Self-healed microcracks in polymer bonded explosives via thermoreversible covalent bond and hydrogen actions

Yu-bin Li , Xu Zho , Y-jun Luo , Zhi-jin Yng , Li-ping Pn , Cheng-cheng Zeng ,Cong-mei Lin , Xue Zheng *

a Institute of Chemical Materials, China Academy of Engineering Physics, Mianyang, 621900, China

Keywords:Polymer bonded explosives Self-healing polymers Diels-alder (DA) bonds H-bond

ABSTRACT Polymeric materials used for the polymer bonded explosive(PBX)or other energetic composite materials(ECMs) that simultaneously possess excellent mechanical properties and high self-healing ability,convenient healing, and facile fabrication are always a huge challenge.Herein, self-healing linear polyurethane elastomers (PTMEG2000-IPDI-DAPU, denoted as 2I-DAPU) with high healing efficiency and mechanical properties were facilely fabricated by constructing reversible covalent bonds and dynamic hard domains into polymer chains.Furthermore,a TATB-based PBX using as-prepared 2I-DAPU polymer as the binder was constructed, disclosing an excellent self-healing property to heal cracks generated during fabrication, transportation and storage.The damage healing manner of such a PBX sample was investigated by means of prefabricated damage through mechanical load, heal treatment via heating at high temperature, and CT-scanning the inner structure and mechanical property characterization via Brazilian test.The self-healing mechanism of internal damage in PBX was preliminarily explored.We propose that this 2I-DAPU binder with Diels-Alder bonds could generate plentiful active surface groups resulting from damage and drive self-healing at fitting temperature and increase the slightly packed hard phase via incorporating a small amount of hydrogen bonds.This work may offer a novel strategy for improving mechanical property and healing ability in the field of self-healing material which could help expand its applications with enhanced versatility in mechanical-enhanced functional materials.

1.Introduction

Polymer bonded explosives (PBXs), a typical polymer-based energetic composite materials (ECMs) with high explosive percent(above 85%)and a small percentage of polymeric binder are bonded to form an integrated component [1-4], which are extensively used in various fields,for example,propellant for deep space exploration.During the fabrication, storage and service of PBXs,undetectable micro cracks and other damages triggered from the influence of heat, force and irradiation [5-8] may affect the structure integrity, function and service durability of the PBX.Therefore, how to effectively solve the problem of crack/damage repair for PBXs charges [9-11] has become a new important research direction of high-performance PBX.

Recently, self-healing polymers are gradually employed in various applications due to their ability to heal and repair internal microcracks and damages, restore the structural integrity during failure, and enhance the material’s longevity and durability.Inspired from the natural healing in an external-free process in biological systems, various approaches have been developed to produce self-healing polymers that is able to repair without the need of detection or human intervention.As for ECMs, the selfhealing polymers may be acted as a key approach to repair the crack/damage in PBXs.Since the explosive crystals are less plastic than polymeric binders, which negatively contributing to the interface rearrangement, the crack self-healing function of PBX is mainly attributed to the self-healing property of binders.Obviously,the introduction of self-healing technology into PBX is expected to reduce the maintenance cost of PBX explosive parts in the storage process,prolong the service life and improve the reliability of PBX.

The self-healing approach relies on the chemical and physical interaction of polymers.Although the wound healing process may occur spontaneously, some of the thermoplastic polymer healing methods developed to date still require an external stimulus such as light or heat to initiate the healing process.Nevertheless, even the best self-healing polymers can only repair damage on a microscopic scale.There is often a mendable polymer phase that repairs the damage under an external stimulus such as heating.There are many kinds of functional groups with self-healing properties [12-17].The self-healing of material damage can be realized through thermal reversible reaction.Diels-Alder(DA)bond is a weak covalent bond, which can undergo retro-DA reaction at about 100-130°C and DA reaction at 60-70°C.Such a characteristic of polymer with DA bonds could meet the temperature processing requirements of PBXs, in which r-DA reaction at high temperature can dissociate macromolecule into short chain molecules, endow them with high mobility, easy flow and processing,while at a lower temperature the DA reaction can occur to reform long chain polymers,increase the strength of resistance to damage and maintain the shape of the materials.This is an incomparable advantage to other type of self-healing polymers, such as polymer with hydrogen bonds or disulfide bonds.Therefore, if the selfhealing system containing DA bonds can be introduced into the polymer binder, appropriate self-healing characteristics could be achieved in PBXs.Our group's preliminary research confirmed this feasibility [18].

