个体冷热调节服装的研究进展

摘 要:为促进个体冷热调节服装(PTRC)在热舒适性调节和建筑节能中的应用与发展,系统介绍了个体冷却服、加热服的分类特性及进展,比较分析了不同类型PTRC的优缺点,提出了未来的发展方向。总结发现:个体冷却服存在笨重、便携性差和冷却效率低等问题,未来应结合实际应用场景,从多方面(面料、结构、附加设备等)进行综合考虑,寻找更高能量密度的电池,降低服装重量;对于个体加热服,多驱动能源技术是未来的发展方向,应充分结合不同学科知识实现服装的智能化控制,满足不同场景中的加热需求;针对使用新型制造工艺与材料的动态调节技术,优化纺织材料的性能和生产工艺,建立全面的适用安全标准体系和评估方法,以促进其商业化的发展进程。

关键词:人体热舒适;个体冷热调节服装;冷却系统;新型纺织品;智能调节;电加热

中图分类号:TS195.7

文献标志码:A

文章编号:1009-265X(2024)09-0028-10

收稿日期:2023-12-29

网络出版日期:2024-05-13

基金项目:教育部人文社会科学规划项目(23YJAZH209)

作者简介:陈雪(1996—),女,安徽阜阳人,硕士研究生,主要从事服装舒适性与功能服装方面的研究。

通信作者:于利静,E-mail:yulijing79@163.com

高低温的工作环境不仅降低了工作效率,且对人体健康造成了严重威胁[1]。近年来研究人员开发了系列的冷热防护服装,通过调节人体与服装之间微环境的温湿度,从而实现对人体热湿舒适性的管理[2]。此外还有研究表明,在保持人体热舒适前提下,室内穿着个体冷热调节服装时,与穿着普通服装相比,可以扩展供热通风与空气调节系统(Heating,ventilation and air conditioning,HVAC)的温度设定点,从而节省15%~55%的建筑能耗[3]。

将进行热湿舒适性管理的服装统称为个体冷热调节服装(Personal thermal regulation clothing,PTRC),包括个体冷却服和个体加热服。个体冷却服可分为主动式、被动式和混合式3类[4],个体加热服根据加热源不同可以分为化学加热、电加热、相变加热、流体/空气加热服[2]。此外随着材料科学的不断发展,出现了可以在加热和冷却之间动态调节的新型PTRC,不消耗电能,具有巨大的节能潜力和应用前景[5-6]。然而在PTRC的发展过程中,也面临诸多挑战,例如PTRC存在着笨重、便携性差、效率低及价格成本高等问题。此外在新型PTRC的生产过程中,一些可动态调节加热与冷却的纺织材料存在着加工工艺过于复杂,难以工业化生产等问题,且成本昂贵,这也限制了新型PTRC的大规模应用与发展。因此为促进PTRC在调节人体热舒适与建筑节能等领域的应用,本文综述了不同类型PTRC的研究现状,对其优缺点进行分析,并对未来PTRC的发展进行了展望,以期能够促进PTRC的可持续发展和商业化进程。

1 个体冷却服装

1.1 主动式冷却服

主动式冷却服装包括风冷服和液冷服,主要应用在航空航天、军事等领域。风冷服通过将微型风扇与服装结合,利用环境空气促进人体表面的汗液蒸发和对流热损失,提高热舒适性[7],在干热环境中具有较好的冷却效果。但在湿热环境下,风冷服的冷却效果不理想,甚至会增加人体负担[8]。因此,研究人员常使用制冷装置来预冷空气,并将冷却后的空气通入人体表面,提高湿热环境中的人体热舒适性[4]。常见的制冷装置包括空气压缩机[9]和热电制冷装置[10]。相较热电制冷装置来说,空气压缩机体积较大,限制了人体的活动范围,因此更适用于工业生产中车间工人固定范围内的使用。而热电制冷装置因具有重量轻、结构紧凑、性能可靠、对环境友好等优点,而且可以实现高精度调控和微型化结构设计,因此得到了研究人员的广泛关注[11]。Lou等[10]开发了热电空调服装系统,该服装系统使用微型鼓风机和热电制冷装置预冷环境风,并将环境风经过服装内表面的硅胶管道输送至人体内表面,使整件服装轻巧且冷却效果显著,可以提供24.6 W的冷却功率。此外,风冷服的冷却性能与许多因素有关,主要包括风温、风量及通风部位等[12]。Zhao等[13]发现通风部位的设计对通风服的冷却性能具有重要影响,应将风扇放置在人体出汗量较多的部位,例如人体下背部。Fan等[14]研究发现代谢率为1.2 met时通向人体背部的风温在26℃、风量在11 L/s左右时最为舒适,而当人体处于一定的体力劳动时(代谢率为2~4.7 met),风温在(24.5±1.5)℃左右时最为舒适[15]。

与风冷服相比,液冷服传热效率更高。液冷服通过在服装内表面安置循环管道,通入水介质进行传导降温,其冷却性能受到包括循环液体的温度与流量、管道参数与覆盖人体面积等因素的影响[16]。舒伟程[17]提出了“热不舒适时间占比”指标来评价人体穿着液冷服时的热舒适性,结果发现在1.5 h的持续冷却中,热不舒适时间占比达到了57.6%,其中液体温度变化对人体热不舒适的影响最为显著。因此Shu等[18]为进一步降低人体热不舒适占比,促进实现了液体进口温度的精准调节控制,开发出了具有温度调节系统的智能冷却服装,在服装总重未增情况下,人体穿着舒适度明显提高,持续工作时间延长了37%以上。Xu等[19]设计了一种基于热电制冷的新型液冷服系统,结果发现该系统可以提供最低15.7℃的水温及340.4 W的冷却功率。还有研究表明,当进水温度控制在22℃左右时[20],可以显著降低人体微气候区域的温湿度,能够满足35℃环境下的冷却需求。

