中深埋缓倾斜梯形切眼围岩变形规律及支护技术

于远祥 廖安全

摘 要:

针对缓倾斜巷道在开挖扰动、孔隙水压及地应力共同作用下变形破坏的高度复杂性和难以控制的显著特点,以马蹄沟煤矿3506工作面缓倾斜梯形切眼为工程背景,基于弹塑性变形理论,建立了垂直地应力、水平构造应力及孔隙水压共同作用下切眼围岩受力计算模型。考虑开挖过程中切眼围岩内摩擦角与黏聚力的扰动劣化效应,推导了非均匀地应力场作用下切眼围岩的应力和位移解析解,进而针对性地提出了倾斜巷道开挖及其围岩支护方案。结果表明:开挖方式、地质强度、切眼倾角、地应力、孔隙水压及岩体应变软化程度是影响切眼围岩的应力分布与位移大小的关键性因素;倾斜巷道不同断面位置所受地应力和孔隙水压存在差异性,不同掘进区段围岩变形量并不相同,应设计不同的开挖预留量及其支护参数。最后,基于上述理论分析,将马蹄沟煤矿3506工作面缓倾斜切眼分为4个掘进区段,确定了切眼第一区段至第四区段掘进预留变形量分别为300,260,220及200 mm,切眼围岩支护加固后,其顶底板最大移近量为204 mm,两帮最大移近量为165 mm,围岩变形控制效果良好,满足现场生产要求。

关键词:缓倾斜煤层;梯形切眼;预留变形量;支护技术中图分类号:TD 353

文献标志码:

A

文章编号:1672-9315(2023)06-1137

-12

DOI:10.13800/j.cnki.xakjdxxb.2023.0612開放科学(资源服务)标识码(OSID):

Surrounding rock deformation law and support technology of

moderately deep buried gently inclined trapezoidal cut

YU Yuanxiang,LIAO Anquan

(College of Civil and Architectural Engineering,Xian University of Science and Technology,Xian 710054,China)

Abstract:

The deformation and failure of gently inclined roadway under the combined action of excavation disturbance,pore water pressure and in-situ stress is highly complex and difficult to control.Taking the gently inclined trapezoidal cut of the 3506 working face in Matigou coal mine as the engineering background,based on the theory of elastic-plastic deformation,a calculation model for the stress on the surrounding rock of the cut under the combined action of vertical geostress,horizontal tectonic stress and pore water pressure was established.Considering the disturbance degradation effect of friction angle and cohesion in the surrounding rock of the cut during excavation,the analytical expression of stress and displacement of the surrounding rock of the cut under the non-uniform geostress field were derived,and a targeted excavation and surrounding rock support scheme for inclined roadway was proposed.The results show that excavation method,geological strength,cut angle,geostress,pore water pressure,and degree of rock strain softening are key factors affecting the stress distribution and displacement of the cut rock mass; there are differences in ground stress and pore water pressure at different sections of inclined roadway,and the deformation of surrounding rock in different excavation sections is not the same.Therefore,different excavation reserves and support parameters should be designed.Finally,based on the above theoretical analysis,the gently inclined cut of the 3506 working face in Matigou coal mine was divided into four excavation sections,and the reserved deformation amounts for excavation from the first section to the fourth section of the cut were determined to be 300,260,220 and 200 mm,respectively.After the reinforcement of the cut surrounding rock support,the maximum displacement of the roof and floor of the surrounding rock is 204 mm,and the maximum displacement of the two sides is 165 mm,the deformation control effect of the surrounding rock is good,meeting the requirements of on-site production.

