Effects of BN on the Mechanical and Thermal Properties of PP/BN Composites

CHEN Houzhen ,WANG Yanzhi* ,NAN Yu ,WANG Xu ,YUE Xianyang ,ZHANG Yifei ,FAN Huiling

(1.School of Textiles,Zhongyuan University of Technology,Zhengzhou 451191,China;2.Kaifeng Power Supply Company,State Grid Henan Electric Power Company,Kaifeng 475000,China;3.School of Materials Science and Engineering,Zhejiang University of Technology,Hangzhou 310014,China;4.Zhengzhou Hengtian Copper Co.,Ltd.,Zhengzhou 451100,China)

Abstract: In order to explore the thermal conductivity of polypropylene (PP)/hexagonal boron nitride(BN) composites,PP composites filled with different proportions of BN were prepared through extrution compounding,injection moulding and compression moulding.The composites were filled with BN particles of 5 and 20 μm respectively,and their mass fractions in composites were considered.Percentage of BN was varied from 0 to 25wt% in steps of 5wt%.The effects of BN filler on mechanical properties of the composites were evaluated.The thermal behaviors were studied using DSC and TGA,and the thermal conductivity was also investigated by Laser Flash Device and the Model of 3D Heat Conduction respectively.The experimental results show that impact strength of PP/BN can be enhanced with the addition of BN,but that composites exhibit lower breaking elongation &tensile strength when compared to unfilled ones.It is found that mass fraction of BN influenced the final thermal stability and degree of crystallization of PP matrix,the degree of crystallization of PP with 15wt% of 20 μm BN can be improved by 25% than neat PP.Meanwhile,crystallization temperatures of PP composites are elevated by about 10 ℃.The thermal conductivity results demonstrate that the maximum value of the thermal conductivity is achieved from PP/BN with 20wt% of 20 μm BN,higher than that of pure PP by 95.65%,close to the simulation one.

Key words: thermal properties;polypropylene;composites;hexagonal boron nitride

1 Introduction

With the development of electronic technology,electronic devices have become intelligent and integrated,and the heat generated in unit volume increases rapidly[1].The advanced materials used in these electronic applications tend to undergo an increase in temperature when they are used.Increasing the thermal conductivity of materials will be helpful to diffuse heat faster to avoid substantial overheating that could seriously affect the stability,safety and service life of the equipment[2,3].Metal materials,as traditional thermal conductive materials,due to their high density and difficult processing,are gradually replaced by high-performance polymers and composites,mainly for the mass savings[4,5].However,the thermal conductivity of most polymers is only 0.1-0.5 W·m-1·K-1,and can not meet the needs of industrial development.In order to improve the thermal conductivity of polymers,it is a feasible method to combine polymers with fillers[6-8].Common high thermal conductive fillers include grapheme[9,10],carbon fiber[11],alumina[12],hexagonal boron nitride (BN)[13-15]and aluminum nitride[16],etc.Among them,carbon materials such as grapheme and carbon fiber,which have good thermal conductivity and mechanical properties,are effective fillers to improve the thermal conductivity of polymers.But their electrical conductivity limits application in the field of electronic packaging[17-19].

In recent years,as ideal inorganic thermal conductive filler,BN has been favored in the field of thermal management.In terms of the microstructure of BN,hexagonal BN possesses the most stable crystalline form,in which B and N atoms are bonded by sp2hybridization on the plane,forming a network lamellar structure,similar to graphite[20,21].In addition to similar mechanical properties and thermal stability to graphite,the thermal conductivity of BN is as high as 300-2 000 W·m-1·K-1,and the high electrical insulation of the material can still be retained while improving the thermal conductivity of the polymer[22-24].Many scholars have studied how BN carries a high thermal conductivity in polymer composites[25,26].Zhanet al[26]prepared PEN/BN composites via solution casting method,and pointed out that 30wt% of BN improved the thermal conductivity of PEN/BN composites by 140%.According to the report by Quillet al[27],ABS composites filled with BN have been prepared through 3D printing and injection molding technology,and suggested that increasing BN content can elevate the thermal conductivity of ABS composites,but reduces its bending strength and impact toughness.