1.2 被动式冷却服

被动式冷却服包括相变冷却服、蒸发冷却服和辐射冷却服。相变冷却服利用相变材料(Phase change material,PCM)的相态变化吸收人体热量,可以直接将PCM放置在服装内表面,或将PCM纺入进纤维在织造成织物,或将PCM制作成整理剂涂覆在织物表面。相变冷却服的冷却效果主要取决于PCM的相变温度、比热、衣身覆盖面积等[21]。通常情况下,PCM的数量越多、衣身覆盖面积越大冷却效果越好,但这会增加整件服装的总重量。此外相变温度也是影响冷却效果的重要因素,因此为了探究相变温度对冷却效果的影响,Gao等[22]进行了人体生理实验,结果发现当PCM相变温度分别为24℃和28℃时,不能有效改善人体在高温环境下的热舒适性,应进一步减小相变温度提高人体热舒适性。Mneimneh等[23]研究表明当相变温度分别为14℃和20℃时,不仅能显著降低核心温度,且对于缓解截瘫患者的热应激也具有显著效果。

蒸发冷却服通过将服装与干冰结合,或者使用具有储存水分能力的织物实现对人体的冷却[24]。蒸发冷却服的冷却效果受到环境湿度、风速等影响。就环境湿度来说,与干冰相结合的蒸发冷却服在湿热环境下冷却效果更显著,但这极易造成局部过冷。而对于具有储存水分能力的蒸发冷却服来说,在干燥环境下的冷却效果更显著[25]。Aarish等[26]研究发现在炎热干燥的环境下,蒸发冷却服不仅能够最大限度的提高劳动生产率,且可以实现与环境温差7℃的冷却效果。其次环境风速也是影响冷却性能的重要因素,较大的风速能够快速加速水分蒸发,从而实现优异的冷却性能。

辐射冷却服通过采用特殊的材料或涂层等方法,实现对红外辐射的选择性阻挡与反射,从而减少人体热吸收,实现降温效果[27]。相对主动式冷却服来说,辐射冷却服的能耗很低,便携性高且方便携带,但冷却效果易受到环境温湿度的影响。Cai等[28]介绍了一种可用于室外辐射冷却的新型光谱选择性纳米复合纺织品,可以反射90%以上的太阳辐射,在同等条件下其表面温度比普通纺织品如棉的温度低5~13℃,具有广泛的应用前景。

1.3 混合式冷却服

混合冷却服是在服装中嵌入了两种或两种以上的冷却介质(见图1),与单一冷却介质相比,能在多变高温环境中提供优异的冷却效果。韦帆汝等[29]探索了相变风扇混合冷却服在四种环境条件下的冷却性能,研究发现在不同环境条件下,同时打开风扇并安装相变材料可以最大限度地提高人体热舒适。之后,Wan等[30]搭建了一个数值模型以探究相变风扇混合冷却服与风扇通风服之间的冷却效果差异。结果发现与风扇通风服相比,相变风扇混合冷却服显著了降低人体的核心温度和平均皮肤温度。此外Wang等[31]探讨了蒸发和风冷相结合的混合冷却服分别与风冷服、蒸发冷却服和液冷服之间的冷却效果差异,结果发现与单一冷却相比,穿着蒸发和风冷相结合的混合冷却服下的皮肤温度最低,是最有效的冷却策略。

2 个体加热服装

现有的个体加热技术主要分为4类:电加热服(Electric heating clothing,EHC)、化学加热服装(Chemical clothing,CHC)、相变材料加热服(Phase change material heating clothing,PCMHC)、空气/流体流动加热服(Air heating clothing,AHC/Fluid heating clothing,FHC)[32]。其中EHC因其轻薄可洗、发热效率高、不限制人体活动、能耗低等优点具有广泛的应用前景。常用的电加热介质包括碳纤维、石墨烯、电阻丝、导电橡胶等[33-34]。冷环境下穿着EHC可以显著改善人体的热舒适性,且能源消耗较低,具有较大的应用前景[35-36]。此外,随着材料科学和纳米技术的发展,更多的新型材料被开发出来,通过感受外界环境变化,材料自身做出反应,控制传导、对流或辐射等传热途径,提升人体热舒适。一些先进的制造技术,例如使用复合结构或孔隙结构,实现织物的高红外反射率,能够更有效的抑制人体热损失,从而实现对人体的被动加热[37-38]。

采用复合结构设计的个体热调节服装不仅能够冷却或者加热效果,也可实现在加热和冷却间的动态调节。Chai等[39]通过在聚乙烯膜(PE)上沉积金属层形成双层复合结构,并与服装结合,在炎热环境中下层的PE膜膨胀致使双层致动器向外界环境方向弯曲,从而加强人体的辐射散热,相反在冷环境下双层致动器则向人体表面方向弯曲,抑制人体散热并保持身体温暖(见图2),研究结果表明该服装在冷热两侧均可扩大舒适区2℃以上,节省约30%的建筑能源。此外,形状记忆材料作为一种智能活性材料,也可对外界刺激(热、光、湿、电等)做出相应的动态变化[40-41],与传统纺织品相比具有更大热舒适性优势。Roach等[42]设计了具有可逆形状记忆能力的液晶弹性体(LCE)纤维的智能纺织品,当外界温度降低时关闭衣物孔隙,温度升高时打开衣物孔隙,从而促进人体的对流冷却和汗液蒸发,有利于人体的热管理。