Until now,the Diels-Alder(DA)reaction,disulfide bond reaction and reversible dynamic metal-ligand interactions or hydrogen bonds have been adopted into the exploratory research of binder matrix of different solid propellants [19-25], realizing an intrinsic self-healing performance of binder system.However,in most cases,these binders exhibit limited mechanical strength (e.g.tensile strength<5 MPa),and the healing performance is obtained in large content (usually 20-50wt%), which induce less practical application value.For highly-filled energetic composites, especially PBXs with low amount (< 10wt%) of polymer binder, there are still relatively few published reports at present.Huang et al.[26]developed a fluoropolymer PVDF-co-HFP/EMIOTf/graphene ternary composite material based on ionic interactions, where cracks in LLM-105-based PBX could be recovered after 48 h at room temperature.Nevertheless, the mechanic strength of this PBX was insufficient(only about 1 MPa).We previously[18]prepared a selfhealing polyurethane (DAPU) with DA bonds by using polytetrahydrofuran (PTMEG-1000) as soft segment, 4,4′-diphenyl methane diisocyanate (MDI) as hard segment, furan end group introduced through 2-furfurylamine (FAm), and bismaleimide(BMI) as chain extender.This DAPU had favorable mechanical strength (about 13 MPa), and its healing efficiency was up to 90%.When it is used as binder in PBX,it can endow PBX with certain of damage-healing capability, and the restoring efficiency of mechanical property can achieve 80%.However, the damage-healing rule has not been explored yet, and the efficiency needs to improve farther.Subsequent studies found that the repair efficiency was related to the flexibility of the molecular chain, and the prepolymer synthesized with long-chain soft segments and alicyclic diisocyanate could obtain better repair effect.

Recently, we prepared a new PTMEG2000-IPDI-DAPU polymer binder (named as “2I-DAPU”), which possessed superior mechanical property with a tensile strength over 17 MPa and an elongation break of above 600%,and the flexible movement of long chain soft segment and hard segment with IPDI endowed the polymer with higher healing efficiency.Owing to the synergistic effect of hydrogen bond and DA bond, this 2I-DAPU polymer could highefficiently complete the self-repairing of scratch by dissociating the DA adduct into furury/maleimide groups at 125°C and then rejoining them through DA cycloaddition reaction at 65°C.Accordingly, a PBX sample was fabricated by using 2I-DAPU as polymeric binder and triaminotrinitrobenzene (TATB) as an explosive.To investigate thoroughly the relationship between damage degree and healing effect, Brazilian compression load mode,deformation,ultrasonic and CT detection were conducted in the PBXs with 2I-DAPU doping amounts of 5,10 and 15%.After that,the healing manner of these PBXs sample was studied by heat treatment, ultrasonic and/or CT detection, and mechanical characterization.The thermal repairing mechanism of internal damage of this kind of PBX was preliminarily explored, providing a reference for the study of damage self-healing of other energetic functional composites.

2.Experimental

2.1.Preparation of TATB based PBXs using 2I-DAPU as binder

The synthesis process of 2I-DAPU is shown in Fig.1(a), and the FTIR spectrum proved its successful synthesis (Fig.1(b)).It can be found that the stretching vibration peaks of methyl (-CH3) at 2940 cm-1and 2855 cm-1and deforming vibration peak of methylene(-CH2-)on aliphatic ring at 1465 cm-1are attributed to reacted IPDI segment of polymer.A typical stretching vibration of the ether oxygen group(C-O-C)occurred at 1103 cm-1belongs to the PTMEG chains.The representative peaks at 1708 cm-1and 1198 cm-1were the existence of carbonyl group (belonging to polyurethane).Moreover, the stretching vibration peak at 3350 cm-1and deforming vibration peak at 1512 cm-1along with the stretching vibration peak at 1369 cm-1were the typical absorption peaks of urethane or urea group (NHCO, -HNCONH-),which indicated that the furfuryl-amine was attached to the NCOprepolymer reacted from IPDI with PTMEG.An absorption peak around 1774 cm-1was attributed to the existence of DA adduct from the reaction between furan and maleimide group.The presence of the DA cycloadduct is verified by the signals at 6.55,5.2 and 3.53 ppm in the1H NMR spectrum of 2I-DAPU.The number-average molecular weight (Mn) and molecular weight distribution of this 2I-DAPU product as determined by GPC were 16,800 g/mol and 2.52, respectively.The thermos-reversible property of 2I-DAPU via DA and r-DA reaction is characterized by DSC (Fig.1(c)).The selfhealing ability of 2I-DAPU was examined quantitatively via investigating tensile property of specimens with cracks before and after heat-treatment (shown in Fig.1(d)).The specimen was cut with 1.5 mm depth, which was about 3/4 of total thickness (inside Fig.1(d)).After heated at 125°C for 20 min and followed by preserving 1 h at 65°C,the cut scratch in the test specimen was healed on the whole.The tensile strength for the first healing event is about 90.3%, and the elongation can recovery about 103.0% of the original value, confirming its excellent self-healing performance.

Several PBX samples with different mass ratios were designed and prepared by coating insensitive explosive TATB with covalent a self-healing polymer PTMEG2000-IPDI-DAPU (2I-DAPU).The molecular structures of TATB and polymer were shown in Fig.1(e).The composition of PBX according to explosive/binder ratio were 95/5,90/10 and 85/15,respectively.Therefore,they were named as PBXTD95,PBX-TD90,PBX-TD85.These PBX products(molding powder)were produced by a modified water slurry method [27].PBX samples for damage-healing study were fabricated by hot pressing these molding powder (90°C, 120 kN, 5 min, re-pressing twice)with a steel mold.

2.2.Damage prefabrication

Fig.1.(a)Synthesis of the PTMEG2000-IPDI-DAPU(2I-DAPU)polymer;(b)FTIR spectrum of 2I-DAPU;(c)thermos-reversible properties of 2I-DAPU;(d)Mechanical properties of 2IDAPU; (e) Molecular structure of 2I-DAPU binder and TATB explosive, optical photographs of as-prepared PBX; (f) Schematics of Brazilian disc load; (g) Loading curve for prefabricating damage; (h) Strain field during loading, and (i) photo of damaged sample in a repairing mold.