As one of the most widely used general plastics,polypropylene (PP) is a semi-crystalline polymer with good mechanical properties,stable chemical properties and easy processing.Moreover,PP has also attracted attention in the field of electronic packaging due to its high melting point and excellent electrical insulation[29-31].For example,Konget al[31]promoted the thermal conductivity of PP/BN composites by 72.3%with the method of alkyl linker BN.Chenet al[32]used mussel method to perform non-covalent functionalization on the surface of BN,and added maleic anhydride grafted PP as a compatibilizer improved the thermal conductivity of PP/BN composites.The above studies have effectively improved the thermal conductivity of PP/BN composites via surface modification of BN,but how to use the characteristics of BN to enhance the thermal conductivity of composites needs further study.In this paper,the effect of BN sizes on the mechanical properties,crystallization properties,thermal stability and thermal conductivity of PP/BN composites were systematically studied,and numerical simulation of the thermal conductivity of PP/BN composites was performed by Digimat and Workbench,which can provide theoretical references for the expanding of its industrial application.

2 Experimental

2.1 Materials

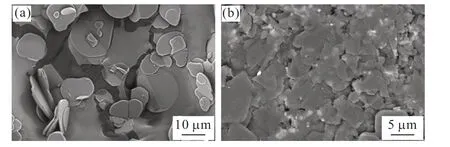

Polypropylene (PP,commercial code: 012) was purchased from Shandong Wusheng Natural Gas Chemical Co.,Ltd.,China.Two kinds of hexagonal boron nitride (BN) particles,provided by Suzhou Napo Material Technology Co.,Ltd.,China,with average particle sizes of 20 μm (packing density is 0.4 g·cm-3)and 5 μm (packing density is 0.2 g·cm-3),designated as BN-I and BN-II,respectively.The SEM images of two BNs are shown in Fig.1.

Fig.1 SEM images of BN: (a) BN-I;(b) BN-II

2.2 Preparation of PP/BN composites

PP powders and BN particles were dried in vacuum oven at 80 ℃ for 5 h.The PP/BN composites were prepared using a SJZS-20 micro twin screw extruder (Wuhan Ruiming Experimental Instrument Manufacturing Co.,Ltd.,China).The screw speed and feeding speed were 40 and 20 rpm,respectively,and the four temperature-controlled zones were set to 170/190/200/210 ℃.The tensile and impact samples were injection molded using WZS series injection molding machine (Shanghai Xinshuo Precision Machinery Co.,Ltd.,China).The melt temperature and mold temperature were set to 220 and 50 ℃,respectively.In addition,PP/BN composites circular sheets were prepared at 190 ℃ and kept for 10 min with pressure of 10 MPa using XLB-D350 plate vulcanizing machine (Shanghai Qicai Hydraulic Machinery Co.,Ltd.,China) for thermal conductivity analysis.

2.3 Characterization

The tensile tests were measured with universal testing machine (AI-7000,High Speed Rail Technology Co.,Ltd.,China) at room temperature,with a rate of 10 mm/min,as specified via ASTM D638.Impact experiments of V type notch sample were determined according to ASTM D6110 on impact testing machine with a 1 J pendulum (EPT1100,Shenzhen Sansi Testing Technology Co.,Ltd.,China).

The thermal behavior and crystallinity of different samples were obtained with differential scanning calorimetry (DSC25,TA Instruments,USA).In nitrogen atmosphere,the samples were heated from room temperature to 200 ℃ with a rapid rate of 20 ℃·min-1and constant temperature for 5 min to eliminate the thermal history,then cooled to 30 ℃ with a rate of 10 ℃·min-1and heated to 200 ℃ at the same rate,the crystallization and melting curves were obtained,respectively.The degree of crystallization (Xc) of PP matrix was calculated according to the following formula,

where,ΔHmis the melting enthalpy of the sample,ΦPPthe mass fraction of PP in the composite,the theoretical melting enthalpy of the PP matrix per unit mass of complete crystallization,209 J·g-1.

Thermal stability of PP/BN composites was researched by a thermal gravimetric analyzer (TGA 209F1 Iris,NETZSCH,Germany).The materials were heated from 40 to 800 ℃ under nitrogen atmosphere at a heating rate of 20 ℃·min-1.

Thermal diffusivity of samples was investigated in a Laser Flash Device (DXF-500,TA Instruments,USA).The circular samples with diameter of 12.7 mm were tested at 30℃,taking three test points for each one,and the average value was calculated.The thermal conductivity (λ) of the samples was calculated from the relation

where,α andCpare the thermal diffusivity and the specific heat capacity of the composites,respectively,andρthe density of the circular sample.

