水性聚氨酯组成结构与力学性能的关系及其染色性能的研究进展

韩雨兰 宋兵 李春霖 杜远远 牛家嵘

摘 要:与传统溶剂型聚氨酯相比,水性聚氨酯(WPU)大大减少了有机溶剂的使用,可有效降低环境污染,正越来越受到人们的关注。然而,WPU中亲水基团的引入会影响其力学性能,限制了WPU产品的使用范围。本文对WPU组成结构和力学性能之间的关系进行了阐述,并对WPU染色方面的研究现状做了介绍和总结,以期为水性聚氨酯超纤革的开发提供借鉴和参考。

关键词:水性聚氨酯;亲水基团;组成结构;力学性能;超细纤维合成革;染色

中图分类号:TS193.8

文献标志码:A

文章编号:1009-265X(2023)03-0225-12

基金项目:技术开发类横向合作项目(21-02-101-0375)

作者简介:韩雨兰(1998—),女,江苏盐城人,硕士研究生,主要从事水性聚氨酯及超纤革染色方面的研究。

通信作者:牛家嵘, E-mail:niujiarong@tiangong.edu.cn

聚氨酯(Polyurethane, PU)是以氨基甲酸酯基(—NHCOO—)為重复单元,由异氰酸酯和带有活泼氢的二元醇、多元醇化合物等加聚而成的一类聚合物[1]。聚氨酯在合成过程中结构易于调控,性能多样,能满足皮革、家具、建筑等多领域的需求。聚氨酯根据分散介质的不同,可分为溶剂型聚氨酯和水性聚氨酯,由于溶剂型聚氨酯在合成和使用过程中用到大量的有机溶剂,会产生大量易挥发有机化合物(VOCs),容易对环境造成严重污染,而水性聚氨酯(Waterborne polyurethane, WPU)是以水为分散介质的乳液,在生产和使用过程中减少了有机溶剂的使用,比传统的溶剂型聚氨酯更环保[2],越来越受到研究者的关注。

WPU成膜力、柔顺性和耐磨性好,且耐低温、黏度易于调节、成本较低,在涂料、油墨、黏合剂、纺织品整理等方面都有着广泛的应用[3-4]。Fang等[5]合成了具有低玻璃化转变温度(Tg)的纳米水性聚氨酯,该材料具有良好的热稳定性和低结晶度,适合做水性油墨黏合剂。Zhang等[3]制备了一种耐腐蚀的水性聚氨酯改性环氧树脂。经固化处理的固化膜相较于原始膜具有更高的耐热性,能经受约60天的盐雾腐蚀实验,在对金属材料的保护上有着许多潜在应用。WPU在羊毛表面形成薄膜可以降低定向摩擦效应[4],因此能够用作羊毛织物的防毡缩整理剂[6-8]。

WPU主链结构与天然皮革中的胶原蛋白相似,生产和使用工艺环保,因此在超细纤维合成革(超纤革)的开发与应用上受到广泛的关注。超细纤维聚氨酯合成革作为新一代的合成革,经过不断的完善,其外观和性能可以与天然皮革相媲美,在鞋服、箱包、家具、汽车等行业有着广泛的应用。但是,由于亲水性单体的引入,水性聚氨酯制备的超纤革在很多性能上与传统的溶剂型聚氨酯超纤革有明显区别,尤其在力学和染色性能方面的差异更为突出。为进一步提高水性聚氨酯超纤革的性能,为高物性产品的开发提供参考,本文介绍了水性聚氨酯的构成、对力学性能的影响及相关研究进展,总结了水性聚氨酯及其超纤革在染色、着色方面的研究现状。

1 水性聚氨酯的主要合成原料

聚氨酯由二(多)异氰酸酯和二(多)元醇交替排列组成,微观结构上由软、硬段形成嵌段共聚物[9]。区别于溶剂型聚氨酯,WPU的分子结构中引入了离子侧基或亲水链段,使其具有自乳化性能,且能够以水取代有机溶剂作为分散介质,使水性聚氨酯在生产和加工过程中符合绿色环保的要求。异氰酸酯、小分子多元醇、扩链剂及亲水基团作为WPU主要合成原料,其性能的差异对最终所制备的水性聚氨酯均会产生不同的影响。

1.1 异氰酸酯

水性聚氨酯硬段结构中的异氰酸酯大都含有两个或两个以上的异氰酸酯基(—NCO),主要分为芳香族异氰酸酯和脂肪族异氰酸酯。芳香族异氰酸酯含有苯环结构,反应活性较高,在制备过程中需严格控制反应条件。芳香族聚氨酯中的刚性苯环结构及

生成的氨基甲酸酯结构,使聚氨酯大分子具有较强的内聚力,因此其力学性能及耐溶剂性能优于脂肪族聚氨酯[10],但因分子中存在苯环双键发色结构,其抗紫外线性能差,易变黄[11-13]。在水性聚氨酯的合成工艺中,较为常用的芳香族异氰酸酯是甲苯二异氰酸酯(TDI)和二苯基甲烷二异氰酸酯(MDI),在早期的研究中也有对亚苯基二异氰酸酯(PPDI)。此外,脂肪族异氰酸酯的常见结构有异佛尔酮二异氰酸酯(IPDI)、六亚甲基二异氰酸酯(HDI)、二聚酸二异氰酸酯(DDI)和4,4′-二环乙基甲烷二异氰酸酯(HMDI)等[14-16]。异氰酸酯结构及对WPU性能的影响见表1[17-21]。

1.2 低聚物多元醇

水性聚氨酯的软段结构主要为官能度2~3的低聚物多元醇类,一般可分为聚酯多元醇和聚醚多元醇两大类[22-23]。目前较为常见的WPU用聚酯多元醇有己二酸系列聚酯多元醇、聚己内酯二醇(PCL)和聚碳酸酯二醇(PCDL)等。通常聚酯多元醇的分子量较低,且具有支链结构,含有的酯基、羟基、羧基等基团可在后续反应中进行交联反应[24],其中酯键可赋予水性聚氨酯良好的力学性能和机械强度[11],但酯键易水解,其耐水性能相较于聚醚多元醇差。常用的聚醚多元醇主要有聚四氢呋喃(PTMGE)、聚丙二醇PPG、聚乙二醇(PEG)等。一般来说,聚醚多元醇中醚键的内聚能低、且易于旋转,由其制备的水性聚氨酯具有较好的低温柔顺性和疏水性[11],但其机械强度低,易老化。

