经纱张力神经反步分数阶快速终端滑模控制

付茂文 沈丹峰 赵刚 尚国飞 柏顺伟

摘 要:为更好地控制经纱张力,提高系统动态响应性能减小抖振,开发了一种神经反步分数阶快速终端滑模控制器(RBF-BCFOFTSMC),通过动力学分析建立了织机送经系统的时变数学模型。同时,推导了一种新的反步分数阶快速终端滑模控制方法。针对织机织造过程中系统总干扰上界的未知性和系统时变性的特点,设计了自适应律来估计外部干扰的上界值,设计神经网络参数自适应律来逼近真实的系统状态,并利用李雅普诺夫稳定性证明系统的合理性。通过其与传统滑模控制(SMC)和神经PID控制(RBF-PID)在仿真实验和实际工况下的对比,结果表明:RBF-BCFOFTSMC在经纱张力控制方面不仅减小了抖振,并且具有较高的鲁棒性和响应性能。

关键词:经纱张力;分数阶;反步;滑模控制;神经网络

中图分类号:TS103;TP183;TP273

文献标志码:A

文章编号:1009-265X(2023)04-0130-09

收稿日期:2022-12-15

网络出版日期:2023-03-21

基金项目:国家自然科学基金项目(51805402)

作者简介:付茂文(1996—),男,山东泰安人,硕士研究生,主要从事送经系统张力控制方面的研究。

通信作者:沈丹峰, E-mail: dfshen@xpu.edu.cn

经纱张力的稳定性对于织机生产不同花纹和提高织造效率具有举足轻重的作用,无论是张力过大或者过小都会降低织造质量[1],严重时还有可能导致纱线崩裂从而停车的现象,需要人工干预后才能再重新织造,加大了人力成本和降低了织造效率。由于送经系统存在电机振动和综框等运动,想要保持较高的张力稳定性,完成更高质量和不同的织造要求,设计一种鲁棒性较高和响应性能较快的控制器迫在眉睫。

为了提高送经系统的张力稳定性,许多智能控制算法被提出用于實际控制系统中,如自适应PID控制[2-3]、反步控制[4-5]、滑模控制[6-7]和神经网络控制[8-9]等,以提高系统控制性能。崔征山等[10]设计扩张状态观测器来对系统扰动进行在线估计,并将估计到的扰动补偿到滑模控制器中,很好地应对了系统中运动产生的强扰动,但扩张状态观测器的引入增加了控制器的调参难度。黄道敏等[11]将分数阶理论融合到积分滑模控制中,设计指数趋近律,并且为估计外部扰动添加扰动估计项,该控制策略具有较快的收敛速度,对于非线性的系统鲁棒性较强。邓槟槟等[12]设计了一种新的快速终端滑模控制方法,经过了有限时间稳定性证明,误差可在短时间内快速收敛,提高了控制系统的跟踪精度。梁相龙等[13]将神经网络和指令滤波融合到滑模控制算法中,指令滤波器用来信号的估计和噪声处理,通过梯度下降算法来自适应更新网络权值系数,对于系统的不确定性和外部干扰具有很强的鲁棒性。还有一部分学者也对反步控制进行了研究,Razmi等[14]设计了一种针对参数不确定性和外部干扰的控制策略,采用神经网络自适应更新滑模面的系数,增加了系统的瞬态和稳态性能。Chen等[15]为了提高反步控制的收敛速度和跟踪性能,设计了具有更多自由度的分数阶反推控制器,并采用模糊神经网络估计系统的不确定性,采用指数调节机制补偿估计误差。熊蕊[16]设计一种改进神经网络反步控制策略,利用神经网络逼近外部未知状态,利用自适应律更新神经网络的参数,实现了系统的高精度控制。Fu等[17]提出了一种自适应神经反步动态表面控制算法,采用动态表面来优化反步控制算法,采用神经网络来逼近系统的动力学模型,最终通过实验证明了控制方法的有效性。通过上述研究和分析可知,送经系统是强非线性系统,采用高效非线性控制算法有利于提高张力稳定性,滑模控制因其自身存在的抖振和奇异问题,在非线性系统的应用中往往需要改进或者与其他算法融合,将分数阶理论融合到滑模控制中并证明有限时间稳定性,可实现滑模控制的性能提升,但是在滑模控制中存在的一些状态变量是不容易测量的,因此将反步控制算法应用到滑模控制中简化控制量。送经系统在运行过程中是时变的,根据传统的数学建模方法得到的模型信息较难反应织机真实的状态,考虑到上述研究采用的神经网络估计外部未知状态得到了很好的效果,故本文将神经网络引入到反步快速终端滑模控制中来估计未知的建模信息,进一步提高算法对系统的控制性能。

