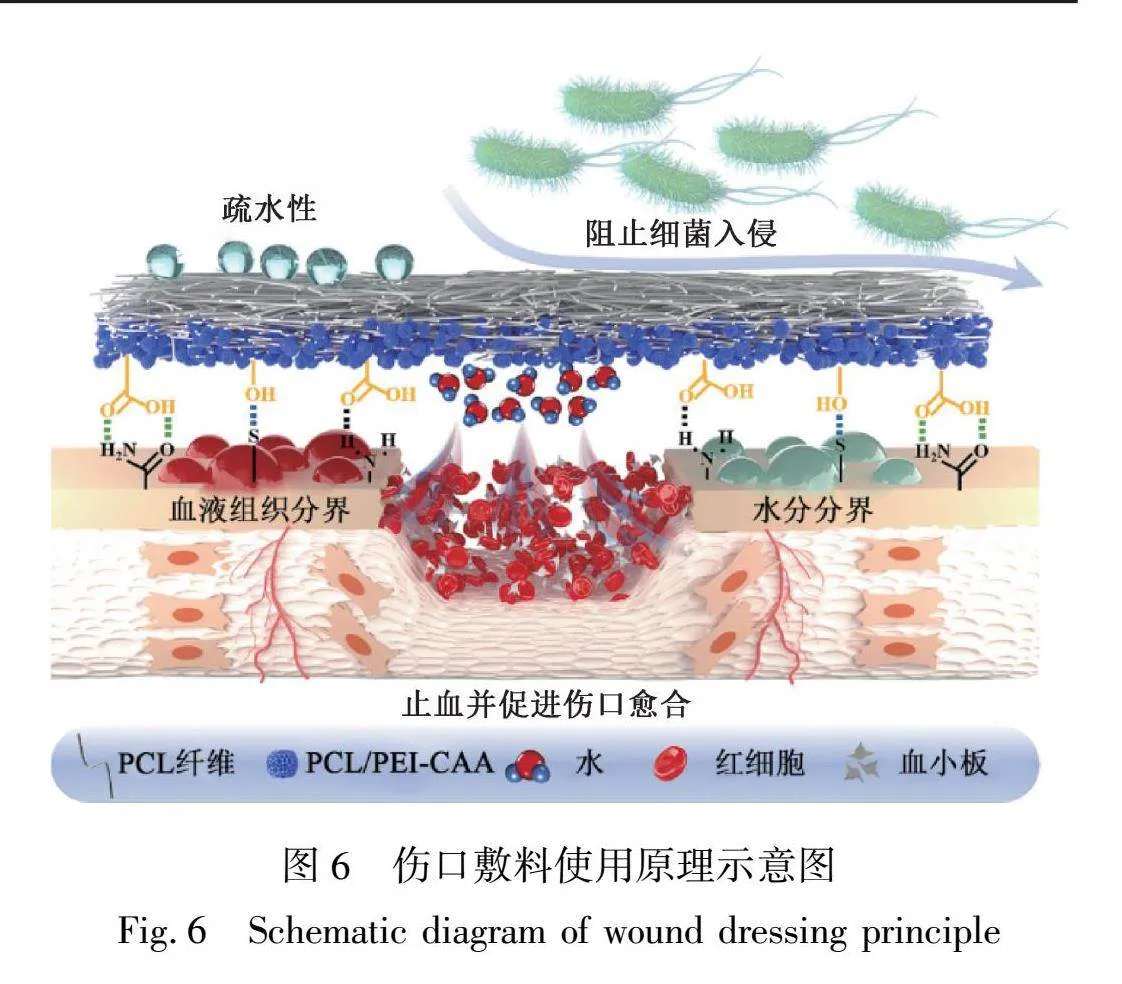

Liu等[28]以聚偏氟乙烯(Polyvinylidene difluoride,PVDF)为成纤聚合物,通过静电纺丝法制得PVDF疏水性纳米纤维膜;将PVDF疏水性纳米纤维膜浸于PDA溶液中,使PDA沉积在PVDF纳米纤维上,纳米纤维膜上层浸润性转变为亲水性,制得PVDF@PDA Janus纳米纤维膜。该纤维膜对水包油乳液具有高分离通量。Zhang等[29]以聚乙烯醇(Polyvinyl alcohol,PVA)、壳聚糖、环丙沙星和虾青素混合溶液为纺丝液,对静电纺丝所得纳米纤维层等离子表面处理改性,制得亲水性纳米纤维层;然后以上述纳米纤维层为接收基体,PVDF为成纤聚合物,通过静电纺丝法制得疏水性纳米纤维层;最后以PVDF/SiO2混合溶液为静电喷涂液在疏水性纳米纤维层表面构建纳米微球结构,制得超疏水性纳米纤维层,最终制得Janus纳米纤维膜。该纤维膜作为伤口敷料可有效缓解渗出液流失,为伤口提供湿润环境,从而加快药物释放,促进伤口愈合。Cheng等[30]通过静电纺丝法和化学修饰法结合制得Janus纳米纤维膜,其制备流程如图3所示。从图3中观察到,首先以PVDF为成纤聚合物,通过静电纺丝法制得疏水性纳米纤维层;以醋酸纤维素(Cellulose acetate,CA)为成纤聚合物,制得亲水性纳米纤维层,并使用NaOH溶液对亲水性纳米纤维层碱处理,使醋酸纤维素纤维脱乙酰,接枝更多羟基,提高亲水性纳米纤维层浸润性,最终制得dCA/PVDF Janus纳米纤维膜。该纤维膜具有优异的分离乳液性能,可重复性和耐酸碱性。