1.3 扩链剂

在聚氨酯合成过程中,小分子扩链剂不仅能够调节聚氨酯分子量,还可以调节软硬段之间的比例,改善材料性能。小分子扩链剂主要分为醇类和胺类,醇类扩链剂是预聚反应中常用的扩链剂,较为常见的有乙二醇(EG)、1,4-丁二醇(1,4-BDO)、三羟甲基丙烷(TMP)等;胺类扩链剂与异氰酸酯基团反应速度快,能够生成极性较强的脲键[14],由二元胺扩链生成的聚氨酯强度大、模量高,黏附性和耐低温性能优良。胺类扩链剂主要有脂肪族和脂环族二胺或三胺、以氨封端的聚醚、肼及其衍生物。

1.4 亲水单体

水性聚氨酯的制备过程需要引入亲水性基团,常用的方法有扩链法、接枝法和多元醇亲水改性等。其中,亲水单体扩链法因操作简便、适用性强等优点,是目前较为常用的方法。

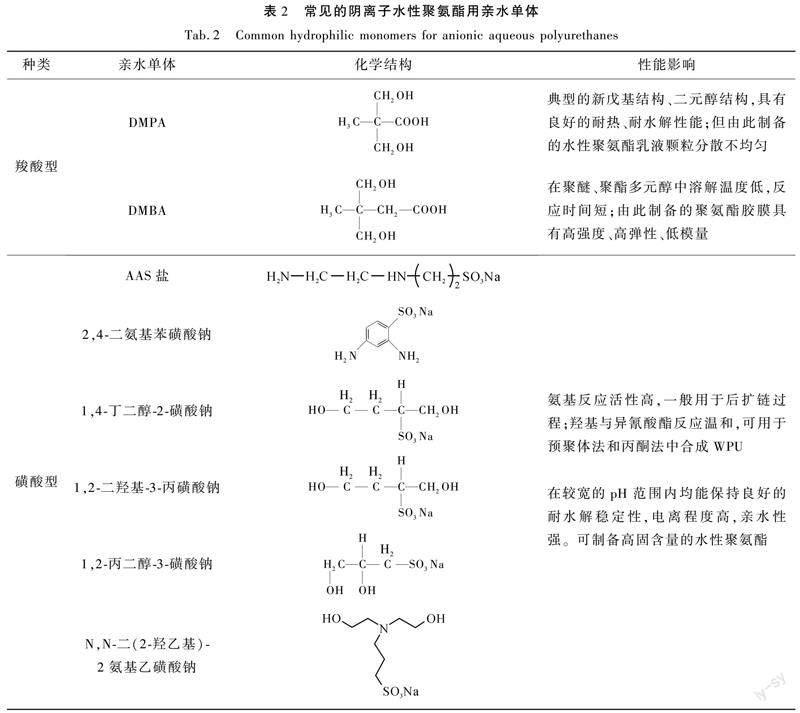

依据亲水基团的离子特性,亲水扩链剂可分为阳离子、阴离子、非离子和两性离子亲水扩链剂[25]。阳离子聚氨酯一般可选用叔胺化合物进行亲水扩链,或利用含卤素化合物通过亲核反应将阳离子引入到主链上[26]。阳离子水性聚氨酯具有抗菌性能,使其在卫生健康领域有着广泛应用,但阳离子型亲水扩链剂中的季铵盐会降低水性聚氨酯的耐热性。而非离子型扩链剂中的环氧乙烯基会对水性聚氨酯的耐水性能造成一定的影响[27]。目前较为常见的水性聚氨酯大都为阴离子型WPU,引入的亲水基团主要包含磺酸型、羧酸型两大类水性单体[25,28,29]。常用的水性单体及性能见表2。

2 水性聚氨酯力学性能影响

聚氨酯是软、硬段交替排列的嵌段共聚物,软、硬段间的不相容性使聚氨酯存在微相分离[30]。离子基團的类型和含量、多元醇结构、扩链剂类型等因素对水性聚氨酯性能均有着重要的影响。