1 张力数学模型

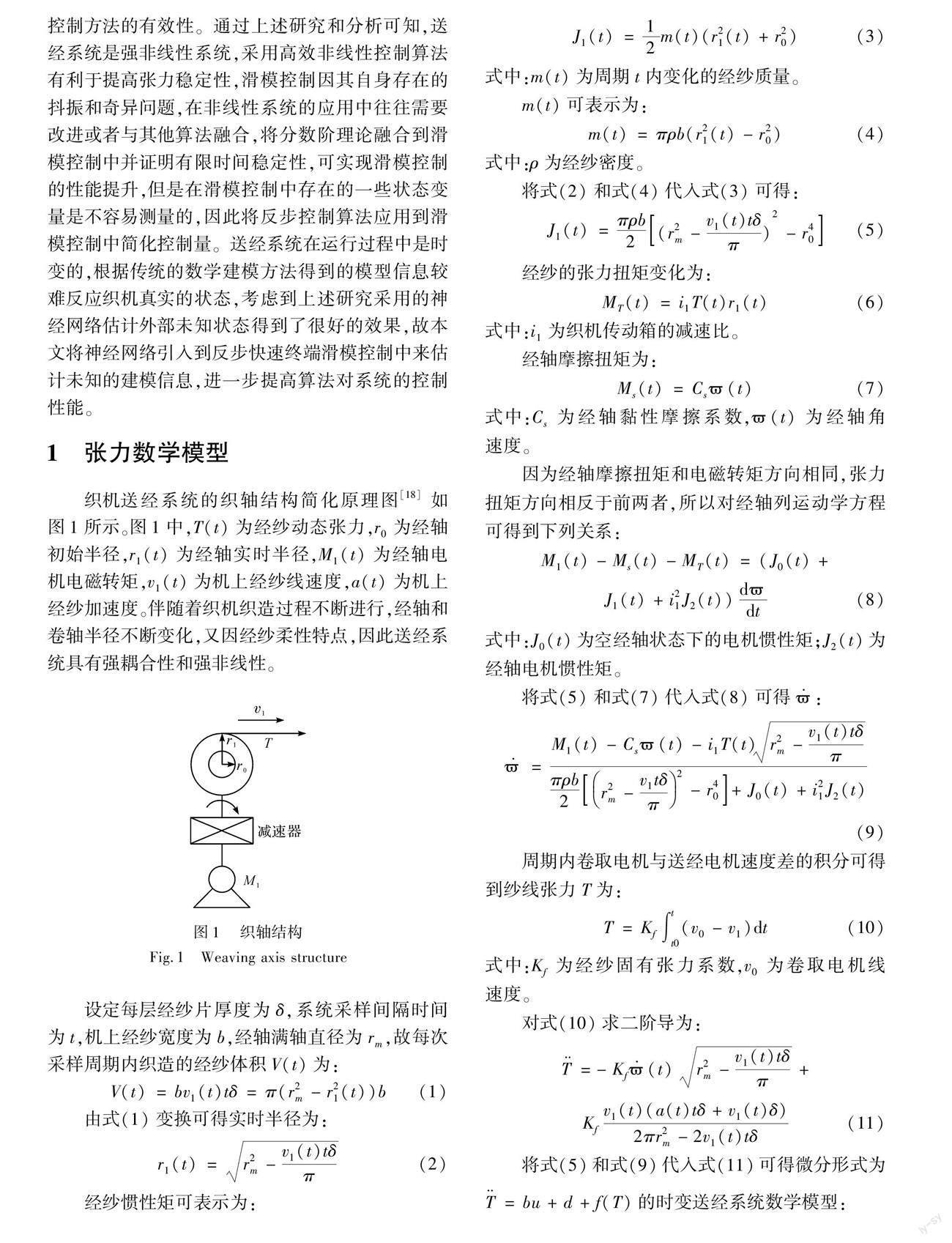

织机送经系统的织轴结构简化原理图[18]如图1所示。图1中,T(t)为经纱动态张力,r0为经轴初始半径,r1(t)为经轴实时半径,M1(t)为经轴电机电磁转矩,v1(t)为机上经纱线速度,a(t)为机上经纱加速度。伴随着织机织造过程不断进行,经轴和卷轴半径不断变化,又因经纱柔性特点,因此送经系统具有强耦合性和强非线性。