Key words:gently inclined coal seam;trapezoidal cut;reserved deformation;supporting technology

0 引 言随着煤炭资源的消耗增加,煤炭开采的地质条件将越来越复杂,新的工程问题不断出现,倾斜巷道围岩的稳定性一直是围绕煤矿生产的重点与难点问题。闫振东等设计了渗水条件下斜井围岩破坏机理物理模型试验,模拟了围岩变形破坏过程[1];包海玲系统分析了自重应力场下倾斜巷道的应力与位移情况,探讨了倾斜巷道围岩变形破坏规律[2];伍永平等分析了多次采动条件下急倾斜煤层巷道围岩失稳破坏机理[3];陈旭分析了斜井围岩的变形失稳的主要原因,并提出针对性的支护方案[4];占有名探究了开挖步距与应力水平对穿越富水层斜井围岩变形影响规律[5];王渭明等根据深埋富水岩层中斜井围岩破坏特征,对塑性区半径经验公式进行修正[6];李晶晶求解了斜井围岩在均匀应力场和非均匀应力场的弹塑性解析式[7];崔增辉依托台格庙矿井建设工程,给出了斜井围岩变形规律和盾构机管片安全性[8];叶文登等对穿越煤层倾斜巷道围岩弱结构进行研究,得到了不同围岩弱结构塑性区分布及变形规律[9];高学通分析了煤层开采过程中孔隙水压力动态变化过程[10];刘波等基于弹塑性理论,推导出考虑渗流场作用下的斜井围岩应力、位移解析表达式[11];熊晓辉等通过多种研究方法预估深埋段煤矿斜井围岩变形值,并提出相应的技术控制措施[12];周霏等探讨了不同支护条件下的斜井围岩支护效果,确定了合理的支护方案[13];郭鹏探讨了斜井冻结工程中井壁变形的主要因素,为斜井冻结设计与施工提供指导[14];高强考虑了倾斜巷道轴向应力,给出了倾斜巷道围岩的弹塑性应力应变计算式[15];郝佩采用理论分析、数值模拟与工程实测等多种研究方法,分析了大断面倾斜巷道围岩的稳定性,为合理优化支护方案提供依据[16];马辉等开展了超大坡度隧道斜井变形监测与数据分析,提出了针对大坡度斜井变形关键控制技术[17];杨仁树等分析了非均匀应力场作用下斜井井壁应力与位移分布规律[18];熊咸玉等根据缓倾斜煤层巷道围岩变形破坏特征,给出针对性的支护措施[19];马天寿探究了不同地应力作用下岩石各向异性对井壁破坏的影响规律[20]。以上专家学者对倾斜硐室围岩的变形破坏规律进行了系统的研究,对工程实践具有一定的指导意义。但工程实际中,开挖扰动损伤和孔隙水压对倾斜硐室围岩的变形破坏及其稳定性具有重要影响,目前尚缺乏考虑扰动损伤和孔隙水压影响下的倾斜硐室稳定性的研究。基于此,文中以马蹄沟煤矿3506开切眼工程为背景,建立并简化倾斜巷道围岩应力分布力学计算模型,给出围岩应力、位移计算公式,并提出针对性的围岩支护技术措施,为有效控制缓倾斜巷道围岩变形、降低工程成本提供新的技术手段。

1 工程概况3506工作面开切眼位于马蹄沟煤矿三采区西北部,东南方向为3506工作面未采实体煤。切眼下口设计标高为+1 105 m,上口设计标高为+1 210 m。切眼设计倾斜长度为155 m,倾角为22.1°,埋深440.1~498.4 m,切眼断面形状为等腰梯形,其上掘宽为7.2 m,下净宽为7.6 m,掘进高度为3.0m,掘进断面积为22.2 m2。切眼布置在5号煤层中,为实体煤层巷道,煤层厚度为14~16 m,顶煤平均厚度为10 m,底煤平均厚度为3 m。煤层老顶为灰色砂质泥岩,厚度大于7 m,砂泥质结构,致密;煤层直接顶为浅灰色粉砂岩,厚度1 m左右,粉砂质结构,较坚硬;煤层老底为砂岩,厚度大于10 m,细粒砂状结构,钙质胶结,老底整体坚硬,较稳定;煤层直接底为砂质泥岩,灰黑色,厚度0.5 m左右,致密。5号煤层的顶底板均为弱含水岩层,据邻近区域水文地质情况分析,该切眼在掘进过程中受上部含水层影响,局部巷道顶板出现渗水现象,倾斜切眼如图1所示。