2.1 硬段对WPU性能的影响

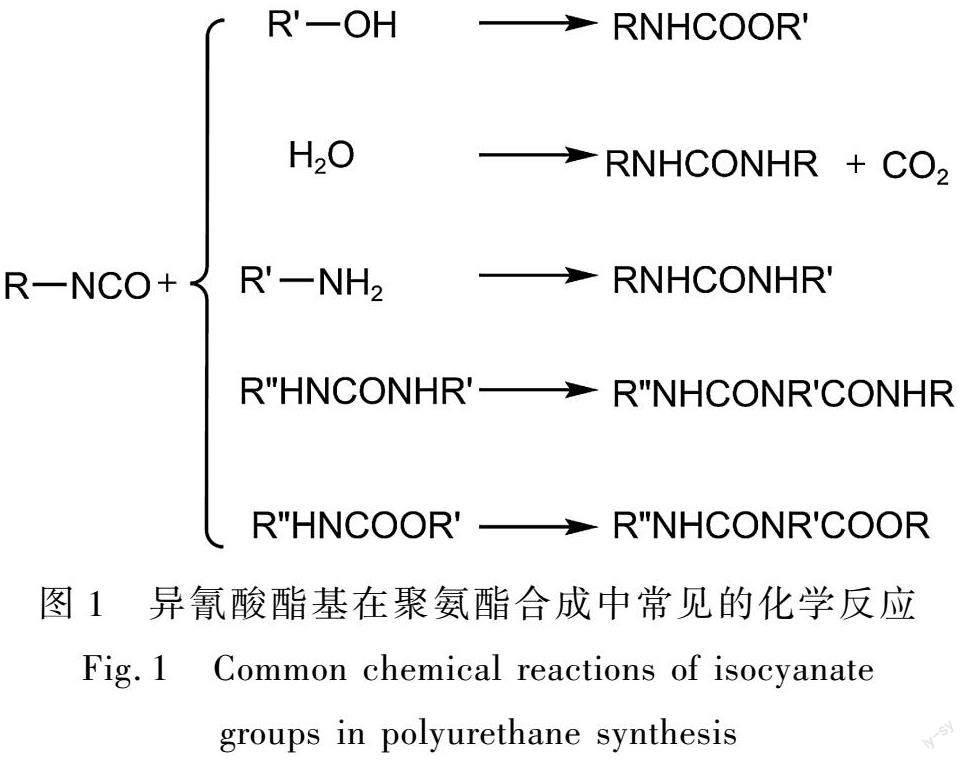

在聚氨酯分子结构中,硬段约占40%,主要是由异氰酸酯基参与合成反应后所生成。异氰酸酯基化学性质活泼,能够与羟基、氨基、氨基甲酸酯基、脲基、水等反应[31]。其常见反应如图1所示。

聚氨酯硬段易形成氢键,有紧凑的晶体结构,使聚合物具有一定的刚性,赋予聚氨酯良好的拉伸强度和弹性恢复力。异氰酸酯结构及含量对水性聚氨酯的结晶及机械性能影响较为显著[20,32]。如二苯基甲基二异氰酸酯分子链段规整,由此制备的聚氨酯结晶性能较高,机械性能较为优良。Xiao等[33]以二苯基甲基二异氰酸酯为原料,二羟甲基丙酸(DMPA)为亲水基团,采用两步聚合法合成了水性聚氨酯(MWPU),与异佛尔酮二异氰酸酯型水性聚氨酯(IWPU)进行了对比和分析。研究发现二苯基甲基二异氰酸酯的双苯环结构使WPU链段间的相分离程度增大,链段间的氢键作用增强,从而使得MWPU的机械性能和耐水性均高于IWPU。

王珂等[34]以异佛尔酮二异氰酸酯和聚酯多元醇为反应物,采用预聚混合法合成了一系列硬段含量不同的脂肪族WPU,发现:当亲水基团DMPA含量固定时,随着硬段含量的增加,分子中的氨基甲酸酯基和脲基增多,微相分离程度也增加。拉伸强度随硬段含量的增加先增大后减小,在30%时达到最高值52 MPa;断裂伸长率随硬段含量增加而减小。吸水率也出现先增大后减小的趋势,在硬段含量为40%时耐水性最好,吸水率低于8%。

扩链剂在聚氨酯合成过程中不仅能够有效调节分子量,也可以参与硬段的形成,影响聚氨酯的力学性能。Orgiles-Calpena等[35]分别以1,4-丁二醇、1,6-己二醇和肼作为扩链剂研究扩链剂类型对聚氨酯性能的影响。经DSC测试发现,扩链剂的类型对玻璃化转变温度、结晶度、相分离程度均有一定程度的影响:以肼为扩链剂时,因硬段结构中脲基的存在,聚合物刚度大,结晶分数小;在以二醇作为扩链剂时,随着扩链剂长度的增加,聚氨酯的软、硬段相分离程度增加,从而导致聚氨酯结晶度较高,力学性能较好。

2.2 软段对WPU性能的影响

构成水性聚氨酯软段的低聚多元醇,一般都具有较低的玻璃化转变温度(Tg),软段结构的变化会引起聚氨酯不同程度的相分离。薛振华等[31]以6种分子量相同、结构不同的多元醇(见表4)制备了含有不同软段结构的WPU乳液。研究发现,以聚酯多元醇为软段的WPU胶膜的100%模量和拉伸强度普遍高于聚醚型WPU。这是因为聚酯中的羰基含量高,能够提供更好的结晶性能,且酯键刚性较醚键强,从而使其力学性能有所提升。含支链的WPU相较于直链WPU耐热性和综合力学性能低,但膜表面更光滑。

聚碳酸酯二醇通常具有较高的水解稳定性和耐低温性能,在水性聚氨酯中作为软段结构可赋予其更好的性能。Garcia等[36]比较了分子量近似的聚碳酸酯、聚酯、聚醚多元醇对WPU涂层性能的影响。研究发现,因聚碳酸酯WPU的相分离程度高,涂层具有较短的干燥时间和较好的剪切附着力,涂层光泽性更好,耐乙醇化学性及泛黄度均优于其它WPU。

2.3 亲水单体对WPU性能的影响

在水性聚氨酯的制备过程中,亲水单体所占比例较小,但其对WPU的分散稳定性、耐溶剂性和耐水性能等影响很大。

二羟甲基丙酸(DMPA)中—OH与异氰酸酯基的反应温和,常作为羧酸型亲水单体用于WPU的制备[37]。DMPA增加了聚氨酯软、硬段间的微相分离,可影响水性聚氨酯的结晶性[38]。Hu等[39]以IPDI、PCDL、DMPA为原料,通过预聚法制备了DMPA含量不同的水性聚氨酯,研究了亲水单体含量对WPU力学性能的影响,如图2所示。

由图2可知,随着DMPA含量的增加,抗拉伸强度先增加后降低,断裂伸长率不断减小。这是因为随着分子链中DMPA的增加,硬段增加,分子柔性下降,分子内氢键和内聚能增加,分子结构中的微相分离明显,从而导致拉伸强度提高,断裂伸长率下降。另外,热重分析表明,随着DMPA的增加,WPU的初始热分解温度降低,这是因为硬段先于软段分解,硬段的增加降低了材料分解温度。

磺酸型水性聚氨酯固含量高、稳定性好、耐热性好,在水性聚氨酯领域中受到广泛的研究。Honarkar等[28]以N,N-二(2-羟乙基)-2氨基乙磺酸钠(BES)为亲水单体,通过预聚体法制备WPU,研究了磺酸基的引入量对WPU热稳定性和力学性能的影响(见表5)。由表5可以看到,随着BES含量的增加,WPU的各热分解温度不断提升,热稳定性提高。这是由于磺酸钠基团可通过库仑力和氢键引起链间作用,从而使稳定性提升。