The damage prefabrication of PBX samples is adopted the Brazilian disc compression method (shown in Fig.1(f)), which is added to the predetermined load value and maintained for 60 s.The PBX samples with different composite ratio are preloaded with different loads to achieve different degrees of damage.The deformation of the sample can be expressed by recording the displacement of the extensometer, and the deformation can reflect indirectly the damage formed in the sample.The loading methods are shown in Table 1.The typical loading curve and the strain field during loading are shown in Figs.1(g) and 1(h).

2.3.Damage repair treatment

The damaged PBX samples are put into the customized repairing molds,and fixed through the bolts on both sides of the half mold,as shown in Fig.1(i).Then the molds containing sample are put into the oven at a fixed temperature and heated for a certain time to heal the damage in the sample.Considering the low heat transfer characteristic of PBX samples,the pre-damaged PBX samples were heated at 125°C for 2 h, so that the binder could adequately carry out r-DA reaction, promote the binder flow and fill the damaged place.Then, it was kept at 65°C for several hours to make DAPU binder fulfill the DA reaction,and form a continuous network again.The specific heat-treatment method of 125°C-2 h +65°C-3.5 h means that the sample is first heated at 125°C for 2 h and then kept at 65°C for 3.5 h.

2.4.Characterization

The change of ultrasonic characteristic parameters of selfhealing PBX samples before and after repair is detected by CTS-36 all-digital ultrasonic detector.The longitudinal wave pulse reflection method of single transducer is adopted, and the probe frequency is 5.0 MHz, wafer size is φ10 mm, the coupling agent is water, and the coupling surface is the end face of the sample.The measured parameters of ultrasonic wave include gain value,sound velocity and waveform.

The inner quality of self-healing PBX samples before and after repair is examined by industrial CT system.The cone beam scanning method is adopted for CT test.The CT detection voltage is 130kv and the current is 180 μA.The sample magnification is 11.3 and the minimum voxel size is 35.2 μm.The slice image of sample can be obtained from the CT scan data.

The Brazilian mechanical properties of self-healing PBX specimens before and after repair are tested by Instron-5582 material tester (Canton, MA, USA).At least three specimens of every PBX composition were tested.

3.Results and discussion

3.1.Damage characterization

3.1.1.Deformation characteristics of PBX-TD series samples

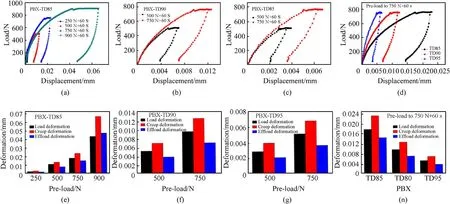

Deformation is a direct response of materials exposed to external force,and the degree of deformation is related to the inner damage of material.With the increase of the load, the internal damage caused by the deformation of the sample under pressure evolves from micro-crack to macro-defect.Fig.2 shows the deformation difference of three different explosive binder ratios under different loads.The deformation of PBX-TD85 sample augments with the increase of load, as shown in Fig.2(a).The creep deformation after maintaining 60s increase as well as the growth of load.After the load is withdrawn,the residual deformation also increases with the load value, which shows that the degree of prefabricated damage in PBX sample augments with the increase of load.The histogram of load deformation, creep deformation and offload deformation of PBX-TD85 along with the load increase are intuitively shown in Fig.2(e).When the applied load increases from 250 to 900 N, these deformations increase several times, and accordingly the damage generated inside the PBX will also increase significantly.Figs.2(b)and 2(f)and Figs.2(c) and 2(g)indicate the same forming rule of damage inside PBX-TD90 and PBX-TD95 along with the preload increases.The deformation of several PBXs under the same load is shown in Figs.2(d)and 2(h),the more self-healing binder content, the greater of the displacement extensometer under the same preload could be demonstrated, which could be ascribe to the easier deformation of binder under stress than that of explosive.Residual deformation can reflect the damage size formed inside PBX.Obviously, from the deformation value of sample after withdrawing load,the greater of the binder amount,the greater of the final deformation and the greater of the damage inside the sample.

3.1.2.Ultrasonic testing of preload PBXs samples

Ultrasonic gain and sound velocity are two important parameters in ultrasonic testing, and their variation is directly related to the internal quality of PBX.Some defects in PBXs may bring the increase of the ultrasonic gain.As can be seen from Fig.3(a), the ultrasonic gain of samples(a to d)change from a slight increase to a sudden increase, while the sound velocity decreases regularly(Fig.3(d)).It also shows that the damage factor produced by mechanical loading has a good correlation with the ultrasonic characteristic parameters, especially the gain value.In addition, the ultrasonic velocity decreases regularly with the increase of preload,which as well as reflects the increasing trend of internal damage.For the same PBX samples (such as TD85 series), as the prefabricated damage load increases from 250 to 750 N, slightly increased gain value was obtained (Fig.3(a)), indicating that no macro-defects were formed in the PBX.Fig.3(b)showed a slightly decreased sound velocity, reflecting that only small damage is generated in the PBX.When the load increases to 900 N (TD85-d samples), the ultrasonic gain value increases obviously, indicating that the damage inside PBX develops into macro-cracks,accompanied by the further decrease of sound velocity.Figs.3(b)and 3(e)show the variation of ultrasonic characteristic parameters of three samples with different binder content under a prefabricated load of 500 N.Because of the light prefabrication damage,the ultrasonic gain values of the three samples are almost the same,but the sound velocity increases with the decrease of binder content in PBX,indicating that PBX with a higher binder content is more prone to form damage.Fig.3(c) shows the ultrasonic parameters change of two PBXs with different damages before and after repairing-treatment.For PBX-TD95-c sample with relativelyslight damage,the ultrasonic gain value before and after repair did not change a lot because there is no macro-damage.While the ultrasonic velocity increases a little(as shown in Fig.3(f)),reflecting that the slight damage in the sample is repaired after heat treatment at 65°C for 3 h.For the PBX-TD85-d-1 sample with obvious damage,the gain decreased and the sound velocity increased to the same level after repair(85d-1-h), indicating that the macro damage in the sample has also been repaired.

