Progress in research on nanoprecipitates in high-strength conductive copper alloys: a review

Jian YU, Feng ZHAO, Huiya YANG, Jiabin LIU, Jien MA, Youtong FANG

Review

Progress in research on nanoprecipitates in high-strength conductive copper alloys: a review

1State Key Laboratory of Silicon Materials, School of Materials Science and Engineering, Zhejiang University, Hangzhou 310027, China2College of Electrical Engineering, Zhejiang University, Hangzhou 310027, China

High-strength conductive Cu alloys play an essential role in high-speed railways, 5G networks, and power transmission. The compound precipitates of alloying elements such as Cr, Zr, Fe, and Si in Cu alloys significantly regulate the microstructure and properties of these alloys. They can ensure that the alloys have high strength without damaging conductivity seriously, which is usually a difficult problem in the development of Cu alloys. This paper systematically expounds on the microstructure and concerned factors of compound precipitates in high-strength conductive Cu alloys such as Cu-Cr-Zr, Cu-Zr, Cu-Ni-Si, and Cu-Fe-P. In particular, factors affecting the precipitates are summarized from the perspectives of composition and process to guide the regulation of properties. Some new, promising, high-performance Cu alloys, including Cu-Co-Si, Cu-Co-Ti, and Cu-Fe-Ti, are described. Finally, we look at the research prospects for precipitation-strengthened Cu alloys.

Cu alloys; Compound precipitate; Strength; Conductivity

1 Introduction

As a primary means of transportation in some countries, high-speed railways play a crucial role in industry and social developments. The running speed of commercial railways has continuously increased from 200 km/h to 300 and even 350 km/h and the Chinese government has arranged to construct 38000 km of high-speed railways before 2025 (Xiao et al., 2022). Since trains have been run safely and stably at a speed of 350 km/h for more than 10 years, the next generation of 400 km/h high-speed railway is in demand and is likely to be introduced on the route between Chongqing and Chengdu, China (Zhou et al., 2022). As the source of electricity for the trains, contact wires are the heart of high-speed railways. The electrical resistance of contact wires should be low to minimize Joule heating, while the tensile strength should be high to reduce vibration. Therefore, contact wires are commonly made of high-strength conductive Cu alloys. Cu-Sn (Yan et al., 2011), Cu-Ag (Jia et al., 2007), Cu-Mg (Kim et al., 2016), and Cu-Cr-Zr (Liu et al., 2011) alloys have been applied in high-speed railways.

Most countries require a tensile strength ≥550 MPa and a conductivity ≥75% IACS for contact wires in high-speed railways operating at 350 km/h (Chen et al., 2021). In 2010, China set the world high-speed railway operation test-speed record of 486.1 km/h using Cu-Cr-Zr contact wires. New high-performance Cu-based alloys should be designed to match the incr easing demands of next-generation high-speed railways.

The common methods of improving the strength of copper alloys include solution strengthening, precipitation strengthening, deformation strengthening, and fine-grain strengthening. The strength increment obtained by deformation strengthening and fine-grain strengthening is not stable enough, however, solution strengthening leads to a large reduction in conductivity (Geng et al., 2020b). Compared with these three methods, adding a certain amount of Ag, Cr, Zr, Co, Ti, and other alloy elements to Cu can produce precipitation-strengthened Cu alloys, in which compound precipitates are the key to strengthening the Cu matrix (Fine and Isheim, 2005). These elements are often characterized by high solid solubility at high temperatures that decreases sharply with decreasing temperature, which makes the formation of stable precipitates and little effect on the conductivity (Hocker et al., 2017). Obtaining high-strength conductive Cu alloy by this microalloying method has become a research paradigm in the field. In recent years, many studies have focused on the multi-component copper alloys that form compound precipitates. The compound precipitates not only strengthen the matrix, but also help precipitate alloying elements. One type of precipitation-strengthened Cu alloys uses multiple elements to form compound precipitates such as Cu-Cr-Zr, Cu-Ni-Si, Cu-Co-Si, and Cu-Fe-P. Compared to Cu-Cr, Cu-Ag, and other binary Cu alloys, the precipitation mechanism in those ternary Cu alloys is more complex and offers better performance.

This review covers the key factors affecting the precipitates of precipitation-strengthened Cu alloys and reviews the research progress to date on compound-precipitate-strengthened copper alloys in mature alloy systems. In addition, several alloy systems that offer potential improvement of properties are described. Finally, we look at the future development trends in the field.

2 Concerned factors of precipitates

The precipitates in high-strength conductive Cu alloys often come from the combined precipitation of several elements in the alloy or from direct precipitation due to the solubility change during aging. Their shape, coherence, and orientation relationship are closely linked to the microstructure and properties of Cu alloys.

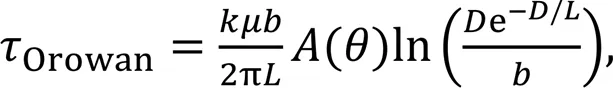

The strengthening mechanism of nano-precipitates in alloys is usually explained by the Orowan mechanism. The relationship between precipitate width, distance between adjacent precipitates, and Orowan bypass stress (Orowan) was proposed in Eq. (1) (Szajewski et al., 2021),

where A(θ) is a function of the angle θ between the Burgers vector and the direction of the straight dislocation line. The isotropic shear modulus, Burgers vector magnitude, the diameter of precipitate and the distance between precipitates are denoted by μ, b, D, and L, respectively. While k is a coefficient. A physical model of the equation is shown in Fig. 1.

The same team also analyzed precipitates with ellipsoidal, rod, and disc morphologies, based on their shape and size (Szajewski et al., 2020). Simulation results showed that spherical precipitates with smaller aspect ratios were more favorable for increasing the Orowan bypass stress, thus enhancing the strengthening effect of precipitates. For example, the addition of Zr promoted the transformation of the Cr phase to spherical, with smaller size, and more uniform distribution and dispersion, compared to the Cr phase in Cu-Cr alloy (Liu et al., 2017). As a result, Cu-Cr-Zr alloys are stronger than Cu-Cr alloys.

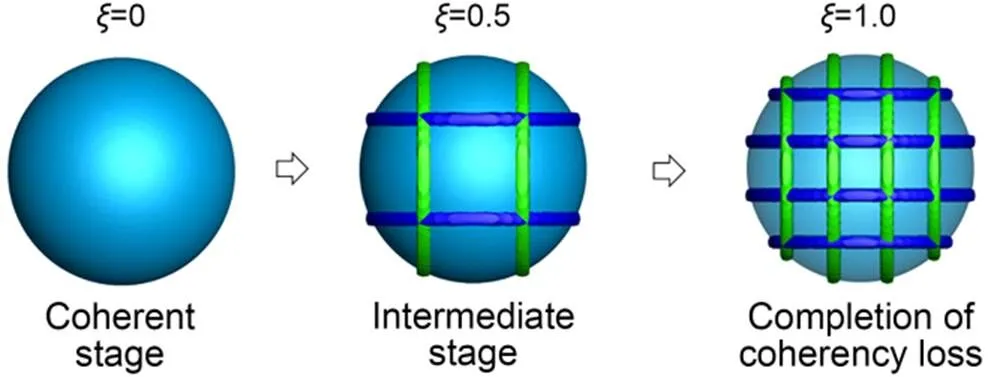

The principle of nucleation and growth of precipitates is the result of multi-element diffusion. At the beginning of aging, coherent fine precipitates tend to form due to the lower energy of the coherent interface compared to the non-coherent interface (Cheng and Wen, 2021). When precipitates are small, it is easy to maintain coherence with the matrix. Dislocations tend to cut through the coherent precipitates. As aging time is extended, the precipitates grow, and the coherent interface gradually changes to semi-coherent and even non-coherent interfaces. Fig. 2 shows the transition process of a precipitate from coherent to incoherent due to the increased degree of coherence loss. The horizontal and vertical lines represent dislocations with different Burgers vectors. At this point, dislocations tend to bypass the precipitates and form dislocation rings (the Orowan bypass mechanism) (Yang et al., 2020). Non-coherent precipitates only act as obstacles to prevent sliding dislocations in the alloy, and the stress generated between precipitates and the matrix may lead to cracks. In contrast, the interaction between coherent precipitates and dislocations tends to be sheared, and it is resistant to cracks and has a stronger blocking effect (Wang et al., 2021).

Fig. 2 Schematic diagram of the transition of a precipitate from coherent to incoherent (Cheng and Wen, 2021)

In short, the ideal precipitation to produce high performance in Cu alloys is dispersed coherent nano-spherical precipitates. The effect of orientation relationship on alloy properties needs to be further clarified, and optimal control of the dispersed coherent nano-spherical precipitates is a research hotspot in this field.

3 Some mature systems

Precipitation strengthening is a very suitable stren gthening method for Cu alloys. With this approach, many kinds of alloy systems with high conductivity and high strength have been invented, of which Cu-Cr-Zr, Cu-Ni-Si, and Cu-Fe-P are typical and common in both research and application.

3.1 Cu-Cr-Zr alloys

In the study of Cu-Cr alloys, researchers found that the addition of Zr can cause the Cr phase to tend to be spherical, as well as inhibiting Cr growth so as to produce better properties in Cu-Cr-Zr alloys (Batawi et al., 1990). Although there is still no unified understanding of the strengthening mechanism of Cu-Cr-Zr, the research technology of in-process production is relatively mature. Therefore, Cu-Cr-Zr alloys have been widely used in contact wires (Wang et al., 2020), heat exchangers (Wang et al., 2013), integrated circuit lead frames (Jha et al., 2021), and other products.

In 1979, after adding Cr to Cu-Zr alloy, it was found that the strengthening effect of precipitates could be significantly improved and excellent overall properties could be obtained (Sarin and Grant, 1979). In the 1990s, four alloying elements were added to the Cu-Cr alloy to study the effects of different elements on the alloy (Batawi et al., 1990). The experimental results showed that adding a certain amount of Zr, Mg, and Si could optimize the precipitation order of the alloy. In addition, Zr could improve the strength of the alloy and effectively maintain the strength at higher temperatures.

