Composition optimization and performance prediction for ultra-stable water-based aerosol based on thermodynamic entropy theory

Tingting Kng ,Cnjun Yn ,Xinying Zho ,Jingru Zho ,Zixin Liu ,Chenggong Ju ,b,Xinyue Zhng ,b,*, Yun Zhng , Yn Wu ,b,***

a College of Chemical Engineering and Materials Science, Tianjin University of Science and Technology, No.29 13th Avenue, Economic and Technologic Development Zone, Tianjin 300457, China

b Tianjin Key Laboratory of Brine Chemical Engineering and Resource Eco-utilization, Tianjin University of Science and Technology, Tianjin 300457, China

c College of Meteorology and Oceanography, National University of Defense Technology, Changsha 410073, China

Keywords:Ultra-stable Water-based aerosol Thermodynamic entropy Composition optimization Performance prediction

ABSTRACT Water-based aerosol is widely used as an effective strategy in electro-optical countermeasure on the battlefield used to the preponderance of high efficiency, low cost and eco-friendly.Unfortunately, the stability of the water-based aerosol is always unsatisfactory due to the rapid evaporation and sedimentation of the aerosol droplets.Great efforts have been devoted to improve the stability of waterbased aerosol by using additives with different composition and proportion.However, the lack of the criterion and principle for screening the effective additives results in excessive experimental time consumption and cost.And the stabilization time of the aerosol is still only 30 min,which could not meet the requirements of the perdurable interference.Herein,to improve the stability of water-based aerosol and optimize the complex formulation efficiently,a theoretical calculation method based on thermodynamic entropy theory is proposed.All the factors that influence the shielding effect,including polyol,stabilizer,propellant, water and cosolvent, are considered within calculation.An ultra-stable water-based aerosol with long duration over 120 min is obtained with the optimal fogging agent composition, providing enough time for fighting the electro-optic weapon.Theoretical design guideline for choosing the additives with high phase transition temperature and low phase transition enthalpy is also proposed, which greatly improves the total entropy change and reduce the absolute entropy change of the aerosol cooling process, and gives rise to an enhanced stability of the water-based aerosol.The theoretical calculation methodology contributes to an abstemious time and space for sieving the water-based aerosol with desirable performance and stability, and provides the powerful guarantee to the homeland security.

1.Introduction

The precision guided weaponry is widely used on the battlefield due to the advantages of high accuracy and high anti-jamming ability, which gives a great threat to the modern ships, tanks, and large land targets[1].As an effective countermeasure to the electrooptic weapons,the aerosol shows promising application prospects in modern information warfare, for instance, electromagnetic damage and protection, obscure targets from detection and attack of the enemy photoelectric guided weapons,etc.[2-4].The aerosol can be mainly classified into solid type aerosol (smoke) and liquid type aerosol (fog) including oil-based aerosol and water-based aerosol.Recently, massive efforts have focused on combustion smoke and oil-based aerosol, such as exploiting HC (Halogenated Organic Compound) [2,5] smoke agents, red phosphorus-based smoke agents [6], metal powder [7], mineral and vegetable oils[8], etc.Though obvious shielding effect has been shown with combustion smoke agents and oil-based aerosol,the duration time is not optimistic and the defects of environmental pollution,human carcinogenesis, storage and transportation difficulties prevent the extensive application [6,9,10].Compared with traditional smoke and oil-based aerosol,water-based aerosol is a new type of passive interfering material[11]featured with broad spectral interference,low cost, environment friendliness and excellent shielding effect,which offers a promising prospect for large-scale interfering and shielding application within visible light, laser, infrared light and radar[1,12,13].

However,the aerosol droplets tend to flop and evaporate quickly during spraying that give rise to a short duration and poor stability of the water-based aerosol, which put bounds to the effective interference of the photoelectric countermeasure.For enhancing the durability and stability of the water-based aerosol, numerous efforts have been devoted by using additives with different composition and proportion.For instance,a mixture of oxyethylene docosyl ether (C12H45OC2H4OH) and oxy-ethylene octadecyl ether(C18H37OC2H4OH),was synthesized and introduced into water as a monomolecular film, which results in improved duration of 150 times longer than that of the pure water-based aerosol [14].The long-chain alcohols were also considered for mixing with water to prolong the stability of water-based aerosol [15].Survival time of droplets was extended from 12 min to 30 min by using higher fatty alcohol, butyl alcohol and emulsifiers additives in water [10].Though the stability of the water-based aerosol is greatly improved with the additives proposed so far, the stabilization time is still within 30 min (Table S1) which could not meet the requirements for perdurable interference [16-18].What’s more, almost all the selection of the additive is based on blind trial-and-error tests up till now.And it is urgently needed to explore an efficacious additive with complex formulation to improve the stability of the waterbased aerosol, and explicate a scientific theoretical design principle for guidance.

To optimize the composition and improve the durability of the water-based aerosol, a theoretical thermodynamic calculation is considered.The thermodynamic parameters such as Gibbs free energy, entropy and heat capacity, serve as the important role in determining the thermodynamic stability of system.For example,Chen et al.[19] using the Gibbs free energy to investigate the thermodynamic stability of compounds.Entropy,is supposed to be a key parameter to characterize the state in thermodynamic theory,and it is widely used to explain the state change mechanism and evaluate the process stability in various fields [20].Xu et al.[21]using the entropy concept to investigate the contact condensation process when steam with high temperature and pressure is injected into the subcooled liquid.However, no strategy and principle has been proposed based on thermodynamic entropy for optimizing the water-based aerosol.

Herein, a theoretical calculation method based on the thermodynamic entropy change is proposed for optimizing the composition and predicting the stability of the water-based aerosol.An optimal formulation is obtained with the method,which is verified with the practical spraying experiment.Besides, the guidelines of screening the additives and optimizing the composition of waterbased aerosol are proposed.The theoretical calculation methodology paves the way for a broad application with water-based aerosols in passive interfering technology field and provides a scientific principle for the experiment design and operation.

