Tunable and efficient microwave absorption from mesophase pitch carbide with designable electromagnetic properties

Junyu Lu , Horuo Zhng , Yng Chen , Mushn Yun , Mei Ling ,Zhenggung Heng ,*, Huwei Zou ,**

a The State Key Lab of Polymer Materials Engineering, Polymer Research Institute of Sichuan University, Chengdu 610065, China

b School of New Energy and Materials Engineering, Southwest Petroleum University, Chengdu 610500, China

Keywords:Microwave absorption Mesophase pitch Broadband Dielectric loss Interfacial polarization

ABSTRACT In order to obtain the microwave absorption (MA) materials with light weight, high efficiency and tunable properties, the carbonized mesophase pitch (CMP) with the variation in carbonization temperatures and particle sizes were prepared and characterized.The carbonization temperature mainly controlled the graphitization degree of the CMP to affect their conductive loss.The carbon residues were generated on the CMP surface when the temperature was higher than 700 °C, which contributed significantly to the polarization loss of the CMP.For scale regulation, the segregation between the particles in the paraffin ring caused by the reduction particles of CMP carbonization at 750 °C (750 CMP)resulted in a significant reduction in conductive losses while improving their impedance matching.The 750 CMP over 300 mesh sieved had the strongest MA properties of -53 dB at 3.49 GHz within 5.5 mm.Moreover, the prepared CMPs were multi-layer compounded and optimized by CST microwave studio.The synergistic effect derived from the improved impedance matching and the enhanced interfacial polarization resulted in significant reflection loss in multi-layer CMP.Overall, these findings lead to the systematically regulation of carbon-based materials for MA, showing an attractive application prospect for the preparation of high-performance MA materials.

1.Introduction

To effectively combat the threat of multi-band and ultra-wide band radar reconnaissance, the high-performance broadband lightweight microwave absorption (MA) materials have become a frontier technology for national defense security because of their ability to convert the energy of incident electromagnetic wave into heat loss [1-4].The frequency of military radar is generally concentrated in 2 GHz-18 GHz,such as S-band(2 GHz-4 GHz)for medium-range early warning radar, and X-band (8 GHz-12 GHz)for airborne radar, highlighting the importance of absorbing materials with adjustable and broadband electronic magnetic wave(EMW) absorption performance [2,3,5].Therefore, the effective integration of light weight, high efficiency and tunable bandwidth into MA materials remains a great challenge,depending on creative designs such as multilayer designs, material composites and/or metamaterials [1,5-9].

Traditional magnetic wave-absorbing materials such as ferrites[2,10,11], metallic magnets or their hybrids [12-16] were broadly investigated because of their performance of magnetic loss.However, they have high density, limited magnetic loss properties in high frequency range, which may be not meet the requirements and make them need to compound with dielectric loss materials[14,17,18].Although conductive polymers such as poly (3,4-ethylenedioxythiophene) (PEDOT) [19,20], polyaniline (PANI)[19,21] and polypyrrole [22] have flexible adjustability, they also suffered from poor chemical stability and low heat resistance.In contrast, carbon-based materials, due to their high dielectric loss,light weight and great performance stability, have become a key research direction in the field of EMW absorption fields and been applied in a variety of aerospace devices and scenarios [23-25].

On this basis,a variety of carbon materials such as carbon black[18,25],carbon nanotubes (CNTs) [26,27], graphene [28,29] and so on have been successfully prepared and used in the field of MA[30].However, the CNTs and graphene need to be compound with low dielectric materials or loaded in three-dimensional structures,due to the impedance mismatch caused by their high electrical conductivity [4,5,26].Rather than EMW absorption, CNTs [31] and graphene [11,32,33] are commonly used in the field of electromagnetic shielding in this situation.In comparison, carbon black does not require any additional structural design and can realize the well MA effect using their adjustable electromagnetic parameters via the method of one-step carbonization of natural biomass materials, demonstrating the advantages of low cost and simple preparation process [6,23,34,35].For instance, Qiu et al.prepared porous carbon from a walnut shell using potassium hydroxide(KOH) activation and carbonization, with the minimum reflective loss(RLmin)of-42.4 dB at 8.88 GHz[36].Similarly,by using in situ growth method with nickel nitrate and cotton waste as precursors,magnetic porous carbon composites can be obtained and has the RLminof -40.5 dB at 15.8 GHz [37].Therefore, finding natural carbon precursors with a high residual carbon rate, low cost, and controllable parameters is critical for large-scale MA carbon black production.

Mesophase pitch (MP) is a nematic liquid crystal with liquid crystal-like physical properties such as optical anisotropy and low viscosity[38,39].The MP has a very high coke yield(beyond 80 wt%), while the product is pure and can be used to prepare highquality carbon black, which is rarely available in other natural materials [39-41].In industry, the MP has good process stability and processability,and thus have the potential to be used on a large scale.It is generally recognized that effective frequency regulation is important but challenging for the practical applications of MA materials[42].In view of the excellent carbon formation properties of MP,it is possible to obtain tunable MA materials in scale through system temperature regulation.The MA materials with different particle sizes (especially in nano scale) may have different polarization characteristics and absorption properties [43,44].However,rarely studies are focused on the effects of particle size on the microwave characteristics of materials in the range of gigahertz frequency.On the other hand,it is necessary to explore simple and easily available methods to obtain efficient EMW absorbers due to the complex structures and costly preparation of MOFs or aerogel.

To meet the above challenges, the carbonized mesophase pitch(CMP) with the variation in carbonization temperatures and particle sizes were prepared and characterized.After that,the gradient multilayer CMPs were designed through CST software simulation to achieve the broadband absorption requirement in specific frequency bands.The mechanisms for the enhanced MA were clarified in terms of synergistic effects derived from multiple reflection and increased impedance matching.