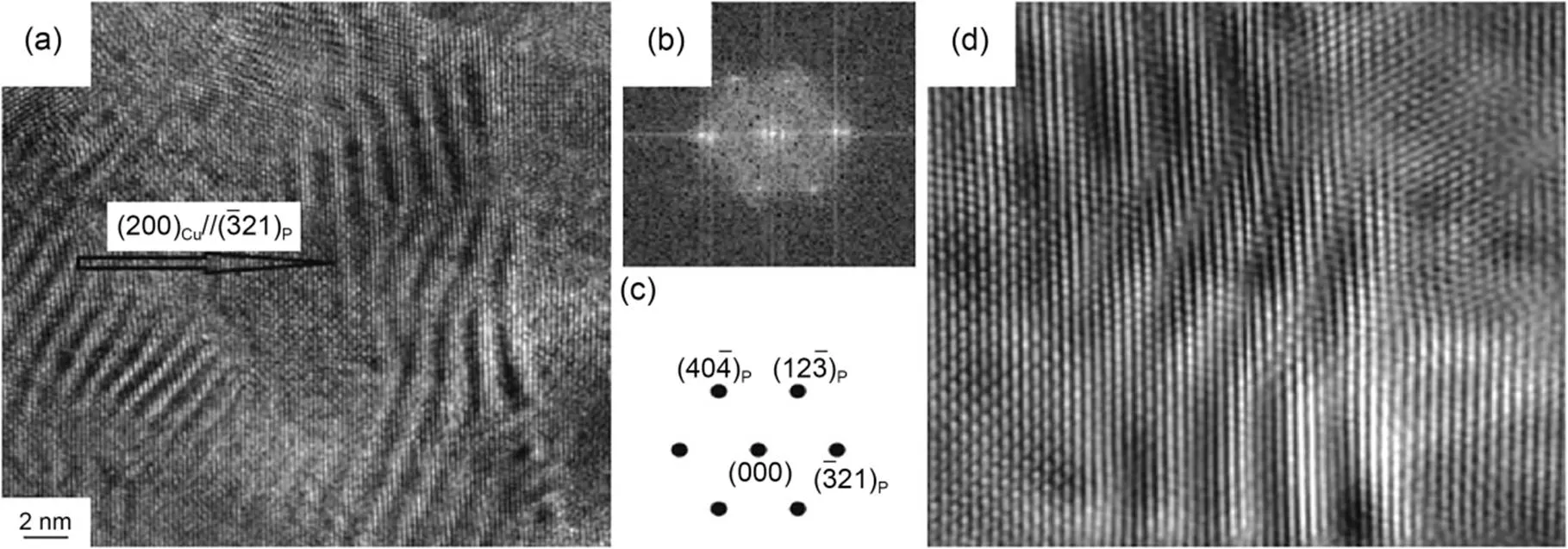

Fig. 3 Transmission electron microscopy (TEM) image of Cu-1.2Ni-1.6Co-0.6Si alloy (a); Fourier transform diffraction spot of Fig. 3a (b); calibration results (c); inverse Fourier transform lattice fringe of Fig. 3a (d). Reprinted from (Xiao et al., 2019), Copyright 2019, with permission from Springer Nature

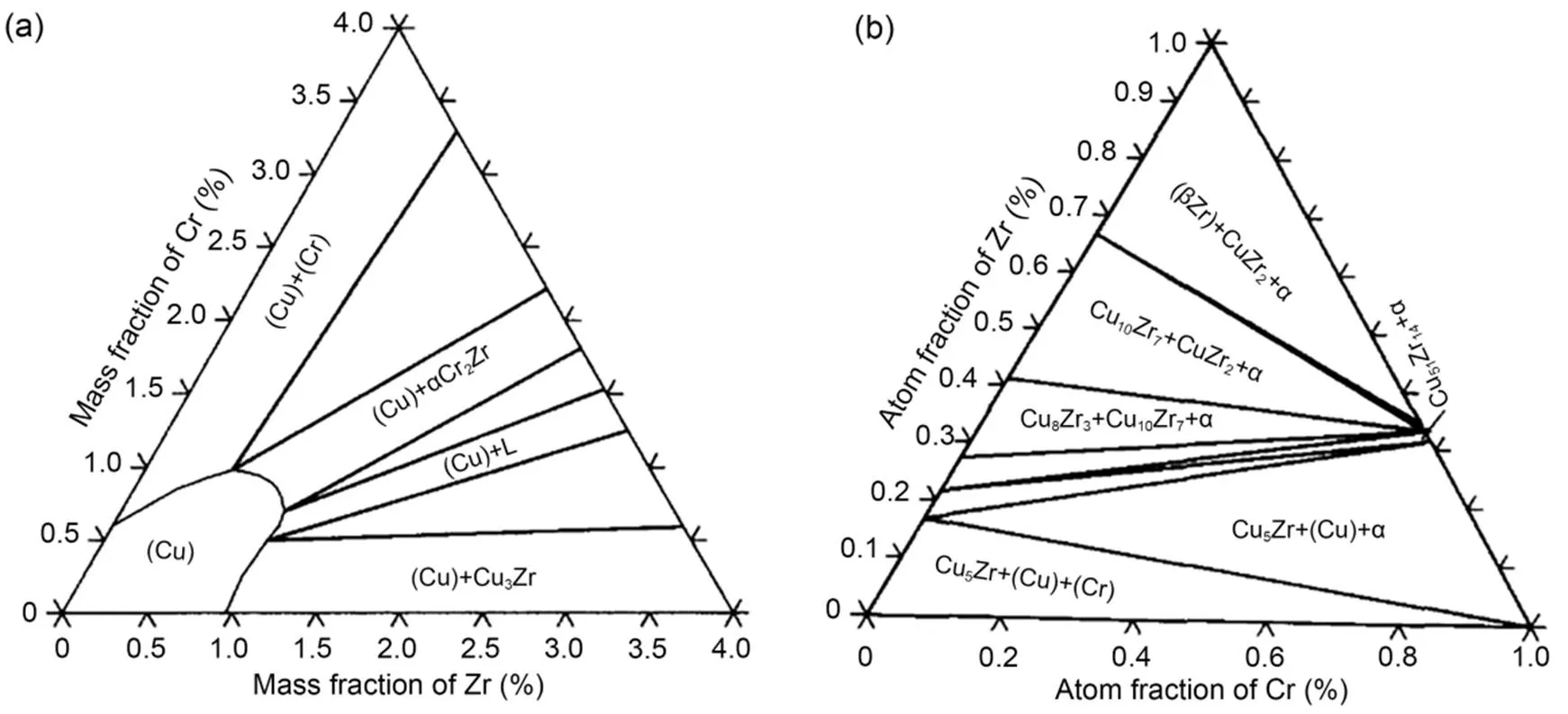

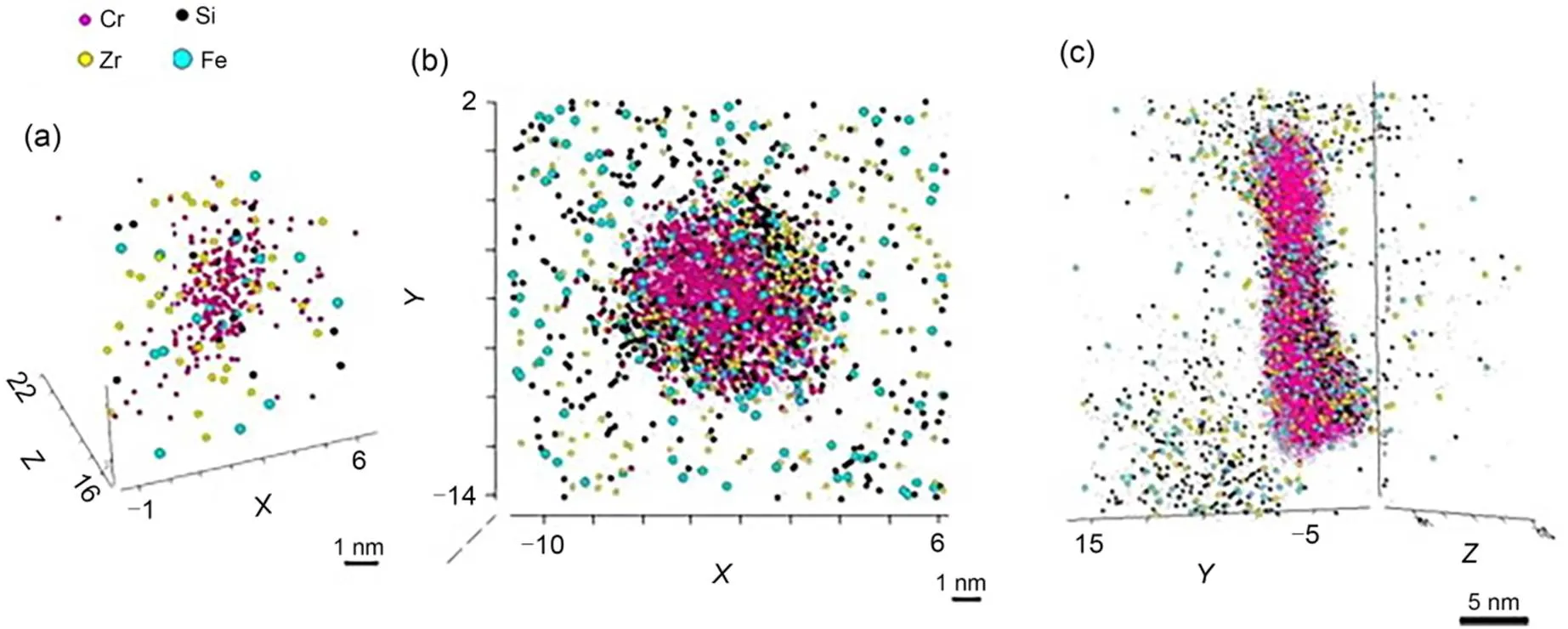

With regard to the types of precipitates, CuZr and Cr2Zr precipitates can be formed from the three elements Cu, Cr, and Zr. Therefore, the possible precipitates of Cu-Cr-Zr after aging treatment are the Cr phase, CuZr compound, and Cr2Zr. Fig. 4 shows the isothermal section of a Cu-rich corner of Cu-Cr-Zr at 940 °C and 600 °C (Zeng and Hämäläinen, 1995). Recent experimental results have shown that the stable Cu5Zr phase can appear in this system (Wang et al., 2019), which is consistent with previous conclusions (Zeng and Hämäläinen, 1995; Holzwarth and Stamm, 2000; Kermajani et al., 2013). Before these discoveries, many researchers thought that Cu51Zr14was the stable precipitate, rather than Cu5Zr (Nagai et al., 1973; Vinogradov et al., 2002). When they studied the precipitation sequence of Cu-Cr-Zr alloy, they found that the CuZr phase which formed near the dislocation and grain boundary was the reason for the high recrystallization temperature of this system. Using a 3D atomic probe to study Cu-Cr-Zr alloy is helpful in reconstructing the structure of Cr-rich precipitate (Hatakeyama et al., 2008). The results from this study by Hatakeyama et al. showed that the core-shell structure of Cr-rich precipitated after aging treatment. The main component of the shell was Cu7Cr3ZrSi, and the core was pure Cr. Moreover, a later study by the same group (Hatakeyama et al., 2009) found that the same results could be obtained with a laser-assisted local electrode 3D atomic probe and positron annihilation spectroscopy (Fig. 5).