2 缓倾斜切眼力学分析模型的建立在不同断面形状的硐室等效分析模型方面,李桂臣等提出了“等效開挖”的概念,认为不同断面形状巷道与该断面外接圆同径的圆形巷道围岩塑性区分布基本一致[21];孟庆彬等认为不同断面形状巷道围岩表面位移值主要受巷道无效加固区变形的影响[22];马德鹏等发现当垂直方向应力与水平方向应力相等时,不同断面形状巷道所释放的能量相差很小,且围岩塑性区分布相差不大[23];郭晓菲等研究了不同围压条件下围岩塑性区分布规律,认为当垂直方向应力与水平方向应力接近或者相等时,不同断面形状巷道可近似为圆形巷道形态[24]。因此,当不同断面形状巷道围岩变形计算结果相近时,为便于指导切眼掘进及支护设计,可将梯形切眼等效为圆形巷道,断面图如图2所示。

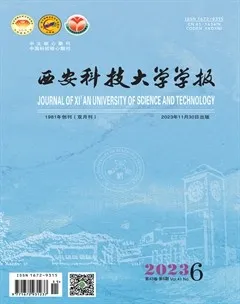

为分析倾斜切眼在开挖过程中的围岩变形问题,考虑非均匀地应力对倾斜切眼围岩的影响,倾斜切眼受力模型在如图3(a)所示。考虑孔隙水压对倾斜切眼围岩的影响,将孔隙水压力看作均匀应力,倾斜切眼受力模型如图3(b)所示。在垂直地应力、水平构造应力及孔隙水共同作用下,对倾斜切眼围岩荷载进行叠加分析,如图3(c)所示。通过对倾斜切眼围岩单元应力分析得到倾斜切眼围岩径向应力,因此可将倾斜切眼力学模型转换为水平巷道力学模型,如图3(d)所示。由此得到倾斜切眼径向荷载为

Pr=P0cosθ+λP0sinθ+Pw

(1)