2.Material and methods

2.1.Materials

MP with a softening point of 290°C and mesophase content of the pitch of 100% were obtained from Mitsubishi Gas Chemical Company (Nagasaki, Japan).Solid paraffin was obtained from Aladdin,China.All of the reagents were of analytical grade and used without further purification.Deionized water was used for the characterization of experiments.

2.2.Preparation of CMP with different particle size

As shown in Fig.1, CMPs were obtained by carbonizing MP at 600°C-800°C for 1 h in a tubular furnace at a heating rate of 5°C/min under Ar atmosphere.After sieving using a 2-300 mesh sieve,the CMPs were named as 600 CMP, 650 CMP, 700 CMP, 750 CMP and 800 CMP according to the carbonization temperature.Apart from the 2-300 mesh sieve (medium powder), these CMPs were also sieved using 1-200 mesh and>300 mesh sieves to obtain the coarse and fine powders.The particle size of 100-200 mesh sieve,200-300 mesh sieve,and>300 mesh sieve was 75 μm-165 μm,50 μm-75 μm and<50 μm,respectively,according to the mesh size of the screen.Meanwhile, superfine powders (nano scale) were also prepared by ball milling, the speed and time were 500 r/min and 2 h respectively.

2.3.Characterization

The appropriate carbonization temperature of the samples was tested by thermogravimetric analyzer (TG 209 F1, NETZSCH, Germany)under nitrogen from 30°C to 800°C at a heating rate of 5°C/min.The structural and surface morphology information of the samples was examined by a field emission scanning electron microscope (Quanta 250, FEI Co.Ltd., USA).X-ray powder diffraction(XRD) patterns were measured to investigate the crystal structure and crystallinity of the samples, using X-ray diffractometer (DY-1291, Philips, Dutch) with Cu Kαline.Raman spectra were performed using a Raman spectrometer(Raman,Dilor,France)ranging from 500 cm-1to 3000 cm-1with Ar ion laser(λ=532 nm).X-ray photoelectron spectra (XPS, Escalab 250Xi type, Thermo Fisher)were measured to investigate the phase combination and valence of the CMP.Polarizing microscope (POM) using UPT200i was also used to investigate the distribution of CMP in paraffin ring.The relative complex permittivity and permeability were obtained by the Agilent N5230 vector network analyzer in the frequency range of 2 GHz-18 GHz using the coaxial-line method, where the CMP were mixed with 50 wt%paraffin and pressed through a mold to be a ring-shaped sample with the outer and inner diameters of 7 mm and 3.04 mm, respectively.Then, in terms of the transmission line theory and Debye relaxation theory, microwave absorbing performance and Cole-Cole semicircle of tested samples can be analyzed.

2.4.CST simulation settings

The gradient CMP design were simulated and optimized using the commercial software CST Microwave Studio (CST 2019, Germany) to achieve efficient absorption at 2 GHz-8 GHz, 8 GHz-12 GHz, and 12 GHz-18 GHz, respectively [45].The electromagnetic parameters of CMP were introduced in to CST.The simulation parameter was set to a unit-cell (4 × 4 mm2) model of the fabricated structure and a frequency domain solver, with Et(electrical field) and Ht (magnetic field) values of 0.During the simulation,the PEC backplane was added to the bottom of the layer structure.The gradient was simply set as a two-layer structure to qualitatively analyze the effect of multi-layer compounding, with medium power of 700 CMP(700 M)as the upper layer and medium power of 750 CMP (750 M) as the bottom layer, considering the impedance matching characteristics.The thickness of each layer was set to 0 mm-3 mm during this parametric study.The optimal amount of absorption performance in a specific frequency band was obtained using the interlayer thickness as a variable and the minimum absorption performance(in a specific frequency band)as the optimization target.

Fig.1.Schematic diagram of the fabrication process of CMP with different particle size.

3.Results and discussion

3.1.Selection of carbonization temperature range

3.1.1.TGA

TGA was used to calculate the mass loss ratio and the proper carbonization temperature for MP.As shown in Fig.2(a), the first weight loss peak near 60°C corresponded to water evaporation[5].The majority of weight loss (e.g., hydrocarbon volatilization)occurred at temperatures below 605°C,with the maximum weight loss rate occurring at 510°C.The dramatic weight loss in the 300°C-600°C softening range was attributed to the release of gaseous MP species.Various reactions occurred during the volatilization processes,including polycondensation,polymerization,cracking of side chains from aromatic rings,and isomerization[46].The weight remained nearly constant after heating to 605°C, indicating that the majority of volatile components had been released.This region was linked to semi-coke aromatization and the onset of coking,both of which contributed to the formation of conductive networks[47].The single factor assessment of the carbonization temperature was set from 600°C to 800°C based on the TGA results.

Fig.2.(a) TG and DTG images; (b) XRD; (c) Raman patterns; (d) XPS survey spectrum and (e) SEM images of CMP.

3.2.Effect of carbonization temperature on CMPs

3.2.1.Morphology and structure

The crystallinity, bonding state and microstructure of the samples were characterized by XRD,Raman,XPS and SEM,respectively,to investigate the effect of carbonization temperature on the chemical structure and morphology of MP.