化学改性法对纳米纤维改性效果显著,但劣势也较为明显,如改性步骤繁琐、降低膜的稳定性、成本较高等。

3 静电纺Janus纳米纤维膜应用

3.1 油水分离

近年来,含油废水等水污染问题日益加重,对生态环境和人类身体健康造成了严重危害。相较于传统油水分离技术,膜分离技术具有操作简单、成本低和高分离效率等优势,在油水分离领域具有较大的应用潜力。在分离膜中,相较于单一浸润性的纳米纤维膜,Janus纳米纤维膜有较高油水分离通量,已广泛应用于油水分离领域[31]。

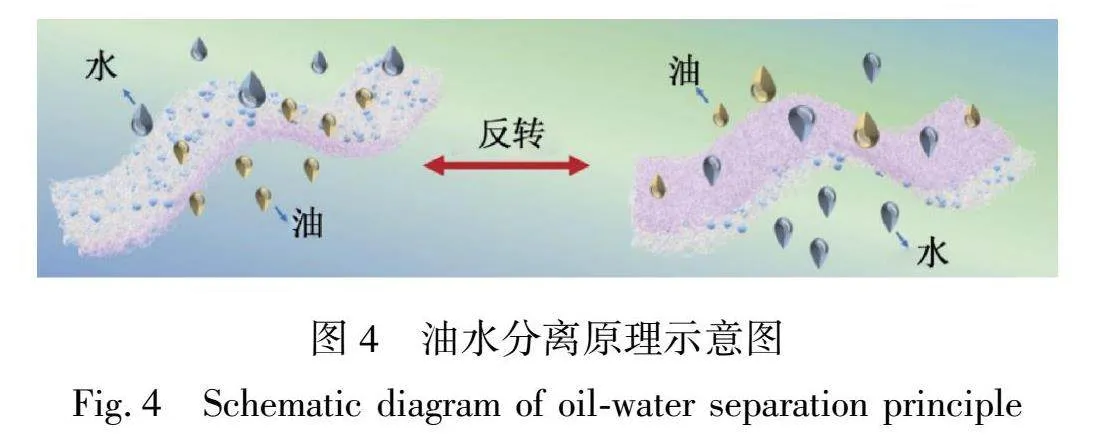

含油废水常以油水乳液的形式存在,包括油包水乳液和水包油乳液,对稳定油水乳液的分离需经破乳化过程,分离过程较难。因此,能够分离不同类型油水乳液的Janus纳米纤维膜具有较大的应用潜力。Xiao等[32]受荷叶表面性能启发,通过顺序静电纺丝法制备PAN亲水纳米纤维层和PVDF疏水纳米纤维中间层;然后以PVDF为成纤聚合物,甲基三乙氧基硅烷(Methyltriethoxysilane,MTES)为添加剂,通过静电喷涂法,在PVDF疏水纳米纤维中间层上构建类似荷叶粗糙表面结构,最终制得三层PAN/PVDF/PVDF-MTES Janus纳米纤维膜。该纤维膜亲水性纳米纤维层的水接触角低至0°,疏水纳米纤维层的水接触角高达170°。图4为该纤维膜油水分离原理示意图,由图可以观察到,当疏水层为上层时,该纤维膜对油水混合物和油包水乳液,分离效率达98%以上;当亲水层为上层时,该纤维膜对水包油乳液分离效率达93%以上。在分离水包油乳液时,Janus纳米纤维膜的通量通常会严重降低,是因为在分离乳液过程中,未充分发挥亲水层和疏水层的协同作用。因此,制备Janus纳米纤维膜的关键在于如何发挥亲水层和疏水层的协同作用。Zhang等[33]通过静电纺丝法制得PAN/Zn(Ac)2纳米纤维层和PVDF-HFP疏水性纳米纤维层,然后通过原位生长法在PAN/Zn(Ac)2纳米纤维表面生长亲水性ZnO纳米针,使得PAN/Zn(Ac)2纳米纤维层浸润性由疏水性转变为亲水性,最终制得多层复合Janus纳米纤维膜。ZnO纳米针穿透PVDF-HFP纳米纤维层,此特殊的多层贯穿连接结构可以协同发挥亲水层的尺寸筛选机制和疏水层的聚集机制,使所得膜具有优异的油水分离性能。该膜的平均孔径为1.1 μm,仅依靠重力可高效分离平均粒径为650 nm的水包甲苯乳液,通量可达32100 L/(m2·h·bar),所得滤液含油量低至4 mg/L,为实现高效分离水包油乳液开辟了新途径。

虽然静电纺Janus纳米纤维膜已成功应用于油水分离领域,但其在实际应用中,会不可避免地受到污染,进而导致Janus纳米纤维膜出现性能衰减、结构被破坏等问题,极大限制了Janus纳米纤维膜应用。因此,开发具有优异抗污染性能和分离性能且结构稳定的Janus纳米纤维膜是未来的研究方向之一。

3.2 膜蒸馏

随着淡水资源紧缺问题日益严重,对海水淡化技术的研究迫在眉睫。其中,膜蒸馏技术具有操作简单和分离效率高等优点,已广泛应用于海水淡化领域。疏水膜在膜蒸馏过程中,抗污染性低,渗透通量和分离效率衰减快,导致其使用周期短。研究发现,相较于疏水膜,Janus纳米纤维膜具有独特的多孔结构和对称选择润湿性,可有效提升其抗污染性,提升膜蒸馏性能[34]。