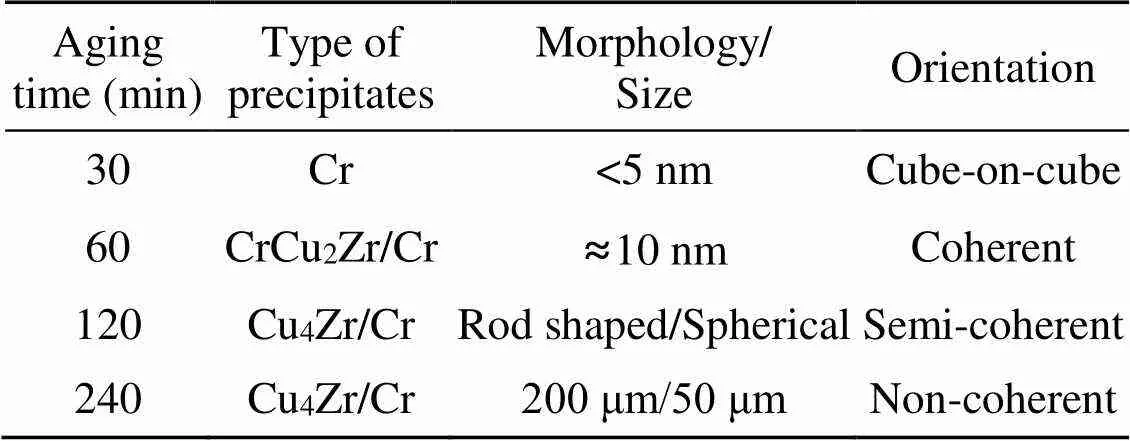

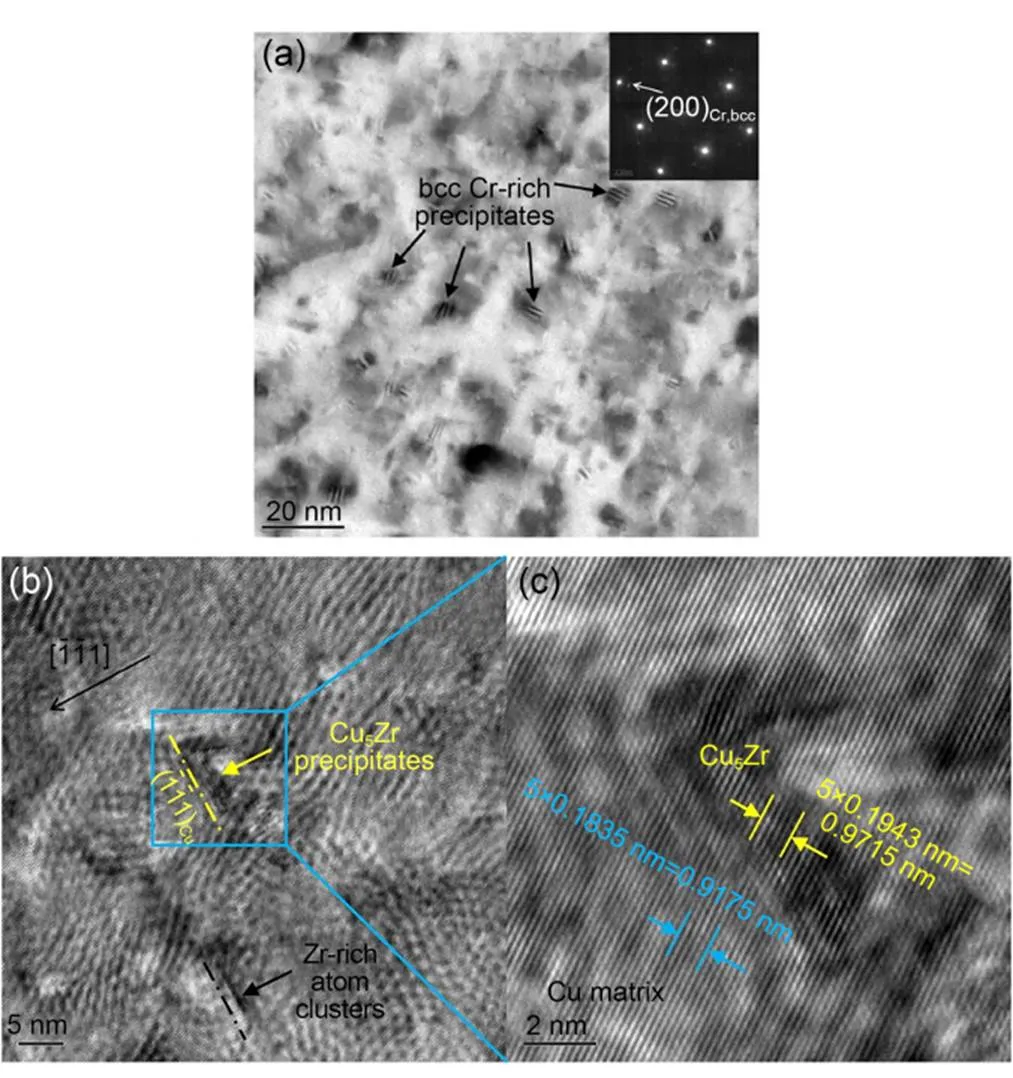

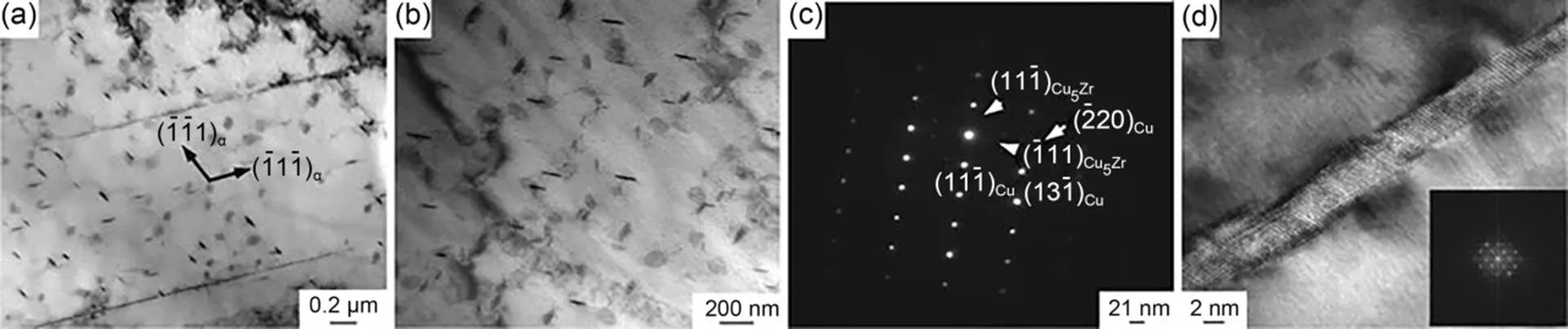

In order to study compound precipitates of Cu-Cr-Zr alloys, their type, morphology, lattice, and orientation can be systematically summarized by measuring the properties and performing microscopic characterization of the alloy at each aging time (Pan et al., 2021). The results of this process, as carried out by Hatakeyama et al. (2009) are shown in Table 1. Fig. 6 shows the micrograph of a Cu-Cr-Zr alloy which was solid-dissolved at 1253 K for 2 h and aged at 763 K for 0.5 h (Du et al., 2021). The results are consistent with the precipitation behavior of Zr-rich clusters in Cu-Zr alloys studied later (Peng et al., 2015b). It can be seen that Cr had little effect on Zr precipitates. In Cu-Cr-Zr, it is mainly the effect of Zr on the Cr phase that produces excellent properties.

In order to optimize the properties of Cu-Cr-Zr alloys, researchers have explored the effects of elements and processes on these properties. By studying the role of Cr and Zr elements in Cu-Cr-Zr alloys (Shangina et al., 2017), it was found that the addition of Cr in excess of the solid-solution limit did not strengthen the alloy. In contrast, the addition of excess Zr refined the grain and improved structural stability. After adding Nb element to Cu-Cr-Zr, large-sized Cr2Nb precipitates were found near the grain boundary (Yang et al., 2018). These coarse Cr2Nb precipitates can hinder grain-boundary movement and improve creep resistance at high temperatures. At the same time, the fine Cr phase and Cu5Zr phase dispersed in the matrix can play a strengthening role. Adding Nb to Cu alloys is a promising direction. However, the melting point of Nb is very high, which makes Cu-Nb alloys difficult to prepare. New material-preparation technology is required to further develop this system.

Fig. 4 Calculated phase diagrams of Cu-Cr-Zr at 940 °C (a) and 600 °C (b). Reprinted from (Zeng and Hämäläinen, 1995), Copyright 1995, with permission from Elsevier

Fig. 5 Atomic diagram of each possible distribution in the Cu-Cr-Zr alloy with different heat treatments: (a) prime aging (PA); (b) RA1: re-aging at 600 °C for 1 h; (c) RA2: re-aging at 600 °C for 4 h. Reprinted from (Hatakeyama et al., 2009), Copyright 2009, with permission from Elsevier

Table 1 Changes in concerned factors in Cu-Cr-Zr alloy aged at 450 °C over different periods of time

Fig. 6 TEM image of a Cu-Cr-Zr alloy: (a) bright-field image with axis of [001]Cu; (b) bright-field image with axis of [011]Cu containing Zr precipitates; (c) high-resolution image with axis of [011]Cu containing Zr precipitates. Reprinted from (Du et al., 2021), Copyright 2021, with permission from Elsevier

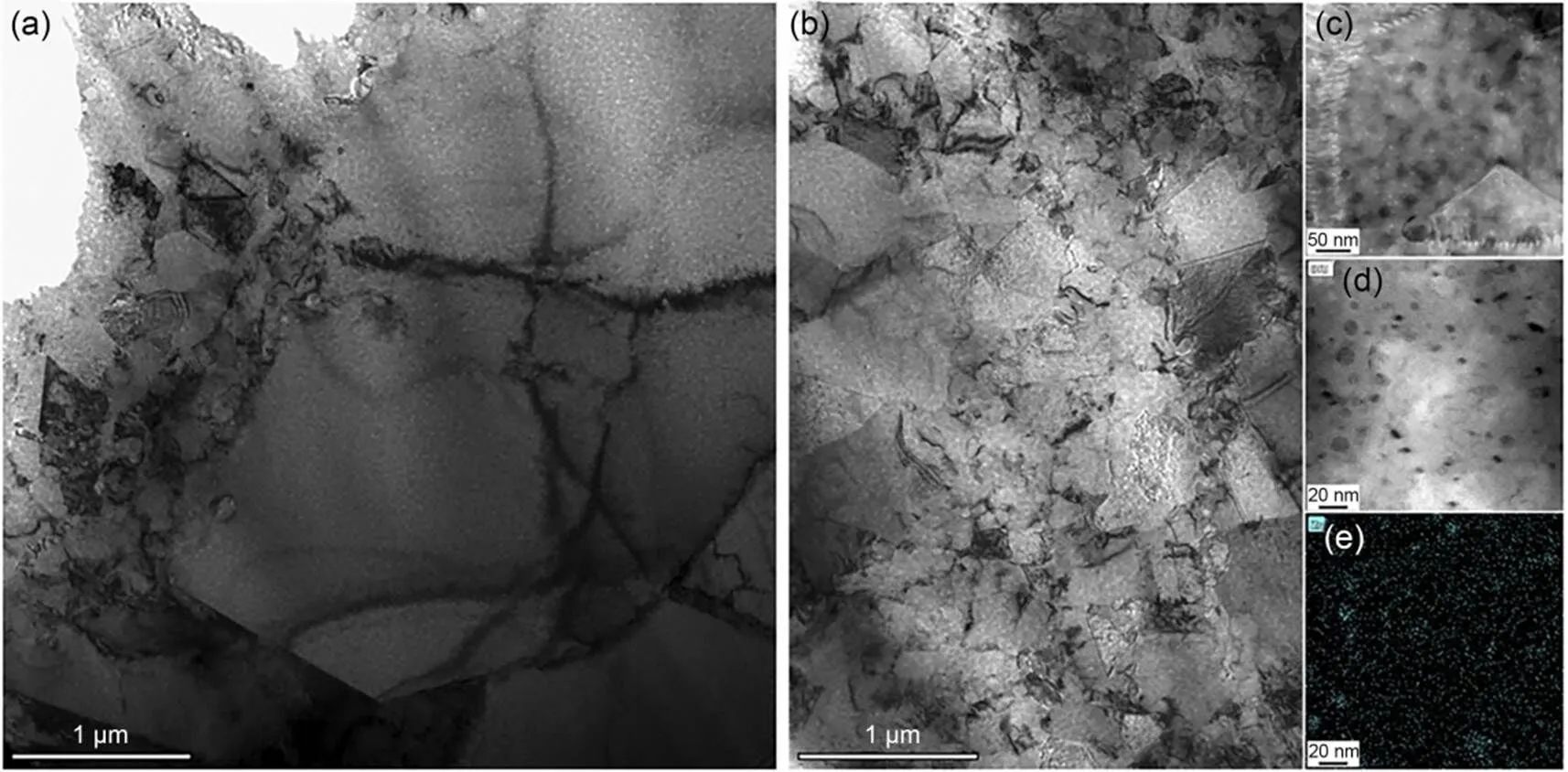

In addition to the traditional solid-solution and rolling strengthening methods, as well as aging methods, many innovative material-preparation processes have been used to prepare and research Cu-Cr-Zr alloys in recent years. The solubility of pre-aged Cu-Cr-Zr after high-pressure torsion treatment changes non-monotonically (Faizova et al., 2021). Their results showed that the initial value of low concentration was stable near a smaller value after a maximum, so it was impossible to explain the nucleation behavior by the diffusion mechanism alone. Therefore, they proposed a new mechanism. The precipitates obtained by pre-aging were broken and re-dissolved into the matrix by means of large deformation, and then the "dissolution-precipitation equilibrium" was established. Another large plastic deformation process was used to treat Cu-Cr-Zr alloys, and also a re-dissolving phenomenon in the alloying elements was detected (Caldatto Dalan et al., 2022). The Cu-Cr-Zr alloy prepared by the new process also exhibited different precipitate behaviors. Pure Cu particles can be embedded in Cu-Cr-Zr alloy by powder metallurgy to form a heterostructure (Lai et al., 2022). This not only changes the distribution of Zr-rich clusters but also enables Zr to surround the Cr phase (Fig. 7). Compared with the forged Cu-Cr-Zr alloy, the Cu-Cr-Zr alloy prepared by laser-beam powder-bed fusion exhibits no Cr or CuZr precipitation without aging (Salvan et al., 2021; Wegener et al., 2021). After aging, the Cr phase is evenly distributed in the matrix, and Zr precipitates are distributed at the grain boundary or Cr phase.