As shown in Fig.2(b),only one peak(002)corresponding to the graphitic structure was observed at around 2θ=25°in all samples,indicating the d-spacing of 0.84 nm and hydrocarbons as the main component of MP [23,39,48].More importantly, as the carbonization temperature was increased, the 002 peak shifted to higher 2θ values due to the volatilization of aromatic and oxidizing components in MP, indicating that the carbonization degree of MP was increased.Similar effects were seen in Co/C composites when the annealing temperature was raised [44] and in Carbon/Carbon composites when the carbonization temperature was increased[39].The bonding state of carbon atoms has a great influence on microwave absorption performance41.As shown in Fig.2(c), all powders had similar spectra with two discernible peaks located in D-bands (nearly 1360 cm-1) and G-bands (nearly 1600 cm-1),representing the vibration of disordered graphite carbon atoms and the stretching vibration mode of sp2hybridized carbon atoms,respectively[49-51].Generally,the ratio of ID/IGcan be utilized to represent the disorder degree of carbon[49].The R ratios(ID/IG)of CMPs carbonized from 600 to 800°C were 0.69,0.69,0.74,0.81 and 0.88, respectively, indicating that all of the CMPs had similar lowdegree graphitization.Furthermore, the ID/IGratio gradually increased with the increase of carbonization temperature, which could be due to an increase in sp2domains during carbonization[52].Other research has found that increasing the annealing temperature increases the degree of disorder in metal-organic framework-derived Co/C composites [44].However, Yang et al.observed the different results that the ID/IGratios of hierarchical hollow C@MnO2composites decreased from 1.13 to 1.01 with the increase of annealing temperature from 650 to 1250°C [49].This difference may be attributed to the C@MnO2as three-dimensional disordered carbon network structure consisting of various hybrid forms of carbon atoms(sp/sp2/sp3),while MP is simply an ordered lamellar structure.The chemical states of CMP were characterized by XPS.Fig.2(d)was the wide scanning results of CMP,confirming the existence of C,N and O elements.The samples still maintained a similar spectrum after heating, while the proportion of C/O increased from 14.57 to 15.64, indicating the removal of the oxygen-containing group.

SEM images of the surface of samples are presented in Fig.2(e).All the samples had similar structural morphology.The deposition of small carbon residues (shown in red arrow) on the CMP increased significantly with the increase of carbonization temperature.These carbon residues could be related to the volatilization of aromatic and oxidizing components in MP and thus resulting in the leaves of residual carbon [47].Hollow flaws or surface defects on the 750 and 800 CMP may contribute to an increase in dielectric loss and achieve superior impedance matching with the surrounding CMP matrix when compared to 600 CMP and 650 CMP [41].Furthermore, the carbon residues on the CMP could act as active interfaces,potentially lengthening microwave propagation distances for multiple reflection propagation paths under the CMP[5,41].

3.2.2.Electromagnetic characteristics and mechanisms

The real parts ε′and μ′represented the storage capability of electric and magnetic energies,while the imaginary parts ε′′and μ′′represented the ability of electric and magnetic energies to be dissipated[30].Both the dielectric loss tangent(tanδε = ε′′/ε′)and the magnetic loss tangent (tanδμ = μ′′/μ′) were important indicators to evaluate the dielectric loss capacity of MA materials.The difference in complex permittivity in carbon materials is usually attributed to their carbon atom bonding state (the degree of graphitization) and microstructure.As illustrated in Fig.3(a),Fig.3(b),the effect of carbonization temperature on the MP can be summarized as higher temperatures resulting in higher ε′and ε′′.These findings were also consistent with a previous study that higher annealing temperatures resulted in higher εr(plural forms of ε′and ε′′)of Co/C composites[44].More importantly,the ε′and ε′′of 600 CMP and 650 CMP in the 2 GHz-18 GHz region approximated to 3 and 0 respectively, indicating that MP dielectric loss is negligible at lower carbonization temperatures.As a result of the dielectric loss of MP resulting from their improvement, the carbonization temperature should be higher than 700°C.Meanwhile, the 800 CMP exhibited the highest dielectric properties (ε′,ε′′and tanε)compared to the other CMPs,which could be attributed to the higher number of conductive carbons in 800 CMP[44].It was worth noting that the ε'' values of 750 and 800 CMP seem to have distinct fluctuating phases corresponding to linear decreases and multiple peaks, which were characteristic of the free-electron model and polarization relaxation [49].The gradual increase in permittivity with increasing carbonization temperature was consistent with the effective medium theory,which indicated that small molecule volatilization promoted the accumulation of carbon residue [18].A moderate tanδε value has a better effect on microwave absorption due to impedance matching [5].As shown in Fig.3(c), the tanδε of CMPs carbonized at 700°C-800°C showed similar moderate values between 0.2 and 0.5 in the range of 2 GHz-18 GHz,while 600 CMP and 650 CMP have no loss capability.This is mainly due to the small molecular heterocycles inside the MP were volatilized during volatilization processes including polycondensation, polymerization, cracking of side chains from aromatic rings and thus improving the conductivity of CMP[44,46].Generally,ε''represents the sum of polarization relaxation(ε′′p)and conductive loss(ε′′c)[49].Apart from dielectric loss,surface defects observed in the SEM images of 750 CMP and 800 CMP (Fig.2(e))could act as polarization centers to consume dielectric energy though dipole orientation, thus the tanδε decreased [30].As illustrated in Fig.3(d)-Fig.3(f), the magnetic loss capacity of CMP is almost negligible.CMP has a much lower μ′′than the ε′′,implying that the excellent reflection loss performance should be primarily due to dielectric loss.

According to Debye relaxation theory, the curve of Cole-Cole was used to describe the relaxation process, in which each semicircle represents one Debye relaxation process.On this basis, the relation of ε′and ε′′can be expressed as Ref.[29].

The more semicircles and the larger radius,the greater degree of multi-polarization [16].Since the 600 CMP and 650 CMP have no dielectric properties,the Cole-Cole curves were observed for CMPs carbonized at 700°C-800°C, as shown in Fig.3(g)-Fig.3(i).Compared to one curve for 700 CMP,two or more semicircles can be observed for 750 CMP and 800 CMP, suggesting that interfacial polarization effects, defects or chemical bonding have play an important role in their dielectric losses [16,53].The interface polarization caused by the surface defect of CMP with higher carbonization temperature is one of the main causes of Debye dipolar relaxation [55].This surface defect acted like a center of polarization, causing the accumulation of charges at the interfaces and production of electric dipole, further resulted in interfacial relaxation [2,55].Moreover, the long straight tails of the curves observed in 750 CMP and 800 CMP compared to 700 CMP may be related to the better conduction loss capability and also reflected their better conductivity [16,29].