Zhu等[35]以PVDF为成纤聚合物,以NH3·H2O和三甲氧基十七烷基硅烷(trimethoxy (1H,1H,2H,2H-heptadecafluorodecyl) silane,17-FAS)为添加剂,通过静电纺丝法制得PVDF纳米纤维层;然后以PVA和聚丙烯酸(Polyacrylic acid,PAA)为原料,通过静电喷涂法在PVDF纳米纤维层表面构建亲水性微/纳串珠层;通过经热处理法使得NH3·H2O和17-FAS发生反应,使得PVDF纳米纤维层的选择润湿性由疏水亲油转变为疏水疏油,最终制得Janus纳米纤维。该纤维膜的疏水性纳米纤维层水接触角高达157°,亲水性纳米纤维层的水下油接触角高达156°。在膜蒸馏处理含油含盐废水的过程中,膜渗透通量可达27 L/(m2·h),脱盐效率可达99%,表现出了优异的膜蒸馏性能及抗油污性能。Ju等[36]以PVA为成纤聚合物,以炭黑为无机添加剂,通过静电纺丝法制得亲QsvPLc/68rVh+yxMLt8S1Lwz55unMFOlqg9p3aZ/3hA=水光热纳米纤维层;然后以PVDF为成纤聚合物,通过静电纺丝法制得纳米纤维中间层;最后以聚四氟乙烯(Polytetrafluor oethylene,PTFE)为成纤聚合物,通过气流纺丝法制得疏水性纳米纤维层,经高温热处理后,最终制得三层Janus纳米纤维膜。当炭黑添加量为15%时,在1 kW/m2光照强度下,渗透通量可达1.05 L/(m2·h),脱盐率大于99.99%,光热转换效率可达71.4%。当膜蒸馏处理含十二烷基硫酸钠、油和CaCl2的含盐废水时,连续运行60 h后,Janus膜的渗透通量仍可达1.035 L/(m2·h),且脱盐率大于99.98%,表现出优异的高光热转换性能和抗污染性。

目前,静电纺Janus纳米纤维膜独特性能可有效地降低膜污染,相较于疏水性膜,使用寿命较长,但其废弃时造成的无机盐、有机物质和微生物等膜污染问题仍无法不可避免。尤其,当化学品或油性污染物接触膜表面时,膜污染问题尤其严重,因此,在膜蒸馏领域,减少或避免膜污染问题是Janus纳米纤维膜的未来研究方向之一。

3.3 催化降解

工业废水成分复杂,其中染料、重金属离子等污染物性能稳定,仅通过物理分离无法彻底处理。为此,科研人员常将催化剂引入纳米纤维膜,从而赋予其优异的催化降解性能[37-39]。

Xu等[40]以PVDF-HFP为成纤聚合物,通过静电纺丝法制得疏水性纳米纤维层;然后以PAN为成纤聚合物,以吡啶配位钴单原子纳米催化剂为添加剂,制得亲水性纳米纤维层。所得Janus纳米纤维膜在2 min内对苯胺的去除率可达92%,表现出优异的催化降解性能。此外,所得Janus纳米纤维膜具有优异的膜蒸馏性能和油水分离性能。Han等[41]以聚苯乙烯为成纤聚合物,通过静电纺丝法制得疏水性纳米纤维层;然后以PAN、聚乙烯吡咯烷酮、TiO2纳米粒子和酞菁铁的混合溶液为纺丝液,通过静电纺丝法制得亲水性纳米纤维层,超声去除聚乙烯吡咯烷酮以构建蜂窝状结构,制得Janus纳米纤维膜。该纤维膜疏水纳米纤维层水接触角可达140°,亲水纳米纤维层水接触角仅为28°。疏水层作为气体通道,将O2输送至亲水催化层,同时光敏剂酞菁铁提高了TiO2对可见光的捕获能力,促进活性氧生成,进一步提高所得Janus纳米纤维膜对有机污染物的降解效率。

静电纺Janus纳米纤维膜具有多级可调控的结构,在催化降解领域具有巨大的应用潜力,但其结构稳定性和抗污染性差、催化物质单一等问题,很大程度上限制其广泛应用。因此,迫切需要开发具有稳定结构的纳米纤维膜和多功能催化剂,以实现对不同物质的催化降解。

3.4 空气过滤

静电纺纳米纤维膜具有高孔隙率和高比表面积等优点,在空气过滤领域具有广泛的应用[42]。研究人员发现单一亲水性材料易被污染和破坏,单一疏水性材料由于其低水蒸气渗透性而不适合长期佩戴。因此,在空气过滤领域,具有不同表面选择润湿性的Janus纳米纤维膜逐渐得到广泛应用。