式中 Pr为围岩径向应力,MPa。

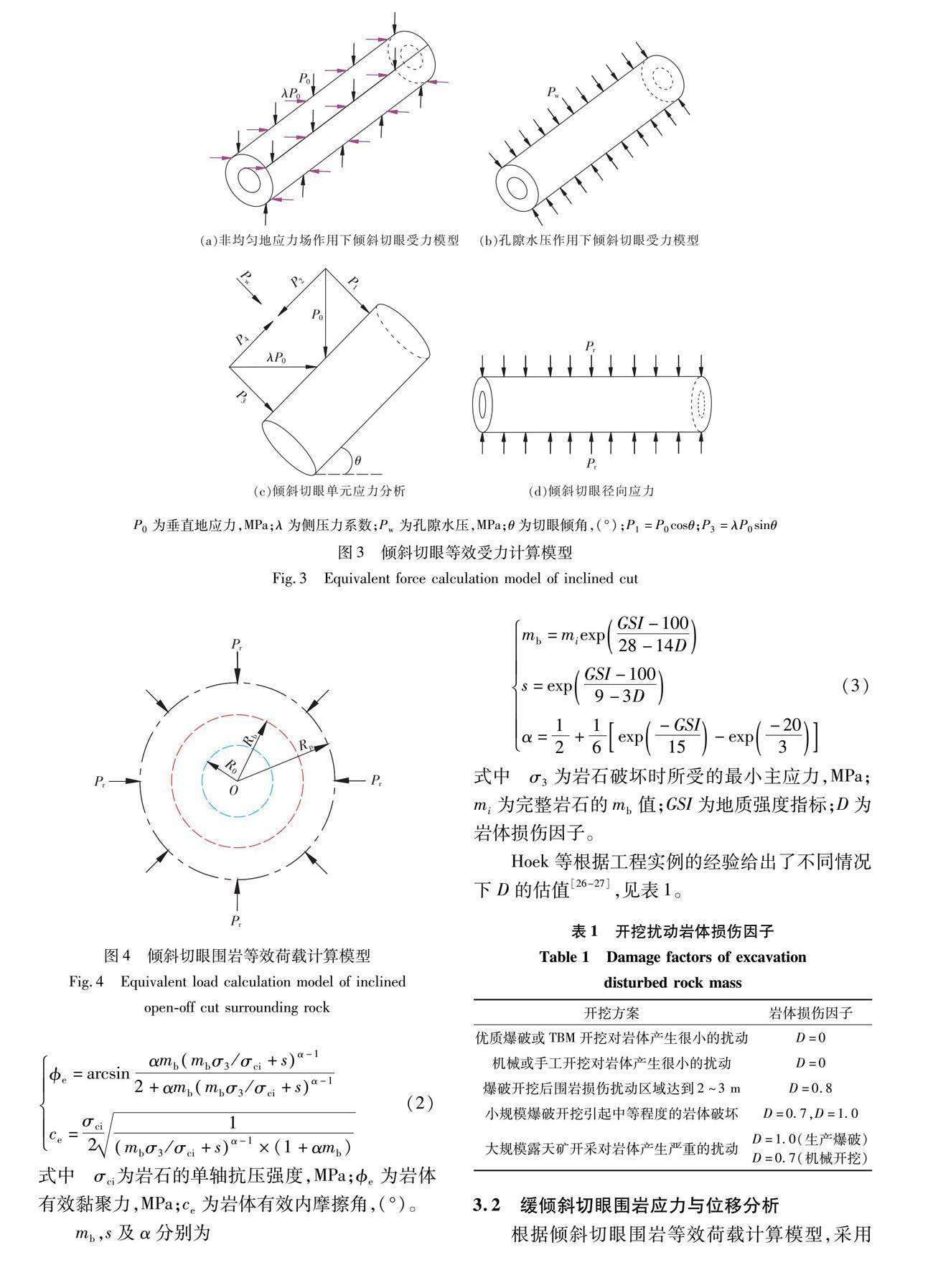

在巷道开挖过程中,岩体受扰动影响,造成应力和强度变化,使围岩发生变形甚至破坏,岩体物理性质发生改变。靠近硐壁的围岩会进入破裂状态,形成一个破裂区;在破裂区外的岩体应力进入塑性状态,产生一定塑性范围;再往外的岩体接近岩体强度,围岩处于弹性状态。倾斜切眼围岩荷载分布如图4所示。

3 缓倾斜切眼围岩弹塑性变形分析

3.1 缓倾斜切眼掘进扰动特征分析工程中开挖扰动会对岩体黏聚力与内摩擦角造成影响,在一定范围内影响岩体的力学性质,从而影响岩体工程的稳定。因此,在工程设计时应考虑扰动状态下的有效黏聚力与有效内摩擦角。刘德峰基于H-B准则和M-C准则,推导出非线性岩体强度参数黏聚力、内摩擦角与工程扰动与岩体地质强度指标之间的关系表达式为[25]

4.3 切眼围岩变形支护方案及其参数

4.3.1 顶板及两帮锚杆参数确定1)锚杆长度的确定。由(40)可知,巷道破裂区半径Rb=6.87 m,故破裂区范围为

4.4 支护效果分析为分析现场切眼围岩支护效果,在掘进区段共布置4组测点,每组测点布置在掘进区段中部,采用十字交叉法对巷道两帮、顶底板的位移变形量进行监测,断面测点布置如图9所示,监测结果如图10所示,切眼围岩表面变形量见表3。