Fig.3.Frequency dependence of (a) real part ε′, (b) imaginary part ε′′, (c) dielectric loss tangent tanδε, (d) real part μ′, (e) imaginary part μ′′, (f) dielectric loss tangent tanδμ, and Cole-Cole semicircle of (g) 700 CMP, (h) 750 CMP and (i) 800 CMP in medium powder.

Impedance matching is an important point in determining the EMW absorbing properties of CMP,which can be fully indicated by the intrinsic impedance [2].

As shown in Fig.4(a), the 600 CMP represented the best impedance matching among the CMPs at different carbonization temperature,with the impedance matching degree greater than 0.6 in 2 GHz-18 GHz.It was clearly observed that with the increase of carbonization temperature, the impedance matching of CMP decreased gradually,mainly due to the overlarge ε′and ε′′[54].The volatilization of aromatic and oxidizing components increased the overall carrier mobility (including surface or interior) in MP,resulting in the formation of conductive network [49].This result demonstrates that except for the strong capacity of dielectric loss,controlling the carbonization temperature to achieve the appropriate impedance matching is another important approach for achieving superior microwave absorption property, which was further verified through the comparation of the microwave absorption performance between 800 CMP and 700 CMP.Based on the transmission line theory,α can be described as Ref.[54].

As seen in Fig.4(b),both 600 CMP and 650 CMP have near-zero attenuation,which corresponds to their low dielectric constant real and imaginary parts.The α of CMPs tends to increase as the temperature warms up.It is worth noting that the increase in the α inevitably leads to a decrease in Zreal,implying that the absorption performance of CMP does not increase linearly with increasing carbonization temperature.The carbonization temperature must be within an appropriate range in order for the attenuation coefficient and impedance matching to be perfectly balanced.

Fig.4.(a) Impedance matching ratio Zreal and (b) attenuation constant α.

3.2.3.EMW absorption properties

The transmission line theory was used to investigate the RL values of 600-800 CMPs in order to characterize the effect of carbonization temperature on the reflection-loss properties of the CMP powders.The following equations can be used to calculate RL values using transmission line theory [30].

where Zinis the input impedance of absorber, Z0is the free space impedance, εris the relative complex permittivity, μris relative complex permeability, f is the EMW frequency, c is the free space light velocity, and d is the thickness of absorber.