力学性能测试可知,WPU膜的拉伸断裂强度随着BES的增加也不断的提高。这是因为BES中的—SO-3Na+可完全电离,当BES含量增加时氨基甲酸酯键间的氢键作用力及离子中心的库仑力增加,使聚氨酯热稳定性和拉伸强度提高。

郭旭东[25]以BES-Na、1,2-二羟基-3-丙酯磺酸钠(DEPS)为亲水扩链剂,含磺酸基的聚酯多元醇(BY-3033)为亲水软链段,制备了3种高固含量的WPU。并探讨磺酸盐亲水扩链剂的分子结构及亲水基位置对WPU性能的影响。研究发现:当3种反应物质量分数分别为8%、5%和50%时所制备的水性聚氨酯固含量均可达到45%以上;3种水性聚氨酯均具有较高的热稳定性、透明度和耐水性。BES-Na制备的WPU相比于DEPS制备的WPU结晶度更高,这是因为对称结构的小分子亲水扩链剂有利于WPU结晶度的提高;含有磺酸根的聚酯多元醇制备的WPU具有更高的结晶性。力学性能测试显示亲水基团位于软段时更有利于WPU强力的提高。

2.4 改性材料对WPU性能的影响

在水性聚氨酯的制备过程中,为了获得更好的应用性能,往往会对其进行适当的改性。常用的改性材料总结于表6。

除上述高分子化合物外,纳米材料和生物质材料对WPU的改性也受到广泛的研究。通过共混、原位聚合等方法将纳米材料引入WPU或使WPU纳米化,利用纳米材料的表面效应、光学效应、小尺寸效应等特性,可使改性后的水性聚氨酯获得新功能或更好的性能[48-49]。生物质材料资源丰富,可再生性和生物相容性好,价格低廉。近年来不少研究将生物质材料如纤维素、植物油、角蛋白等应用到水性聚氨酯的改性中,有效的改善了水性聚氨酯的稳定性、生物可降解性,在提高WPU的应用性能方面取得了明显的进展[50-51]。

3 水性聚氨酯的染色

近年来,随着合成工艺的不断进步和成熟,WPU的性能不断提高,尤其在超细纤维合成革的开发上日益受到相关产业的重视。通过颜料(或染料)共混着色和染色的方式,可使超纤革获得丰富的色彩,更好的满足市场需求。

3.1 聚氨酯超纤革的染色

常见的溶剂型聚氨酯因结构中缺少离子基团,对染料的吸附能力较差,易造成染色不匀,色牢度差等问题[52]。超纤革因PU和基布纤维两组分染色性能的差異易出现匀染性、渗透性和色牢度等染色问题[53]。在溶剂型PU超纤革的染色中,常从染料类型[54]、染色助剂(匀染剂、渗透剂、固色剂)[55-57]、染色工艺[58-59]、基布改性[60-63]等方面来改善。关于溶剂型聚氨酯合成革的染色,虽然实际生产中还存在一些问题,但是总体而言染色工艺比较成熟,国内外有很多相关的研究和文献,本文不再赘述。

水性聚氨酯由于分子中亲水性单体的引入,染色性能发生了很大的变化。首先,离子型WPU电离的亲水性基团可以作为能够与染料结合的染座,通过库仑力与染料结合,从这个角度来看其染色性能得到了改善。其次,根据反应物的不同,受软硬链段比例和水性侧基的影响,WPU的微观结构不同于溶剂型PU,染料与WPU的亲和力不同,染料在染色过程中对WPU的吸附和扩散行为不同,这会导致很多适合溶剂型PU超纤革染色的染料或上染条件不再适用。另外,在笔者的实践中发现,WPU超纤革透染性差,染色湿牢度、色迁移牢度差,固色困难。因此,对于WPU超纤革的染色需做深入而系统的研究。

3.2 有色WPU

无论染料还是颜料,色素都需要通过一定的工艺和设备才能与被染物结合。在染色过程中,大多数染料与被染物之间基本是物理结合,存在各种各样的色牢度问题。将发色基团或染料通过化学方法引入WPU,使之与WPU分子形成化学结合,可以有效改善牢度问题,使用方便。

异氰酸酯基反应性能活泼,将含有活泼氢的有机染料接枝到聚氨酯中,可以得到含发色基团的WPU[64]。发色基团可在聚氨酯链的主链或侧链上引入。

Zheng等[65]以异佛尔酮二异氰酸酯、聚醚乙二醇、二羟甲基丙酸为原料,以自制的N,N-2-(2-羟基乙基)-4-苯基偶氮苯胺(HPB)为扩链剂,成功地将偶氮发色基团通过共价键连接到了聚氨酯大分子中,制备出有色WPU,且水性聚氨酯的热稳定性和耐水性因HPB的刚性芳香结构而有所提高。

Zhao等[66]将2,6-二氨基蒽醌结构引入到水性聚氨酯结构中,制备了黄色WPU,并对WPU薄膜和用其染色的棉布的颜色特征进行了评价。棉布耐干、湿摩擦色牢度可达到4~5级,并且经皂洗后无明显褪色。

Wang等[67]以端羟基水性聚氨酯和活性染料反应,制得自着色水性聚氨酯,并将其应用到超细纤维合成革的制备中。使用自着色WPU制备的超纤革表面颜色比以传统染色方法染色的超纤革颜色深,且超纤革耐水洗牢度可达到3级以上。

Wang等[68]将T/N非织造布浸入含硅阴离子水性聚氨酯并与活性染料“接枝”,反应机理如图3所示。由于活性染料能够与水性聚氨酯中的—OH反应,影响了水性聚氨酯的交联,从而使有色合成革的最大断裂强度和拉伸率有所下降。在染料用量为6% (o.w.f)的时候,具有侧—OH的水性聚氨酯的上染率在80%以上,最高可达到96.1%,且耐水洗牢度可达4~5级。

通过接枝的方法将发色基团或染料引入到聚氨酯结构中,一定程度上提高了WPU的耐水洗牢度和上染率,改善了WPU产品染色工艺面临的问题,但产品暗淡而单一。

还有研究者从化学结构入手,调整、改善聚氨酯的染色性能。Liu等[69]研究了一种酸性可染聚氨酯,此类聚氨酯可通过对软、硬段间相分离程度的调控使聚氨酯呈现完全无定形状态,使染料扩散到聚合物中。与普通聚氨酯相比,酸性可染聚氨酯对酸性染料的染色速度快,上染率高,且具有更好的湿摩擦牢度和耐洗涤牢度,在超纤革上有着较好的应用前景。