從图10可以看出,切眼在支护后的20 d内,顶底板及两帮累计位移量增长明显,20 d后,各测点围岩变形逐步衰减并趋于稳定。第40 d时,顶底板累计相对变形量为分别为204,185,167,135 mm,两帮累计相对变形量为分别为165,144,123,97 mm。

从表3可以看出,经过对切眼支护参数设计后,不同掘进区段顶底板、两帮实际变形量未超过理论变形量。结果表明:在切眼掘进时预留一定的变形量,在此基础上通过合理设计锚杆(索)支

护参数,为工作面的安全高效回采提供了可靠保障。

5 结 论

1)倾斜巷道开挖后,围岩的变形破坏与开挖扰动程度、地应力及孔隙水压力密切相关,具体表现为:随着垂直地应力和孔隙水压的增大,围岩表面径向位移越大。

2)倾斜巷道围岩在开挖扰动、地应力及孔隙水压力作用下将产生一定的径向位移。由于不同断面位置的围岩所受地应力和孔隙水压存在差异性,不同掘进区段围岩变形量并不相同,开挖过程中应设计不同的开挖预留量及其支护参数。

3)基于上述理论分析,将马蹄沟煤矿3506工作面缓倾切眼分为4个掘进区段,确定了切眼第一区段至第四区段掘进预留变形量分别为300,260,220及200 mm,并设计了各区段的围岩支护参数。现场实测表明:切眼顶底板和两帮最大移近量分别为204,165 mm,均未超过设计预留变形量,围岩变形控制效果良好,满足现场生产要求。

参考文献(References):

[1] 闫振东,杨仁树,岳中文,等.渗水厚砾石层斜井围岩破坏机理模型试验[J].煤炭学报,2009,34(12):1599-1604.YAN Zhendong,YANG Renshu,YUE Zhongwen,et al.Mode test on failure mechanism of the surrounding rock of oblique laneway in thick gravel stratum under seepage water[J].Journal of China Coal Society,2009,34(12):1599-1604.[2]

包海玲.地下倾斜巷道变形场数值分析及支护优化[D].合肥:合肥工业大学,2012.BAO Hailing.The underground inclined roadway deformation numerical analysis and optimized support[D].Hefei:Hefei University of Technology,2012.

[3]伍永平,曾佑富,解盘石,等.急倾斜重复采动软岩巷道失稳破坏分析[J].西安科技大学学报,2012,32(4):403-408.

WU Yongping,ZENG Youfu,XIE Panshi,et al.Analysis of unstable failure of soft rock roadway in steep cal seam during repeat mining[J].Journal Xian University of Science and Technology,2012,32(4):403-408.[4]

陈旭.采动影响底板暗斜井围岩破坏机理及支护技术研究[D].湘潭:湖南科技大学,2014.CHEN Xu.Study on failure mechanism and supporting technology of floor roadway under mining influence[D].Xiangtan:Hunan University of Science and Technology,2014.[5]

占有名.第四系富水厚砂层段斜井围岩稳定性评价及其支护技术[D].西安:西安科技大学,2014.ZHAN Youming.The stability evaluation of the surrounding rock of the inclined shaft during the quaternary water-rich and thick sand layer segment and its supporting technology[D].Xian:Xian University of Science and Technology,2014.[6]

王渭明,王丹,宗永宏.富含水岩层斜井塑性区分布规律与变形控制研究[J].煤炭工程,2015,47(9):39-42.WANG Weiming,WANG Dan,ZONG Yonghong.Study on deformation control and plastic zone distribution law of inclined shaft in water-rich strata[J].Coal Engineering,2015,47(9):39-42.[7]

李晶晶.TBM(盾构)施工斜井围岩-支护相互作用机理研究[D].北京:中国矿业大学(北京),2015.LI Jingjing.Research on interaction between surrounding rock and support by TBM techniques[D].Beijing:China University of Mining and Technology(Beijing),2015.[8]