3.2 实验

为验证上述控制方法在实际工况中的有效性,将3种控制方法应用到搭建的实验平台中,分别在张力跟踪精度上和控制器输入上进行对比。如图4所示为STM32和FPGA联合控制的实验平台,两者之间通过SPI通信传输数据,由FPGA采集信号并传递给STM32完成算法运算,其中实验平台模拟了织轴卷径的变化、电机振动和综框运动,综框运动的模拟由轴承外径周围凸起的转动来实现。实验分别在设定张力为1.56 N和2.56 N下进行,如图5为3种控制器的张力跟踪效果和控制器输出情况,表2为3种控制器的实验性能指标。

在16 s的运行过程中织轴卷径变化了1 mm,在此期间送经电机输出合适的转速保持张力稳定。由图5分析可知,由于综框模拟运动和电机振动等原因,3种控制器都上下波动稳定到某一状态,其中RBF-BCFOFTSMC控制器MAXE最小,跟踪精度优于其他两种控制器在最靠近张力设定值附近波动。3种控制器的输出转速都随织轴卷径变化和干扰等不断波动,在设定张力1.56 N和2.56 N下的波动幅度分别为4.41、5.93、5.48和4.42、5.95、5.50,

其中RBF-BCFOFTSMC波动幅度最小,稳定性更好。滑模控制的自适应切换部分和神经网络能够实时估计外部干扰和未建模动力学,使得RBF-BCFOFTSMC控制器随着织轴卷径变化实时调整,输出高精度的控制律保持张力稳定,总结可知RBF-BCFOFTSMC跟踪性能和抗干扰性能较好,具有较高的鲁棒性。

通过联合FPGA和ARM开发出的送经系统张力控制实验平台,不仅控制简单、成本较低,可对于新型控制算法进行稳定性验证,摆脱了测试过程需在真实织机中运行的依赖,极大地减少了经纱张力的检测门槛和技术难度,为控制算法应用到实际工况中的纱线张力检测和调节提供了新的思路。该实验平台通过送经与卷取电机的配合来完成经纱送出,在此基础上对提出的控制算法进行有效性验证,但是该实验平台与真实织机还存在一定差异,对于其中的一些其他运动也只是采用模拟的方式,后续研究还有必要在该实验基础上追加实验,证明其他运动对送经系统张力的影响。

4 结 论

织机织造过程中,张力过小容易导致出现粗纱或冒纱,降低织物平整度,而当张力过大时,又会导致纱线断裂停车,从而降低织造效率,由于送经系统时变性和各种干扰的存在,常规控制算法存在超调严重和稳态精度低等问题,因此为改善织机送经系统的张力稳定性,设计了一种神经反步分数阶快速终端滑模控制算法。首先建立了织机送经系统的数学模型,采用自适应律实时更新控制器参数达到对外部干扰估计的效果,将RBF神经网络介入滑模控制中,逼近送经系统的真实系统状态,以此得到更为精确的数学模型。采用反步控制和滑模控制相结合的方法避免了更多系统变量的使用,简化了滑模控制的控制律,引入分数阶理论给控制器带来更多的自由度,通过李雅普诺夫函数验证了控制器的有限时间收敛性和稳定性。最终通过仿真和实验证明RBF-BCFOFTSMC控制器具有较高的张力稳定性,提高了系统的控制精度。所设计的控制器改善了织机的送经系统控制水平,对于经轴上的纱线退绕下来进入综框运动时的张力精度具有提高作用,有利于减少纱线断头现象,增强送经量的恒定水平,对于提高织机的生产效率和胚布质量具有较高的意义。

参考文献:

[1]马宏帅,赵世海.基于线性自抗扰控制的放卷张力控制系统[J].现代纺织技术,2019,27(1):87-92.