2.Experiment

2.1.Materials and characterization

The fogging agent is mainly composed of polyol (glycerol, triethylene glycol and polyethylene glycol-200),cosolvents(ethanol),propellant(ammonium bicarbonate)stabilizer(amyl butyrate)and distilled water.All the chemical used are analytically pure degree.The fogging agent is prepared by adding the propellant into the mixture of water, polyol, cosolvents and stabilizer, followed by continuously stirred.

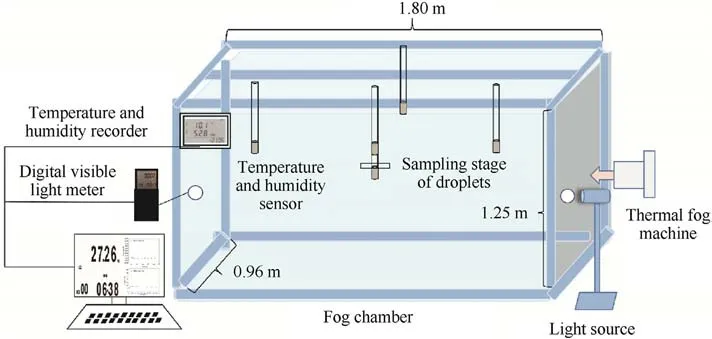

The water-based aerosol is prepared with the aggregation methods [22] inside a fog chamber of 1.80 m × 0.96 m × 1.25 m,which is covered with a piece of black plastic cloth(Fig.1;Fig.S1).The basic environmental conditions of temperature and relative humidity are 298.15 K and 40%, respectively.

To obtain the water-based aerosol, the thermal fog machine(DMX512) containing the fogging agent is pre-heated for 20-30 min and simultaneously record the temperature and pressure at the exit.The fogging agent is sprayed out from the machine into the chamber until the consumption reached 10 g.

The stability of water-based aerosol is characterized with the duration time in fog chamber, and the aerosol concentration in visible light is confirmed with the value of obscuration rate.The led spotlight (MIOGD20A) is used as a light source on one side of the fog chamber,and the digital visible light meter(TES-1330A)is used as a receiver on the other side.The distance between the light source and the receiver is 1.80 m.The change of light intensity with time inside the chamber is recorded.According to Beer Lambert’s Law, the obscuration rate is calculated as follows [10],

Fig.1.Schematic illustration of the experimental setup.

Table 1 Factor level of the orthogonal experiment.

where I0is the intensity of the incident light,and Itis the intensity of the transmitted light.τ is transmittance,and η is the obscuration rate.

2.2.Orthogonal experimental design

To ensure the rationality of the experimental data, the orthogonal experiment was designed to optimize the composition of the fogging agent,and it is important to choose appropriate factors and levels.According to the design principles of orthogonal table,usually 2 or 3 levels are used.Herein,three levels and seven factors correspond to seven different substances are used in the orthogonal experiment design.We did a lot of pre-experiments and the range of levels for each component was determined.And the finally designed results of the orthogonal experiment(L18(37))is shown in Table 1.

Annotation:A is glycerol,B is triethylene glycol,C is polyethylene glycol-200, D is water, E is ethanol, F is amyl butyrate and G is ammonium bicarbonate.

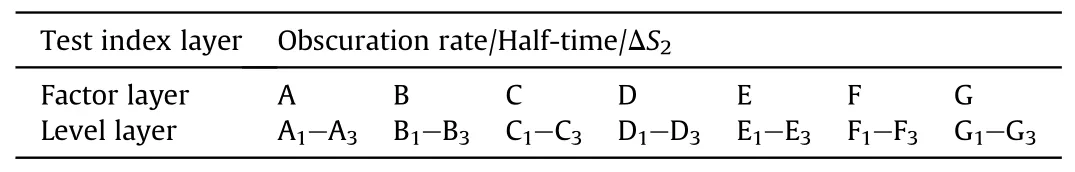

The obscuration rate, half-time (the time from the obscuration rate peak to fall back to the half of peak) and the entropy change during the cooling process are used as the indicators to evaluate the fogging effect.Two methods, range method by comparing the maximum difference between the average value of each factor and weight analysis method [23] by calculating and evaluating weight value, are used to analyze the importance of each parameter and further optimize the composition of fogging agents.In the weight analysis method, three layers structure model is further built,including test index layer, factor layer and level layer (Table 2).

For L18(37)orthogonal experiment,the average value of the test index on j level of the factor Aiis kij.The matrix of factor layer (T)and level layer (E) are built according to Eqs.(2)-(4).The weight matrix is shown in Eq.(5) and the average value is determined as the final analysis result [24].

Table 2 Layers structure design of the orthogonal experiment.

3.Results and discussion

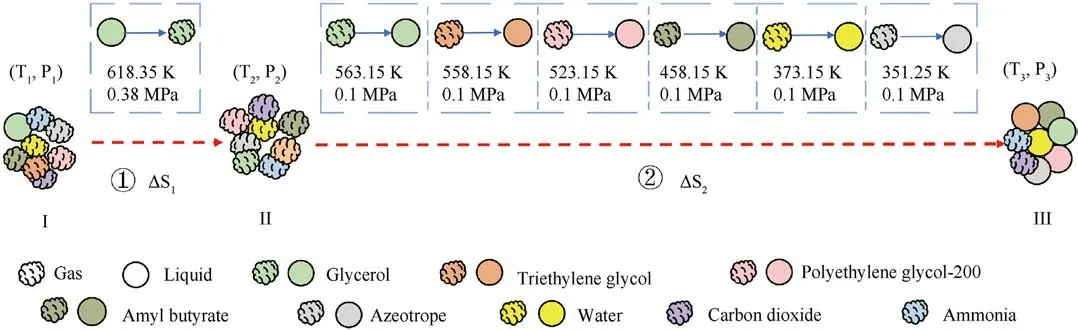

3.1.Formation process analysis

The formation process of the water-based aerosol is systematically analyzed from the perspective of thermodynamic.The fogging agent is firstly vaporized under high temperature and high pressure then congealed into small droplets upon cooling,corresponding to the depressurization process and cooling process (Fig.2).Three states are included during the formation process,the initial state(I),intermediate state (II) and the final state (III).The initial temperature T1and pressure P1at the exit of the fog machine is fixed at 618.35 K and 15.61 MPa.When the fogging agent is sprayed from the fog machine, the pressure instantaneously drops to the atmospheric pressure P2(0.1 MPa).However,the change of the ambient temperature is a relatively slow process that the temperature T2of state II still keeps constant with T1(618.35 K).Stable water-based aerosol can be obtained at the final state with the temperature lowers down to room temperature T3(298.15 K) and pressure of 0.1 MPa(P3).