3 个体冷热调节服装的综合比较

3.1 个体冷热调节服装的优缺点

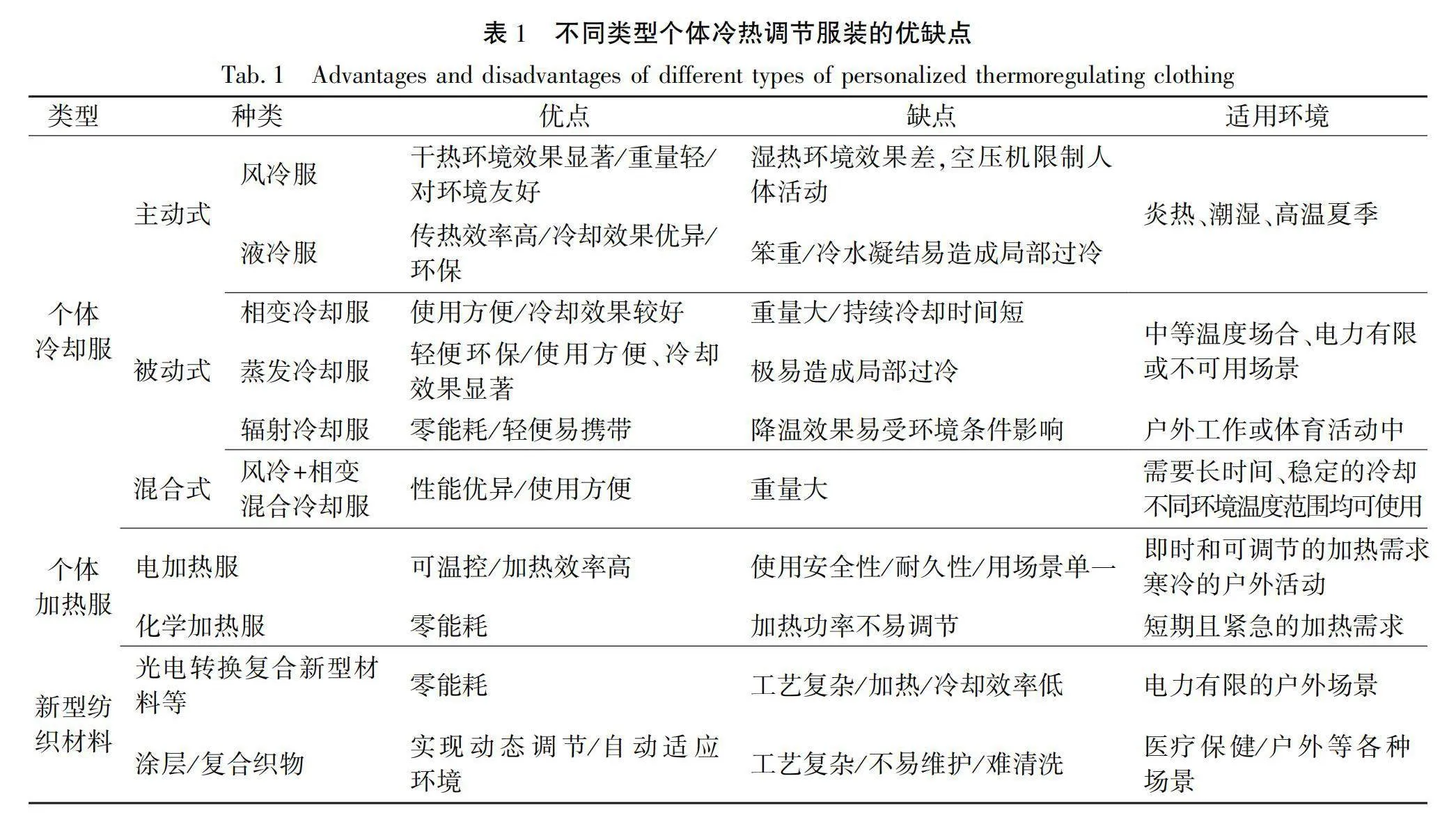

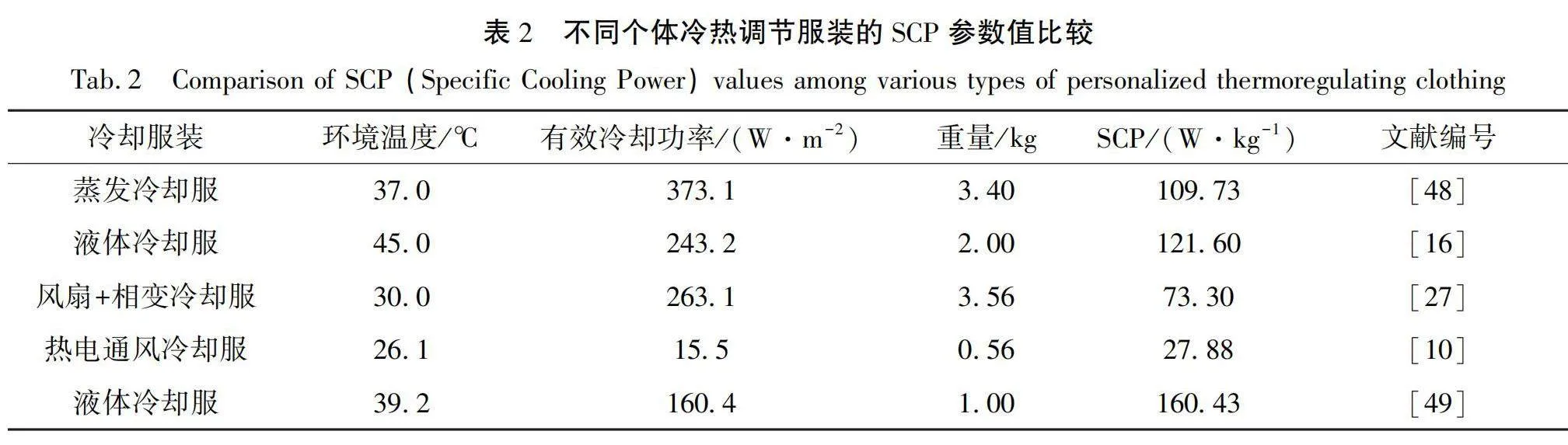

不同类型个体冷热调节服装(PTRC)的优缺点如表1所示。与传统HVAC系统相比,PTRC可以提供个性化的舒适方案以及更大的灵活性,但调节效果受材料选择、服装结构设计以及使用环境等多种因素的综合影响。在个体冷却服的研发历程中,服装的重量大小及便携性一直是研发者面临的一个大问题,这不仅影响着个体冷却服的冷却性能和穿着便利[43],同时过大的服装重量会对人体造成更大的负荷,从而导致人体产热量增加,影响工作效率[44]。Yong等[45]和Critoph等[46]将冷却服的有效冷却功率与重量的比值定义为特定冷却功率(SCP),较高的SCP反映了冷却服更强的冷却性和紧凑性。表2总结了各类冷却服的SCP大小,其中风扇与相变混合冷却服、液冷服的SCP值比其他类型冷却服更大,这表明其冷却效率更高,可用于具有高冷却需求的人群穿着。而风冷服虽然重量较小,更轻便,但冷却效率相对较低。此外,虽然已经开发出了重量最低为556 g的制冷通风服,但这是在不包含电池组重量的情况下,而所用的锂电池组通常较为沉重,因此,在之后的发展中,寻找更高能量密度的电池组是必要的。

此外,在不同使用环境中,个体冷却服的研发重点不一,应从面料选择、结构设计和附加设备等多方面进行综合考虑[47]。对于建筑、环卫、交通等户外高温场景中,服装的轻便性是首要的,其次也要考虑面料的防晒性和透气速干性,可考虑使用更为便携轻巧的通风冷却和蒸发冷却服。而对于医用、化学、消防等场景,除了需要考虑服装的降温性能外,面料的抗菌性及柔软舒适性是关键,同时要避免有害气液体进行服装内,因此更适合采用封闭式的液体冷却服和相变冷却服。对于更为特殊的场景,例如军事应用等,冷却服的持久性是必要的,此外更需要注意面料的强度和耐久性。