4 结 语

聚氨酯的嵌段结构使其具有良好的拉伸强度和弹性,通过对软、硬链段比例和微晶相分离程度的调控能够有效调整其力学性能。在阴离子水性聚氨酯中,通过对羧酸盐、磺酸盐种类及含量的调控可以改善其力学性能及热稳定性。水性超纤革的透染性及色牢度差,固色困难。通过染料接枝的方法,将含有活泼氢的有机染料接枝到水性聚氨酯中,可改善色牢度。但产品颜色过于单一,无法大范围的应用于超纤革的染色中。

目前,对水性聚氨酯的合成及构效关系的研究较多,但对水性聚氨酯及WPU超纤革染色性能和机理的研究甚少。在笔者的实践过程中发现,水性聚氨酯在染色过程中存在一定程度的“凝胶化”,这种结构变化直接影响其染透性、染色牢度、染色效率。对WPU及其超纤革的染色不能仅做工艺方面的研究,而要进行深入而系统的研究,这样才能满足高质量、高物性产品的开发,推动WPU相关产业的发展。

参考文献:

[1]刘长伟,史颖,马驰,等.异氰酸酯硬段对聚氨酯结构及性能的影响[J].高分子材料科学与工程,2021,37(3):79-84.

LIU Changwei, SHI Ying, MA Chi, et al. Effect of isocyanate hard segment on structure and property of polyurethane[J]. Polymer Materials Science & Engineering, 2021,37(3): 79-84.

[2]凡永利,郑水蓉,苏航,等.水性聚氨酯改性及其应用研究进展[J].中国胶粘剂,2011,20(5):56-60.

FAN Yongli, ZHENG Shuirong, SU Hang, et al. Research progress of modification and application of waterborne polyurethane[J]. China Adhesives 2011, 20(5): 56-60.

[3]ZHANG J J, HUANG H, MA J, et al. Preparation andproperties of corrosion-resistant coatings from waterborne polyurethane modified epoxy emulsion[J]. Frontiers in Materials, 2019, 6: 185.

[4]杜壮.羊毛织物防毡缩整理及羊毛角蛋白的生物医用研究[D].上海:东华大学,2019.

DU Zhuang. Research on Anti-taping Treatment of Wool Fabric and Biomedical Application of Wool Keratin[D]. Shanghai: Donghua university, 2019.

[5]FANG C Q, ZHOU X, YU Q, et al. Synthesis and characterization of low crystalline waterborne polyurethane for potential application in water-based ink binder[J]. Progress in Organic Coatings, 2014, 77(1): 61-71.

[6]谢珍,杜壮,阎克路.蛋白酶和有机硅改性聚氨酯联合防毡缩工艺[J].毛纺科技,2017,45(9):27-33.

XIE Zhen, DU Zhuang, YAN Kelu. Anti-felting process of wool fabric by protease and polysiloxane modified waterborne polyurethane[J]. Wool Textile Journal, 2017, 45(9):27-33.

[7]丁会会.功能性羊绒针织制品聚氨酯整理剂的研发与应用[D].西安:西安工程大学,2020.

DING Huihui. Development and Application of Functional Cashmere Knitted Polyurethane Finishing Agent[D]. Xi'an: Xi'an Polytechnic University, 2020.

[8]张冰,张弛,肖升木,等.改性蛋白酶的制备及其在羊毛防毡缩整理中的应用[J].纺织学报,2012,33(5):74-80.

ZHANG Bing, ZHANG Chi, XIAO Shengmu, et al. Preparation of modified protease and its application on antifelting finishing of wool[J]. Journal of Textile Research, 2012, 33(5): 74-80.

[9]杜鹃.聚氨基甲酸酯弹性纤维的染色性能及染色原理研究[D].苏州:苏州大学,2001.

DU Juan. A Study on the Behaviours and Principles of Dyeing for Polyurethane Fibers[D]. Suzhou: Suzhou University, 2001.

[10]SHAMSI R, MAHYARI M, KOOSHA M. Synthesis of CNT-polyurethane nanocomposites using ester-based polyols with different molecular structure: Mechanical, thermal, and electrical properties[J]. Journal of Applied Polymer Science, 2017, 134(10): 13.

[11]張赛楠.芳香族水性聚氨酯材料的合成及其性能研究[D].哈尔滨:黑龙江大学,2018.

ZHANG Sainan. Synthesis and Properties of Aromatic Waterborne Polyurethane Materials[D]. Harbin: Heilongjiang University, 2018.

[12]邱峻,韋军,王宝总,等.亲水性封闭型芳香族异氰酸酯交联剂的合成及性能研究[J].聚氨酯工业,2011,26(6):39-42.

QIU Jun, WEI Jun, WANG Baozong, et al. Synthesis and performance research of waterborne blocked aromatic isocyanate crosslinking agent[J]. Polyurethane industry, 2011, 26(6): 39-42.

[13]崔海世.无溶剂型脂肪族聚氨酯合成与性能研究[D].长春:吉林大学,2008.

CUI Haishi. Study on the Preparation and Properties of Aliphatic Polyurethane without Imprgnant[D]. Chang-chun: Jilin University, 2008.

[14]张基智.脂环族双组分水性聚氨酯材料的合成及固化研究[D].哈尔滨:黑龙江大学,2018.

ZHANG Jizhi. Study on Synthesis and Curing of Aliphatic Cyclic Two-component Aqueous Polyurethane[D]. Harbin: Heilongjiang University, 2018.

[15]夏会华.水性聚氨酯性能的影响因素[D].合肥:安徽大学,2013.

XIA Huihua. Influencing Factors of Properties of Water-borne Polyurethane[D]. Hefei: Anhui University, 2013.

[16]YUAN F, LIU W B, Yang F, et al. Preparation and properties of MDI-based polyester polyurethane elastomer[J]. Polymers & Polymer Composites, 2014, 22(3): 341-346.