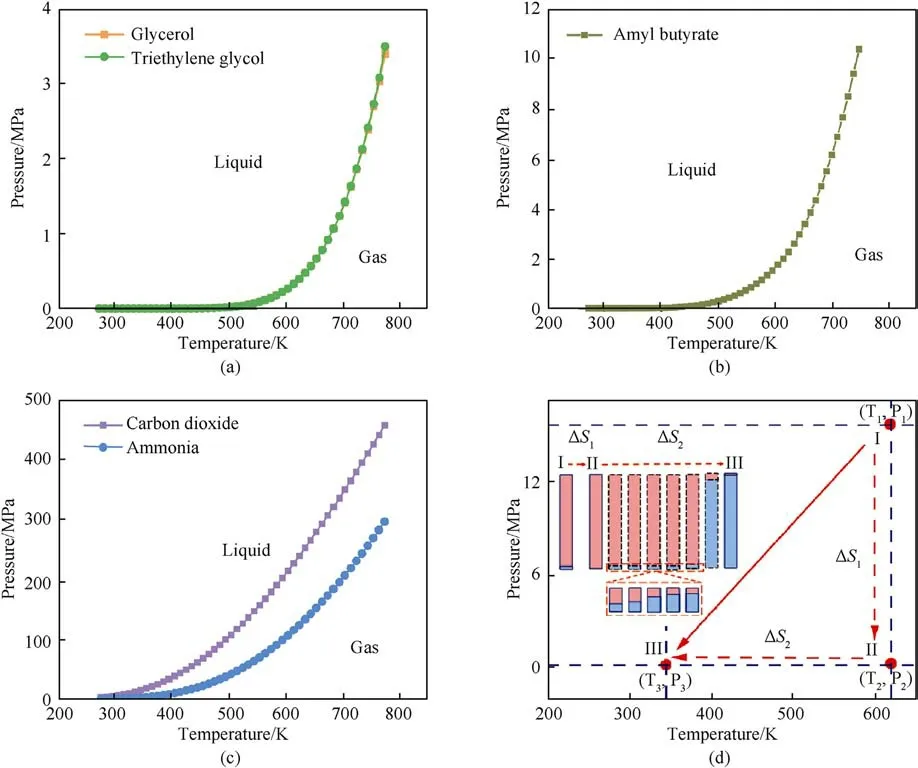

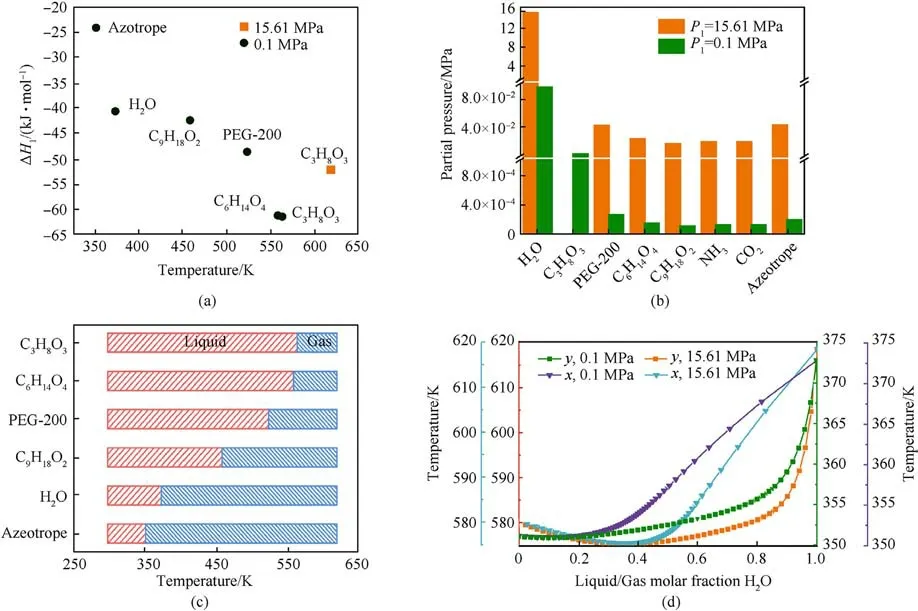

To calculate the entropy change during the formation process,the phase states are specified concretely based on pressuretemperature phase diagram (Figs.3(a)-3(c)).The diagram is divided into liquid and gas phase.At initial state I,assuming that all substances are in the gas phase,the partial pressure of the fogging agent is calculated, it is found that all the components are in gasphase zone except for glycerol, which means all the components are gaseous except for liquid glycerol.With the pressure plunging to atmospheric pressure, gasification of glycerol occurs in the depressurization process,and all the fogging agents turn to gaseous at intermediate state II.When the temperature cools down to room temperature, all the fogging agent liquefies into small droplets in sequence that forms a water-based aerosol at state III.A reverse phase transition from gas-liquid to gas phase occurs at the depressurization process and cooling process (Fig.3(d)).Note that the ammonia and release carbon dioxide would be generated from NH4HCO3according to Eq.(6) at the temperature above 343.15 K[25].

Fig.2.Schematic illustration of the formation process of water-based aerosol.Two process and three states occur during the aerosol formation.