在个体加热服的发展进程中,主要聚焦于加热技术改进[50]和服装舒适性提升[51-52]两方面。随着加热技术的不断发展,实现了对多种驱动能源的利用[53],进一步提高了织物的加热效率,且扩展了应用场景。例如,Guo等[54]开发了一种同时具有电热和光热转换的复合加热织物,在1.8 V的电压下,温度可达70℃,光照240 s后温度可达74℃左右。这项技术为改善个人热调节织物的性能和实现节能提供了一种新的途径。然而,在该技术的实际应用中,其发热效率尚未得到充分的研究和验证,例如在极端高温或低温环境条件下,其性能表现及长时间佩戴下的持久性和稳定性等方面,需要更深入的调查和评估。此外,随着智能化技术的迅速发展,在个体加热服装的设计中,可通过向服装内部嵌入传感器或者智能控制系统,实现更加精确的温度调节和个性化的加热设置,这将满足更多人群的加热需求,同时为个体加热服的进一步优化和发展提供了新的可能性。

通过特殊复杂的织造技术或使用创新材料,也可以实现纺织品在加热和冷却间的动态调节,且在零电能消耗的情况下,可以自动根据环境变化调节加热与冷却,这一技术在实现个体热舒适性和能源效率方面具有重要意义[37]。例如,将具有不同功能的织物进行复合,Chen等[55]将可拉伸电热织物、弹性织物和热致变色织物进行复合组装,实现了纺织品的温度可视化和动态温度调节功能,使得复合织物同时具有辐射冷却和焦耳加热的双重热调节功能,且保持了复合织物的灵活性、透气性和优异的拉伸性,在医疗保健和个人热管理领域具有巨大的潜力,为柔性可穿戴设备提供了广泛的应用前景。