Table 1Damage prefabrication mode of TATB-DAPU based PBX.

Fig.2.Load-displacement curves and deformation of several PBXs under different loads:(a),(e)PBX-TD85;(b),(f)PBX-TD90;(c),(g)PBX-TD95;(d),(h)PBXs with different content binder under the same load.

3.1.3.CT detection of pre-damaged PBXs samples

CT images can directly reflect the shape and location of the internal damage of PBXs.Fig.4 showed the CT image of the predamaged PBX-TD85 sample under different loading modes.With the increasement of load,the stress acting on the sample increases,leading to the microstructure damage in PBX.Non-detectable damage could be found in Fig.7(a) (250 N), while some slight damages appeared when the load increased to 500 N(Fig.4(b))and 750 N (Fig.4(c)).Furthermore, the CT image of sample has shown distinguishable damage signal when the load increases to 900 N(Fig.4(d)).

3.2.Damage healing performance

3.2.1.Characterization of damage-repaired samples

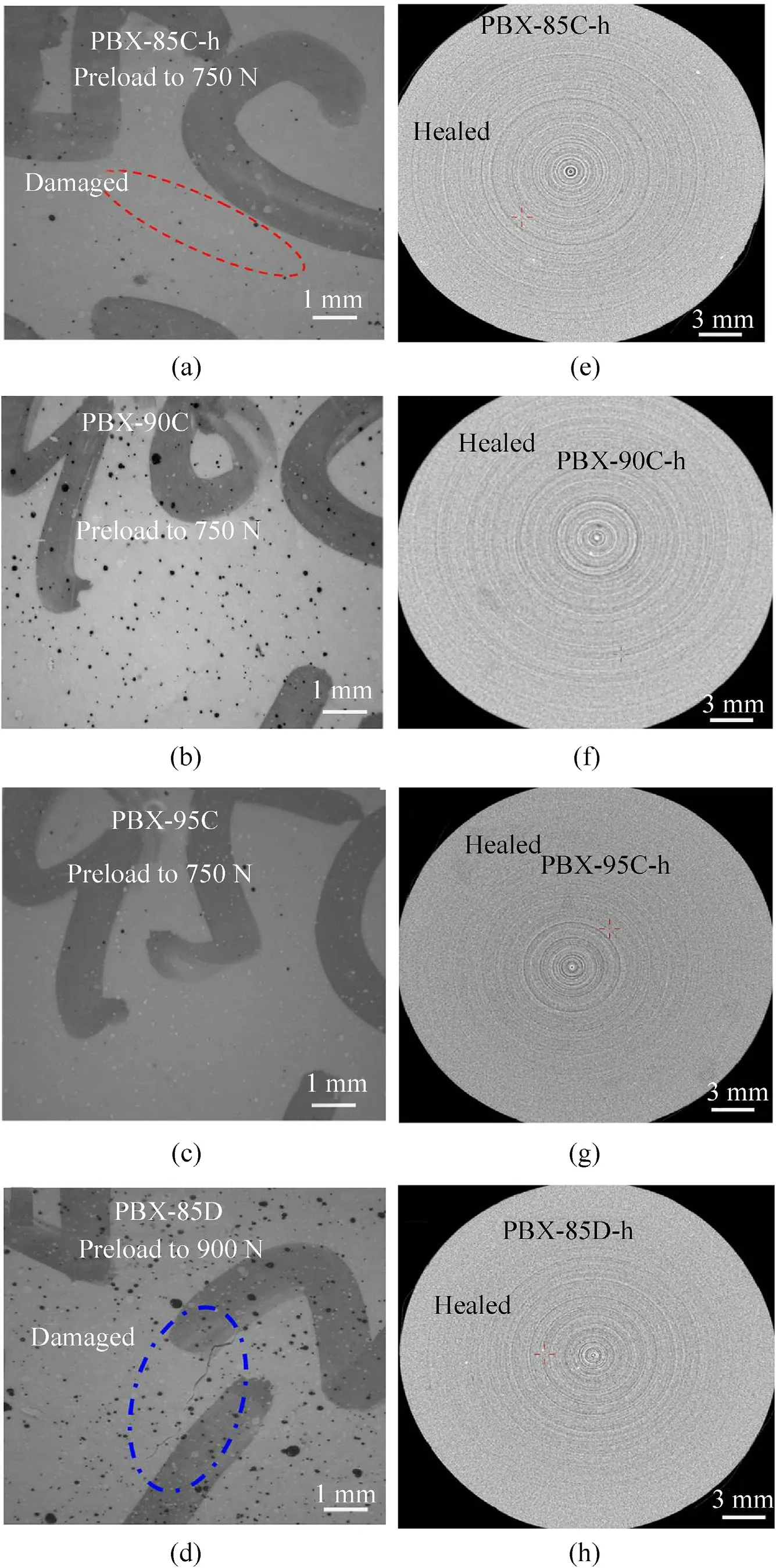

The healing degree of damage in PBXs could be detected by ultrasound (see Figs.3(c) and 3(f)) and CT techniques.Fig.5 displayed micro-image and CT images of PBX-TD85, PBX-TD90 and PBX-TD95 samples before and after heat repairment.From the micro-image,it can be found that the imperceptible microcracks of PBX-TD85-c samples may expanded from the inner to the surface(red ring in Fig.5(a)).While for PBX-TD90-c and PBX-95-c samples(Figs.5(b) and 5(c)), the cracks damage generated inside of them are relatively small,and these microcracks have not yet extended to the surface of the samples,as a result it could not be easily observed via microscopic means.This is due to less damage caused by fewer binders in PBX.After the samples were thermally healed,weakened damage signals could be focused in their CT images(Figs.5(e)and 5(f)), and the damage signal in the CT image of TD95-c sample(Fig.5(g)) is almost invisible, indicating that the slight damage in PBX samples gradually healed.While for PBX-TD85-d samples,the obvious microcracks occur on the surface (blue ring in Fig.5(d)),indicating more several prefabricated damages formed in these PBX samples.After being repairment, CT images of PBX-TD85-d samples (Fig.5(h)) also showed these damages disappeared or being healed.