Fig.3.The relationship between the pressure-temperature phase diagram of(a)glycerol(C3H8O3)and triethylene glycol(C6H14O4);(b)amyl butyrate(C9H18O2);(c)ammonia(NH3)and carbon dioxide(CO2)fogging agent;(d)The entropy change and phase state transition during aerosol formation.The gaseous state is denoted with red,and the liquid state is indicated with blue.

3.2.Entropy change analysis

The total entropy change is defined as the sum of the entropy change generated inside the system and the entropy exchanged with surroundings [26].The fogging agent system and the immediate air surrounding is viewed as a "closed system".The entropy balance can be expressed with Eq.(7),

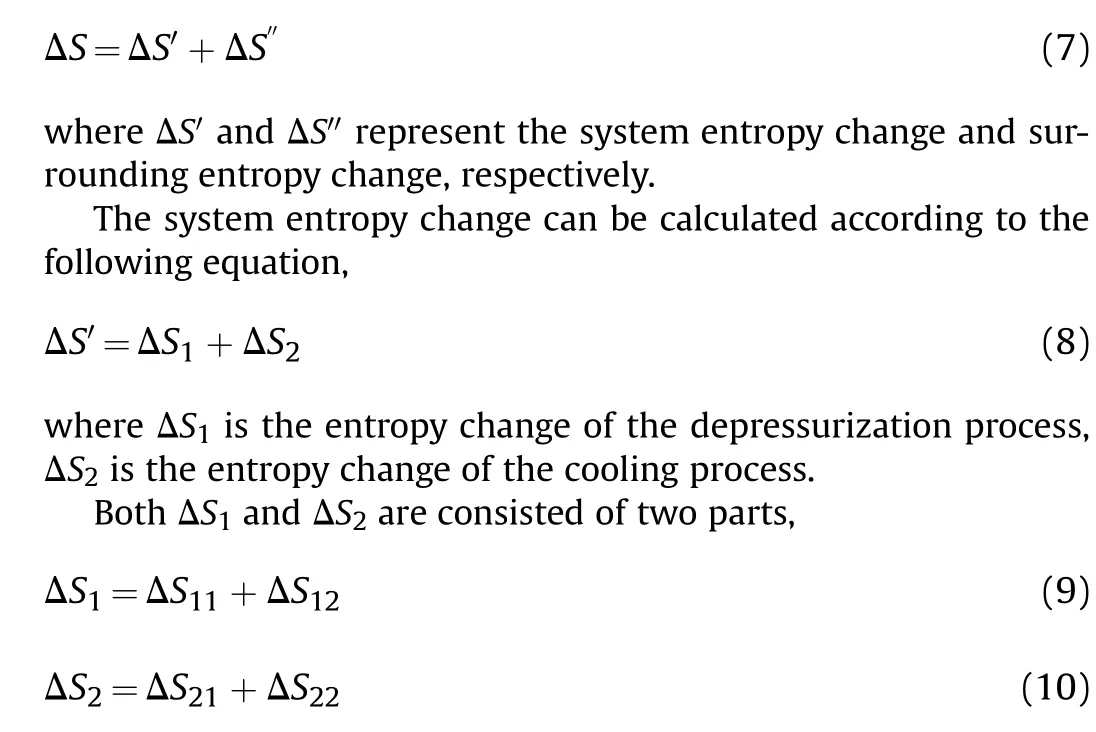

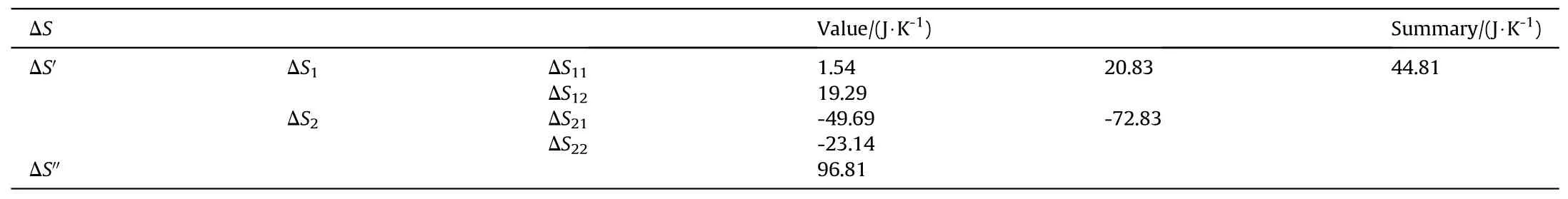

where ΔS11and ΔS21are the entropy changes in the phase transition, ΔS12and ΔS22are the entropy changes caused by pressure change and temperature change, respectively.