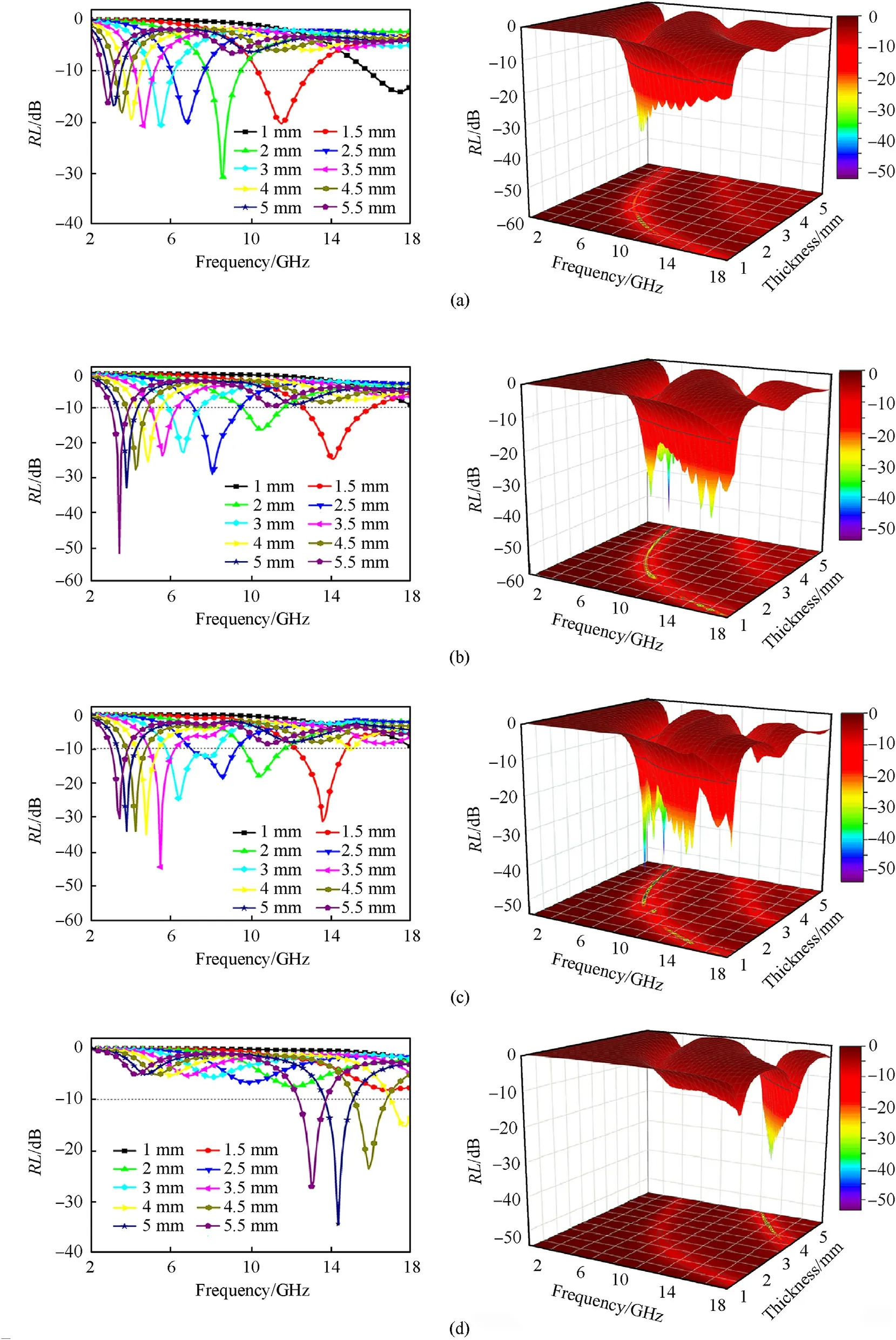

The CMPs were mixed with 50 wt%paraffin,and the calculated 2D and 3D RL values of the absorbers with thicknesses ranging from 1 mm to 5.5 mm were shown in Fig.5(a)-Fig.5(e).Generally, less than -10 dB of the reflection loss (RL) was recognized as the threshold of effective absorption [30].The 600 CMP and 650 CMP powders exhibited quite weak microwave absorption capability with|RL|values less than 10 dB at all thicknesses.The carbonization of more than 700°C makes CMP have better absorption performance in different frequency bands.As the carbonization temperature increased,an obvious improvement of microwave absorption was observed,with the RLminvalue of 750 CMP lower than-53 dB at 3.49 GHz in the thickness of 5.5 mm.The effective absorption bandwidth (EAB, RL < -10 dB) of 700 CMP reached 5.0 GHz (11.6 GHz-16.6 GHz),corresponding to a matching thickness of 2.5 mm.The EAB of 750 CMP reached 3.4 GHz (12.6 GHz-16.0 GHz) when matching thickness was 1.5 mm,confirming the better attenuation coefficient in comparison with 700 CMP.Compared with 750 CMP,800 CMP had a relatively weak microwave absorption performance.At a matched thickness of 2.5 mm,the EAB of the 800 CMP reached only 2.3 GHz (6.9 GHz-9.2 GHz).This is mainly due to the impedance mismatch originating from the high dielectric loss and low magnetic loss, which will further lead to higher microwave reflection rather than absorption [5].Li et al.obtained similar results for organic-inorganic hybrid aerogels in which the amount of CNT has been varied from 3.40 wt% to 4.08 wt%, resulting in a weakened microwave absorption property [30].Furthermore, all CMPs demonstrated that the absorption peaks shifted towards lower frequencies as thickness increased, which was consistent with the 1/4 quarter-wavelength theory [2].Apart from the electrical conductivity, adjusting the thickness of absorbing materials also played a promising role in optimizing the reflection loss performance of CMP.These results demonstrated that CMP can be transformed from a wave-transmitting material to a highperformance wave-absorbing material by regulating the appropriate carbonization temperature.

3.3.Effect of particle size on CMPs

In this section, the particle size regulation was performed by tuning the size of mesh sieve or ball-milling treatment after the carbonization process which enabled variations in the microstructure.Considering that 750 CMP has the strongest MA performance, the effect of particle size on absorbing performance and electromagnetic parameters of 750 CMP was continued to be tested and characterized.

3.3.1.Morphology and structure

Fig.6 presented the SEM images of 750 CMP powder with different sizes (coarse powder, medium powder, fine powder and superfine powder).The particle size of 750 CMPs decreased with mesh sieving elevation and reached the smallest particle size after 2.5 h of ball-milling.The CMP powders have distinct sharp edges and a large number of small carbon residues deposited on their surface, as seen by SEM at 1000 times magnification.This was mainly ascribed to the thermal decomposition reaction and light aromatic compound escape occurred during the carbonization of MP47.More importantly, the aspect ratio of the CMP powders appeared to increase as the mesh sieving was increased from 100 to 200 to 300+.Powders with a higher aspect ratio may exhibit more interface polarization and shape anisotropy43.Such observation indicated that four kinds of CMP with varying particle size and aspect ratio appeared to have distinct electromagnetic loss mechanisms, which could significantly affect the EMW absorption [3].

Fig.5.2D and 3D reflection loss of (a) 600 CMP, (b) 650 CMP, (c) 700 CMP (d) 750 CMP and (e) 800 CMP in medium powder.

Fig.6.SEM and POM (with 50% paraffin) images of 750 CMP in (a) coarse powder, (b) medium powder, (c) fine powder and (d) superfine powder.

The POM of the CMPs was determined after they were blended with paraffin wax to form wave-absorbing rings.As shown in Fig.6,the green particles were optically anisotropic CMPs,while the black parts were paraffin wax.After sieving or ball milling, the CMP particles in the paraffin wax became thinner and more uniformly distributed.The coarse powder displayed a continuous optical morphology and a well connection between each particle in paraffin.As the particle size of the CMP powders decreased, the connections between them were isolated by paraffin wax,resulting in a uniform distribution of discontinuous optical morphology.It could be imagined that the connection between coarse powder was like a bridge of CMP skeleton, while the fine particle was like crushed skeleton dispersed evenly in a larger space,which may not be conducive to the fine powder connections and partly hinder the formation of conductive networks.More particles at heterogeneous interfaces may imply an increase in multiple scattering effects.