3.2.2.Mechanical properties

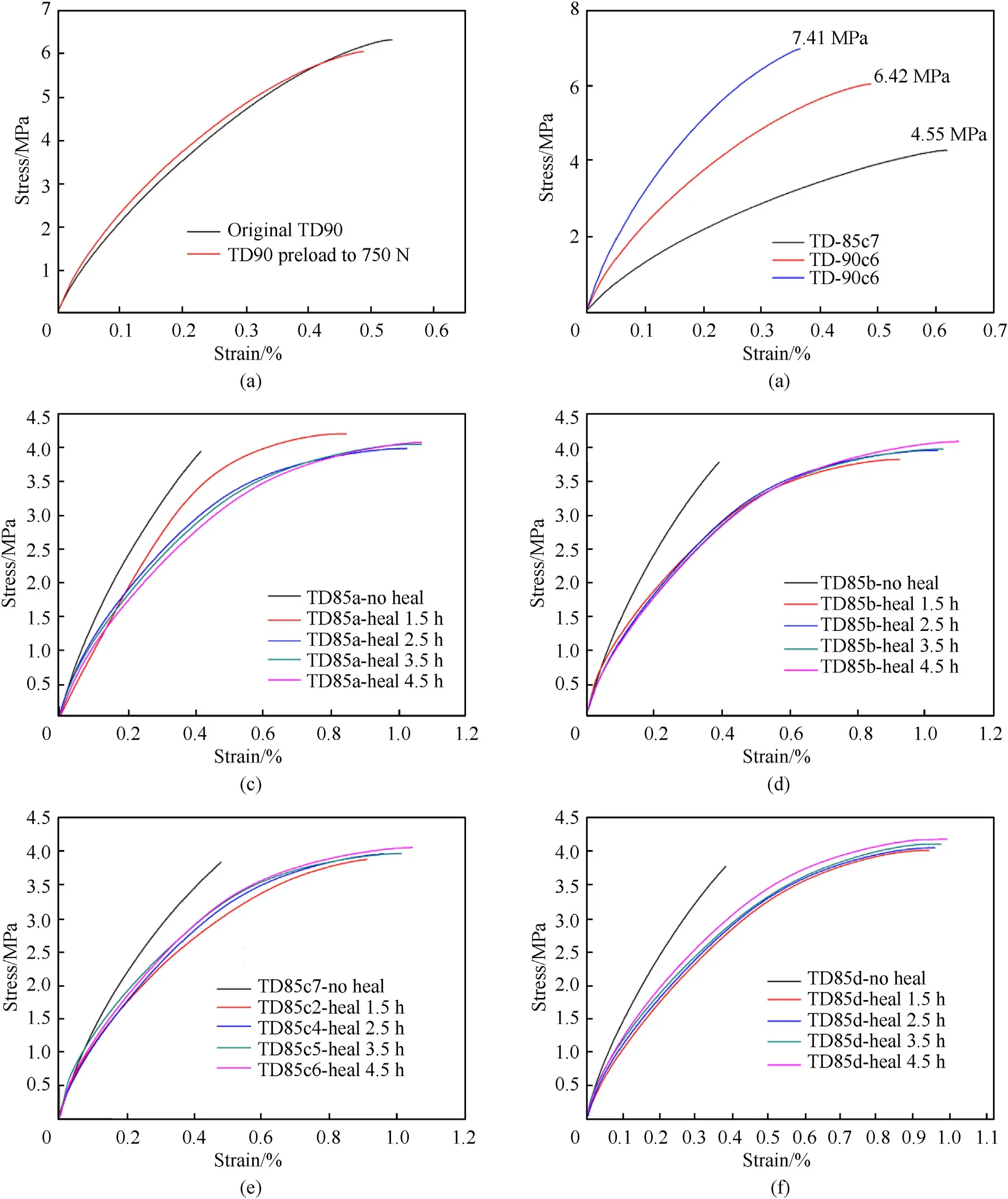

The internal damage will weaken the mechanical properties of PBX.The failure strength and elongation of PBX-TD90 (Fig.6(a))decreased to a certain extent compared with the initial sample(strength decreased by 4.2% and elongation decreased by 8.5%).In general, the mechanical properties of the damaged samples are correlative with the amount of polymer binder in PBX (Fig.6(b)).With the binder content increasing from 5 to 15 wt%, the failure strength decreased from 7.4 to 4.5 MPa,although the elongation at failure increased from 0.36 to 0.64%.This is because solid particles are the main bearing body of PBX materials.The less the organic binder phase, the greater the stress that can be withstood and the greater the strength of composite materials.From Figs.6(c)to 6(f),it can be seen that the mechanical properties of the naturally placed samples without healing treatment are much worse than those of the healed samples with different repair times.Its elongation at failure is only about half of the healed samples.This shows that even if the binder molecules in the naturally placed samples have creep recovery or segment migration, their mechanical properties are difficult to recover because their internal damage has not been repaired.This indicate that the damage repair of PBX is mainly reflected in the reversible r-DA/DA reaction of 2I-DAPU binder molecule.For the same degree of damage samples,the mechanical properties after repairing will enhance with the extending of repairing time, but do not increase continuously after exceeding a certain value (i.e., 3.5 h).

3.2.3.Repair efficiency

Fig.3.(a),(d)Ultrasonic gain and velocity of PBX-TD85 after different loading;(b),(e)Ultrasonic gain and velocity of PBXs with different composition ratio after same loading,and(c), (f) changes of ultrasonic parameters of PBXs with different damages before and after repairing treatment.