[17]常伟林,王建伟,池俊杰,等.二聚酸二异氰酸酯在水性聚氨酯中的应用进展[J].化学推进剂与高分子材料,2017,15(1):35-39.

CHANG Weilin, WANG Jianwei, CHI Junjie, et al. Application progress of dimer acid diisocyanate in waterborne polyurethane[J]. Chemical Propellants and Polymer Materials, 2017, 15(1): 35-39.

[18]高喜平,王勃,曹光宇,等.异佛尔酮二异氰酸酯分子中异氰酸酯基团活性比较[J].河南科技大学学报(自然科学版),2009,30(2):101-104,115.

GAO Xiping, WANG Bo, CAO Guangyu, et al. Active comparison of isocyanates in isophorone diisocyanatek[J]. Journal of Henan University of Science and Technology(Natural Science Edition), 2009, 30(2): 101-104,115.

[19]陈卓.六亚甲基二异氰酸酯固化剂的合成及结构表征[D].广州:华南理工大学,2014.

CHEN Zhuo. The Synthesis and Characterization of HDI-based Curing Agent[D]. Guangzhou: South China University of Technology, 2014.

[20]BARIKANI M, EBRAHIMI M V, MOHAGHEGH S M S. Influence of diisocyanate structure on the synthesis and properties of ionic polyurethane dispersions[J]. Polymer-Plastics Technology and Engineering, 2007, 46(11): 1087-1092.

[21]冼文琪.二氧化碳基多元醇(PPCD)及水性聚氨酯的合成与应用研究[D].广州:广东工业大学,2021.

XIAN Wenqi. Synthesis and Application of CO2 based Polyols(PPCD) and Waterborne Polyurethane[D]. Guangzhou: Guangdong University of Technology, 2021.

[22]石磊,杨浩,沈连根,等.无溶剂聚氨酯合成革技术的研究进展[J].现代纺织技术,2021,29(1):76-81.

SHI Lei, YANG Hao, SHEN Liangen, et al. Research progress of solvent-free polyurethane synthetic leather technology[J]. Advanced Textile Technology, 2021, 29(1): 76-81.

[23]SUN Z, FAN H J, Chen Y, et al. Synthesis of self-matting waterborne polyurethane coatings with excellent transmittance[J]. Polymer International, 2018, 67(1): 78-84.

[24]庞灿.聚酯多元醇合成工艺研究及其在水性聚氨酯塑料涂层中的应用[D].合肥:合肥工业大学,2017.

PANG Cai. Study on Synthesis of Polyester Polyol and Its Application in Waterborne Polyurethane Plastic Coatings[D]. Hefei: Hefei University of Technology, 2017.

[25]郭旭东.基于羟基磺酸型亲水扩链剂制备高固含量水性聚氨酯及其性能研究[D].西安:陕西科技大学,2021.

GUO Xudong. Preparation and Performance of High solid Content Waterborne Polyurethane Based on Hydroxysulfonic Acid Hydrophilic Chain Extender[D]. Xi'an: Shaanxi University of Science and Technology, 2021.

[26]张淼.侧链胺基型阳离子扩链剂的合成及其合成水性聚氨酯的研究[D].合肥:安徽大学,2020.

ZHANG Miao. Synthesis of Side Chain Amino Type Cationic Chain Extender and Study on Synthesis of Waterborne[D]. Hefei: Anhui university, 2020.

[27]叶青萱.亲水基团对水性聚氨酯性能的影响[J].聚氨酯工业,2007,22(6):1-5.

YE Qingxuan. Effect of hydrophilic radicals on property of waterborne polyurethane[J]. Polyurethane industry, 2007, 22(6): 1-5.

[28]HONARKAR H, BARMAR M, BARIKANI M. Newsul-fonated waterborne wolyurethane dispersions: Preparation and characterization[J]. Journal of Dispersion Science and Technology, 2016, 37(8): 1219-1225.

[29]曾俊,王武生,阮德礼,等.DMBA与DMPA聚氨酯乳液主要性能比较[J].皮革化工,1999,16(5):19-22.

ZENG Jun, WANG Wusheng, RUAN Deli, et al. Comparison between main properties of polyurethane dispersions based on DMBA and DMPA [J]. Leather and Chemicals, 1999, 16(5): 19-22.

[30]Zhang Q Q, Lin X Q, Chen W S, et al. Applications of characterization methods in polyurethane materials: analysis of microphase-separated structures[J]. Applied Spectroscopy Reviews, 2022, 57(2): 153-176.

[31]薛振華.水性聚氨酯中不同二元醇结构对性能的影响[D].济南:齐鲁工业大学,2019.

XUE Zhenhua. A Thesis Submitted for the Application of the Master's Degree of Engineering[D]. Jinan: Qilu University of Technology, 2019.

[32]徐恒志.硬段含量和类型对水性聚氨酯性能的影响[D].合肥:安徽大学,2012.

XU Hengzhi. Influence of Hard Segment Content and Type on the Performance of Waterborne Polyurethane[D]. Hefei: Anhui University, 2012.

[33]XIAO Y, ZHAO H B, WU B, et al. Preparation and characterization of waterborne polyurethane based on diphenylmethane diisocyanate-50[J]. Advances in Polymer Technology, 2018, 37(2): 596-605.

[34]王柯,彭娅,王燕.硬段含量对脂肪族阴离子水性聚氨酯性能的影响[J].化工进展,2010,29(1):119-123.

WANG Ke, PENG Ya, WANG Yan. Effect of hard segment content on the properties of aliphatic anionic waterborne polyurethanes[J]. Chemical Industry and Engineering Progress, 2010, 29(1): 119-123.

[35]ORGILES-CALPENA E, ARAN-AIS F, TORRO-PALAU A M, et al. Influence of thechain extender nature on adhesives properties of polyurethane dispersions[J]. Journal of Dispersion Science and Technology, 2012, 33(1-3): 147-154.

[36]GARCIA P V, COLERA M, IWATA Y, et al. Incidence of the polyol nature in waterborne polyurethane dispersions on their performance as coatings on stainless steel[J]. Progress in Organic Coatings, 2013, 76(12): 1726-1729.