The fracture morphologies of PP/BN composites were studied using a scanning electron microscope(SEM,ZEISS,Germany) at 10 kV acceleration voltage.

3 Results and discussion

3.1 Mechanical properties

Fig.2(a) presents the average tensile strength results for PP/BN composites loaded with 0wt%,5wt%,10wt%,15wt%,20wt%,and 25wt% BN (BN-I and BN-II) filler,and Fig.2(b) is for breaking elongation.The tensile strength of the composites decreased sharply with BN loading below 5wt%,and from this loading,the decreased trend became gentle with the increasing of the BN content.Meanwhile,the results indicated that the tensile strength of the PP/BN-I composites decreased significantly,and its elastic properties was better than those of PP/BN-II composites.The strong intermolecular forces in the chain caused the formation of rigid and stiff PP matrix,which exhibited organized and tightly packed molecular chains.The addition of BN destroyed the homogeneous phase of PP matrix,and with the loading of BN content,the distribution of BN in the matrix was more intensive,leading to an increase of stress concentration points and a reduction of force between PP molecules.Therefore,there is a continuous decrease in tensile strength and breaking elongation of the composites.Moreover,it was found that the introduction of large size BN was more likely to reduce the tensile strength of the composites and thus it is expected that the BN particles of small size can be effectively contained in the matrix,while large size BN were prone to defects such as gaps and porosity when compounded with PP.

Fig.2 (a) Tensile strength and (b) breaking elongation of PP/BN composites

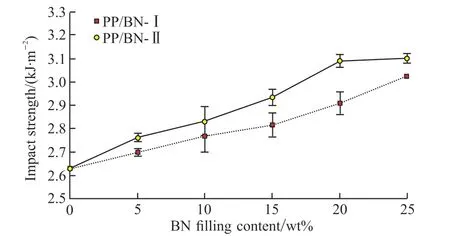

Addition of different types of BN fillers at varying loading levels to PP showed significant improvement in impact strength values of composites and the trend in impact strength was dependent upon the aspect of the BN filler as shown in Fig.3.The impact strength of composites increased gradually with the increase of BN loading amount.When comparing the two sets of samples,it is evident that addition of BN with smaller particle size (5 μm) provides a higher improvement in impact strength values compared to the addition of BN(20 μm) for corresponding loading levels.For example,when the content of BN with smaller particles size in the composites was 20wt%,the impact strength of composites increased more rapidly,which was higher than that of neat PP by 17.47%.While the same loading for BN (20 μm) just enabled a 13.73% improvement in impact strength values.The presumable reason is that the strong rigidity of inorganic BN particles in composites induced a large number of crazes and shear yielding in PP matrix when subjected to impact stress,exhausting impact energy massively.Meanwhile,owing to its wider dispersion and higher surface area,5 μm BN particles in composites can exhaust more impact energy.Therefore,the matrix resin had more energy absorption capacity,and finally the generation of cracks in which slowed down.

Fig.3 Impact strength of PP/BN composites

3.2 Thermal behavior

3.2.1 DSC analysis

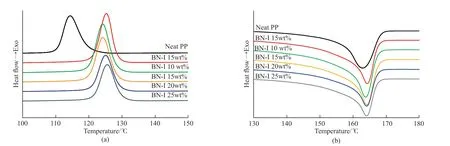

The addition of BN changed the thermal behavior of PP/BN composites.The cooling and heating DSC curves of PP/BN-I composites are plotted in Fig.4.The crystallization temperature (Tc),the melting peak temperature (Tm),the melting range (ΔTm) and the degree of crystallization (Xc) of derived composites are indicated in Table 1.As shown in Fig.4(a) and Table 1,the addition of BN particles had shifted the crystallization temperature of the composites to higher temperatures,in the case of PP filled with BN-I,the crystallization temperature was 10 ℃ higher than that of neat PP(115.08 ℃),whereas,with increasing loadings of BN,the crystallization temperature of the filled polymer was not further influenced.The reason may be attributed to the fact that smaller loadings of BN filler serve to be heterogeneous nucleating sites for PP and effectively accelerates the rate of crystallization of the polymer matrix.Higher loadings of BN increased the nucleation density but hindered the regular arrangement of molecular chains which retards the growth process.This could be the primary reason for no increase in crystallization temperature with higher loadings of BN.