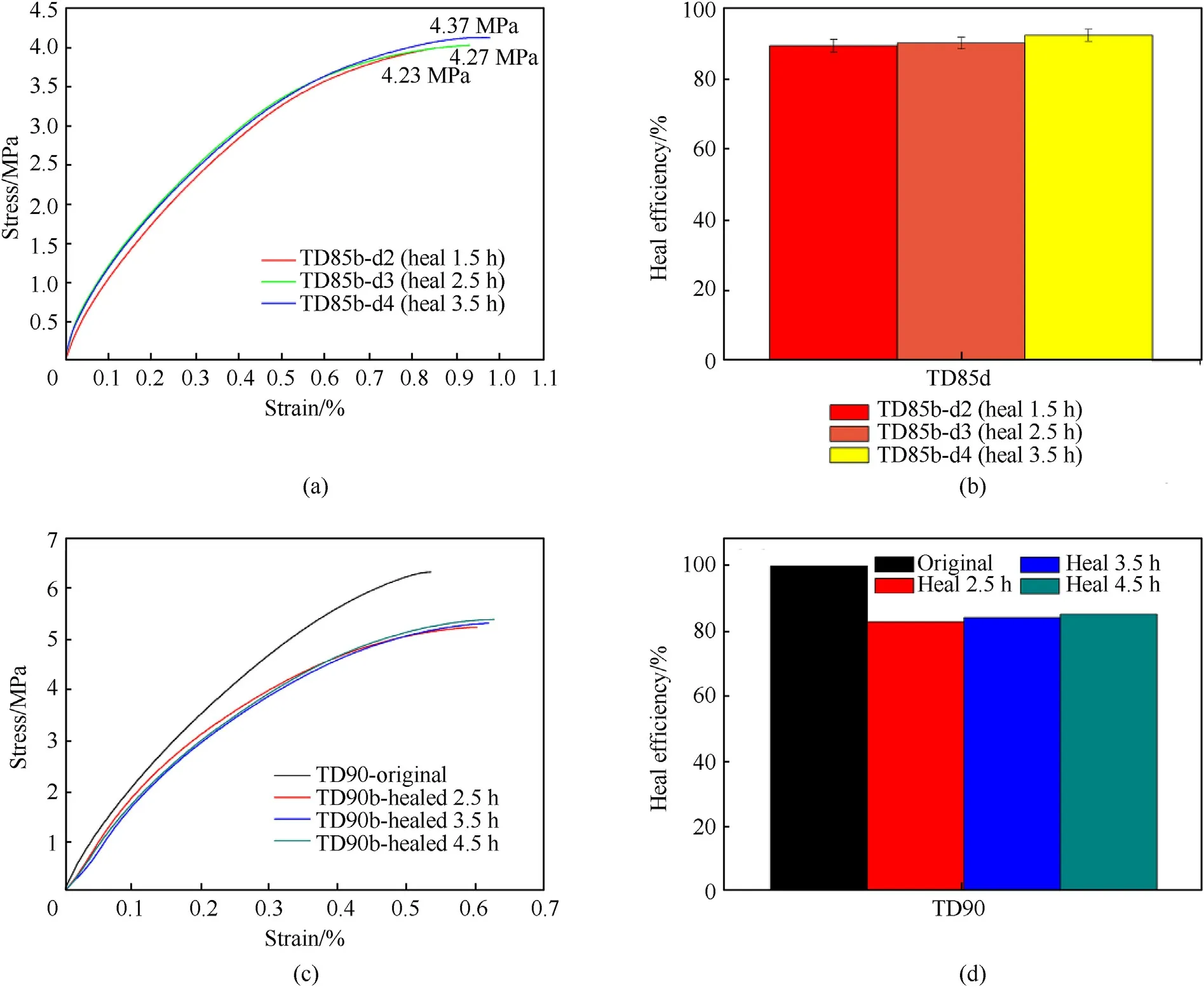

Fig.7(a) showed a relatively heavy damage in the PBX-TD85 after being maintained for 60 s under the prefabricated load of 900 N.After being heat at 125°C for 2 h and several hours repairing treatment at 65°C, the failure strength and elongation increase with the increase of repair time,and the repair efficiency increases from 89%to about 93%(Fig.7(b)).This implies that a high content of self-healing binder is conducive to the full healing of PBX internal damage.Furthermore, for PBX-TD90 samples after repairing at 65°C for 2.5-4.5 h (Fig.7(c)), the overlapping phenomenon of Brazilian load-displacement curves could be found, indicating the almost same repair effect.The repair efficiency is about 80%(Fig.7(d)), slightly lower than that of PBX-TD85, which may be related to the reduction of self-healing binder content.This result further confirmed that the damage repair of PBX is mainly achieved through self-healing binder molecules.

3.3.Healing mechanism

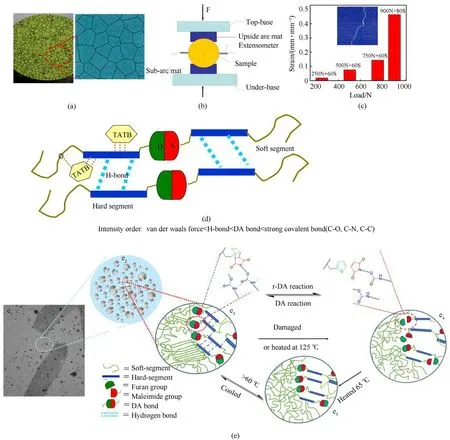

Most of these micro level structure changes in PBX can only be indirectly reflected through mesoscopic/macroscopic means that could be associated to the location and size of the defects, such as CT detection and ultrasonic detection.PBX has a composite structure with explosive particles as dispersed phase and polymer binder as continuous phase, the practical picture and microstructure sketch map of PBX are shown in Fig.8(a).Multiple interactions may exist in PBX, including the hydrogen bond in molecular chains of binder 2I-DAPU and the van der Waals force between explosive particles and polymer binder (Fig.8(d)).The external force would trigger the stress transforming from the continuous phase to the whole PBX structure, which may firstly damage the relatively weak joints in PBX,i.e.the interface between explosive and binder.Therefore, the polymer binder in the continuous phase is the main bearing base.

Fig.4.CT slice images of damage-prefabricated PBX-TD85 under different loads: (a) 250 N; (b) 500 N; (c) 750 N; (d) 900 N.