[37]LEE H T, WU S Y, JENG R J. Effects of sulfonated polyol on the properties of the resultant aqueous polyurethane dispersions[J]. Colloids and Surfaces a-Physicochemical and Engineering Aspects, 2006, 276(1-3): 176-185.

[38]LIU X H, HONG W, CHEN X D. Continuousproduction of water-borne polyurethanes: A Review[J]. Polymers, 2020, 12(12): 2875.

[39]HU L Q, PU Z J, ZHONG Y Q, et al. Effect of different carboxylic acid group contents on microstructure and properties of waterborne polyurethane dispersions[J]. Journal of Polymer Research, 2020, 27(5): 9.

[40]QIU F X, ZHANG J L, WU D M, et al. Waterborne polyurethane and modified polyurethane acrylate compo-sites[J]. Plastics Rubber and Composites, 2010, 39(10): 454-459.

[41]刘思彤.含氟丙烯酸酯/环氧树脂复合改性水性聚氨酯的制备及性能研究[D].长春:长春工业大学,2021.

LIU Sitong. Preparation and Properties of Waterborne Polyurethane Modified by Fluorinated Acrylate/Epoxy Resin Composite[D]. Changchun: Changchun University of Technology, 2021.

[42]王芳芳,钱年龙,商杭,等.硅改性疏水型水性聚氨酯的制备及性能研究[J].中国皮革,2021,50(5):55-63.

WANG Fangfang, QIAN Nianlong, SHANG Hang. Preparation and properties of silicon modified hydrophobic waterborne polyurethane[J]. China Leather, 2021, 50(5): 55-63.

[43]張晓静.有机硅改性水性聚氨酯的制备及性能探究[D].杭州:浙江大学,2021.

ZHANG Xiaojing. Preparation and Properties of Silicone Modified Waterborne Polyurethane[D]. Hangzhou: Zhejiang University, 2021.

[44]王雪.有机氟和交联双重改性水性聚氨酯的制备及性能研究[D].长春:长春工业大学,2020.

WANG Xue. Study on the Preparation and Properties of Organic Fluorine and Crosslinked Double Modified Waterborne Polyurethane[D]. Changchun: Changchun University of Technology, 2020.

[45]LIM C H, CHOI H S, NOH S T. Surface modification with waterborne fluorinated anionic polyurethane disper-sions[J]. Journal of Applied Polymer Science, 2002, 86(13): 3322-3330.

[46]兰芬芬.聚氨酯改性水性环氧树脂及其在防腐涂料中的应用[D].合肥:安徽大学,2021.

LAN Fenfen. Polyurethane Modified Waterborne Epoxy Resin and Its Application in Anticorrosive Coatings[D]. Hefei: Anhui university, 2021.

[47]赵明恩.合成革用水性聚氨酯/环氧树脂/丙烯酸酯IPN结构构筑及性能研究[D].青岛:青岛科技大学,2019.

ZHAO Ming'en. Structuralconstruction and Properties of Waterborne Polyurethane/Epoxy Resin/Acrylate IPN for Synthetic Leather[D]. Qingdao: Qingdao University of Science and Technology, 2019.

[48]丁晓丹.纳米SiO2改性水性聚氨酯的制备及性能研究[D].长春:长春工业大学,2020.

DING Xiaodan. Study on Preparation and Properties of Waterborne Polyurethane Modified Polyurethane by Nano-SiO2[D]. Changchun: Changchun University of Tech-nology, 2020.

[49]宋永华.水性聚氨酯基纳米复合材料的制备及其性能研究[D].西安:西安理工大学,2021.

SONG Yongha. Preparation and Properties of Waterborne Polyurethane-Based Nanocomposites[D]. Xi'an: Xi'an University of Technology, 2021.

[50]WU G F, LI Y C, YANG Z H, et al. Preparation andcharacterization of glucose and sulfamate double-modified biodegradable waterborne polyurethane[J]. Chemistryselect, 2021, 6(31): 8140-8149.

[51]TRAVINSKAYA T, SAVELYEV Y, MISHCHUK E. Waterborne polyurethane based starch containing materials: Preparation, properties and study of degradability[J]. Polymer Degradation and Stability, 2014, 101: 102-108.

[52]TRET'YAKOVA A E, SAFONOV V V, YUSINA A Y. Study of processes of dyeing polyurethane fibres by various classes of dyes[J]. Fibre Chemistry, 2013, 44(5):284-287.

[53]LEE S K, LEE H Y, KIM S D. Dyeing properties ofmixture of ultrafine nylon and polyurethane with different types of dye[J]. Fibers and Polymers, 2013, 14(12): 2020-2026.

[54]潘笑娟,王利民,杨柳波,等.超细PA/PU合成革用酸性染料的染色性能研究[J].染料与染色,2006,43(4):27-31,40.

PAN Xiaojuan, WANG Limin, YANG Liubo, et al. A Study on dyeing properties of superfine fiber PA/PU syntheticleather[J]. Dyestuffs and Coloration, 2006, 43(4): 27-31, 40.

[55]胡雪丽,马兴元,郭梦亚,等.固色剂SLA在超细纤维合成革染色中的应用研究[J].中国皮革,2014,43(23):24-27.

HU Xueli, MA Xingyuan, GUO Mengya, et al. Appli-cation of fixing agent SLA in microfiber synthetic leather dyeing[J]. China Leather, 2014, 43(23): 24-27.

[56]李峥嵘,涂偉萍,赖应光,等.超细锦纶PU革增深匀染剂IntratexLPUA[J].印染,2010,36(21):27-29.

LI Zhengrong, TU Weiping, LAI Yingguang, et al. Deepening and leveling agent intratex LPUA for supermicro PA/PU leatheroid [J]. China Dyeing & Finishing, 2010, 36(21): 27-29.

[57]白刚,刘艳春.苯甲醇对超细纤维合成革染色性能的影响[J].纺织学报,2011,32(1):78-81.

BAI Gang, LIU Yanchun. Effect of benzoic alcohol on dyeing properties of microfiber synthetic leather[J]. Journal of Textile Research, 2011, 32(1): 78-81.