MA Hongshuai, ZHAO Shihai. Unwinding tension control system based on linear auto disturbance rejection control[J]. Advanced Textile Technology, 2019, 27(1): 87-92.

[2]KARAHAN O. Design of optimal fractional order fuzzy PID controller based on cuckoo search algorithm for core power control in molten salt reactors[J]. Progress in Nuclear Energy, 2021, 139: 103868.

[3]姜磊.智能梳棉机自调匀整控制系统设计开发[J].现代纺织技术,2020,28(3):89-96.

JIANG Lei. Design and development of autoleveling control system for intelligent carding machine[J]. Advanced Textile Technology, 2020, 28(3): 89-96.

[4]FANG Y M, FEI J T, YANG Y Z. Adaptive backstepping design of a microgyroscope[J]. Micromachines, 2018, 9(7): 338.

[5]徐子琴,雷明.风扰动下固定翼无人机指令滤波反步着陆控制[J].计算机仿真,2022,39(9):55-62.

XU Ziqin, LEI Ming. Command filtered backstepping landing control of fixed-wing unmanned aerial vehicle considering wind disturbance[J]. Computer Simulation, 2022, 39(9): 55-62.

[6]ZAIHIDEEM F, MEKHILEF S, MUBIN M. Robust speed control of PMSM using sliding mode control (SMC): Areview[J]. Energies, 2019, 12(9): 1669.

[7]陶慧,艾朋偉.改进滑膜控制双降压式逆变器的动力学特性[J/OL].电力系统及其自动化学报:1-8[2022-10-21].DOI:10.19635/j.cnki.csu-epsa.001115.

TAO Hui, AI Pengwei. Dynamic characteristics of double buck inverter with improved sliding mode control [J]. Proceedings of the CSU-EPSA: 1-8[2022-10-21].DOI:10.19635/j.cnki.csu-epsa.001115.

[8]WANG H Q, LIU S W, YANG X B. Adaptive neural control for non-strict-feedback nonlinear systems with input delay[J]. Information Sciences, 2020, 514: 605-616.

[9]李建伟,张磊安,黄雪梅,等.基于改进径向基神经网络的风电叶片模温串级PID控制算法[J].太阳能学报,2022,43(3):330-335.

LI Jianwei, ZHANG Lei′an, HUANG Xuemei, et al. Cascade PID control algorithm for wind turbine blade mold temperature based on improved RBF neural network [J]. Acta Energiae Solaris Sinica, 2022, 43(3): 330-335.

[10]崔征山,周扬忠,张竞,等.基于滑模和扩张状态观测器的双绕组无轴承磁通切换电机转子悬浮控制策略研究[J].仪器仪表学报,2022,43(6):269-279.

CUI Zhengshan, ZHOU Yangzhong, ZHANG Jing, et al. Research on rotor suspension control strategy of dual-winding bearingless flux-switching permanent magnet machines based on sliding mode control and extended state observer[J]. Chinese Journal of Scientific Instrument, 2022, 43(6): 269-279.

[11]黄道敏,韩丽君,唐国元,等.水下机械手分数阶积分滑模轨迹跟踪控制方法研究[J].中国机械工程,2019,30(13):1513-1518.

HUANG Daomin, HAN Lijun, TANG Guoyuan, et al. Fractional integral sliding mode control for trajectory tracking of underwater manipulators[J]. China Mechanical Engineering, 2019, 30(13): 1513-1518.

[12]邓槟槟,尚伟伟,张彬,等.6自由度绳索牵引并联机器人的快速终端滑模同步控制[J].机械工程学报,2022,58(13):50-58.

DENG Binbin, SHANG Weiwei, ZHANG Bin, et al. Fast terminal sliding mode control with synchronization error for a 6-dof cabel-driven parallel robot[J]. Journal of Mechanical Engineering, 2022, 58(13): 50-58.

[13]梁相龙,姚建勇.基于神经网络的机电伺服系统非线性控制[J].控制与决策,2023,38(4):1008-1014.