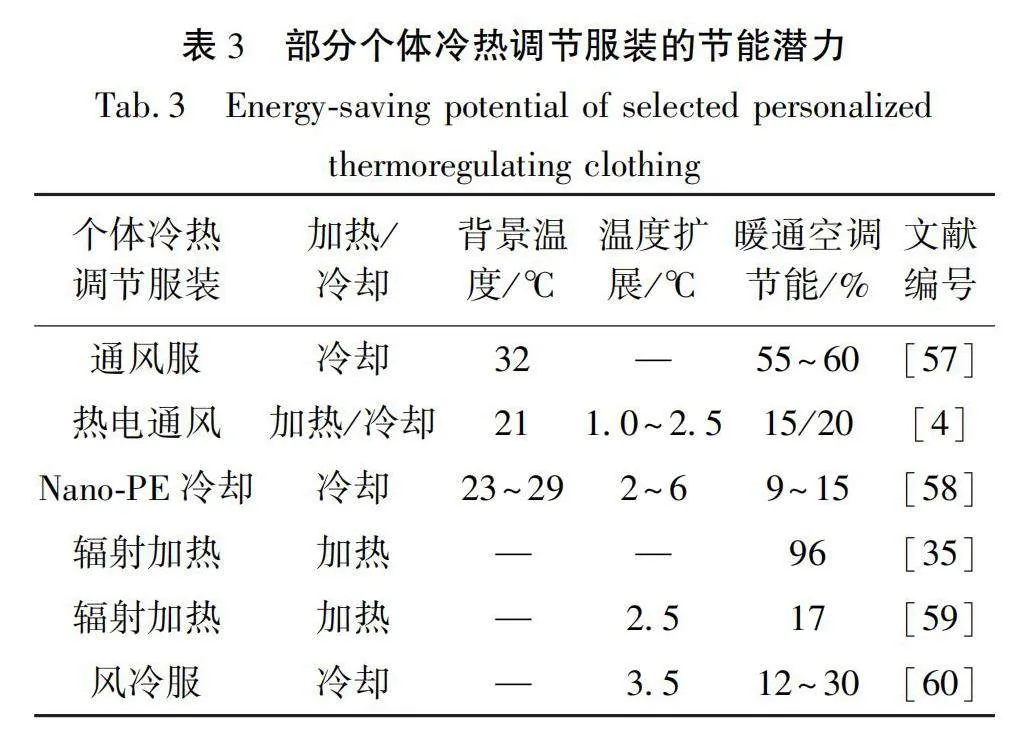

3.2 个体冷热调节服装的能耗

传统的HVAC系统可以保持室内多数人员的热舒适需求,但这需要消耗大量的建筑能源。在不影响人体热舒适的前提下,在室内穿着PTRC可以扩展HVAC系统的温度设定点,从而达到节省HVAC电能消耗的目的,同时PTRC所使用的调温介质一般都是清洁能源(水/空气等),不会对环境造成压力。在电力不足等特殊场景中,一些新型的PTRC可利用光能实现光热能源之间的转换,具有零电能消耗的优势。为量化PTRC在建筑节能上的表现,在保持人体热舒适的前提下,研究人员测试了室内穿着PTRC时,HVAC温度设定点的扩展范围,并计算了前后HVAC系统消耗的能源差值即可得到PTRC所节省的电能消耗占比。早期研究表明,室内HVAC的加热或冷却温度设定点扩展1~2℃可节省超过15%以上的建筑节能[56],表3列出了部分PTRC的节能潜力,可节省的能耗范围集中在15%~55%之间,可以看出PTRC具有较大的节能潜力。其次PTRC为穿着者提供了个性化的加热和冷却调节需求,也可以满足更多人群的热舒适需求。

然而,实现PTRC在建筑节能领域的广泛应用上目前还面临一些挑战。首先,较高的服装生产成本限制了大规模的生产与应用。且就目前已开发出的PTRC来说,如何在不影响穿着者行为活动的前提下提供更持久且便携的能源供应也是一个重要的问题。随着光电材料的不断发展,实现服装与太阳能电池板的一体化已经成为实现绿色环保的新途径。但目前太阳能电池板的转换效率和可靠性仍然存在挑战,需要深入研究以提高其能源转换效率。在此背景下,除了考虑电池板性能的提升,更要关注当太阳能电池板与服装结合时,存在的柔性性能和穿着舒适性方面所面临的一系列难题,由于太阳能电池板表面通常采用硬质材料,因此平衡太阳能电池板与服装之间的舒适性和功能性显得尤为重要。在未来的研究中,应综合考虑材料科学与人体工程学等多方面因素,为太阳能电池板与服装一体化的发展提供更为全面和可行的解决方案。

PTRC的能源转换效率主要取决于所使用的技术和材料,为了评价不同PTRC间的能源转换效率,将PTRC的制冷量/制热量与其能源消耗值之间的比值定义为能效比(Coefficient of performance,COP),一般来说,COP值越大代表其加热/冷却转换效率越高。表4列出了部分冷热调节服装的COP值,COP范围多大于1.5,但在热电效应中,能源转换效率相对较低,这受制于热电材料和技术的发展,未来随着材料科学和纺织技术的不断发展,有望实现更高的能源转换效率。

3.3 个体冷热调节服装的商业化发展

随着社会的不断进步,人们越来越重视自身的热舒适性调节,而PTRC有望成为维持人体热舒适的替代方案。但目前PTRC的商业化进展还处于相对早期的阶段,已商业化使用的服装包括风扇通风服、相变冷却服、电加热服等。然而,风扇通风服和相变冷却服在冷却效率提高和服装轻便性上还需进一步提升。采用新型技术与材料的新型PTRC,由于其昂贵且复杂的生产加工技术限制了批量生产的可能性。且目前研究中缺少PTRC的标准使用安全规范,进一步限制了其商业化进程的脚步。未来应从实际应用的角度出发,深入研究新型纺织材料的性能和制造工艺,以解决批量生产的难题。此外,建立全面的使用安全标准体系,并制定相应的评估方法,这对于确保PTRC在商业应用中的可持续发展至关重要。

4 结论与展望

PTRC对于保障人体在高低温环境中的热舒适性具有重要意义,因此提高冷热调节服装的转换效率及促进其商业化的发展是必要的。针对液冷服和风冷服存在的穿着不便和笨重等问题,需进一步提高其穿着舒适度和轻便性。而对于热电冷却服装,应进一步提高冷热转换效率,从而实现更有效的降温效果。同时,针对新型功能纺织材料,应进一步探讨如何降低材料的生产加工成本,以及提高服装的热调节性能。通过以上的总结与分析,未来个体冷热调节服装的相关研究可从以下几个方面展开:

a)在个体冷却服中,应充分发挥主观能动性并结合实际应用场景进行优化设计,从面料选择、结构设计和附加设备等方面综合考虑冷却服的设计,寻找更轻便的材料和高能量密度的电池组,实现服装便携性与高效性。

b)针对个体加热服装,应提升加热效率并增强其与多种驱动能源的结合,以增强服装在各种环境下的适用性。同时应充分结合不同学科领域的知识和先进的计算机编程技术实现智能调节与个性化控制,满足不同人群的加热需求。

c)针对新型纺织材料与技术,应深入研究新型纺织材料的性能和制造工艺,并建立全面的使用安全标准体系,制定相应的评估方法,促进商业化发展进程。

参考文献:

[1]HABIBI P, MORADI G, DEHGHAN H, et al. The impacts of climate change on occupational heat strain in outdoor workers: A systematic review[J]. Urban Climate, 2021, 36: 100770.