[58]李金华,李晓霞,张悦.超纤锦纶PU合成革的涂料染色工艺研究[J].皮革与化工,2014,31(5):28-30.

LI Jinhua, LI Xiaoxiao, ZHANG Yue. Research on pigment dyeing process for microfiber Nylon PU synthetic leather[J]. Leather and Chemicals, 2014, 31(5): 28-30.

[59]胡忠杰.超纖染色牢度的工艺优化[J].印染,2018,44(15):32-34.

HU Zhongjie. Process optimization for improving color fastness of microfiber leather[J]. China Dyeing & Finishing, 2018, 44(15): 32-34.

[60]强涛涛,王晓芹,王学川,等.水解胶原蛋白对超细纤维合成革基布染色性能影响的研究[J].功能材料,2014,45(14):14066-14071.

QIANG Taotao, WANG Xiaoqin, WANG Xuechuan, et al. Study on the effect of dyeing properties of microfiber synthetic leather base by hydrolyzed collagen[J]. Journal of Functional Materials, 2014, 45(14): 14066-14071.

[61]龚燕燕,吉婉丽,徐欣欣,等.易染色超细纤维合成革用聚氨酯树脂的研制[J].聚氨酯工业,2007,22(4):34-37.

GONG Yanyan, JI Wanli, XU Xinxin, et al. Study on the preparation of polyurethane resin applied in superfine synthetic leather[J]. Polyurethane Industry, 2007, 22(4): 34-37.

[62]张卫东.易染色超细纤维合成革用聚氨酯树脂的合成与表征[D].上海:华东理工大学,2012.

ZHANG Weidong. Preparation and Characterization of Easy Dying Polyurethane for Micro Fiber Leather[D]. Shanghai: East China University of Science and Technology, 2012.

[63]黄玲,成松涛,符晓兰.壳聚糖/乙二醛交联体系对超细纤维合成革染色性能的影响[J].陕西科技大学学报(自然科学版),2010,28(4):52-55.

HUANG Ling, CHEN Songtao, FU Xiaolan. Influence of chitosan-glyoxal cross-link on performance of dyeing in superfine fiber synthetic leather[J]. Journal of Shaanxi University of Science and Technology (Natural Science Edition), 2010, 28(4): 52-55.

[64]祝彬.超细纤维合成革用水性聚氨酯的研究进展[J].中国皮革,2020,49(4):32-36.

ZHU Bin. Research progress of waterborne polyurethane for superfine fiber synthetic leather[J]. China Leather, 2020, 49(4): 32-36

[65]ZHENG Y, ZHANG X Y, LI J P. Synthesis and photochromism properties of anionic waterborne polyure-thane containing azobenzene chromophores[J]. Journal of Macromolecular Science Part a-Pure and Applied Chemi-stry, 2015, 52(11): 942-949.

[66]ZHAO J, HOU J H, CHAI C P, et al. Preparation and characterization of yellow waterborne polyurethane with 2,6-diaminoanthraquinone structure[J]. Polymer Testing, 2022, 106: 107451.

[67]WANG Y L, JIN L Q. Preparation andcharacterization of self-colored waterborne polyurethane and its application in eco-friendly manufacturing of microfiber synthetic leather base[J]. Polymers, 2018, 10(3): 289.

[68]WANG H H, TZAI G M, CHANG C C. Alkali reduction and reactive dye dyeing of T/N nonwoven fabrics dipped into silicon-containing, water-borne polyurethane[J]. Journal of Applied Polymer Science, 2005, 96(6): 2324-2335.

[69]LIU R W, CHEN Y, FAN H J. Design,characterization, dyeing properties, and application of acid-dyeable polyure-thane in the manufacture of microfiber synthetic eather[J]. Fibers and Polymers, 2015, 16(9): 1970-1980.

Abstract: With the shortage of natural leather resources and the continuous development of synthetic leather products, synthetic leather products have a wider application prospect on home furnishing, automotive decoration and other aspects. Microfiber synthetic leather is the most closely imitated product to natural leather. Although its physical and chemical properties are comparable to those of natural leather, its moisture permeability and dyeing properties are still far behind those of natural leather. Solvent-based polyurethane synthetic leather has been gradually replaced by environmental-friendly waterborne polyurethane due to the use of a lot of organic solvents in the production process.

Polyurethane is a kind of block copolymer with alternating hard and soft segments. The hard segments are mainly composed of isocyanates and small molecular chain extenders, which are easy to form hydrogen bonds, so that the polymer has fair rigidity and shows good tensile strength and elastic recovery force. The soft segments are mainly composed of polyester type or polyether type polyols, which are easily to form amorphous region, so that the polymer shows excellent flexibility. Compared with solvent-based polyurethane, hydrophilic monomers with carboxylic acid groups or sulfonic acid groups are introduced into the molecular structure during the polymerization of water-based polyurethane, which can make the product self-emulsified in water and effectively reduce the use of organic solvents. However, due to the introduction of hydrophilic monomer into the polymer chains, the mechanical properties and dyeing properties of waterborne polyurethane are significantly different from those of solvent-based polyurethane.

In the structure of waterborne polyurethane, the composition of soft and hard segments and the type and content of hydrophilic monomers would affect the degree of microphase separation, which have certain influence on its mechanical properties such as elongation at break and tensile strength. The dyeing properties and application properties can be effectively improved by regulating its composition and structure.

The difference of dyeing properties between microfiber and polyurethane leads to poor levelness and penetration of microfiber synthetic leather in the dyeing process. For the solvent-based polyurethane microfiber leather,the current dyeing methods and technological conditions can meet the market demand. But because of the introduction of hydrophilic groups in the macromolecules, the microstructure and packing state of waterborne polyurethane are different from those of solvent-based polyurethane, and the adsorption and diffusion behavior of dyes of the waterborne polyurethane microfiber leather has been changed. Although there are some studies on preparing the microfiber synthetic leather with colored waterborne polyurethanes, the dyeing mechanism and dyeing properties of the waterborne polyurethane microfiber leather are still few.

Keywords: waterborne polyurethane; hydrophilic group; composition and structure; mechanical property; the microfiber synthetic leather; dyeing