The properties of the alloys obtained by the above-mentioned modification methods are summarized in Table 2. Cu-Cr-Zr alloys have great potential in developing high-strength conductive Cu alloys. New high-quality precipitates (such as Cr2Nb) can be obtained by using the appropriate alloying method, and the distribution, morphology, and size of precipitates can be controlled by new production processes. In future research, the alloy's principle should be further explored to determine how to combine modern material-preparation technologies and modification technologies (such as powder-metallurgy technology, rapid solidification technology, or laser-additive technology) to change the alloy's microstructure and improve its properties for adaptation to complex and harsh working conditions.

3.2 Cu-Zr alloys

Strictly speaking, the main strengthening effect of Cu-Cr-Zr alloy comes from the Cr phase. The Zr element is added to hinder the growth of the Cr phase from playing a better strengthening effect and anti-softening effect. The remaining Zr forms precipitates such as Cu5Zr with Cu and plays a strengthening role. However, Cu-Zr alloys are also essential for studying compound precipitates and the development of new high-performance alloy systems.

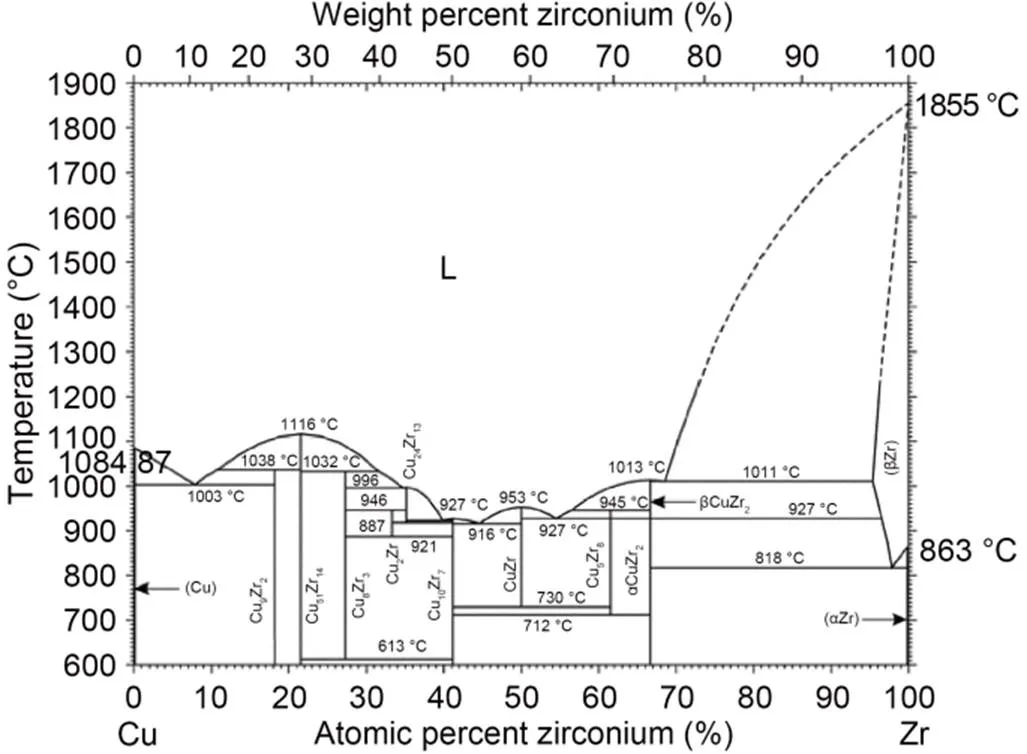

The solubility of Zr in Cu is very low, up to 0.15% (mass fraction). According to the binary phase diagram of Cu-Zr (Fig. 8) (Okamoto, 2012), the solubility of Zr will decrease sharply with decreasing temperature. When the temperature is 500 °C, the solubility of Zr is only 0.01% (mass fraction). This change is conducive to the formation of precipitates by Zr through aging. Therefore, the Zr element often appears in high-strength conductive Cu alloys systems to strengthen precipitation and reduce weakening of conductivity.

Fig. 7 Microstructure of Cu-Cr-Zr/Cu180 min: (a and b) bright-field TEM images; (c) high angle annular dark field (HAADF) image of intragranular precipitates; (d) enlarged image of intragranular precipitates; (e) Zr element map of Fig. 7d. Reprinted from (Lai et al., 2022), Copyright 2022, with permission from Elsevier

Table 2 Properties of some Cu-Cr-Zr alloys mentioned above and their compositions and processes

Fig. 8 Binary phase diagram of Cu-Zr alloys. Reprinted from (Okamoto, 2012), Copyright 2012, with permission from Springer Nature

Researchers have explored and debated the compound precipitates in Cu-Zr alloys over the past few decades. At first, they thought that the precipitates in the alloy were the Cu3Zr phase (Kawakatsu et al., 1967), but only with the development of electron micro scopy was the Cu5Zr phase determined (Lou and Grant, 1984; Holzwarth and Stamm, 2000; Watanabe et al., 2008). As computer science developed, researchers could use thermodynamic models and first principles to verify the relative stability of some precipitates. For example, the relative stability of Cu5Zr and Cu51Zr14at low temperature can be verified through experiments and first-principle calculations (Zhou and Napolitano, 2010), and they also found that decomposition of Cu5Zr→Cu51Zr14+Cu occurred in the temperature range of 802–955 K. At the same time, it was pointed out that the previously proposed Cu5Zr8(Zaitsev et al., 2003) was an unstable phase. These precipitates are displayed in the phase diagram updated by Okamoto (Fig. 7).

Fig. 9 TEM photos of Cu-Zr alloy: bright-field images with crystal band axis of [011]Cu (a) and [112]Cu (b); electron diffraction pattern of selected area of Fig. 9b (c); high-resolution image of [112]Cu (d). Reprinted from (Peng et al., 2015b), Copyright 2015, with permission from Elsevier

Cu-Zr alloy is a promising system for developing new high-strength conductive copper alloys. Its microstructure and properties can be controlled by adding other elements or adopting other unique processes. Some experiments tried to add the rare earth element Y to Cu-0.2Zr, and prepared precipitation-strengthened Cu-0.2Zr-0.15Y alloy after solid-solution, rolling, and aging (Gao et al., 2019). After TEM observation, it was found that a large number of Cu10Zr7precipitates with a size of 5–8 nm. It can be seen that the addition of Y changed the types of precipitates in Cu-Zr alloy. Finally, the properties of samples were hardness of 145 HV and conductivity of 90.6% IACS. The existing research (Zhang et al., 2017) showed that rare earth elements could promote the grain refinement and increase the grain boundaries, to provide more sites for nucleation. Meanwhile, they used the phase-transformation dynamics method to analyze the rationality of the selected process parameters. The Cu-0.15Zr (%, mass fraction) alloy prepared by rapid solidification and the hot forging process overcame the macro-segregation phenomenon caused by low solidification rates in traditional casting methods, and exhibited a uniform and fine structure (Zhang et al., 2021). The group then carried out high-temperature annealing at 700 °C for 2 h. Ultimately, they found that Cu5Zr had a blocking effect on grain growth and that Zr-rich clusters had a strengthening effect. The conductivity of the samples reached a peak value of 88% IACS. It is clear that the Cu5Zr phase and Zr-rich clusters in Cu-Zr alloy have good thermal stability, which will enable researchers to study and improve the composition and process to develop more high-performance copper alloy systems.

3.3 Cu-Ni-Si alloys

Cu-Ni-Si alloy is a widely used precipitation-strengthened alloy. After solid-solution and aging treatment, Ni and Si elements precipitate to form the nano Ni-Si phase, which hinders migration of dislocations and improves the strength of the alloy. The precipitation of solute atoms reduces the scattering effect of electrons to improve conductivity (Krupińska et al., 2020). Therefore, Cu-Ni-Si alloy offers high strength and maintains excellent electrical conductivity. The alloy has been widely used in lead frames, electrical-contact devices, electro-elastic devices, and other applications (Zhang et al., 2014).

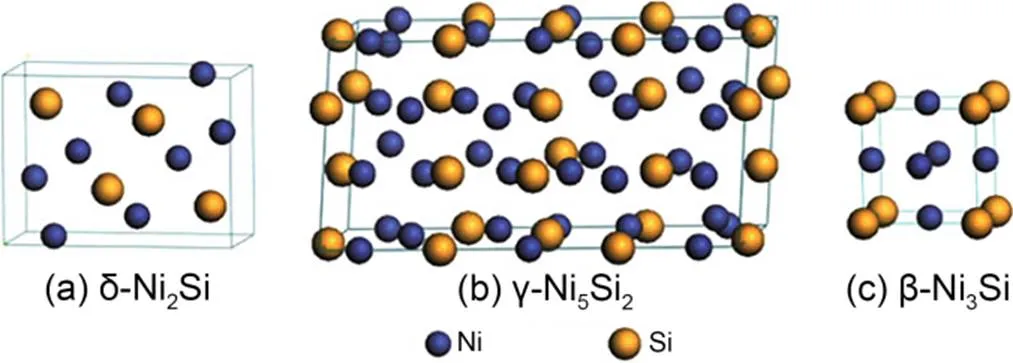

Precipitation has a decisive influence on the properties of Cu-Ni-Si alloys. The precipitate of Cu-Ni-Si alloy is generally considered to be a Ni-Si binary phase. Early study showed that the precipitate was δ-Ni2Si phase and the orientation relationship with Cu matrix was (100)Cu//(001)P, [001]Cu//[010]P(Lockyer and Noble, 1994). The calculation results verified this conclusion (Long et al., 2011), and the lattice constant of the δ-Ni2Si phase in cubic system was found to be=0.708 nm,=0.502 nm, and=0.371 nm (Hu et al., 2013). The structure of some precipitates that may appear in the alloy has been determined, as shown in Fig. 10. The actual precipitation behavior of Cu-Ni-Si alloy was studied experimentally (Zhao et al., 2003a, 2003b). During aging, the alloy first formed an amplitude-modulated structure with fluctuating concentration through amplitude-modulated decomposition, then nucleated and formed an ordered DO22 type (Cu, Ni)3Si phase, and finally transformed into a discoid δ-Ni2Si phase.