[2]YANG B, DING X, WANG F, et al. A review of intensified conditioning of personal micro-environments: Moving closer to the human body[J]. Energy and Built Environment, 2021, 2(3): 260-270.

[3]VESELY M, ZEILER W. Personalized conditioning and its impact on thermal comfort and energy performance-A review[J]. Renewable and Sustainable Energy Reviews, 2014, 34: 401-408.

[4]ZHAO D, LU X, FAN T, et al. Personal thermal management using portable thermoelectrics for potential building energy saving[J]. Applied Energy, 2018, 218: 282-291.

[5]PENG L, SU B, YU A, et al. Review of clothing for thermal management with advanced materials[J]. Ce-llulose, 2019, 26(11): 6415-6448.

[6]FANG Y, ZHAO X, CHEN G, et al. Smart polyethylene textiles for radiative and evaporative cooling[J]. Joule, 2021, 5(4): 752-754.

[7]党天华, 赵蒙蒙, 钱静. 基于微型风扇阵列的通风服研发与测评[J]. 现代纺织技术, 2022, 30(4): 214-221.

DANG Tianhua, ZHAO Mengmeng, QIAN Jing. Deve-lopment and evaluation of ventilation clothing based on micro fan array[J]. Advanced Textile Technology, 2022, 30(4): 214-221.

[8]吴国珊, 刘何清, 吴世先, 等. 不同环境下个体通风服的制冷量[J]. 纺织学报, 2021, 42(10): 139-145.

WU Guoshan, LIU Heqing, WU Shixian, et al. Cooling capacity of personal ventilation systems in different environ-ments[J]. Journal of Textile Research, 2021, 42(10): 139-145.

[9]米立华. 气冷服与体表空间内流动传热模拟研究[D]. 湘潭: 湖南科技大学, 2019.

MI Lihua. Simulation of Flow and Heat Transfer in Air Cooling Garment and Surface Space[D]. Xiangtan: Hunan University of Science and Technology, 2019.

[10]LOU L, SHOU D, PARK H, et al. Thermoelectric air conditioning undergarment for personal thermal manage-ment and HVAC energy saving[J]. Energy and Buildings, 2020, 226: 110374.

[11]曹海山. 热电制冷技术进展与展望[J]. 制冷学报, 2022, 43(4): 26-34.

CAO Haishan. Progress and prospect of thermoelectric refrigeration[J]. Journal of Refrigeration, 2022,43(4): 26-34.

[12]张昭华, 陈之瑞, 李璐瑶, 等. 人体局部皮肤的气流敏感性及其影响因素[J]. 纺织学报, 2021, 42(12): 125-130.

ZHANG Zhaohua, CHEN Zhirui, LI Luyao, et al.[J]. Airflow sensitivity of human local human skin and its influencing factor[J]. Journal of Textile Research, 2021, 42 (12): 125-130.

[13]ZHAO M, GAO C, WANG F, et al. A study on local cooling of garments with ventilation fans and openings placed at different torso sites[J]. InternaxDCkHy48/amYrbltQGu22HUmys6UfEDyqeAD40R5Zac=tional Journal of Industrial Ergonomics, 2013, 43(3): 232-237.

[14]FAN C, ZHANG Z, LI L. Sensitivity and preference of local airflows beneath garments with personalised tem-peratures and velocities[J]. Building and Environment, 2023, 234:110128.

[15]DING Y, ZHANG Z, CHEN Z. Effect of local ventilation temperature and speed under garments on the thermal response of humans at different metabolic rates[J]. Applied Ergonomics, 2023, 113: 104102.

[16]GUO T, SHANG B, DUAN B, et al. Design and testing of a liquid cooled garment for hot environments[J]. Journal of Thermal Biology, 2015, 49: 47-54.

[17]舒伟程. 便携式液冷服系统设计及其热舒适性研究[D]. 武汉: 华中科技大学, 2021.

SHU Weicheng. Design of Portable Liquid Cooling Garment and Its Thermal Comfort Study[D]. Wuhan: Huazhong University of Science and Technology, 2021.

[18]SHU W, ZHANG X, YANG X, et al. A smart tem-perature-regulating garment for portable, high-efficiency and comfortable cooling[J]. Journal of Electronic Pac-kaging, 2022, 144(3): 031010.

[19]XU Y, LI Z, WANG J, et al. Man-portable cooling garment with cold liquid circulation based on thermoel-ectric refrigeration[J]. Applied Thermal Engineering, 2022, 200: 117730.

[20]ZHANG M, LI Z, WANG Q, et al. Research on refrigerant optimization and characteristic parameters based on thermoelectric refrigeration cooling garment[J]. Applied Thermal Engineering, 2022, 212: 118606.

[21]GAO C, KUKLANE K, HOLMÉR I. Cooling vests with phase change material packs: The effects of temperature gradient, mass and covering area[J]. Ergonomics, 2010, 53(5): 716-723.

[22]GAO C, KUKLANE K, HOLMÉR I. Cooling vests with phase change materials: The effects of melting temperature on heat strain alleviation in an extremely hot environment[J]. European Journal of Applied Physiology, 2011, 111(6): 1207-1216.

[23]MNEIMNEH F, GHADDAR N, GHALI K, et al. Experiment study for evaluation of phase change material cooling vest's effectiveness at two melting points used by people with paraplegia during exercise[J], 2020, 11: 1-9.