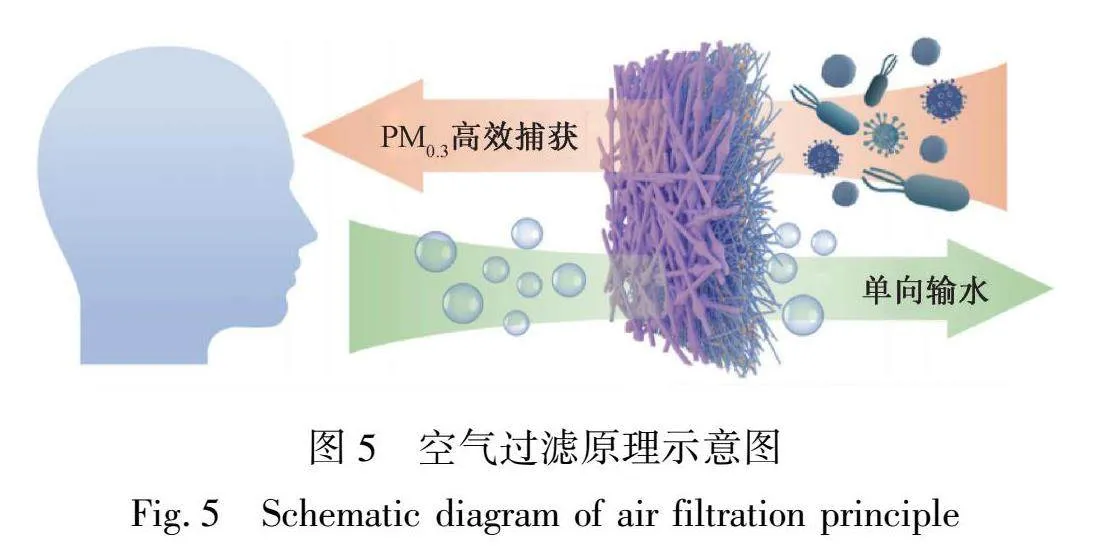

Chen等[43]以PVDF为成纤聚合物,通过静电纺丝法制得串珠结构疏水性纳米纤维层,然后以PAN为成纤聚合物,甲基溴化铵为添加剂,制得亲水性纳米纤维层。在5.33 cm/s的空气速度下,所得双层串珠/无珠Janus纳米纤维膜对PM0.3过滤效率高达99.17%,压降仅为83 Pa,品质因子为0.0578 Pa- 表明其具有优异的空气过滤性能,Janus纳米纤维膜的空气过滤原理如图5所示。甲基溴化铵增加了纤维的总体偶极矩,进而增强了纤维与NaCl颗粒的相互作用,从而提高其过滤能力,同时也赋予所得膜优异的抗菌性。Cui等[44]以PAN为成纤聚合物,TiO2纳米粒子为添加剂,通过静电纺丝法制得亲水性纳米纤维层;然后以PVDF-HFP为成纤聚合物,SiO2纳米粒子为添加剂,通过静电纺丝法制得疏水性纳米纤维层。上述所得Janus纳米纤维膜对PM0.225和PM0.875-7.25的过滤效率分别高达99.56%和100%,压降仅为27 Pa。在连续过滤测试中,所得膜对PM2.5的过滤效率高达100%,压降保持不变,表现出优异的空气过滤性能。

得益于独特的结构与性能,静电纺Janus纳米纤维膜在空气过滤领域具有较为广泛的应用。随着膜功能化研究的不断深入,开发低压降,多功能(如耐高温、光催化、吸附有毒气体、自清洁等)的静电纺Janus纳米纤维膜已成为当前研究的趋势,以满足更严苛条件下的高效空气过滤。