Table 1 Characteristic data of PP/h-BN composites prepared from BN with different particle sizes by DSC analysis

Fig.4 DSC curves of PP/BN-I composites: (a) Cooling run;(b) Second heating run

Meanwhile,the temperatures and enthalpy of fusion of the neat PP and composites were determined.Fig.4(b) showed that the addition of BN particles hardly had influence on the melting temperature of the polymer,but had influence on the melting range.During the melting process,DSC thermograms curve for PP reveals the presence of the phase-change peak(Tm) at 162.87 ℃,the onset temperature was 155.88 ℃,and the end of the melting point was 168.52 ℃.As a result,the melting range was 12.64 ℃ for virgin polypropylene.By contrast,the melting range of PP with BN-I decreased by nearly 4 ℃,whereas that of PP/BNII composites narrowed at first and then widened with the increasing loadings of BN.The degree of crystallization of PP increased after the addition of BN as Table 1.The degree of crystallization first increased with the addition of 5wt% BN-I,and then reached a maximum of 60.62% with the addition of 15wt% BN-I,compared with the value (46.56%) of pure PP,increased by 30%.However,the degree of crystallization of PP with the addition of BN-II changed slightly.

As mentioned above,acting as a nucleating agent,the incorporation of fillers BN-I accelerates the degree of crystallization of polypropylene.As a result,at higher crystallization temperatures,the chain segments of PP were active enough for being sufficiently adjusted and regularly rearranged into crystalline regions.The degree of crystallization of PP thus became higher and the lamellae thickness distribution became narrower,therefore the materials could be completely melted within a narrower temperature range.Moreover,smaller BN particles are more widely dispersed in the matrix compared to the larger ones,at the same filling amount,which limited the activity of the polymer segment in the PP/BN-II composite materials and reduced the degree of crystallization.The crystal morphology of different stages coexisted at the same time,the crystallites of the lower stage were heated and melted at a lower temperature,while those of the higher stage begins to melt at a higher temperature,and therefore the overall melting range of the composites became wider.

3.2.2 Thermal stability

The TG and DTG curves of neat PP and PP/BN composites are shown in Fig.5,and Table 2 represents the detailed thermal data.It can be seen from Fig.5(a)that the degradation of all samples mainly occur at 350-450 ℃.After heated to 500 ℃,the residual mass of the composite almost kept constant with the increasing of temperature,and the residual mass was basically as same as the initial filler mass.Compared with temperatures of 10wt% loss (T10) of neat PP,the thermal decomposition temperature of all PP/BN composites were enhanced after adding BN particles with different sizes,which is similar to the phenomenon in previous reports of BN filled polymers[26,34].With 10wt% BN,the thermal decomposition temperatures of the composites were increased than neat PP by 7 and 60 ℃ for BN-I and BN-II,respectively.Similar results were observed at a loading of 20wt%.As shown in Fig.5(b),it was found that the introduction of BN-I had little effect on the temperature of the maximum thermal decomposition rate (Tp) of the composites,while BN-II increased it by about 25 ℃.

Table 2 Characteristic thermal data of PP/BN composites with different particle sizes

The thermal stability of polymer composites relies on the combined effect of the barrier effect and accelerated degradation of thermally conductive fillers.On the one hand,there were certain interfacial interactions between a variety of thermally conductive fillers and the matrix,and the filler could act as a physical barrier of the matrix to limit the movement of its segments,thereby delaying the thermal degradation of the polymer[35,36].On the other hand,the introduction of high thermal conductive fillers would enhance the thermal conductivity of the composites and accelerate the rise of internal temperature of composites,resulting in accelerated degradation of the composites.For PP/BN composites,the shielding effect of large size BN was mostly offset by its excellent thermal conductivity,which could not significantly improve the thermal stability of composites.However,the dispersion of small size BN particles was relatively wide in the matrix,and the physical barrier limitation could dominate the thermal degradation of PP,which greatly improved the thermal stability of PP/BN-II composites.