崔增辉.盾构法施工煤矿斜井围岩变形规律及管片安全性评价[D].北京:北京交通大学,2015.CUI Zenghui.Study on the deformation of surrounding rocks and the safety assessment of lining segments during the construction of mine inclined shaft by TBM[D].Beijing:Beijing Jiaotong University,2015.[9]

叶文登,徐营,李贇,等.穿煤层倾斜巷道围岩弱结构分析及支护技术[J].煤矿安全,2015,46(9):221-224.YE Wendeng,XU Ying,LI Yun,et al.Weak structure of surrounding rock and support technology in inclined roadway crossing coal seam[J].Safety in Coal Mines,2015,46(9):221-224.[10]

高學通.底部含水层孔隙水压力采动波动及影响机制的试验研究[J].矿业安全与环保,2016,43(2):8-12.GAO Xuetong.Experiment study of pore water pressure fluctuation and influence mechanism in bottom aquifer during mining[J].Mining Safety & Environmental Protection,2016,43(2):8-12.[11]

刘波,刘璐璐,徐薇,等.基于统一强度理论的TBM斜井围岩弹塑性解[J].采矿与安全工程学报,2016,33(5):819-826.LIU Bo,LIU Lulu,XU Wei,et al.Elastic-plastic analytical solution of TBM inclined shaft based on unified strength criterion[J].Journal of Mining & Safety Engineering,2016,33(5):819-826.[12]

熊晓晖,张旭东,夏明锬,等.煤矿斜井盾构深埋段极限位移及变形控制研究[J].施工技术,2016,45(22):1-5.XIONG Xiaohui,ZHANG Xudong,XIA Mingtan,et al.The control technology applied to the limit displacement and deformation of the deep-buried section in coal mine inclined shaft shield construction[J].Construction Technology,2016,45(22):1-5.[13]

周霏,景国勋.不同位置斜井井筒围岩变形破坏规律的数值分析[J].煤炭技术,2017,36(1):69-72.ZHOU Fei,JING Guoxun.Surrounding rock deformation and failure rules numerical analysis of inclined shaft in different position[J].Coal Technology,2017,36(1):69-72.[14]

郭鹏.斜井冻结壁受力与变形规律研究[J].煤炭工程,2018,50(6):100-104.GUO Peng.Stress and deformation law of inclined shaft freezing wall[J].Coal Engineering,2018,50(6):100-104.[15]

高强.深部巷道分区破裂动力分析及支护研究[D].济南:山东大学,2019.GAO Qiang.Study on dynamic analysis and support control of zonal disintegration in surrounding rock of deep tunnel[D].Jinan:Shandong University,2019.[16]

郝佩.变倾角变埋深大断面巷道围岩稳定性控制研究[D].太原:太原理工大学,2019.HAO Pei.Study on stability control of surrounding rock of large section roadway with variable inclination and buried depth[D].Taiyuan:Taiyuan University of Technology,2019.[17]

马辉,王飞,刘泽挂,等.深埋特长大坡度斜井变形规律与影响因素分析[J].地下空间与工程学报,2020,16(S2):950-956.MA Hui,Wang Fei,LIU Zegua,et al.Research on geological prediction and monitoring technology for steeply inclined and deep buried shaft[J].Chinese Journal of Underground Space and Engineering,2020,16(S2):950-956.[18]杨仁树,王千星.非均匀荷载下斜井井壁应力和位移场弹性分析[J].煤炭学报,2020,45(11):3726-3734.YANG Renshu,WANG Qianxing.Elastic analysis of full stress and displacement field for inclined shaft liner subjected to nonuniform stresses[J].Journal of China Coal Society,2020,45(11):3726-3734.[19]