Generally speaking, the binding intensity for each hierarchical structure in PBX could be concluded in Fig.8(d).Therefore, the dissociation of various level of force is list as follows:(1)when the external force is small,the first change is that the binder molecules are gradually stretched from curly shape.At this time, the PBX presents a certain small deformation, but the microstructure will not change.After the external force is removed, the tiny deformation restores,and no damage signal of the sample can be detected by CT or ultrasound means.(2)With the increase of external force,the van der Waals effect between explosive and binder may be destroyed,and the deformation will increase appreciably,resulting in the separation of the contact interface between explosive and binder.After the external force is removed,the damage signal of the sample may still not be detected by CT or ultrasound means,but the mechanical strength of the sample will be slightly weakened.(3)If the external force continues to increase,the molecular chain of the binder will be straightened,large deformation appears,which will successively cause the destruction of the hydrogen bond within the binder molecule and the hydrogen bond between the molecular chains.After the external force is removed, the deformation partially reverts, the gain value of the sample may still not change during ultrasonic testing, but the sound velocity will decrease, a weak damage signal may also appear in the CT detection image,and the mechanical strength of the sample will decrease to a certain extent.(4) The external force keeps on augment will cause the destruction of the relatively weak covalent bond(such as DA bond)in the binder molecule.The PBX sample shows large deformation,the sound velocity decreases and the gain value increases in ultrasonic testing, strong damage signals (such as microcracks)appear in the CT image,and the mechanical strength of the sample decreases significantly.(5) Further increase the external force, the strong covalent bond in the main chain of the binder molecule(such as C-C,C-N or C-O bonds)will break,the PBX sample shows greater deformation, cracks are visible to the naked eye, or even direct fracture.

Fig.5.Micro-images of PBXs:(a)TD85C preload to 750 N;(b)TD90C preload to 750 N;(c)TD95C preload to 750 N,and(d)TD85D preload to 900 N,CT slice images of PBXs after healing; (e) TD85C; (f) TD90C; (g) TD95C and (d) TD85D.

Fig.6.Brazilian test load-displacement curves of(a)original TD90 sample and prefabricated damage sample by preload to 750 N,(b)TD serial samples with prefabricated damaged by preload to 750 N, (c)-(f) TD85 prefabricated damage sample by preload from 250 to 900 N after different repair times.