3.3 Thermal conductivity

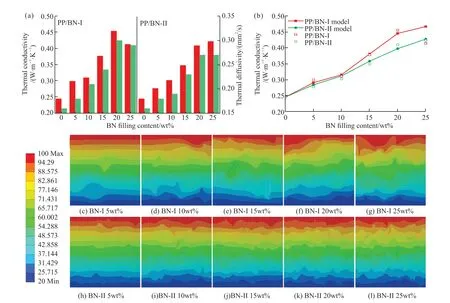

The average thermal conductivity and thermal diffusivity results based on two sets of data for PP composites loaded with 5wt%,10wt%,15wt%,20wt%,and 25wt% BN filler are reported in Fig.6(a).It can be seen that all the composites showed improvement in thermal conductivity as compared to the neat PP which had a thermal conductivity of 0.23 W·m-1·K-1,consistent with the reported values[37].The thermal conductivity and thermal diffusivity of the composites were elevated at loading of BN from 5wt% to 20wt%,and enhanced with the increasing of BN particles size at the same filling content.When filled with 20wt% BN-I particles,showed the highest values of 0.45 W·m-1·K-1and 0.30 mm2·s-1,which were higher than those of pure PP by 95.65% and 87.50% respectively,while the thermal conductivity in another study is only 0.36 W·m-1·K-1with the same content[33].Nevertheless,by further increasing the filling amount to 25wt% BN,both the thermal conductivity and thermal diffusivity of PP/BN-I composites decreased.While those of the PP/BN-I composites slightly increased with the addition of BN.When comparing the two sets of samples,it was evident that addition of BN-I provided a higher improvement in thermal conductivity values compared to the addition of BN-I for corresponding loading levels.

Fig.6 (a) The thermal conductivity and thermal diffusivity of PP/BN composites;(b) Comparison of FEA and experimental results of PP/BN composites;(c-l) Simulation of temperature field distribution of PP/BN composites with different particle sizes

It is well known that thermal conduction is a process of energy transfer within a material,generally carried out in the form of free electrons,phonons and photons,while the polymer solid materials connected by covalent bonds,due to lack of free electrons inside,thermal conduction mainly depend on lattice vibration.For the filled thermal conductive polymer,the thermal conductivity of the material depends on the synergy between the polymer and the filler.As thermal conductive filler,BN induces crystallization of PP and improves the crystallinity of the polymer to a certain extent,and the free path of thermally conductive phonons is increased,thereby the thermal conductivity is improved,but not consistent with the changes in the crystallinity,which is the same as the previous studies[32,38].More importantly,the contact and interaction among the fillers are promoted with the increased BN mass fraction.Most of BN were wrapped by PP matrix and could not play its own thermal conductivity at low filling amount and thus the particle size of BN had little effect on the thermal conductivity of composites.When the loading of BN was 20wt%,BN particles could be uniformly dispersed in the matrix,and BN particles of large size were more easily oriented than those of the small ones with the same loading,leading to significantly improved the thermal conductivity and thermal diffusivity of the composites.However,a large amount of loose BN appeared agglomeration with the further increasing of the BN loading,which had not conducive to the phonon transport.On the other hand,attributed to the poor compatibility between filler and matrix,the composite materials with high filling amount of BN particles were more likely to produce defects such as gaps,bubbles,resulted in decreased in the thermal conductivity of the PP/BN-I composites.

Furthermore,Finite Element Analysis (FEA) was utilized to studied the PP/BN composites,and the thermal conductivity (λ) of the composites was calculated by using the Fourier's Law based on one-dimensional steady-state analysis method,as given by the expression

where,qis the heat flux of composites,which was obtained via FEA,and gradTthe temperature gradient,set to 80 ℃.

Fig.6(b) displays the comparison between FEA and experimental results of PP/BN composites.As shown in Fig.6(b),the simulation results were basically consistent with the experimental ones.Only when the filling amount of BN-I reached 25wt%,the thermal conductivity of the PP/BN-I model reached 0.47 W·m-1·K-1,which was quite different from the experimental results.The results indicated that the model can be effectively reduced the phonon scattering under the condition of ensuring the uniform dispersion of the filler,thereby improving the thermal conductivity of the composite materials.Additionally,the thermal conductivity of the composites was mainly affected by the thermal conductivity of the matrix and the filler itself.As a result,when the BN-I loading increased to 25wt%,the thermal conductivity decreased instead.The temperature field distributions along the X-direction of PP/BN composites with different particle sizes are shown in Figs.6(c)-6(g) and 6(h)-6(l),respectively.It can be seen that the temperature transfer rate was accelerated with the loading of BN,and the temperature transfer rate of the composites prepared by BN particles with large size was faster than that of the small ones.This model suggested that the PP/BN-I composites had superior thermal conductivity and heat dissipation capacity,which were more conducive to improving the thermal management performance of the composite materials.