Fig. 10 Models of δ-Ni2Si (a), γ-Ni5Si2 (b), and β-Ni3Si (c) in Cu-Ni-Si alloy. Reprinted from (Long et al., 2011), Copyright 2021, with permission from Springer Nature

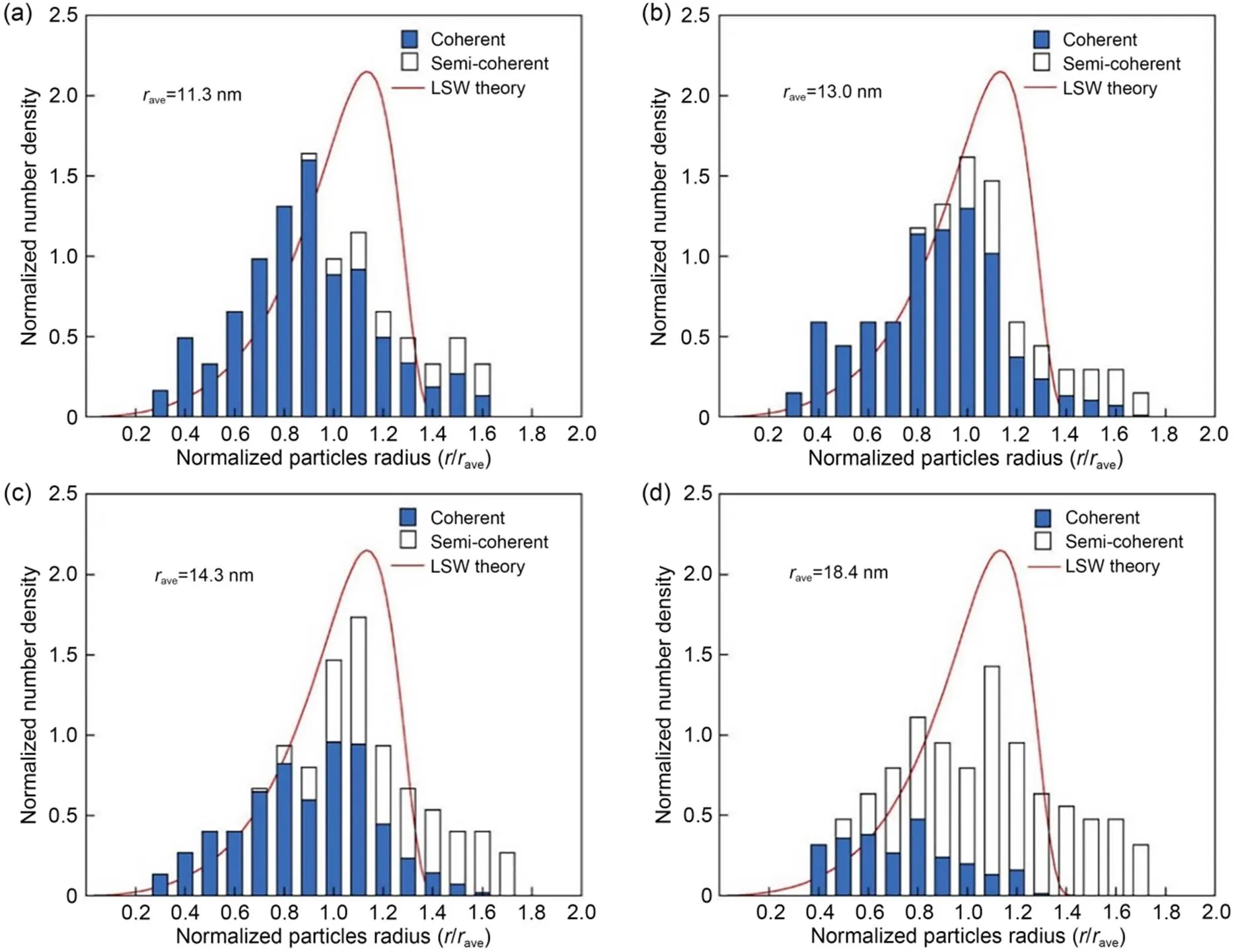

Fig. 11 Lifshitz-Slyozov-Wagner (LSW) theoretical distribution function and experimental results for (Ni, Co)2Si phase with different aging times at 500 °C: (a) 1 h; (b) 2 h; (c) 4 h; (d) 16 h. rave is the average radius of precipitates. Reprinted from (Xiao et al., 2019), Copyright 2019, with permission from Springer Nature

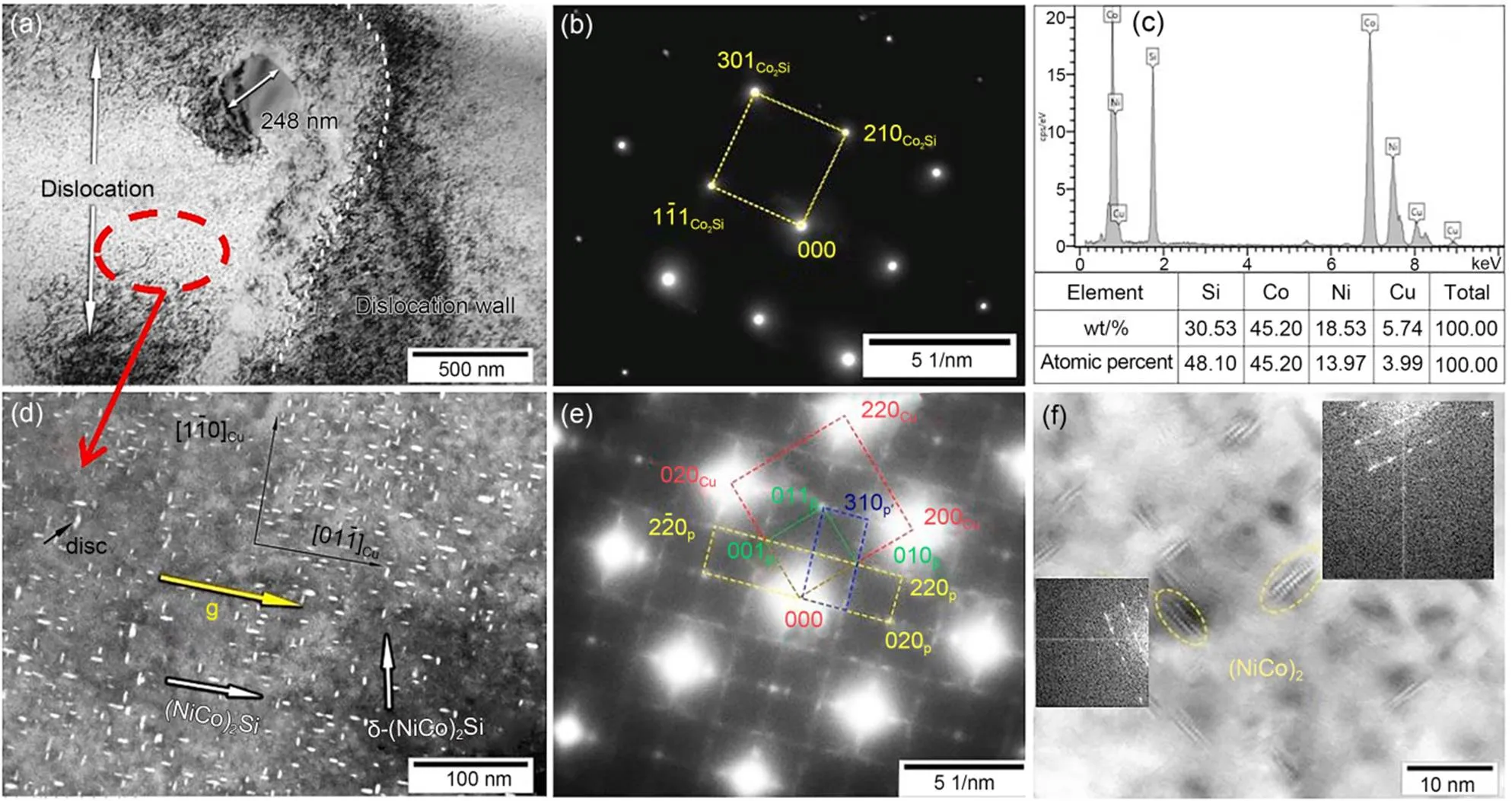

Because Cu-Ni-Si alloy has high strength, a non-toxic production process, and low requirements for production conditions, it is a cheap and high-performance Cu alloy with excellent market prospects. In recent years, two main approaches have been used to improve the comprehensive properties of the alloy: adding alloy elements and improving processing technology. Adding Co to Cu-2Ni-0.5Si alloy could form the (Ni, Co)2Si phase, promote precipitation of the Co2Si and Ni2Si phases, reduce the second phase spacing, increase dislocation density, and significantly improve strength and heat resistance (Izawa et al., 2014). After studying the secondary aging behavior and precipitate characteristics of Cu-Ni-Co-Si alloy (Feng et al., 2019), the results showed that the secondary aging produced a (Ni, Co)2Si phase with orthogonal structure as the primary aging, and the precipitate distribution of secondary aging was denser and more minor. These delicate and dense δ-(Ni, Co)2Si phases play the central strengthening role in the alloy. After studying the coarsening behavior of the (Ni, Co)2Si phase in Cu-Ni-Co-Si alloy after aging at different temperatures and times, Xiao et al. (2019) discovered that the critical particle radius of coherent mismatch of (Ni, Co)2Si phase was 10.3 nm, and the particle size distribution conformed to the Lifshitz-Slyozov-Wagner coarsening theoretical distribution (LSW distribution) (Fig. 11). Fig. 12 shows the clear morphology of the two kinds of precipitates obtained by using HRTEM (Zhao et al., 2019). The Co2Si phase usually presented large particles, while other phases were more dispersed and fine. Adding Co into Cu-Ni-Si alloy is expected to broaden the application prospect of the material further.

Fig. 12 TEM image of a Cu-1.5Ni-1.0Co-0.6Si alloy (a); electron diffraction pattern of the large particle in Fig. 12a (b); corresponding energy-dispersive spectrometer results (c); dark-field image showing nano-precipitates (d); corresponding electron diffraction pattern (e); high-resolution image of nano-precipitates (f). Reprinted from (Zhao et al., 2019), Copyright 2019, with permission from Elsevier