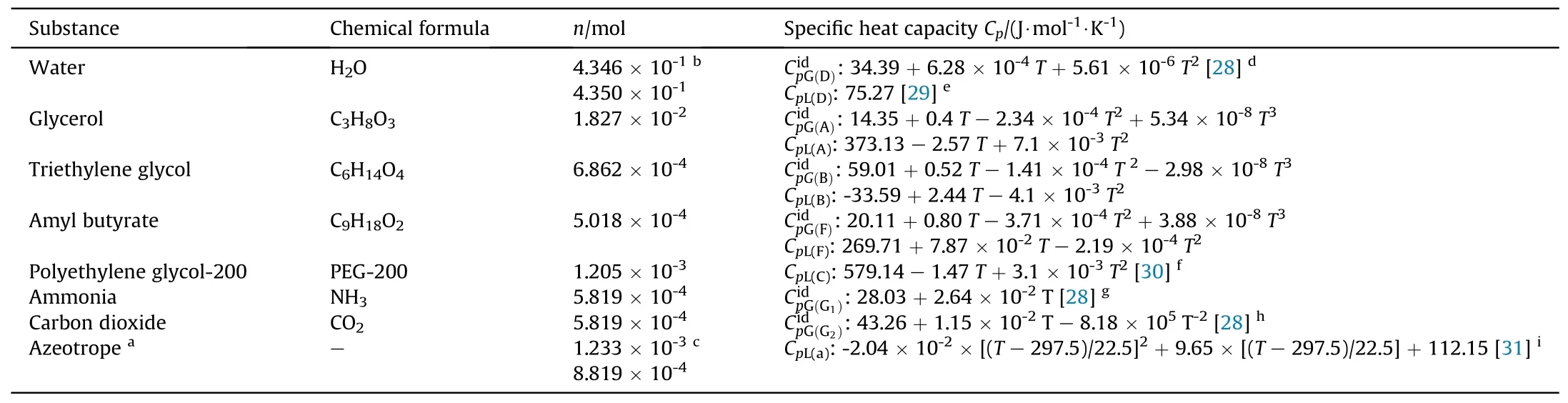

In the isothermal depressurization process (I-II), the pressure decreases to atmospheric pressure instantaneously.The glycerol transforms from liquid into gas while the other component remains in gaseous.Because the pressure variation has little effect on entropy change at the condensed phase,the entropy change of liquid glycerol can be ignored from 15.61 MPa to 0.38 MPa (the phase transition pressure of glycerol at 618.35 K).The entropy change of glycerol phase transition can be calculated according to Eq.(11),

where nAis amount of glycerol(Table 3),ΔH1Aand T′Ais the phase transition enthalpy of glycerol and the phase transition temperature of glycerol,respectively(Fig.4(a); Table S2).

The ΔS12can be calculated according to Eq.(12),

where W is the system work from surroundings.

ΔS12is obtained by substituting the ideal gas state equation(PV = nRT) and Eq.(16) into Eq.(12),

where n is amount of the substance.R is the universal gas constant(8.314 J·mol-1·K-1).P′1and P′2are the partial pressure of the fogging agent in total pressures 15.61 MPa and 0.1 MPa (Fig.4(b)).The glycerin, triethylene glycol, polyethylene glycol -200, water, amyl butyrate,ammonia,carbon dioxide and azeotrope are indicated by subscript of A, B, C, D, F, G1, G2and a here, respectively.

The related parameter in Figs.4(a) and 4(b) is substituted into Eqs.(11)and(17),and ΔS11and ΔS12are calculated to be 1.54 J·K-1and 19.29 J·K-1, respectively.The total entropy of the depressurization process is 20.83 J·K-1, indicating that the process is spontaneous which is beneficial to the formation of water-based aerosol.

In the cooling process, the liquid-gas phase transition occurs when the temperature drops to the boiling point.The entropychange in the phase transition can be calculated according to Eq.(18),

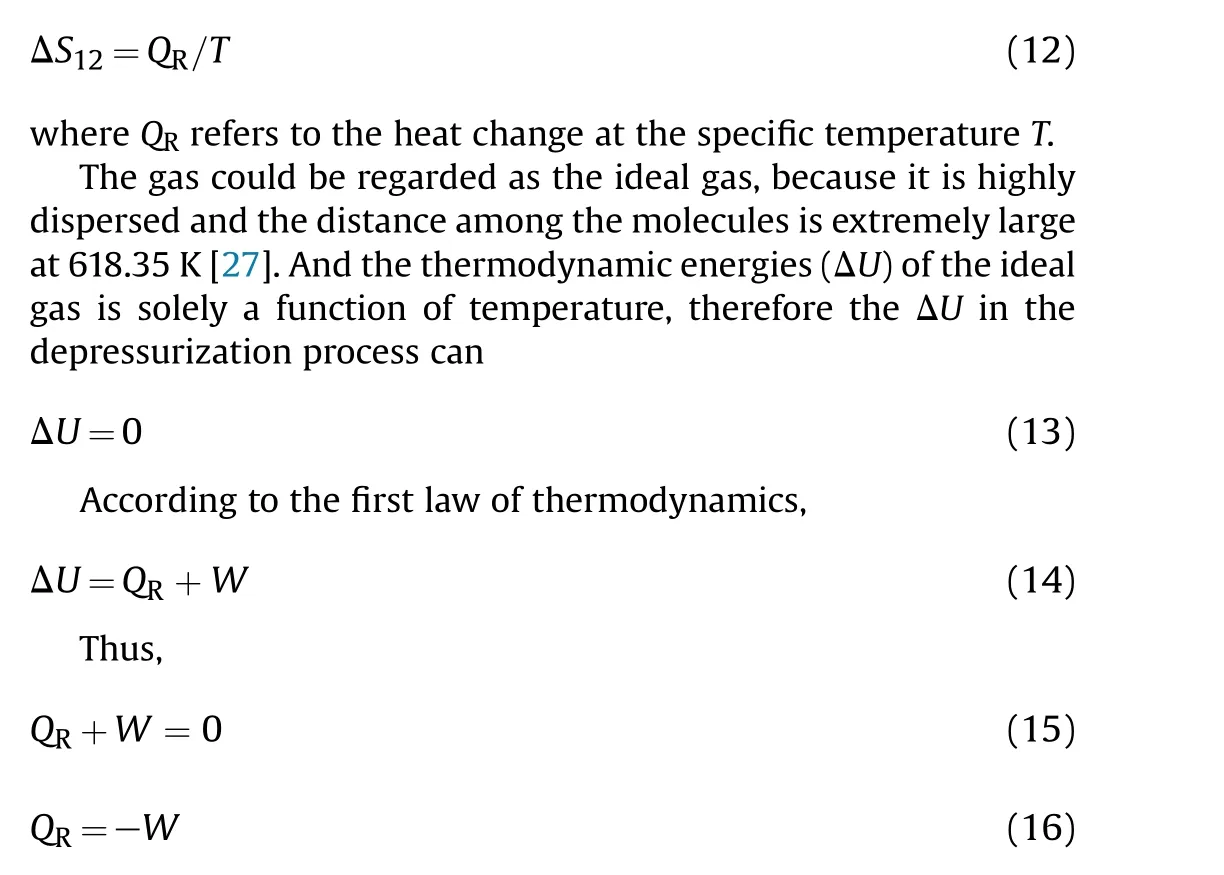

Table 3 The heat capacity of the fogging agent.

where T′is phase transition temperature under the atmospheric pressure (0.1 MPa).ΔH1is the enthalpy of phase transition(Fig.4(a); Table S2).The glycerin, triethylene glycol, polyethylene glycol-200, water, amyl butyrate and azeotrope are indicated by subscript of A, B, C, D, F and a here, respectively.