When the PBX sample is preloaded using the circular arc Brazilian test device(Fig.8(b)),the pressing load will mainly apply on the centerline of the disc sample, leading to the stress induced damage in center of the sample and the micro cracks.When conduction a slight load at 250 N and 500 N(Fig.8(c)),small(less than 0.1)deformation of the sample and light internal damage could be obtained.The van der Waals effect and weak hydrogen bond at the interface between binder and explosive particles may be destroyed,but the damage signal can hardly be detected by CT or ultrasound techniques.In addition, an increased sample deformation (0.15)could be realized under a high load of 750 N.In this situation,straightened binder molecular chains and destroyed intra/intermolecular hydrogen bonds may result in the slip of molecular chains appears and the appearance of damage signals in CT image,the ultrasonic velocity and other parameters showed a downward trend.After loading to a high level(900 N),the deformation of the sample increases significantly to 0.45, leading to the destroyed physical crosslinking of the binder network.The relatively weak covalent DA bond in the binder molecule is destroyed (Fig.8(e4)),the CT image shows relatively obvious microcracks, the ultrasonic velocity further decreases and the gain value increases.

Fig.7.(a), (c) Brazilian test load-displacement curves of TD85 and TD90 pre-damaged samples after different repair times, and (b), (d) their repair efficiency.

In order to close the damaged surface inside PBX,prefabricated damaged samples were fixed and restrained into a special retainer cavity through bolts.After heating at a relatively high temperature of 125°C, the 2I-DAPU binder can be softened, the damaged surfaces will contact together, and the molecular chain at the end of binder can be entangled by diffusion.Meanwhile,the short chains and small molecules present in 2I-DAPU through a r-DA reaction,which could move and diffuse more easily than long chains upon thermal action.Various molecular actions in PBX will be recombined after cooling down to 65°C, leading to a repair effect.The strong covalent bond destruction will occur in binder molecules(i.e., C-C bond breaking) due to strong external force.In the subsequent heat-treatment process, it is difficult to re-form covalent bonds between the broken atoms owing to their irreversibility, so the strength of the sample cannot be restored to the initial state even though being heat-treatment.However,the binder matrix will soften after being heat-treatment, their molecular chain will reconglutinate with the explosive particles, and the van der Waals effect and hydrogen bond between them will restore at a lower heating environment(Fig.8(e5)).Moreover,the molecular chains of the binder have sufficient movement ability, and the molecular chains will entangle with each other and return to curly shape,which promotes the reformation of hydrogen bonds inside and between molecular chains.Especially, the molecular chain with furan-end group will also be close to the molecular chain with maleimide-end, and the cyclohexene structure will be reformed through DA cycloaddition, therefore the disconnected molecular chain will be connected to a long chain or formed a cross-linking network (Fig.8(e3)), so as to the damaged structure in the PBX will heal basically and farther restore its mechanical property.

4.Conclusions

In summary, a self-healing TATB-based PBX has been designed and prepared by using the self-healing polyurethane PETMG2000-IPDI-DAPU as a binder.The different damages were prefabricated via the Brazilian test, and the healing effects of as-damaged PBX were investigated by CT detection and mechanical test.Results show that the damage degree formed in PBXs could be related to the applied load and the 2I-DAPU doping amount.The mechanical strength and elongation of PBXs increased with the prolonging of repair time.In addition, the thermal repairing efficiency of PBX is correlative with the degree of damage.The strength of PBX with mild damage can be restored to more than 90%,while the strength of PBX with more severe damage can be restored above 80%.In terms of damage healing mechanism, the external force will produce internal damage in PBX microstructure through deformation,elimination of hydrogen bonds,and rupture of weak covalent bond(i.e., DA bond) of polymer binder.After being heat treatment, the binder matrix will soften and fit with the explosive particles again,the molecular chains can diffuse, entangle with each other due to thermal movement, and the van der Waals effect, hydrogen bond and DA bond will recover one after another, then the internal damage of the PBX samples will gradually heal and the mechanical properties will be restored mostly.This healing strategy combined with the DA bonds and intermolecular H-bonding will provide meaningful research ideas and directions for the development of self-healing technologies.

Fig.8.(a)Practical picture and micro-structure sketch map of PBX;(b)Schematics of Brazilian disc load;(c)Deformation histogram of PBX-TD85 at different preloads and crack in PBX after large deformation (inside c); (d) Order of multifarious interaction in the PBX; (e) Mechanism of damaged and healed process via DA bonds and H-bonds.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

We thank the National Natural Science Foundation of China(Grant No.21875229)and NSAF(Grant No.U2030202)for grants in support of this wok.

- Defence Technology的其它文章

- The dynamic response and damage models of rebar reinforced polymer slabs subjected to contact and near-field explosions

- Study of the axial density/impedance gradient composite long rod hypervelocity penetration into a four-layer Q345 target

- Active learning accelerated Monte-Carlo simulation based on the modified K-nearest neighbors algorithm and its application to reliability estimations

- Dynamic compressive response of porcine muscle measured using a split Hopkinson bar system with a pair of PVDF force transducers

- Damage of a large-scale reinforced concrete wall caused by an explosively formed projectile (EFP)

- Air target recognition method against ISRJ for radio frequency proximity sensors using chaotic stream encryption