3.3.2.Electromagnetic characteristics and mechanisms

The calculated 2D and 3D reflection loss of 750 CMP with different particle sizes were shown in Fig.7.As shown in Fig.7(a)-Fig.7(c), the influence of particle size can be summarized as follows: the finer the particles (micrometer to nanoscale), the lower the ε′and ε′′.Similar results were also reported by Kumar et al.,the ε′and ε′′of SiC decreased with extending ball milling time from 10 h to 20 h[56].On the contrary,Cai et al.reported that the lower particle size (86.97 μm-31.80 μm) on the microwave absorption properties of FeSiAl magnetically soft alloy hollow microspheres(MSAHMs) leaded the higher ε′and ε′′, attributing to the larger specific surface area and more free electrons at smaller particle size[3].This difference could be due to that the control range of MSAHMs was limited to micrometer-scale,while the control range of our experiment was characterized from micrometer to nanoscale.Consequently, a similar trend could be found in the CMP for particles ranging from medium (75 μm-165 μm) to fine (50 μm-75 μm), with ε′and ε′′showing a slight increase in 2 GHz-18 GHz.The tanδε of 750 CMP with different particle sizes showed similar moderate values in the range of 2 GHz-18 GHz,as shown in Fig.7(c), with superfine powder having the lowest dielectric loss capability.As shown in the Supplemental Fig.S1,the real (μ′) and imaginary (μ'') permeabilities of 750 CMPs with different particle size were approach to 1 and 0,respectively,with the tangent of magnetic loss (tanδμ) was nearly 0.Therefore, the attenuation loss of CMP mainly comes from dielectric loss.

Compared with other particles, the tanδε of fine powders showed a higher peak in the range of 6 GHz-9 GHz,and showed a fluctuating trend with the increase of frequency.This could be attributed to the fact that fine powder has the most diverse particle size distribution as seen in SEM (Fig.6(c)).The contact area between fine powders was significantly different, which may induce the generation of interfacial polarization[10].The Cole-Cole curves shown in Fig.7(d)-Fig.7(g) further confirmed the generation of multiple polarization of the powder with smaller particle size.As seen in Fig.7(f),the fine powder has the most fluctuating relaxation peak.This can be attributed to the larger particle size distribution(<50 μm), which may generate more polarization sites during EM wave transmission.Such observation confirmed that the dielectric loss was mainly attributed to the interfacial polarization in fine powders of CMP [29,44].Kumar et al.also reported that charge polarization became more dominant with the increase in surface area space, resulting in an increase of complex permittivity [56].Moreover, a long tail of the curves for all powder can be clearly observed,which is related to the conduction loss[29].The interface polarization caused by the links between particles of different sizes may be the primary cause of Debye dipole relaxation.Similarly,the polarization process of Co/C composites with larger particle sizes(S1-700)was significantly lower than that of Co/C composites with smaller particle sizes(S2-700)at the same pyrolysis temperature44.The effect of particle size on MA performance at the same filling ratio was primarily due to conductive loss, and it was also consistent with the interfacial polarization theory [10,44].

Fig.7.Frequency dependence of (a) real part ε′, (b) imaginary part ε′′, (c) dielectric loss tangent tanδε, Cole-Cole semicircles of (d) coarse powder, (e) medium powder, (f) fine powder, (g) superfine powder, (h) impedance matching ratio of Zreal and (i) attenuation constant α.

As shown in Fig.7(h),the superfine powder represents the best in terms of impedance matching among these 750 CMP particles,with the intrinsic impedance matching degree greater than 0.3 over 2 GHz-18 GHz With the decrease of particle size, the impedance matching of CMP increased gradually mainly due to the decrease of ε′and ε′′[54].The POM (Fig.6) confirmed that as particle size decreased, the interparticle connections were isolated by paraffin wax, resulting in a uniformly distributed discontinuous optical morphology.These results showed that for the same absorbing material, controlling the particle size to achieve appropriate impedance matching was another important way to obtain superior microwave absorption performance.

As seen in Fig.7(i),both 600 CMP and 650 CMP have near-zero attenuation,which corresponds to their low dielectric constant real and imaginary parts.The α of CMPs tends to increase as the temperature warms up.The high frequency absorbing performance of carbon materials at GHz is mainly attributed to the resistive loss caused by the reciprocal motion and migration of relaxed electrons,which generally leads to faster electron relaxation loss [5,54].It is worth noting that the increase in the α inevitably leads to a decrease in Zreal,implying that the absorption performance of CMP does not increase linearly with increasing carbonization temperature.

3.3.3.EMW absorption properties

As shown in Fig.8, all of the particles demonstrated good microwave absorption properties in the specific frequency band, and showed a trend of fluctuation with the change of particle size.It was discovered that as the thickness of the samples increased,the absorption peak shifted to a lower frequency.This could be due to the thickness of samples is equal to the odd times of 1/4 wavelength, resulting in destructive interference between the samples and electromagnetic wave [30].Among all the samples, the fine powder had the strongest absorption peak at the thickness of 5.5 mm with the minimum RL of -53 dB at 3.49 GHz, demonstrating a superior absorbability in S bands (2 GHz-4 GHz).It is noteworthy that the effective absorption peaks showed a trend toward higher wave frequencies as the sample particles become finer.For example, the effective absorption of superfine powder with different thickness was mainly concentrated at 12 GHz-18 GHz,while both course powder and medium powder were mainly concentrated at 2 GHz-14 GHz, indicating the lower complex permittivity requires higher frequency to achieve better loss effects.The decrease in complex dielectric constant was mainly due to the paraffin wax isolating the connection between the ultrafine powders,which prevents the formation of a continuous conducting network as shown in Fig.6 (POM)[43].In summary,the thickness and particle size of absorbing material also play an important role in optimizing the reflection loss performance of CMP.

Fig.8.2D and 3D reflection loss of 750 CMP in (a) coarse powder, (b) medium powder, (c) fine powder and (d) superfine powder.

3.3.4.EMW attenuation mechanism

Based on the above experiments and analysis, the MA mechanism of the paraffin ring loaded with CMPs were revealed and shown in Fig.9.