In this process, the phase state of fogging agents at different temperatures is shown in Fig.4(c) (Table S3).The entropy change can be calculated according to Eq.(19),

where CidpGis the ideal-gas heat capacity and CpLis the liquid heatcapacity.All the data are obtained from the literature or estimated using group contribution methods (Table 3).The glycerin, triethylene glycol, polyethylene glycol-200, water, amyl butyrate,ammonia,carbon dioxide and azeotrope are indicated by subscript of A, B, C, D, F, G1, G2and a here, respectively.

Annotation:

a.The composition of azeotropic is acquired based on the temperature-composition phase diagram that 64 mol% ethanol and 36 mol%water at 15.61 MPa while 89.47 mol%ethanol and 10.53 mol% water at 0.1 MPa (Fig.4(d)).

b.The n of water(nD) is calculated by the following formula:

in which m1is the mass of water at fogging agents, m2is the mass of water in azeotrope,m3is the mass of water is produced by resolving the ammonium bicarbonate.At 15.61 MPa and 0.1 MPa,the results of nDare calculated as 4.346 × 10-1and 4.350 × 10-1,respectively, with modest difference.

c.The n of azeotrope(na) is calculated by the following formula:

where m, M and x represents the mass, the average relative molecular mass,and the molar fraction of the corresponding substance shown by the subscript,respectively.The azeotrope is indicated by subscript of a here.The value of Mwaterand Methanolare 18 g·mol-1and 46 g·mol-1, respectively.At two pressures, the results of the numerical calculation are 1.233 × 10-3and 8.819 × 10-4,respectively.

d.The heat capacities of H2O from 300 K to 2500 K,at atmospheric pressure.

e.The heat capacity of H2O at 298 K and atmospheric pressure.

f.The experimental heat capacities of PEG-200 from 288.15 K to 323.15 K, at atmospheric pressure.

g.The heat capacities of NH3from 300 K to 800 K,at atmospheric pressure.

h.The heat capacities of CO2from 273 K to 1200 K,at atmospheric pressure.

i.The experimental heat capacities of the azeotrope from 275 K to 320 K, at atmospheric pressure.

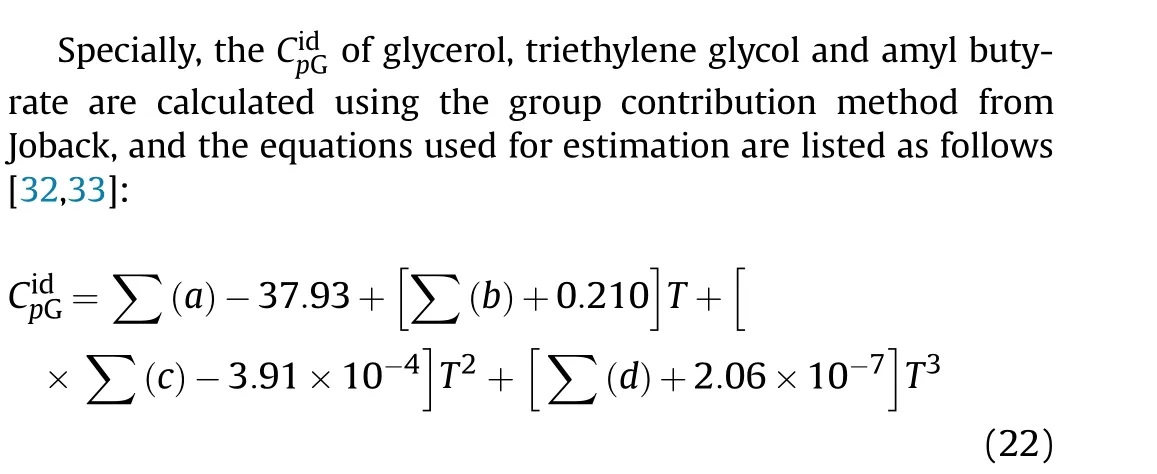

where a, b, c and d are the parameters of the groups.∑(·) is the sum of the product of the times that a group appears in the compound and group contributions.

Fig.4.Parameters of the entropy change:(a)The temperatures and enthalpy for the phase transitions of the fogging agent at 15.61 MPa and 0.1 MPa;(b)The partial pressure of the fogging agent in total pressures 15.61 MPa and 0.1 MPa.The partial pressure is the product of the mole fraction of the fogging agent and the total pressure, specially, the partial pressure of glycerol is 0.38 MPa;(c)Phase states of the fogging agent at different temperatures;(d)The temperature-composition phase diagram of azeotrope:the composition of azeotrope is represented by the intersection of blue line and orange line at 15.61 MPa,while the intersection point for green lines and purple lines corresponds to the composition of azeotrope at 0.1 MPa.

In the group contributions method, the molecular structure of the compound is firstly broken down into a set of groups[34].Two-CH2- groups, a -CH- group and three -OH groups of are comprised in the structure of glycerol,and six-CH2-groups,two-O- groups, and two -OH groups in triethylene glycol.The amyl butyrate is consisted of two-CH3-groups,six-CH2-groups,and a-COO-group.The contribution value of different groups is given in Table S4 [32].Taking the above value of groups into Eq.(22),separately,the CidpGof glycerol,triethylene glycol and amyl butyrate can be obtained (Table 3).