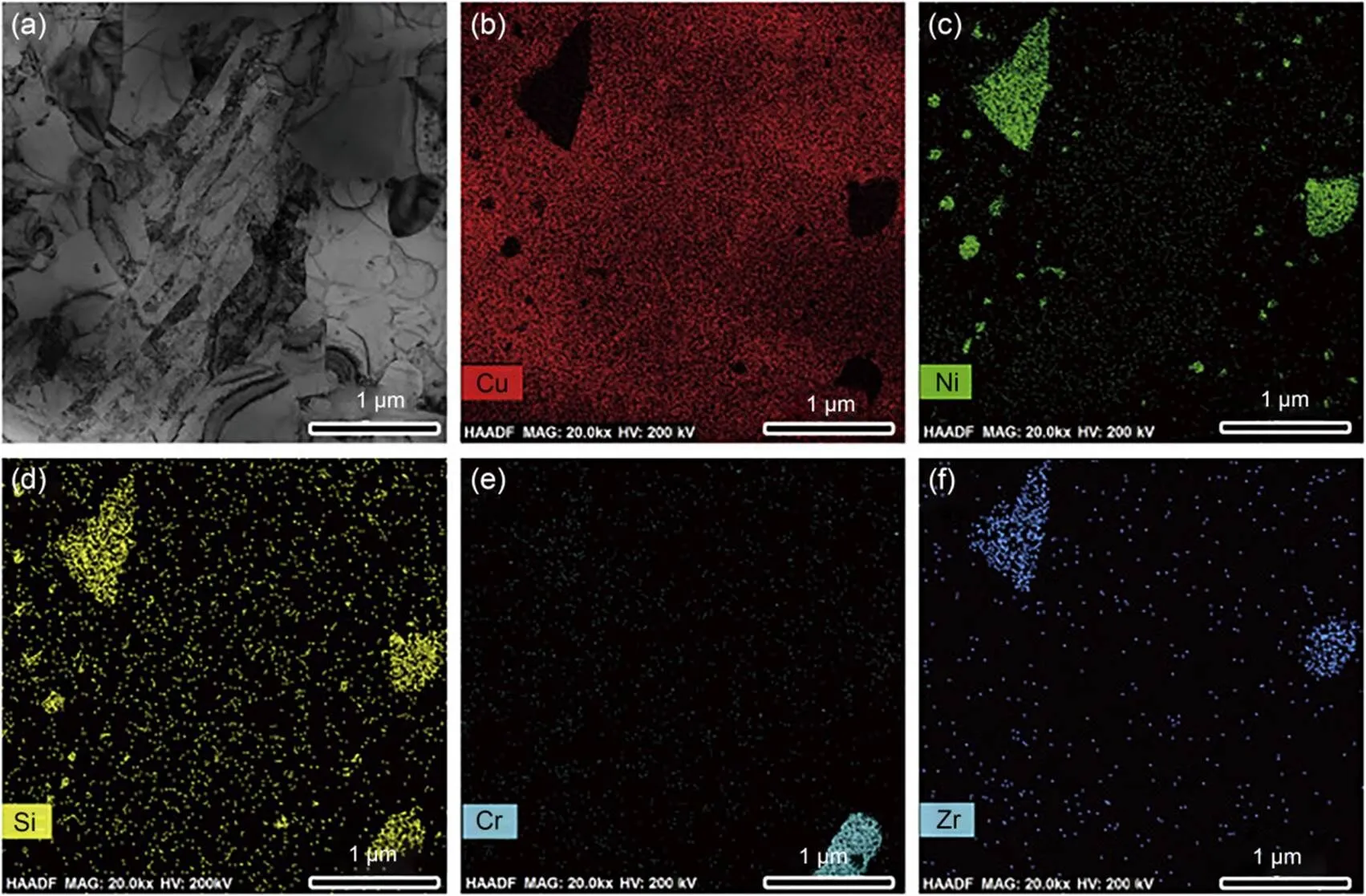

Some researchers added Cr and Zr elements into Cu-Ni-Si alloy and rolled them at liquid-nitrogen temperature (Wang et al., 2018). The microscopic results showed that the addition of Cr and Zr formed Cr3Si and Ni2SiZr phases in the alloy (Fig. 13). The remaining Cr and Zr elements were evenly distributed in the matrix. In addition, Ni and Si segregated at the interface to form the Ni2Si phase. The effects of Cr and Zr on the precipitates can compensate for each other to some extent. The former can refine the precipitates, inhibit the disappearance of dislocation, and improves the strength, but reduces the conductivity. The latter can promote the precipitation and growth of precipitates, reducing the strength of the alloy but improving its conductivity. However, when studied the fatigue properties of Cu-Ni-Si-Cr-Zr alloy, it was found that the addition of Cr and Zr can improve the strength (Atapek et al., 2020). Still, the precipitation of hardcore will adversely affect the fatigue properties of the material and establish a location for crack formation.

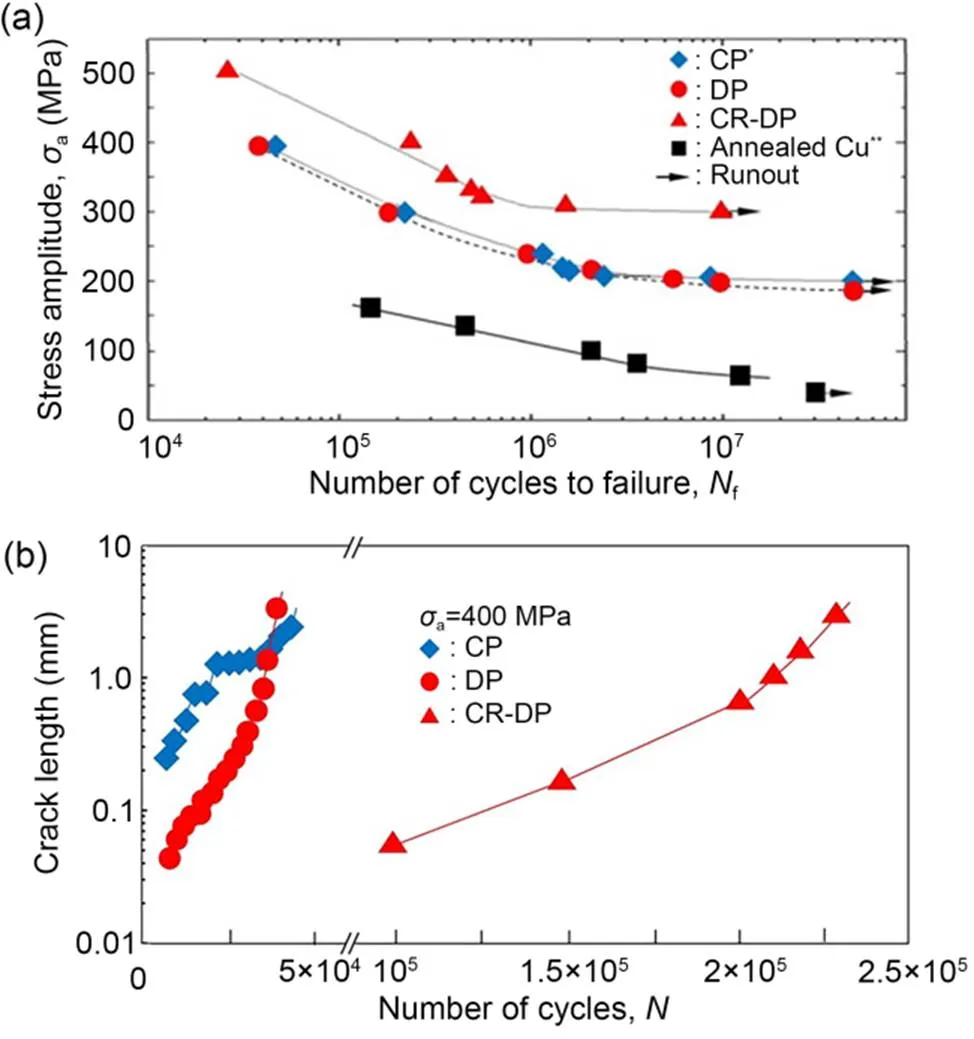

The precipitates in Cu-Ni-Si alloy can also be controlled by an appropriate preparation process. Researchers explored the microstructure of Cu-Ni-Si alloy after heat treatment, especially the morphology, quantity, and size of Ni-Si precipitates (Xie et al., 2020). The results showed that solid-solution, hot forging, and aging could make the Ni3Si phase at the grain boundary and the δ-Ni2Si phase in the Cu matrix more evenly dispersed and more delicate, to improve the electrical breakdown performance of the alloy. A method to guide the processing parameters of Cu-Ni-Si alloy based on thermal simulation and calculation was summarized and proposed (Zhang et al., 2019). The effects of primary cold rolling and secondary cold rolling on the properties of Cu-Ni-Si alloy were compared (Jiang et al., 2020). The results showed that precipitates in the alloy would break and re-dissolved into the matrix during the second cold rolling, so finer and more dispersed precipitates could be obtained during the second aging. Discontinuous precipitation occurred in the Cu-Ni-Si alloy. Under normal conditions, the discoid δ-Ni2Si phase obtained by continuous precipitation in the alloy was fine and dispersed, which could dramatically hinder dislocations and improve the strength of the Cu-Ni-Si. However, discontinuous precipitation may occur in the over-aging grain or large deformation (Han et al., 2018), resulting in significant fibrous δ-Ni2Si phases, which greatly reduce the strength. The orthogonal types of the two δ-Ni2Si precipitates are the same. Still, the discontinuous precipitation has micro-scale fibers consistent with the crystal orientation, and has a preferential extension direction on the (111)Cuplane. It even replaces the formed continuous δ-Ni2Si phase (Semboshi et al., 2016). Therefore, selecting appropriate processes and parameters to avoid discontinuous precipitation is very important for preparing high-strength Cu-Ni-Si alloy. In addition, the discontinuous precipitation of Ni2Si phase will also occur during cold rolling of pre-aged Cu-Ni-Si alloy (Goto et al., 2021). They found that its strength (Fig. 14a) and fatigue properties (Fig. 14b) were better than those of the original sample (annealed Cu). Its conductivity also rebounded to a certain extent. Using the sub-rapid solidification characteristics of twin-roll thin-strip continuous casting, a Cu-Ni-Si alloy with fine grain and no micro-segregation was prepared (Cao et al., 2021). Electric-pulse aging treatment was also used for the preparation of Cu-Ni-Si alloys (Zhu et al., 2021). Compared with the conventional heating-furnace aging method, when the properties of the obtained alloy were the same, the electric-pulse-aged sample only needed lower temperature and less time. The main reason was that the local Joule heat and drift electrons generated by electric pulse caused kinetic energy conversion, which increased the migration rate of solute atoms and reduced the energy barrier of the precipitation process. Finally, it accelerated the formation of precipitation. Electric-pulse aging is expected to be an ideal process for preparing high-strength conductive Cu alloys.

Fig. 13 Scanning TEM image (a) and element maps of Cu (b), Ni (c), Si (d), Cr (e), and Zr (f) of a Cu-Ni-Si-Cr-Zr alloy. Reprinted from (Wang et al., 2018), Copyright 2018, with permission from Elsevier

Fig. 14 Stress amplitude-number curves (a) and crack-growth curves (b) of continuous precipitate (CP) samples, discontinuous precipitate samples (DP), and cold-rolled discontinuous precipitate samples (CR-DP). * Goto et al., 2019. ** Goto et al., 2008. σa is the stress amplitude, which is half of the difference between the maximum stress and the minimum stress of the applied load. Reprinted from (Goto et al., 2021), Copyright 2021, with permission from Elsevier

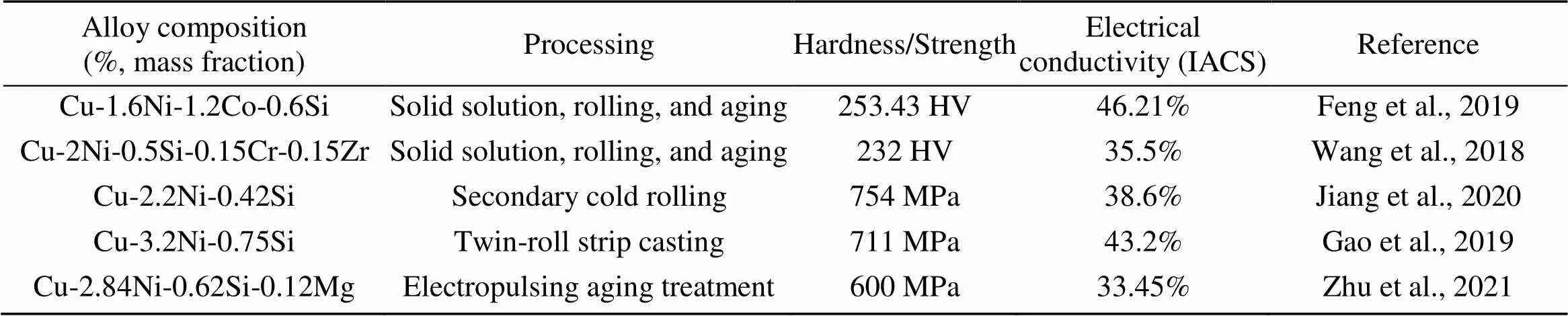

Table 3 lists the properties of some alloys mentioned above. The strength of Cu-Ni-Si alloy is its advantage compared with other systems, but its poor conductivity limits the improvement of its comprehensive properties. Therefore, finding a way to control the conductivity of the alloy by means of the critical factor of the Ni-Si binary phase is a compelling entry point. On the one hand, other elements could be added to promote the precipitation of alloying elements.