3.5 伤口敷料

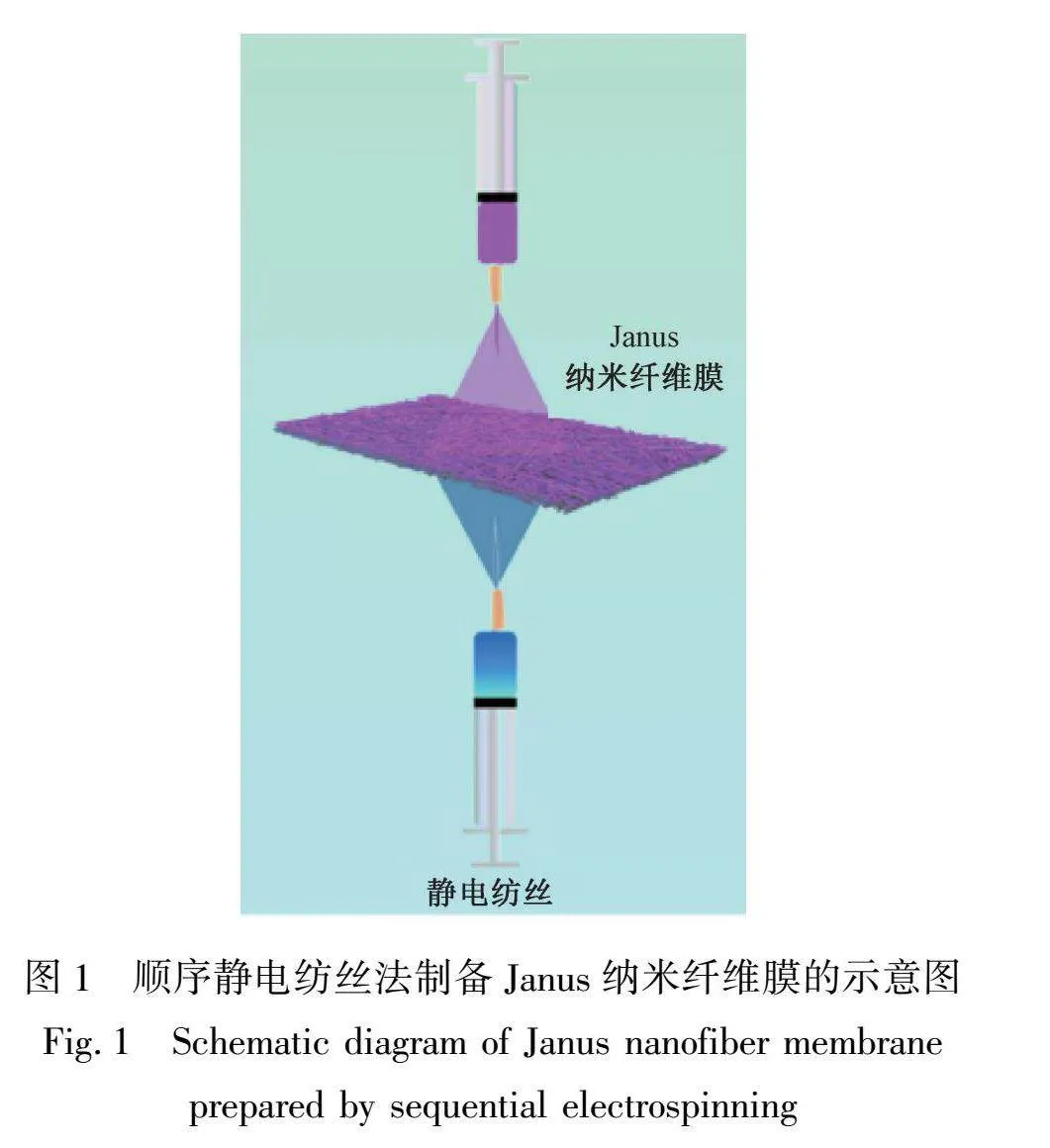

伤口敷料长期与血液、皮肤和其他组织接触,需要为创口和创面提供适宜的微环境[45]。然而,传统纱布生物相容性和渗透性较差,不能满足上述要求。静电纺纳米纤维膜用作伤口敷料时,高孔隙率确保了气液交换,膜的结构与细胞基质结构类似,可以促进细胞生长繁殖[46]。静电纺Janus纳米纤维膜的亲水层和伤口直接接触,疏水外层隔绝外界水分和微生物,免受外界微生物干扰。Janus纳米纤维膜在伤口敷料领域展示的这些优势为伤口敷料朝功能化方向发展提供了一条途径。

Zhu等[47]以多孔铜网为接收基体,聚己内酯(Polycaprolactone,PCL)为成纤聚合物,通过静电纺丝法制备疏水性纳米纤维层;然后将PCL纳米纤维层从多孔铜网上剥离,并以其为接收基体,以PCL为成纤聚合物,聚乙二醇和去铁胺为添加剂,通过静电纺丝法制得亲水性纳米纤维层。所亲水纳米纤维层的水接触角低至0°,疏水纳米纤维层的水接触角为133°,具有优异的单向输水性。亲水层贴近伤口,促进伤口周围液体渗出,网状结构的设计,有利于细胞的生长和附着。疏水层负载的去铁胺既避免了伤口直接接触引起的细胞毒性,又能促进血管的生成活性,为伤口愈合提供一种方法。除了在纳米纤维膜上负载药物促进伤口愈合,静电纺Janus纳米纤维膜还有优异的止血性能。Hui等[48]以PCL溶液为纺丝液,在静电纺丝PCL纳米纤维过程中,空气喷涂PAA/聚乙烯亚胺-羧甲基纤维素粉末,制得亲水性纳米纤维层;然后停止空气喷涂,继续静电纺丝PCL纳米纤维,制得疏水性纳米纤维层,最终制得Janus纳米纤维膜。该纤维膜的亲水纳米纤维层的水接触角低至4°,疏水纳米纤维层的水接触角为134°。Janus纳米纤维膜的使用原理如图6所示,该纤维膜可在1 min内实现血液凝固,与医用纱布和市售明胶止血海绵相比,止血时间缩短4/5,伤口失血量减少2/3,止血效果显著。

3.6 其他应用

除了上述应用之外,Janus纳米纤维膜在摩擦纳米发电机、食品保鲜、智能纺织品等领域也具有较大的应用潜力。Xie等[49]通过顺序静电纺丝法制备了一种基于柔性二维Janus膜和聚甲基丙烯酸甲酯纳米带阵列的新型摩擦纳米发电机,拓展了Janus纳米纤维膜的应用领域,为开发新型摩擦纳米发电机提供了新型复合材料和理论支持。Jiao等[50]通过顺序静电纺丝法制备了PVA/聚氨酯Janus纳米纤维膜,该纤维膜具有良好的单向导水性、吸水性和抗菌性,能有效延长肉类的保鲜时间。Tang等[51]通过顺序静电纺丝法和浸渍法结合制备了一种基于MXene的多功能柔性Janus纳米纤维膜,该纤维膜具有优异的光热转换性能和温度传感能力,展示了在Janus纳米纤维膜在智能和可穿戴电子产品领域的广阔应用前景。随着制备技术、改性方法等方面研究的不断深入,静电纺Janus纳米纤维膜受到了越来越多的关注,应用范围不断拓宽。

4 结论与展望

本文首先简要介绍了静电纺丝技术制备纳米纤维膜的原理和影响因素,然后对顺序静电纺丝法、静电纺丝法和物理方法结合、静电纺丝法和化学方法结合制备Janus纳米纤维膜进行详细阐述,最后对Janus纳米纤维膜在不同领域的应用进行了介绍,表明了其在不同领域的应用潜力。虽然静电纺丝技术制备Janus纳米纤维膜具有较大潜力,但仍面临以下挑战:

a)双面性质差异的平衡:Janus纳米纤维膜两面通常具有不同的化学或物理性质。在制备过程中,需要平衡不同溶剂溶解度、表面张力等物性差异,以确保纺丝过程顺利进行,并获得可控的Janus结构。

b)纳米纤维膜稳定性:Janus纳米纤维膜的双面可能具有不同的机械性能和稳定性,这会影响到整个纳米纤维膜的稳定性。如何提高Janus纳米纤维膜的力学强度和稳定性是一个关键问题。

c)应用领域的限制:静电纺Janus纳米纤维膜目前在实际应用中的限制较多,需要进一步研究和探索其在过滤、分离、催化等领域的实际应用能力,并解决相应的技术难题。

目前,静电纺丝技术制备Janus纳米纤维膜已取得了一些进展。例如,通过改变纤维膜的厚度、纤维形状或表面形态等,可以实现对纳米纤维膜性能的调节。未来的静电纺Janus纳米纤维膜的发展趋势主要包括以下几个方面:

a)新型功能性材料的应用:开发出新型的功能性材料,如纳米颗粒、聚合物、金属等,用于制备Janus纳米纤维膜,并实现对其性能的调控。

b)表面改性技术的研究:通过表面改性技术,如化学修饰、物理处理等,改变纳米纤维膜的表面性质,从而实现对其浸润性能的调节。

c)功能性纳米纤维膜的应用研究:探索Janus纳米纤维膜在领域中的应用,如过滤分离、催化、能源转换等,实现其广泛应用。

参考文献:

[1]SHARMA C, GUPTA R, GEORGE J K, et al. Janus resorcinol-formaldehyde-based membrane with opposite wettability for efficient separation of oil and water emulsion [J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2023, 676: 132246.