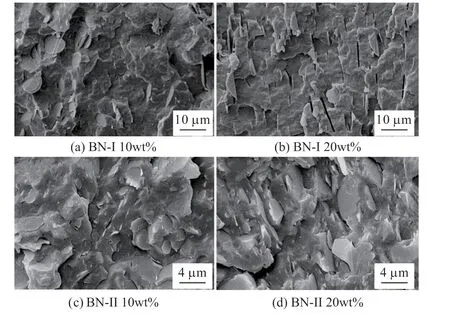

3.4 Morphology

The results of the fracture morphology of PP/BN composites are depicted Fig.7,and all samples were obtained by mechanical impact.As illustrated in Figs.7(a)and 7(c),at loading 10wt% BN,BN particles were randomly distributed in the matrix and separated by a large area of PP,therefore it is difficult to exploit the high thermal conductivity of BN.As shown in Figs.7(b)and 7(d),it can be obviously observed that some BN particles were perpendicular to the section.The reason was that BN presented certain orientation arrangement under the action of shear force in the injection molding process,for which was easier to form a thermal conduction pathway.Accordingly,it can be expected that the thermal conductivity of injection molding samples was higher than that of heat-pressed ones.In addition,it was also found that the orientation degree of large size BN was higher than that of small ones,and the BN particles of small size were partially agglomerated,resulting in the lower thermal conductivity of PP/BNII composites than that of PP/BN-I composites.Compared the SEM images of Figs.7(b) and 7(d),the BN particles of small size were widely distributed in the PP matrix and could absorb more external force when the samples impacted,thereby significantly improving the impact strength of the composites.

Fig.7 SEM images of fractured surface of PP/BN composites

4 Conclusions

In this paper,PP/BN composites were prepared by melt blending in a twin-screw extruder with PP as the matrix and BN with different particle sizes as the filler.Firstly,it is shown that introduction of the rigid BN filler improves the impact strength of the composites,but reduces tensile strength and breaking elongation,which is primarily attributed to disruption of the homogeneous phase of the PP matrix.Secondly,because BN is a heterogeneous nucleation agent for PP,it is found to be important in improving thermal properties.Addition of BN increases the crystallization temperature of PP by 10-15 ℃,but has little effect on its melting temperature.It is also found that BN particles of large size can significantly improve the crystallinity of PP,and make the melting range of PP matrix narrower.In addition,the thermal decomposition temperature of PP/BN composites is improved by adding different sizes of BN,Especially,BN particles of small size are widely dispersed in the matrix and the shielding effect is dominant the thermal degradation,which greatly enhances the thermal stability of PP/BN composites.Thirdly,it is demonstrated that different loading levels of BN fillers with high thermal conductivity play a significant role in enhancing the thermal conductivity values of the composites.The results of thermal conductivity exhibited that BN enhances thermal conductivity and thermal diffusivity coefficients of all the BN composites as compared to the neat PP which has a thermal conductivity of 0.23 W·m-1·K-1.The thermal conductivity scales with increasing BN content and increases to 0.47 W·m-1·K-1with the addition of 20wt% BN-I,higher than that of pure PP by 95.65%.Meanwhile,SEM images reveal that the aligned BN platelet particles into composites facilitate the heat transfer.Lastly,the mathematical simulation results also show that the heat transfer of PP/BN is significantly improved when BN particles are at high loading levels and uniformly dispersed in the matrix.

Conflict of interest

All authors declare that there are no competing interests.

Journal of Wuhan University of Technology(Materials Science Edition)2024年2期

Journal of Wuhan University of Technology(Materials Science Edition)2024年2期

- Journal of Wuhan University of Technology(Materials Science Edition)的其它文章

- Biotin-modified Galactosylated Chitosan-gene Carrier in Hepatoma Cells Targeting Delivery

- Mussel-inspired Methacrylic Gelatin-dopamine/Ag Nanoparticles/Graphene Oxide Hydrogels with Improved Adhesive and Antibacterial Properties for Applications as Wound Dressings

- Effect of Polyvinyl Alcohol in Inner Aqueous Phase on Stability of Millimeter-scale Capsules

- Synthesis and Characterization of Nonionic Waterborne Polyurethane and Application to Wool Fabric Finishing

- Fluorescent Double Network Hydrogels with Ionic Responsiveness and High Mechanical Properties for Visual Detection

- Damage Mechanism of Ultra-thin Asphalt Overlay (UTAO)based on Discrete Element Method