The CpLof glycerol,triethylene glycol and amyl butyrate are also estimated using the group contribution method from Zabransky and Ruzicka [35,36] as following expression.The interactions between groups in the same molecule are considered in this method,

where R is the universal gas constant,niis the number of additivity units of type i,Δciis a dimensionless value of the additivity unit of type i,and k is the total number of additivity units in a molecule.Δciis expressed with the method of Ruzicka and Domalski as follows,

where T is temperature in K and ai,bi,diare adjustable parameters.

The value of ai, bi, diare given in Table S5 with regard to the molecular structures, the group additivity for the glycerol is represented as [2 × C-(H)2(C)(O)]+[1 × C-(H)(C)2(O)]+[3 × O-(H)(C)].Similarly, the group additivity for the triethylene glycol is expressed as [6 × C-(H)2(C)(O)]+[2 × O-(H)(C)(diol)]+[2 × O-(C)2(alcohol)].In the same way,the group additivity for amyl butyrate is represented as [2 × C-(H)3C]+[4 × C-(H)2(C)2]+[1 × O-(C)(CO)]+[1×CO-(C)(O)]+[1×C-(H)2(C)(CO)]+[1×C-(H)2(C)(O)].The CpLof glycerol, triethylene glycol and amyl butyrate can be obtained by substituting the value of ai,biand dicorresponding to the individual groups in Table S5 into Eqs.23 and 24, separately.

It is worth noting that the present estimation method is applicable from the melting temperature to the boiling temperature at atmosphere pressure [36].There is negligible difference between the parameters for the O-(C)2(alcohol) group of triethylene glycol at the temperature ranged from 460 K to 558.15 K(the boiling point of triethylene glycol at atmosphere pressure) and from 273 K to 460 K.

Based on the data mentioned above, ΔS2is calculated to be-72.83 J·K-1,ΔS21is -49.69 J·K-1and ΔS22is -23.14 J·K-1.Therefore,the cooling process is an entropy reduction process, which is nonspontaneous and contributes negatively to the water-based aerosol formation process.

Assuming that the surrounding temperature is essentially unchanged,the surrounding entropy changes(ΔS′′)can be calculated with

ΔS′′= Q/T3

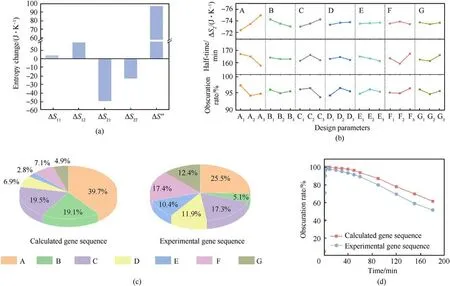

Fig.5.The calculation results of entropy change and orthogonal experiment results:(a)The calculation results of entropy change;(b)The analyzed results of ΔS2,obscuration rate and half-time; (c) The importance of the impact factor in the calculation results and experiment results.The composition of water-based aerosol was represented in A-G, specifically,A is glycerol,B is triethylene glycol,C is polyethylene glycol-200,D is water,E is ethanol,F is amyl butyrate and G is ammonium bicarbonate;(d)Obscuration rate obtained from calculated and experimental gene sequence.

where T3is the room temperature(298.15 K),Q is the heat absorbed by the surrounding air which is equal to the heat released from fogging agent.

According to Eqs.(11),(17-19)and(25),the entropy changes of each process are summarized in Fig.5(a) and Table 4.And to understand the specific function of the entropy change based on the volume fraction of the water-based aerosol composition, figures that presents the entropy changes with different volume fraction with some of the volume fraction unchanged are further plotted based on the specific system obtained by experimental tests(Fig.S2).

The calculated entropy change reveals that the depressurization is an entropy-increasing process, while the cooling process is an entropy reduction process.And the whole water-based aerosol formation process is entropy-increasing with the positive surrounding entropy change.According to the second law of thermodynamics, the entropy represents the driving force of transformation, and the positive ΔS corresponds to a spontaneous reaction and the negative ΔS contributes to the non-spontaneous reaction [37].Compared with the non-spontaneous formation process, the spontaneous aerosol formation process with high absolute entropy change leads to much higher droplet formation efficiency.And more aerosol droplets with small particle size can be generated in a short period which significantly reduces the aerosol droplet coagulation and sedimentation.Stability of the duration time of the aerosol can be thus improved by increasing the total entropy change [38].Therefore, the entropy change of the cooling process plays a crucial role in determining the water-based aerosol stability.It is beneficial to promote the aerosol formation and meliorate the aerosol stability by maximizing the total entropy change or minimizing the absolute entropy change of cooling process.

Orthogonal experiments are thus designed with three levels(L18(37))based on the thermodynamic entropy theory.And the entropy changes of the gene sequence (refers to the composition andproportion of water-based aerosol) during cooling process are calculated (Table S6).The aerosol composition is optimized to obtain the ultra-stable water-based aerosol through the entropy change(Fig.5(b);Table S6;Table S7).In orthogonal experiments,all the factors that influence the stability, including glycerol (A), triethylene glycol (B) and polyethylene glycol-200 (C), water (D),ethanol(E),amyl butyrate(F)and ammonium bicarbonate(G),are considered within calculation.Specifically, the weight matrix analysis was applied to obtain the weights for seven factors.The best choice for each factor should be considered.Herein, the entropy change during the cooling process is used as the indicators to evaluate the fogging effect.The stability of the water-based aerosol is indicated with the absolute value of entropy change, and the stability increases with the absolute value of entropy change decrease in cooling process, which corresponds to a much low weight value.According to the principle of weight matrix analysis,the lowest weight value should be determined as the best choice for the factor.It can be seen clearly that the weight and of A1is the smallest in the factor of A,and similarly,B3,C1,D1,E1,F3and G2has the smallest weight among the factors of B, C, D, E, F and G,respectively (Table S7).Therefore, A1B3C1D1E1F3G2(Glycerol 14.5 mL, triethylene glycol 3 mL, polyethylene glycol-200 3 mL,water 80 mL, ethanol 1 mL, amyl butyrate 1 mL, ammonium bicarbonate 1 g) is identified as the best gene sequence and the optimized composition for ultra-stable water-based aerosol.The corresponded volume fraction is 78.05 vt% for water,14.15 vt% for glycerol, 2.93 vt% for polyethylene glycol-200, 2.93 vt% for triethylene glycol,0.97 vt%for amyl butyrate and 0.97 vt%for ethanol with 9.76 g/L ammonium bicarbonate.And the proportion of the weight values for each factor of calculated gene sequence is finally obtained by dividing the weight values of each factor by the sum of all value as shown in Fig.5(c, left).