(i) At mesoscopic-scale, multiple scattering (Fig.9(a)) between CMP particles was encouraged by the uniform distribution of CMP in paraffin.EMW was easily reflected multiple times between CMP particles, as shown in Fig.6, due to the disorder of CMP particles,promoting the effective improvement of MA performance.Furthermore, Fig.6(c) illustrated that the fine powder of 750 CMP has varying pore sizes with a higher shape anisotropy, which could cause more multiple reflection and absorption processes of EMW, increasing the MA intensity.

(ii) As shown in Figs.2(d)and Fig.6,there are a lot of disordered carbon residues on the surface of CMP, and the adhesion between the low-scale carbon residues and the larger CMP particles could cause polarization in the interfacial region(Maxwell-Wagner effect)[30].To sum up,CMP with varying particle sizes realized tunable and high-intensity MA via the above mesoscopic-scale MA mechanism.

3.4.Multilayer design of CMPs

Based on the obtained results, CMPs can gradually transition from low to high complex permittivity.Through simulation and optimization, it is possible to achieve effective broadband absorption in different absorption frequency bands[35].

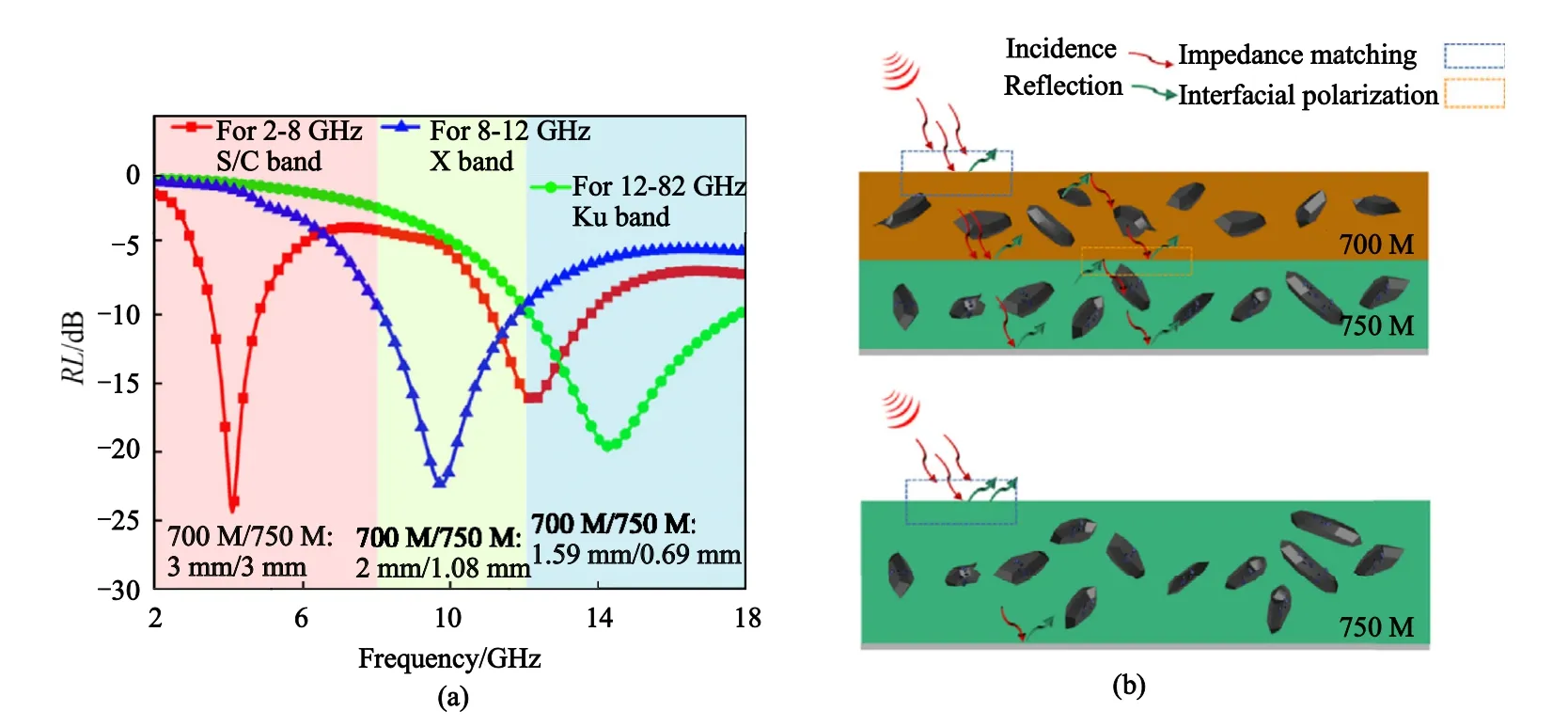

3.4.1.CST optimization

Fig.10.Optimized reflection loss of double-layer structure for different specific frequency bands (a) and the illustration of the muti-layer structure (b).