LIANG Xianglong, YAO Jianyong. Nonlinear control of mechatronic servo system based on neural network [J]. Control and Decision,2023,38(4):1008-1014.

[14]RAZMI H, AFSHINFAR S. Neural network-based adaptive sliding mode control design for position and attitude control of a quadrotor UAV[J]. Aerospace Science and Technology, 2019, 91: 12-27.

[15]CHEN S Y, LI T H, CHANG C H. Intelligent fractional-order backstepping control for an ironless linear synchronous motor with uncertain nonlinear dynamics[J]. ISA Tran-sactions, 2019, 89: 218-232.

[16]熊蕊.考慮瞬态性能的工业机器人双臂反步控制方法[J].现代制造工程,2022(8):53-59.

XIONG Rui. Back-stepping control method of industrial robot dual-arm considering transient performance[J]. Modern Manufacturing Engineering, 2022(8): 53-59.

[17]FU C Y, HONG W, LU H Q, et al. Adaptive robust backstepping attitude control for a multi-rotor unmanned aerial vehicle with time-varying output constraints[J]. Aerospace Science and Technology, 2018, 78: 593-603.

[18]XU G W, ZHOU R X, LIU W, et al. The equivalent sliding mode tension control of carbon fiber multilayer diagonal loom[J]. International Journal of Control, Auto-mation and Systems, 2019, 17(7): 1762-1769.

Neural backstepping fractional order fast terminal sliding mode control of warp tension

FU Maowen1, SHEN Danfeng1, ZHAO Gang2, SHANG Guofei 1, BAI Shunwei1

(1.School of Mechanical and Electrical Engineering, Xi'an Polytechnic University, Xi'an 710048, China;

2.Shaanxi Changling Textile Mechanical & Electronic Technological Co., Ltd., Baoji 721013, China)

Abstract:

With the progress of current computer technology and modern control methods and theories, the textile field has been fully developed in the past decade, gradually realizing intelligence and advancement. However, the domestic textile industry still has the problems of low competitiveness and high labor costs. Looms in textile machinery need to be closely integrated with electromechanical equipment. High-quality looms apply more advanced algorithms to looms on the basis of continuous pursuit of higher weaving efficiency and fabric quality, reducing the degree of manual intervention. The performance of the let-off mechanism, a direct tension control mechanism, determines the speed and efficiency of the loom spindle. Studying the let-off system and developing a more efficient control algorithm or structure is an important factor to improve the performance of the loom, which meets the national economic needs and social significance of China.

In order to enhance the matching degree between the let-off mechanism and weaving requirements of looms, the key control algorithm of the let-off mechanism is designed, which is combined with modern control theory to improve the robustness and stability of the control algorithm. This research aims to develop a neural backstepping fractional order fast terminal sliding mode controller (RBF-BCFOFTSMC) to control the warp tension. Firstly, the time-varying mathematical model of the let-off system of the loom was established through dynamic analysis. In order to improve the dynamic response performance of the system and reduce chattering, a new backstepping fractional order fast terminal sliding mode control method was derived. Since there are disturbances such as motor vibration and heald frame motion in the weaving process of the loom, and the upper bound of the total disturbance of the system is unknown, an adaptive law was designed to estimate the upper bound of the external disturbance. The time-varying characteristics of the system make the controller have unmodeled and modeling uncertainties. The neural network parameter adaptive law was designed to approximate the real system state, and the Lyapunov stability was used to prove the rationality of the system. In order to verify the effectiveness of the designed control strategy, it was compared with traditional sliding mode control (SMC) and neural PID (RBFPID) in simulation experiments and actual working conditions. The results show that RBF-FOTSMC not only reduces chattering in warp tension control, but also has high robustness and response performance.

Through the research, the algorithm design and experiment of the let-off control system have been successfully completed, which has greatly improved the control effect, robustness and stability of the system. However, as the loom let-off system is a complex control system, more research needs to be supplemented in the future from two main points. First, it is necessary to study the influence of heald frame, weft insertion, beating up and other movements on loom tension, and analyze the influencing factors for corresponding tension compensation. Second, the adopted hardware needs to be optimized. If the controller with faster processing speed can be replaced, the high-speed and advanced level of the loom will be improved.

Keywords:

warp tension; fractional order; backstepping; sliding mode controller; neural network