[2]WANG C, MA Z, QIU Y, et al. Patterned dense Janus membranes with simultaneously robust fouling, wetting and scaling resistance for membrane distillation [J]. Water Research, 2023, 242: 120308.

[3]ZHANG L, PAN S, LIU Y, et al. Janus carbon nitride membrane for robust and enhanced nanofluidic power generation from wastewater [J]. Water Research, 2023, 242: 120285.

[4]朱染染, 岳洪印, 陈永辉, 等. 静电纺PCL纤维膜的制备及其性能 [J]. 现代纺织技术, 2023, 31(1): 130-135.

ZHU Ranran, YUE Hongyin, CHEN Yonghui, et, al. Preparation and properties of membranes based on PCL by electrospinning [J]. Advanced Textile Technology, 2023, 31(1): 130-135.

[5]ZHANG Y, LI T T, REN H T, et al. Tuning the gradient structure of highly breathable, permeable, directional water transport in bi-layered Janus fibrous membranes using electrospinning [J]. RSC Advances, 2020, 10(6): 3529-3538.

[6]WU W, SOTA H, HIROGAKI T, et al. Investigation of air filter properties of nanofiber non-woven fabric manufactured by a modified melt-blowing method along with flash spinning method [J]. Precision Engineering, 202 68: 187-196.

[7]AN H J, CHOI Y C, OH H J, et al. Structure development in high-speed melt spinning of high-molecular weight poly(ethylene terephthalate)/polypropylene islands-in-the-sea bicomponent fibers [J]. Polymer, 202 238: 124365.

[8]GAO M, LI J, WANG Z, et al. Hierarchical nickel cobaltite nanoneedle arrays armored flexible electrospinning carbon nanofibers membrane for electrochemical deionization [J]. Separation and Purification Technology, 2024, 328: 125084.

[9]高翼飞, 肖长发, 冀大伟, 等. 熔融纺丝-拉伸法制备PVDF中空纤维膜及其油-水分离性能 [J]. 高等学校化学学报, 202 42(6): 2065-2071.

GAO Yifei, XIAO Changfa, JI Dawei, et al. Preparation of PVDF hollow fiber membranes via melt spinning-stretching method and its oil-water separation performance [J]. Chemical Journal of Chinese Universities, 202 42(6): 2065-2071.

[10]李箫, 刘元军, 赵晓明. 静电纺丝纳米纤维基吸声材料的研究进展 [J]. 现代纺织技术, 202 30(5): 246-258.

LI Xiao, LIU Yuanjun, ZHAO Xiaoming. Research progress of electrospinning nanofiber-based sound-absor-bing materials [J]. Advanced Textile Technology, 202 30(5): 246-258.

[11]苏芳芳, 经渊, 宋立新, 等. 我国静电纺丝领域研究现状及其热点:基于CNKI数据库的可视化文献计量分析[J]. 东华大学学报(自然科学版), 2024,50(1):45-54.

SU Fangfang, JING Yuan, SONG Lixin, et al. Present situation and hotspot of electrospinning in China: Visual bibliometric analysis based on CNKI database[J]. Journal of Donghua University (Natural Science), 2024,50(1):45-54.

[12]JIAO Y, JING C, WANG Y, et al. Electrospinning synthesis of Co3O4 porous nanofiber monolithic catalysts for the room-temperature indoor catalytic oxidation of formaldehyde at low concentrations [J]. Applied Surface Science, 2023, 639: 158215.

[13]高磊, 牛家嵘, 金欣, 等. 超细纤维合成革柔软改性的研究进展[J]. 皮革科学与工程, 202 32(4): 54-59.

GAO Lei, NIU Jiarong, JIN Xin, et al. Research progress on soft modification of microfiber synthetic leather[J]. Leather Science and Engineering, 202 32(4): 54-59.

[14]朱豆豆, 付少海, 张继超. 基于静电纺丝技术的防水透湿微纳米纤维膜研究进展[J]. 服装学报, 2023, 8(2): 95-101.

ZHU Doudou, FU Shaohai, ZHANG Jichao. Research progress on waterproof and moisture permeable micro-nanofibrous membranes based on electrospinning technology[J]. Journal of Clothing Research, 2023, 8(2): 95-101.

[15]宋凯,袁文博,王旭杰,等.基于 Hofmeister 效应改性明胶静电纺丝纤维膜的制备与表征[J].皮革科学与工程,2023.33(4): 7-10.

SONG Kai, YUAN Wenbo, WANG Xujie, et al. Preparation and characterization of modified gelatin electrospun fiber films based on hofmeister effect[J]. Leather Science and Engineering, 2023, 33(4): 7-10.

[16]CHENG N, MIAO D, WANG C, et al. Nanosphere-structured hierarchically porous PVDF-HFP fabric for passive daytime radiative cooling via one-step water vapor-induced phase separation [J]. Chemical Engineering Journal, 2023, 460: 141581.

[17]SAJESH K M, KIRAN K, NAIR S V, et al. Sequential layer-by-layer electrospinning of nano SrCO3/PRP loaded PHBV fibrous scaffold for bone tissue engineering [J]. Composites Part B: Engineering, 2019, 167: 754.

[18]WANG P, LI Y, ZHANG C, et al. Sequential electrospinning of multilayer ethylcellulose/gelatin/ethylce-llulose nanofibrous film for sustained release of curcumin [J]. Food Chemistry, 2020, 308: 125599.

[19]CHEN Z, LI J, ZHOU J, et al. Photothermal Janus PPy-SiO2@PAN/F-SiO2@PVDF-HFP membrane for high-efficient, low energy and stable desalination through solar membrane distillation [J]. Chemical Engineering Journal, 2023, 451: 138473.