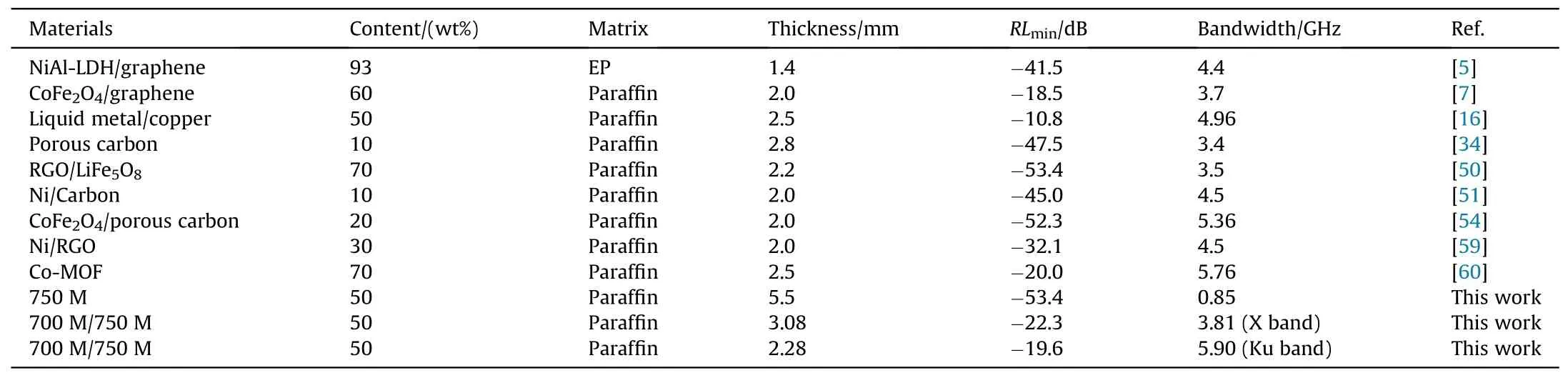

Table 1EMW absorption properties of different materials in the frequency range of 2-18 GHz.

As shown in Fig.10(a),the parametric simulations revealed that the designed and optimized multilayer absorbing structure exhibited excellent absorption performance.The optimized thicknesses of 700 M and 750 M for the S-C band ranges were both 3 mm, with the RL less than -10 dB in the 3.56 GHz-4.85 GHz range.The optimized thicknesses of 700 M and 750 M for the X band were 2 mm and 1.08 mm, respectively, which demonstrated excellent RL(-10 dB)at 8.09 GHz-11.90 GHz,covering nearly 95%of the X band.The optimized thicknesses for the Ku band were 1.589 mm and 0.689 mm, respectively, with the effective RL covering 98.3% (12.0 GHz-17.9 GHz).It is demonstrated that the CMP gradient material has a tunable and efficient wave absorption performance by optimizing the double-layer gradient thickness.The CMP with double-layer structure has significantly improved the broadband absorption effect compared to the single-layer 700 M or 750 M (Fig.5(c) and Fig.5(d)).

These remarkable results, as shown in Fig.10(b), could be attributed to the improved impedance matching (e.g., from air to the first layer and from the first layer to the second layer)as well as improved interfacial polarization, which increases reflection between each layer and extends the electromagnetic wave propagation path [48,58].The combination of low dielectric loss (700 M)and high dielectric loss (750 M) resulted in improved loss absorption.Since the reflectivity gradually increased from top to bottom,the electromagnetic waves can penetrate deeper in a multilayer sample than in a single layer [57].Overall, these findings demonstrated that CMP has excellent adjustability across multiple frequency bands and is expected to be valuable in a variety of absorbing ranges and applications.

Table 1 compared previously reported absorption materials to determine the superiority of CMP in the preparation of MA materials.The medium powder of 750 CMP containing 50 wt% paraffin exhibited relatively high EMW absorption values at lower thicknesses compared to other works.The absorbent simply using carbonized MP and controlled particle size has better EMW performance than part of multiphase composite absorbents with complicated process, showing an obvious application prospect for the preparation of high performance of EMW absorption material.The absorbent prepared by carbonized MP with controlled particle size has better MA performance than other absorbents with complicated process, showing an obvious application prospect for the preparation of high performance of MA material.Benefitting from the tunable dielectric permittivity and multi-layer gradient of CMP, it exhibits attractive multifunction and EMW absorption capability for more complex absorption environments and fields.

4.Conclusions

CMPs were used as a highly efficient absorber for EMW absorption due to their strong complex permittivity after carbonization.Hollow defects or surface defects on the 750 CMP and 800 CMP were found by SEM to endow the multiple reflection propagation paths under the CMP,resulting in strong reflection loss in the 2 GHz-18 GHz range.The multiple reflection such as interface polarization effect and defect or chemical bonds under CMP were confirmed by Cole-Cole semicircle and SEM.The increase in carbonization temperature leaded to a stronger complex dielectric constant and also increases the impedance mismatch.Besides, it was observed that the complex dielectric decreased with the reduction of particle size for 750 CMP due to the connection between the fine particles was isolated by paraffin as shown in POM.The medium powder of 750 CMP exhibited the strongest EMW absorption at a thickness of 5.5 mm, with a maximum reflection loss of -53 dB at 3.49 GHz and a maximum effective absorption(<-10 dB) of 3.4 GHz at 1.5 mm.More importantly, through CST optimization, the CMP can be multi-gradient compounded to achieve absorption effects in specific frequency bands.Overall, the absorption performance of CMP can be flexibly tuned by either controlling the carbonization temperature/particle size or the thickness of muti-layer, showing an obvious application prospect for the large-scale preparation of specific highly efficient EMW absorption material.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This work was supported by Sichuan Science and Technology Program, Grant No.2022YFG0111, the Postdoctoral Innovative Talent Support Program(Grant No.BX20190220),and the State Key Laboratory of Polymer Materials Engineering (Grant No.sklpme2019-2-02) for financial support.

Appendix A.Supplementary data

Supplementary data to this article can be found online at https://doi.org/10.1016/j.dt.2022.07.011.

- Defence Technology的其它文章

- The dynamic response and damage models of rebar reinforced polymer slabs subjected to contact and near-field explosions

- Study of the axial density/impedance gradient composite long rod hypervelocity penetration into a four-layer Q345 target

- Active learning accelerated Monte-Carlo simulation based on the modified K-nearest neighbors algorithm and its application to reliability estimations

- Dynamic compressive response of porcine muscle measured using a split Hopkinson bar system with a pair of PVDF force transducers

- Damage of a large-scale reinforced concrete wall caused by an explosively formed projectile (EFP)

- Air target recognition method against ISRJ for radio frequency proximity sensors using chaotic stream encryption