Table 4 Calculation results of entropy change for water-based aerosol formation process.

The important order of each factor’s influence on orthogonal test index value corresponds to the order of the matrix values.The greater the value of weight,the more important the corresponding factor.According to the weight value of above seven factors, the importance of the impact factor on stability can be described in sequence of glycerin (polyol), polyethylene glycol-200 (polyol),triethylene glycol(polyol), amyl butyrate (stabilizer), water,ammonium bicarbonate (propellant), ethanol (cosolvent)(A >C >B >F >D >G >E).The polyol is the primary factor in affecting fogging due to the hydroxy groups, which can form hydrogen bonds with water and help the formation of water-based aerosol.From the perspective of thermodynamic, polyol exhibits high boiling point which could reduce the absolute entropy change in the cooling process and increase the spontaneity of aerosol formation.For example, the boiling point of glycerol reaches up to 563.15 K, giving rise to a much easier aerosol formation and improved stability.

3.3.Experimental validation

To verify the validity of the thermodynamic entropy calculation method, practical spraying experiment is performed in a fog chamber.A series of fogging agent with different formulation is prepared based on the orthogonal test and sprayed from the outlet of the thermal fog machine into the fog chamber.In contrast to the entropy change,two evaluation indicators including obscuring rate and half time are used in experiment and the average of weight value was used (Fig.5(b); Table S8; Table S9).The best stability of water-based aerosol increases with the increase of obscuring rate and half time.Therefore, it is reasonable to choose the largest weight value as the optimal addition.The best gene sequence can be expressed as A1B1C2D2E2F3G3, i.e., glycerol 14.5 mL, triethylene glycol 1 mL, polyethylene glycol-200 2 mL, water 85 mL, ethanol 0.5 mL, amyl butyrate 1 mL, ammonium bicarbonate 0.5 g.The corresponded volume fraction is 81.73 vt% for water,13.94 vt% for glycerol, 1.93 vt% for polyethylene glycol-200, 0.96 vt% for triethylene glycol,0.96 vt%for amyl butyrate,0.48 vt%for ethanol,and 4.81 g/L ammonium bicarbonate.According to the weight value of seven factors, the importance of influencing factors can be determined in the sequence of glycerol (polyol), amyl butyrate (stabilizer) [polyethylene glycol-200 (polyol)], ammonium bicarbonate(booster),water,ethanol(cosolvent)and triethylene glycol(polyol)(Fig.5(c), right), which is well in accordance with the theoretical entropy theoretical calculation result.The obscuration rate variation of the best gene sequence obtained from both experiment and calculation is also tested in the fog chamber, which exhibits coherent trend with long-lasting stability (Fig.5(d)).However, in practical application, meteorological elements can have a great impact on the formation and stability of the aerosols.For example,He et al.[39]systematically demonstrated the effect of wind speed on the smoke-screen dispersion, where wind speed mainly affects smoke-screen concentration and the smoke-screen concentration would decrease slowly when wind speed is low and decreases rapidly with wind speed increasing.The effect of meteorological elements on the practical stability of the water-based aerosol will be considered and investigated in the future research.

4.Conclusions

To sum up, a theoretical calculation method based on thermodynamic entropy theory is proposed for optimizing the composition and predicting the stability of the water-based aerosol.All the factors that influence the fogging effect,including polyol,stabilizer,propellant, water and cosolvent, are considered within the calculation, the main conclusions are as follows:

(1) The optimal formulation with 78.05 vt% water, 14.15 vt%glycerol, 2.93 vt% polyethylene glycol-200, 2.93 vt% triethylene glycol,0.97 vt%amyl butyrate,0.97 vt%ethanol,and 9.76 g/L ammonium bicarbonate is acquired and verified through the practical experiment.

(2) An ultra-stable water-based aerosol with the duration over 120 min is obtained with the optimal fogging agent,winning plenty of time for protection against the target from visible light, laser and infrared radiation.

(3) The design principles for screening effective additives and optimizing the composition of the water-based aerosol is established by choosing the additives with high phase transition temperature and low phase transition enthalpy.The total entropy change and absolute entropy change should be specifically considered, and the water-based aerosol with much higher total entropy change and much smaller absolute entropy change of the cooling process in the formation process exhibit significant stability.

The theoretical calculation methodology gives rise to an abstemious time and space for sieving the water-based aerosol with desirable performance and stability, and greatly reduces the complexity and blindness in the development of water-based aerosol.Relationship between the composition and stability of water-based aerosol is explicated in this work, which lays a theoretical foundation for long duration interfering of water-based aerosol and provides a novel insight for the further design of aerosol by machine learning in future.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work was supported by the Preparation and Characterization of Fogging Agents, Cooperative Project of China (Grant No.1900030040) and Preparation and Test of Fogging Agents, Cooperative Project of China (Grant No.2200030085).

Appendix A.Supplementary data

Supplementary data to this article can be found online at https://doi.org/10.1016/j.dt.2023.08.014.

- Defence Technology的其它文章

- Explosion resistance performance of reinforced concrete box girder coated with polyurea: Model test and numerical simulation

- An improved initial rotor position estimation method using highfrequency pulsating voltage injection for PMSM

- Target acquisition performance in the presence of JPEG image compression

- Study of relationship between motion of mechanisms in gas operated weapon and its shock absorber

- Data-driven modeling on anisotropic mechanical behavior of brain tissue with internal pressure

- The effect of reactive plasticizer on viscoelastic and mechanical properties of solid rocket propellants based on different types of HTPB resin