熊咸玉,戴俊.缓倾斜煤层直角梯形巷道支护技术[J].煤炭学报,2020,45(S1):110-118.XIONG Xianyu,DAI Jun.Research on support technology of right angle trapezoidal roadway in generally inclined coal seam[J].Journal of China Coal Society,2020,45(S1):110-118.[20]

马天寿,王浩男,杨赟,等.不同地应力状态下各向异性地层斜井井壁破裂规律[J].中南大学学报(自然科学版),2022,53(3):1123-1135.MA Tianshou,WANG Haonan,YANG Yun,et al.Wellbore fracture regularity of inclined wells in anisotropic formation under different in-situ stress states[J].Journal of Central South University(Science and Technology),2022,53(3):1123-1135.[21]

李桂臣,张农,王成,等.高地应力巷道断面形状优化数值模拟研究[J].中国矿业大学学报,2010,39(5):652-658.LI Guichen,ZHANG Nong,WANG Cheng,et al.Optimizing the section shape of roadways in high stress ground by numerical simulation[J].Journal of China University of Mining & Technology,2010,39(5):652-658.[22]

孟庆彬,韩立军,乔卫国,等.深部高应力软岩巷道断面形状优化设计数值模拟研究[J].采矿与安全工程学报,2012,29(5):650-656.MENG Qingbin,HAN Lijun,QIAO Weiguo,et al.Numerical simulation of cross-section shape optimization design of deep soft rock roadway under high stress[J].Journal of Mining & Safety Engineering,2012,29(5):650-656.[23]

马德鹏,杨永杰,曹吉胜,等.基于能量释放的深井巷道断面形状优化[J].中南大学学报(自然科学版),2015,46(9):3354-3360.MA Depeng,YANG Yongie,CAO Jisheng,et al.Optimization design of cross section shape of deep roadways based on characteristics of energy release[J].Journal of Central South University(Science and Technology),2015,46(9):3354-3360.[24]

郭晓菲,郭林峰,马念杰,等.巷道围岩蝶形破坏理论的适用性分析[J].中国矿业大学学报,2020,49(4):646-653,660.GUO Xiaofei,GUO Linfeng,MA Nianjie,et al.Applicability analysis of the roadway butterfly failure theory[J].Journal of China University of Mining & Technology,2020,49(4):646-653,660.[25]刘德峰,郭兵兵,刘长武,等.考虑工程扰动和地质条件的巷帮极限平衡区分析[J].煤炭学报,2017,42(3):597-603.LIU Defeng,GUO Bingbing,LIU Changwu,et al.Analysis of limit equilibrium zone for roadway side wall considering engineering disturbance and geological condition[J].Journal of China Coal Society,2017,42(3):597-603.[26]

陈鹏.基于Hoek-Brown准则的边坡等效Mohr-Coulomb参数估算[D].西安:长安大学,2021.CHEN Peng.Estimation of equivalent Mohr-Coulomb parameters of slope based on Hoek-Brown criterion[D].Xian:Changan University,2021.[27]

于远祥,秦光,陈盼.露天矿烧变岩高边坡卸荷机理与稳定性研究[J].西安科技大学学报,2023,43(5):941-951.

YU Yuanxiang,QIN Guang,CHEN Pan.Study on unloading mechanism and stability of high rock slope in burnt rock open-pit mine[J].Journal Xian University of Science and Technology,2023,43(5):941-951.

[28]付國彬.巷道围岩破裂范围与位移的新研究[J].煤炭学报,1995,20(3):304-310.FU Guobin.Recent investigation of extent of fractured zone and displacement of rocks around the roadways[J].Journal of China Coal Society,1995,20(3):304-310.[29]

于远祥.矩形巷道围岩变形破坏机理及在王村矿的应用研究[D].西安:西安科技大学,2013.YU Yuanxiang.Study on deformation mechanism of surrounding rock in rectangular roadway and its application in Wangcun coal mine[D].Xian:Xian University of Science and Technology,2013.

(责任编辑:刘洁)