[24]RYKACZEWSKI K. Rational design of sun and wind shaded evaporative cooling vests for enhanced personal cooling in hot and dry climates[J]. Applied Thermal Engineering, 2020, 171: 115122.

[25]MALEY M, MINETT G M, BACH A J, et al. Extending work tolerance time in the heat in protective ensembles with pre-and per-cooling methods[J]. Applied Ergono-mics, 2020, 85: 103064.

[26]AARISH M, MAHMOOD R, MAHMOOD M, et al. Study on an evaporative cooling vest for farm workers[J]. Proceedings of International Exchange and Innovation Conference on Engineering & Sciences (IEICES), 2020, 6: 116-121.

[27]ZENG S, PIAN S,SU M, et al. Hierarchical-morphology metafabric for scalable passive daytime radiative cooling.[J]. Science, 2021, 373 (6555): 692-696.

[28]CAI L, SONG A Y, LI W, et al. Spectrally selective nanocomposite textile for outdoor personal cooling[J]. Advanced Materials, 2018, 30 (35): 1802152.

[29]韦帆汝, 王发明. 基于相变材料与微型通风风扇的新型个体混合冷却服在温热环境下的制冷效果研究[J]. 丝绸, 2016, 53(3): 1-8.

WEI Fanru, WANG Faming. The cooling performance of a portable hybrid personal cooling system(PCS) based on phase change materials and micro-ventilation fans in a warm environment[J]. Journal of Silk, 2016,53(3): 1-8.

[30]WAN X, WANG F, UDAYRAJ. Numerical analysis of cooling effect of hybrid cooling clothing incorporated with phase change material (PCM) packs and air ventilation fans[J]. International Journal of Heat and Mass Transfer, 2018, 126: 636-648.

[31]WANG F, SONG W. An investigation of thermophy-siological responses of human while using four personal cooling strategies during heatwaves[J]. Journal of Thermal Biology, 2017, 70: 37-44.

[32]SONG W, WANG F, ZHANG C, et al. On the improvement of thermal comfort of university students by using electrically and chemically heated clothing in a cold classroom environment[J]. Building and Environment, 2015, 94: 704-713.

[33]SORA S, HAE-HYUN C, BIN K Y, et al. Evaluation of body heating protocols with graphene heated clothing in a cold environment[J]. International Journal of Clothing Science and Technology, 2017, 29(6): 830-844.

[34]XU J, GAO L, XIAO M, et al. Isogeometric topology optimization for rational design of ultra-lightweight archi-tected materials[J]. International Journal of Mechanical Sciences, 2020, 166: 105103.

[35]UDAYRAJ, LI Z, KE Y, et al. A study of thermal comfort enhancement using three energy-efficient persona-lized heating strategies at two low indoor temperatures[J]. Building and Environment, 2018, 143: 1-14.

[36]杨玉桐. 冷环境下局部电加热对人体热反应的影响[D].上海: 东华大学,2021.

YANG Yutong. Effect o6+asxoy3Y8M6FyQJX93FWQ==f Local Electric Heating on Human Thermal Response in Cold Environment[D]. Shanghai: Donghua University, 2021.

[37]HSU P, LIU X, LIU C, et al. Personal thermal manage-ment by metallic nanowire-coated textile[J]. Nano letters, 2015, 15(1): 365-371.

[38]WEI X, XIAO Y. Polyester fabric impregnated with carbon nanotubes directly to form a flexible heating fabric[J]. Journal of Physics: Conference Series, 2022, 2206(1): 012041.

[39]CHAI J, KANG Z, YAN Y, et al. Thermoregulatory clothing with temperature-adaptive multimodal body heat regulation[J]. Cell Reports Physical Science, 2022, 3(7): 100958.

[40]MELOCCHI A, UBOLDI M, CEREA M, et al. Shape memory materials and 4D printing in pharmaceutics[J]. Advanced Drug Delivery Reviews, 2021, 173: 216-237.

[41]WANG Y, YU X, LIU R, et al. Shape memory active thermal-moisture management textiles[J]. Composites Part A: Applied Science and Manufacturing, 2022, 160: 107037.

[42]ROACH D, YUAN C, KUANG X, et al. Long liquid crystal elastomer fibers with large reversible actuation strains for smart textiles and artificial muscles[J]. ACS Applied Materials & Interfaces, 2019, 11(21): 19514-19521.

[43]SHAID A, WANG L, ISLAM S, et al. Preparation of aerogel-eicosane microparticles for thermoregulatory coating on textile[J]. Applied Thermal Engineering, 2016, 107: 602-611.

[44]TANG J, LIU Y, DU H, et al. The effects of portable cooling systems on thermal comfort and work performance in a hot environment[J]. Building Simulation, 2021, 14(6):1667-1683.

[45]YONG L, SUMATHY K. Performance analysis of a continuous multi-bed adsorption rotary cooling system[J]. Applied Thermal Engineering, 2005, 25(2/3): 393-407.

[46]CRITOPH R, METCALF S. Specific cooling power intensification limits in ammonia-carbon adsorption refri-geration systems[J]. Applied Thermal Engineering, 2004, 24(5/6): 661-678.

[47]辛丽莎,李俊,王云仪. 防护服装功能设计模式研究[J]. 纺织学报, 2011, 32(11): 119-125.

XIN Lisha, LI Jun, WANG Yunyi. Research on func-tional design pattern of protective clothing[J].Journal of Textile Research, 2011,32(11): 119-125.

[48]YANG Y, STAPLETON J, DIAGNE B, et al. Man-portable personal cooling garment based on vacuum desic-cant cooling[J]. Applied Thermal Engineering, 2012, 47: 18-24.

[49]ZHANG M, LI Z, XU Y, et al. Design and research of liquid cooling garments in thermal environment[J]. International Journal of Refrigeration, 2022, 139: 136-147.