[20]WU M, XIANG B, MU P, et al. Janus nanofibrous membrane with special micro-nanostructure for highly efficient separation of oil-water emulsion [J]. Separation and Purification Technology, 202 297: 121532.

[21]GAO Y, SANG X, CHEN Y F, et al. Polydopamine modification electrospun polyacrylonitrile fibrous membrane with decreased pore size and dendrite mitigation for lithium ion battery [J]. Journal of Materials Science, 2020, 55(8): 3549-3560.

[22]ZHANG X, ZHU Y, FANG W, et al. Thin film composite structured Janus membrane for fast gravity-driven separation of a trace of blood [J]. Journal of Membrane Science, 202 620: 118853.

[23]ZHANG C, LAN X, LIU Q, et al. Bi-functional Janus all-nanomat separators for acid scavenging and manganese ions trapping in LiMn2O4 lithium-ion batteries [J]. Materials Today Physics, 202 24: 100676.

[24]YANG R, LI X, WANG X, et al. Preparation of PVA/Ag antibacterial hydrophobic slow-release composite films with core-shell structure by one-step method [J]. Materials Letters, 2023, 352: 135086.

[25]HE T, CHEN F. Enhanced separation performance of composite nanofiltration membranes via electrostatic air spray PSS/PEI interlayer [J]. Desalination, 2024, 573: 117221.

[26]LI S M, LI L Z, ZHONG J H, et al. Engineering beads-on-string structural electrospun nanofiber Janus membrane with multi-level roughness for membrane distillation [J]. Desalination, 202 539: 115950.

[27]LI T T, SUN L, ZHANG Y, et al. Chitosan-based antibacterial microspheres loaded multifunctional Janus composite membranes with unidirectional biofluid transport, antioxidant and pH-responsive monitoring [J]. Chemical Engineering Journal, 2023, 472: 144820.

[28]LIU M, WANG J, DING Y, et al. Highly efficient recovery of viscous oil through nondispersive solvent extraction using polydopamine modified PVDF Janus membrane [J]. Journal of Water Process Engineering, 2023, 54: 103946.

[29]ZHANG W, GUAN X, QIU X, et al. Bioactive composite Janus nanofibrous membranes loading Ciprofloxacin and Astaxanthin for enhanced healing of full-thickness skin defect wounds [J]. Applied Surface Science, 2023, 610: 155290.

[30]CHENG C, WEI Z, GU J, et al. Rational design of Janus nanofibrous membranes with novel under-oil superhydro-philic/superhydrophobic asymmetric wettability for water-in-diesel emulsion separation [J]. Journal of Colloid and Interface Science, 202 606: 1563-1571.

[31]WANG H X, ZHOU H, NIU H T, et al. Dual-layer superamphiphobic/superhydrophobic-oleophilic nanofibrous membranes with unidirectional oil-transport ability and strengthened oil-water separation performance [J]. Advanced Materials Interfaces, 2015, 2(4):1-7.

[32]XIAO Y, XIAO F, JI W, et al. Bioinspired Janus membrane of polyacrylonitrile/poly (vinylidene fluoride)@poly (vinylidene fluoride)-methyltriethoxysilane for oil-water separation [J]. Journal of Membrane Science, 2023, 687: 122090.

[33]ZHANG X, ZHU Y, ZHANG F, et al. Hydrophilic/hydrophobic nanofibres intercalated multilayer membrane with hierarchical structure for efficient oil/water separation [J]. Separation and Purification Technology, 202 288: 120672.

[34]AFSARI M, SHIRAZI M M A, GHORBANI A H, et al. Triple-layer nanofiber membrane with improved energy efficiency for treatment of hypersaline solution via membrane distillation [J]. Journal of Environmental Chemical Engineering, 2023, 11(5): 110638.

[35]ZHU Z, ZHONG L, CHEN X, et al. Monolithic and self-roughened Janus fibrous membrane with superhydrophilic/omniphobic surface for robust antifouling and antiwetting membrane distillation [J]. Journal of Membrane Science, 2020, 615: 118499.

[36]JU J, HUANG Y, LIU M, et al. Construction of electrospinning Janus nanofiber membranes for efficient solar-driven membrane distillation [J]. Separation and Purification Technology, 2023, 305: 122348.

[37]刘巍, 廖伟龙, 宁杨, 等. 纳米纤维负载MnOx催化剂在甲醛催化净化中的应用[J]. 天津工业大学学报, 2023, 42(4): 44-50.

LIU Wei, LIAO Weilong, NING Yang, et al. Application of nanofiber-supported MnOx catalyst in catalytic purification of formaldehyde[J]. Journal of Tiangong University, 2023, 42(4): 44-50.

[38]QI X, ZHU Y, SONG L, et al. Photocatalytic degradation of PET coupled to green hydrogen generation using flexible Ni2P/TiO2/C nanofiber film catalysts [J]. Applied Catalysis A: General, 2023, 656: 119130.

[39]朱永军, 宋立新, 熊杰. 柔性碳基复合纳米纤维膜光催化降解PET纤维与析氢 [J]. 丝绸, 202 59(10): 66-73.

ZHU Yongjun, SONG Lixin, XIONG Jie. Photocatalytic degradation of PET fibers and hydrogen evolution by flexible carbon-based composite nanofiber membranes [J]. Journal of Silk, 202 59(10): 66-73.

[40]XU C, XU S, SONG J, et al. Janus C-PAN/PH membrane for simulated shale gas wastewater (SGW) treatment in membrane distillation: Integrating surface property and catalytic degradation for anti-fouling [J]. Journal of Membrane Science, 2023, 683: 121785.