On the other hand, new technology could be used to regulate the precipitated phases of the alloy.

3.4 Cu-Fe-P alloys

Cu-Fe-P alloy has become the most widely used material for lead frames because of its excellent performance, low cost, and ease of processing. The solubility of Fe in Cu decreases significantly with decreasing temperature, which is conducive to obtaining fine dispersed precipitates. While the addition of Fe can refine the grain and delay the recrystallization process, too much Fe will seriously affect the conductivity of the alloy. The precipitates formed after the addition of P are mainly Fe, Fe2P, and Fe3P, which can hinder the dislocation movement and have a strengthening effect. The type of precipitates depends on the content ratios of Fe and P (Geng et al., 2020a). Fig. 15 shows calculated phase diagrams of the Cu-rich angle of Cu-Fe-P alloy at 1000 °C and 700 °C and summarizes various possible precipitates.

Table 3 Properties of some Cu-Ni-Si alloys mentioned above and their compositions and processes

Fig. 15 Calculated phase diagrams of Cu-Fe-P at 1000 °C (a) and 700 °C (b). Reprinted from (Raghavan, 1998), Copyright 1998, with permission from Springer Nature

As the Cu-Fe-P system is relatively mature in terms of application, the exploration of the system in recent years has mainly looked at its unique properties and mechanism. The addition of B and Ce in Cu-Fe-P alloy affects corrosion resistance (Zou et al., 2016). The results from this study showed that the addition of B promoted grain refinement and increased grain boundaries, so that corrosion resistance was reduced. At the same time, it was easy to combine Ce with O, S, H, and other elements in the material to form compounds and then discharge the system so as to purify it and improve corrosion resistance. High-performance Cu-Fe-P alloy could be successfully prepared by alloying and hot pressing (Han et al., 2019). They found that the alloy had ultra-fine grain and nanocrystalline structure. The results showed that P only reduced the solubility of Fe in Cu without forming Fe2P or Fe3P phases with Fe. And thanks to the ultra-fine grains in the alloy, the tensile strength of Cu-Fe-P alloy was 517 MPa, and the conductivity was maintained at about 80% IACS, which was far better than the traditional system. The effect of C addition on the microstructure of as-cast Cu-Fe-P alloy was systematically studied (Chen et al., 2019). The results showed that the addition of C could refine the matrix structure and Fe particles, helped to decompose the supersaturated solid solution and promote the precipitation of Fe. Some researchers focused on the martensitic transformation of Fe phases in Cu-Fe-P alloy (Du et al., 2020). The results showed that when external stress aging, the element Fe will undergo a martensitic transformation during precipitation, specifically reflected in the change of the orientation relationship between Fe precipitates and the matrix. The changes in Fe3P and Fe particles during solid-solution treatment of as-cast Cu-Fe-P can be observed by simulation (Papaefthymiou et al., 2018). The group found that only when the temperature was higher than 1000 °C could all the particles dissolve into the matrix.

Cu-Fe-P alloy also faces limitations in large-scale application, such as possible magnetism and low strength. Adding some alloying elements, such as Ti, can form a compound precipitate Fe2Ti phase (or FeTi phase) with excess Fe in alloys, which may be a way to prevent magnetism. Inhibiting the growth of precipitates and grains is the key to improving the strength of Cu-Fe-P alloys.

4 Promising systems

The research progress on some mature precipitation-strengthened Cu alloys in terms of exploration of precipitates is described above, and these systems have been widely used in production. However, there is no end to the development and performance improvement of high-strength conductive copper alloys. Below, we outline several alloy systems with development potential, including some work done by our research group in recent years.

4.1 Cu-Co-Si alloys

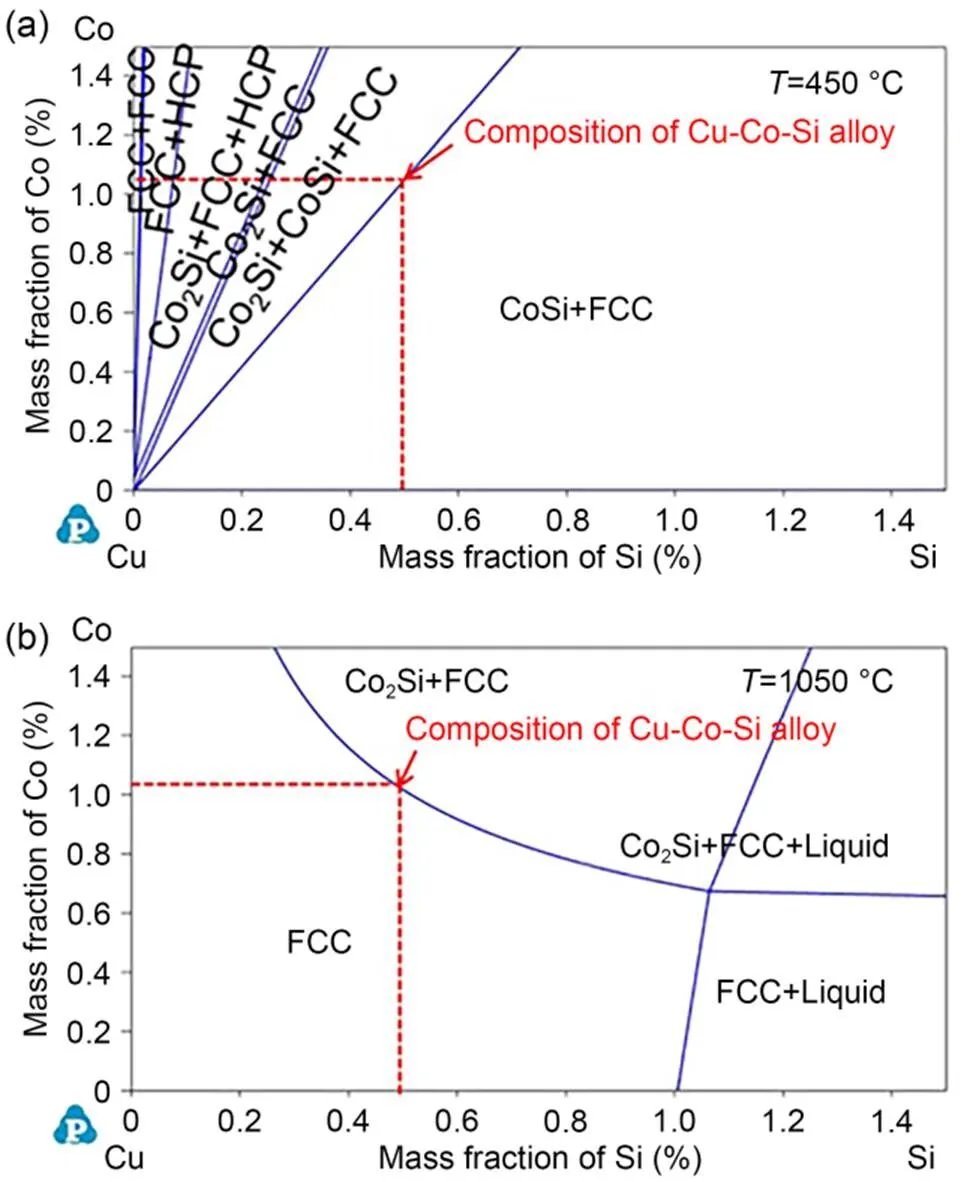

One disadvantage of Cu-Ni-Si alloys is that the content of Ni and Si is difficult to control, and the remaining dissolved Ni drastically affects electrical conductivity (Li et al., 2019). Therefore, we developed Cu-Co-Si into a new precipitation-strengthened copper alloy. The precipitates that play a major strengthening role in Cu-Co-Si are the Co2Si phase with an orthogonal structure similar to Ni2Si and the CoSi phase with a cubic structure. The ternary phase diagrams of Cu-Co-Si alloy at the Cu-rich corner were calculated by Pandat software (Fig. 16), and the appropriate composition point was used to obtain Cu-1.06Co-0.45Si (Lei et al., 2021).

Fig. 16 Calculated ternary phase diagrams of the Cu-rich corner of Cu-Co-Si alloy at 450 °C (a) and 1050 °C (b). HCP: hexagonal lose-packed. Reprinted from (Lei et al., 2021), Copyright 2021, with permission from Springer Nature

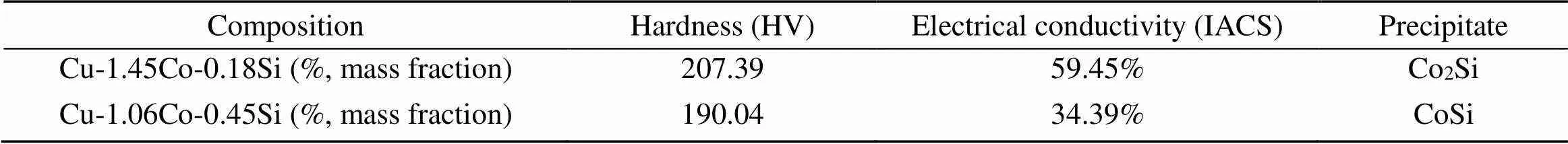

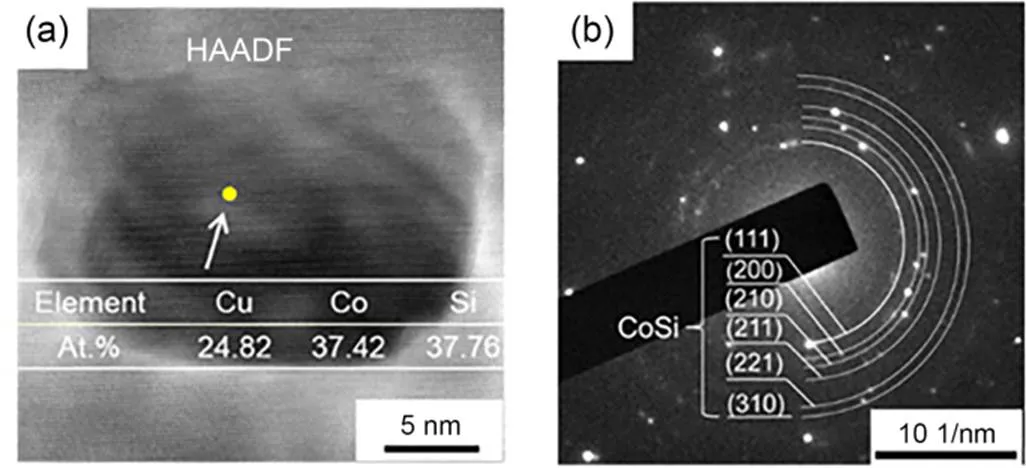

The hardness and electrical conductivity of the Cu-Co-Si alloy after solution strengthening, cold rolling, and aging heat treatment reached 190 HV and 30% IACS, respectively. The specific data are shown in Table 4. We attribute the high hardness of the Cu-1.06Co-0.45Si alloy to the CoSi phase coherent with the copper matrix. The high-angle annular dark-field image of the CoSi phase is shown in Fig. 17.

Table 4 Actual contents, precipitates, and properties of Cu-Co-Si alloys

Using machine learning and computational phase diagrams, we found that the various types of precipitates caused by compositional differences in Cu-Co-Si alloys significantly affect performance. Based on this, we developed a Cu-1.45Co-0.18Si alloy (207.39 HV and 59.45% IACS) with better comprehensive properties, which is mainly strengthened by the Co2Si phase (Zhao et al., 2022).