[50]XIAO Y, ZHANG L R, LI L X. Investigation of processing factors affecting flexible heating wire by coating polyester yarns with carbon nanotubes[J]. IOP Confer-ence Series: Materials Science and Engineering, 2020, 770(1): 012051.

[51]CHEN X, ZHANG Z, YANG Y. Preferred local electrical heating and its effect on overall thermal response[J]. International Journal of Clothing Science and Technology, 2023, 35(4): 526-544.

[52]王富香. 人体姿势对电加热服加热效果及着装人体热舒适的影响研究[D].上海: 东华大学, 2023.

WANG Fuxiang. Effect of Human Postures on The Heating Performance and Thermal Comfort of Human Body in Electric Heating Suit[D]. Shanghai: Donghua University, 2023.

[53]LIU X, JIN X, LI L, et al. Air-permeable, multi-functional, dual-energy-driven MXene-decorated polymeric textile-based wearable heaters with exceptional electro-thermal and photothermal conversion performance[J]. Journal of Materials Chemistry A, 2020, 8(25): 12526-12537.

[54]GUO Z, SUN C, WANG J, et al. High-performance laminated fabric with enhanced photothermal conversion and joule heating effect for personal thermal management[J]. ACS Applied Materials Interfaces, 2021,13(7): 8851-8862.

[55]CHEN W, WEI X, LIU W, et al. Dual-functional thermal management textiles for dynamic temperature regulation based on ultra-stretchable spiral conductive composite yarn with 500%-strain thermal stability and durability[J]. Materials Horizons, 2024, 11(3): 792-802.

[56]HOYT T, ARENS E, ZHANG H. Extending air tempera-ture setpoints: Simulated energy savings and design considerations for new and retrofit buildings[J]. Building and Environment, 2015, 88: 89-96.

[57]LI Z, KE Y, YANG B et al.Personal cooling strategies to improve thermal comfort in warm indoor environments: Comparison of a conventional desk fan and air ventilation clothing[J]. Energy and Buildings, 2018, (174): 439-451.

[58]KE Y, WANG F, XU P, et al. On the use of a novel nanoporous polyethylene (nanoPE) passive cooling mate-rial for personal thermal comfort management under uniform indoor environments[J]. Building and Environment, 2018, 145: 85-95.

[59]VISSERS D. The Human Body as Sensor for Thermal Comfort Control[D]. Eindhoven University of Technology, 2012.

[60]LOU L, ZHOU Y, YAN Y, et al. Wearable cooling and dehumidifying system for personal protective equipment (PPE)[J]. Energy and Buildings, 2022, 276: 112510.

[61]HONG S, GU Y, SEO J K, et al. Wearable thermo-electrics for personalized thermoregulation[J]. Science Advances, 2019, 5(5): 0536.

Review of personal cold and heat regulating clothing

CHEN Xue1, YU Lijing2, ZHANG Zhaohua1

(1.College of Fashion and Art Design, Donghua University, Shanghai 200051, China; 2.College of Design and Art, Liuzhou Institute of Technology, Liuzhou 545616, China)

Abstract: Adjusting the temperature and humidity of the microenvironment between the human body and clothing can effectively enhance thermal comfort and improve work efficiency in extreme temperature environments. Moreover, it offers significant advantages in terms of building energy efficiency. To further advance the application and progress of personal thermal regulating clothing in enhancing human thermal comfort and improving building energy efficiency, this paper systematically introduced the classification, characteristics, and current research progress of various types of personal thermal regulating clothing, including personal cooling clothing, personal heating clothing, and dynamically regulated clothing. The paper also summarized the advantages and disadvantages of different types of personal thermal regulating clothing, and conducted a comprehensive comparative analysis to propose potential future development directions for this type of clothing.Personal cooling clothing encompasses three primary categories: active, passive, and hybrid cooling ones. Compared to active cooling garments, liquid cooling clothing (passive cooling) has higher cooling efficiency and is suitable for individuals with greater cooling needs. Hybrid cooling clothing, which combines two or more cooling mediums, can provide superior cooling effects in dynamically changing high-temperature environments. In comparison to single cooling mediums, hybrid cooling demonstrates more significant cooling effects and thermal comfort. Future research and development should concentrate on enhancing the cooling efficiency of cooling clothing, improving garment portability, and fostering sustainable energy practices. This involves exploring lighter materials and higher energy-density batteries. Additionally, integrating solar panels into clothing design should be considered to save energy consumption and achieve sustainable development. In the development of personal heating clothing, electric heating clothing has gained widespread attention from researchers due to its advantages of being lightweight, thin, washable, and having high heating efficiency. With the advancement of heating technology, further exploration is needed to enhance the heating efficiency of heating fabrics in low-temperature environments and to implement various drive energy technologies to meet heating demands in diverse scenarios. Additionally, there should be exploration into the smart development of heating clothing by incorporating sensors or intelligent control systems to achieve precise temperature regulation and personalized heating control, so as to cater to the heating needs of different individuals. In recent years, new types of personal thermal regulation clothing that can dynamically adjust between heating and cooling have also been developed, capable of rapidly responding to real-time changes in human physiology and the environment. These textiles can monitor real-time changes in human physiology and the environment, providing rapid responses. However, in practical applications, the complex manufacturing processes and high production costs of these garments limit the possibility of mass production. Furthermore, there is a need to further improve the efficiency of heating and cooling and enhance dynamic response rates. In summary, the future development of personal thermal regulation clothing should focus on innovation and advancements in garment portability, efficient energy conversion, intelligent applications, and sustainable development.

Keywords: human thermal comfort; personal cold and heat regulating clothing; cooling systems; new textiles; smart regulation; electric heating