[41]HAN Z, FEI J, LI J, et al. Enhanced dye-sensitized photocatalysis for water purification by an alveoli-like bilayer Janus membrane [J]. Chemical Engineering Journal, 202 407: 127214.

[42]殷妮,刘福娟.空气过滤用纳米纤维膜研究进展[J].现代纺织技术,202 29(5):26-36.

YIN Ni, LIU Fujuan. Research progress on nanofiber membranes in air filtration[J]. Advanced Textile Techno-logy, 202 29(5): 26-36.

[43]CHEN J, RAO Y, ZHU X, et al. Electrospun nanofibrous membranes with asymmetric wettability for unidirectional moisture transport, efficient PM capture and bacteria inhibition [J]. Journal of Membrane Science, 202 662: 121006.

[44]CUI W, FAN T, LI Y, et al. Robust functional Janus nanofibrous membranes for efficient harsh environmental air filtration and oil/water separation [J]. Journal of Membrane Science, 202 663: 121018.

[45]YANG Q, GUO J, ZHANG S, et al. PVA/PEO/PVA-g-APEG nanofiber membranes with cytocompatibility and anti-cell adhesion for biomedical applications [J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2023, 657: 130638.

[46]石佳博,张睿祯,盛理,等. 生物大分子基纳米复合功能膜的制备及应用研究进展[J].皮革科学与工程,2023,33(3):24-30.

SHI Jiabo, ZHANG Ruizhen, SHENG Li, et al. Research progress on the preparation and application of multifunctional biopolymer: Based nanocomposite films[J]. Leather Science and Engineering,2023,33(3):24-30.

[47]ZHU Y, ZHOU W, XIANG J, et al. Deferoxamine-loaded Janus electrospun nanofiber dressing with spatially designed structure for diabetic wound healing [J]. Materials & Design, 2023, 233: 112166.

[48]HUI C, GAO Y, YAN B Y, et al. Collocalia birds inspired Janus-structured bandage with strong wet tissue adhesion for rapid hemostasis and wound healing [J]. Chemical Engineering Journal, 2023, 464: 142458.

[49]XIE Y, MA Q, YUE B, et al. Triboelectric nanogenerator based on flexible Janus nanofiber membrane with simultaneous high charge generation and charge capturing abilities [J]. Chemical Engineering Journal, 2023, 452: 139393.

[50]JIAO X, XIE J, DU H, et al. Antibacterial smart absorbent pad with Janus structure for meat preservation [J]. Food Packaging and Shelf Life, 2023, 37: 101066.

[51]TANG Y, YAN J, WANG J, et al. MXene based flexible Janus nanofibrous membrane composite for unidirectional water transportation [J]. Composites Science and Tech-nology, 2023, 239: 110032.

Research progress in electrospun Janus nanofiber membranes

WANG Qi, CHEN Mingxing, ZHANG Wei, WU Yanjie, WANG Xinya

(a.College of Textile and Garments; b.Hebei Province Technology Innovation Center of Textile and Garment,

Hebei University of Science and Technology, Shijiazhuang 050018, China)

Abstract:

The Janus separation membrane, a special kind of thin film material, is named for its two sides having different properties. One side of the Janus membrane is hydrophilic (oleophobic), while the other side is hydrophobic (oleophilic), which gives the Janus membrane a unique advantage in oil-water separation, membrane distillation, catalytic degradation and other fields. Electrospun Janus nanofiber membranes have attracted much attention due to their advantages of high specific surface area, slender fiber structure, and controllability. In order to better understand the research progress of electrospun Janus nanofiber membranes, this paper reviewed the recent research in this field. The preparation methods of electrospun Janus nanofiber membranes and their applications in various fields were highlighted.

First, this paper described the method and principle to prepare Janus nanofiber membranes through electrostatic spinning. In electrospinning, the polymer solution or melt was deformed under the action of high voltage electric field to form the "Taylor cone", and then the nanofibers were prepared by stretching, refining and curing. In this paper, the commonly used methods for the preparation of Janus nanofiber membranes based on electrospinning technology, such as sequential electrospinning, electrospinning combined with physical methods, and electrospinning combined with chemical methods, were summarized, and their principles, advantages and disadvantages were described in detail.

Then, this paper detailed the applications of electrospun Janus nanofiber membranes in various fields. In this paper, recent advances in the application of Janus nanofiber membranes in oil-water separation were introduced. The synergistic role played by the sieving mechanism of porous structure and the aggregation mechanism of symmetrically selected wettability in the oil-water separation process was emphasized in this part. Secondly, its application in membrane distillation was introduced. Researchers found that, in membrane distillation, the lower the resistance to pollution of the hydrophobic membrane is, the lower its permeability and separation efficiency will be. The unique porous structure and symmetrical selective wettability of the Janus nanofiber membrane can effectively improve its pollution resistance and enhance its membrane distillation performance. Then its application in catalytic degradation was described. Based on the multi-level controllable structure of electrospun Janus nanofiber membranes, researchers often introduce catalysts to give Janus nanofiber membranes excellent catalytic degradation performance, in order to remove dyes, heavy metal ions and other pollutants that cannot be thoroughly treated by physical separation. Finally, the applications of electrospun Janus nanofiber membranes inair filtration and biomedicine were introduced, which fully indicates that the unique structure and properties of electrospun Janus nanofiber membranes play an important role in in these two aspects.

In summary, this paper reviews the recent research progress of electrospun Janus nanofiber membranes, and introduces their preparation methods and applications in various fields. Through the discussion of their advantages and disadvantages, as well as the prospect of future development, it is hoped that the paper can provide some reference for the research and application of electrospun Janus nanofiber membranes.

Keywords:

electrospinning; Janus nanofiber membranes; preparation method; water treatment; air filtration; biomedical use