4.2 Cu-Co-Ti alloys

Cu-Ti is also a typical precipitation strengthening alloy system. Cu-Ti has a spinodal decomposition process during aging. The precipitates in the Cu-Ti alloys were investigated to be β'-Cu4Ti and β-Cu3Ti (Nagarjuna et al., 1997). Cu-Ti alloys have very high strength (>1 GPa) but poor conductivity (<30% IACS) (Nagarjuna et al., 1999). We can learn that Co and Ti can form CoTi2, CoTi, Co2Ti, and Co3Ti intermetallics, according to a Co-Ti binary phase diagram (van der Straten et al., 1976). The researchers added Co and Ti to Cu simultaneously to explore whether the Cu-Co-Ti alloy could precipitate CoTi compounds, and thus reduce the deterioration effects of Co and Ti on electrical conductivity.

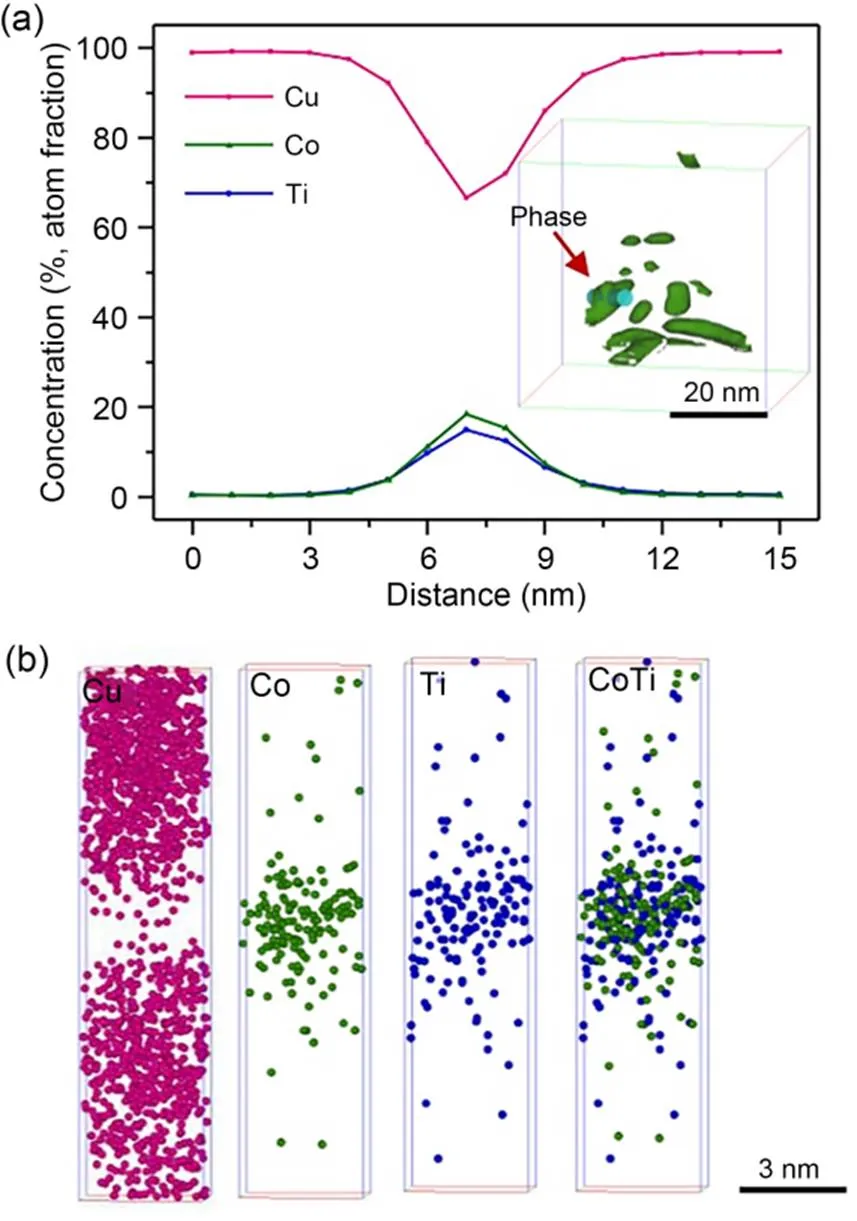

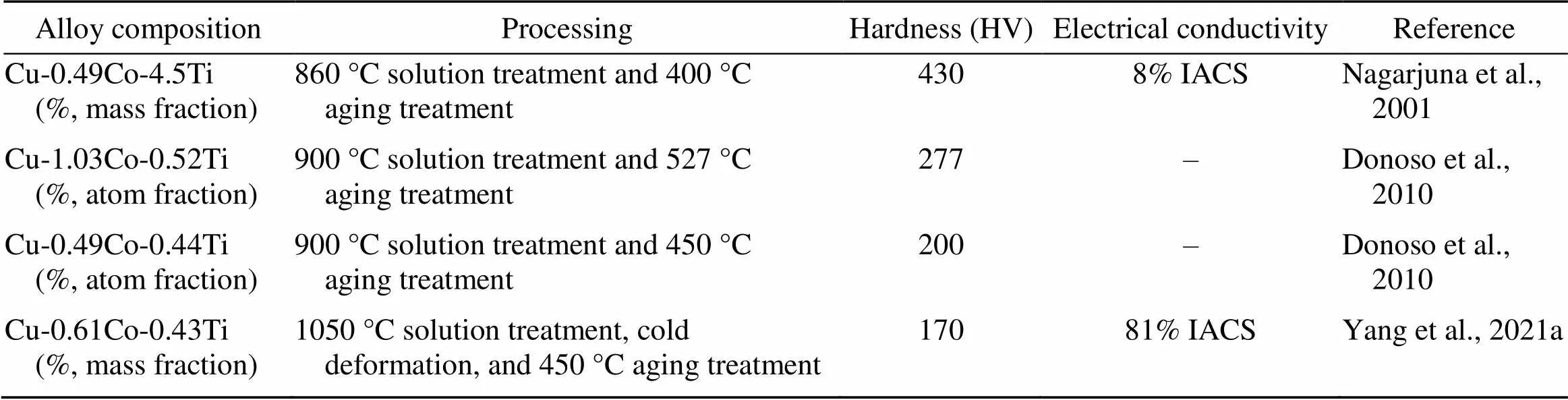

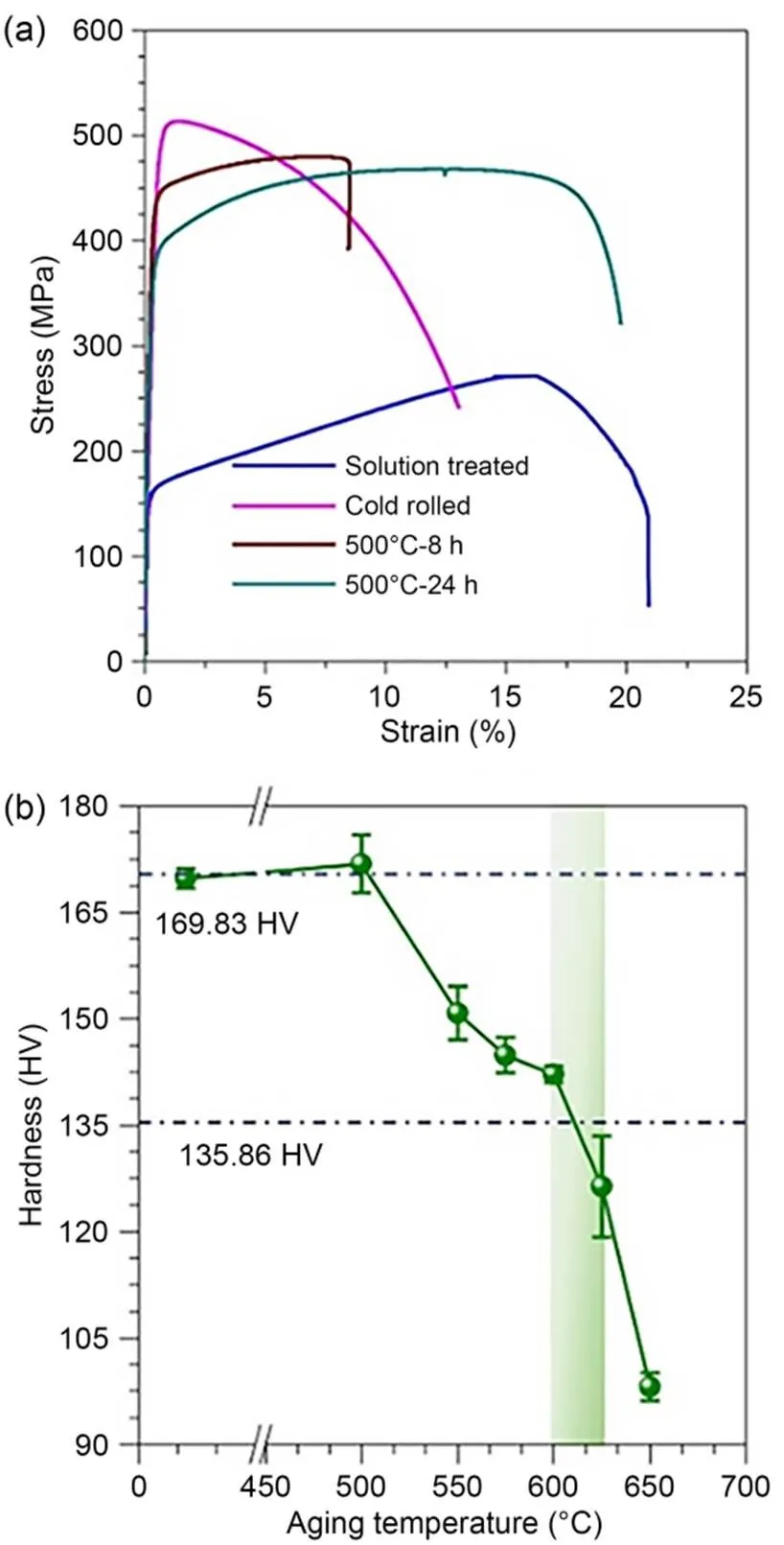

Some researchers have suggested that the precipitates should be CoTi phases in the Cu-0.49Co-0.44Ti (%, atom fraction) alloy and CoTi and Co2Ti phases in the Cu-1.03Co-0.52Ti (%, atom fraction) alloy, based on differential scanning calorimetry analysis (Donoso et al., 2010). The addition of a small amount of Co could inhibit the precipitation of Cu3Ti, which was the overaged phase of the Cu-4.5Ti (%, mass fraction) alloy, thus delayed over-aging (Nagarjuna et al., 2001). This phenomenon was proved by others in the Cu-4.0Ti-0.5Co (%, mass fraction) alloy (Batra et al., 2005). In 2021, we found that CoTi compounds precipitate in Cu-0.61Co-0.43Ti (%, mass fraction) alloy (Fig. 18) (Yang et al., 2021a). As for the properties of the Cu-Co-Ti alloy, Table 5 lists some existing results. We also found that a strength of 480 MPa and an excellent softening temperature up to 600 °C were simultaneously obtained (Fig. 19), while the alloy retained a conductivity of 81% IACS, proving that Cu-Co-Ti is a potential high-performance system.

Fig. 17 HAADF image of a precipitate in the aged Cu-1Co-0.5Si alloy (a); electron diffraction pattern of the nano-precipitates (b). At.%: atom fraction. Reprinted from (Lei et al., 2021), Copyright 2021, with permission from Springer Nature

Fig. 18 Three-dimensional atom-probe results showing that CoTi compounds precipitate in a Cu-0.61Co-0.43Ti alloy. Reprinted from (Yang et al., 2021a), Copyright 2021, with permission from Elsevier. References to color refer to the online version of this figure

Table 5 Properties of some Cu-Co-Ti alloys and their compositions and processes

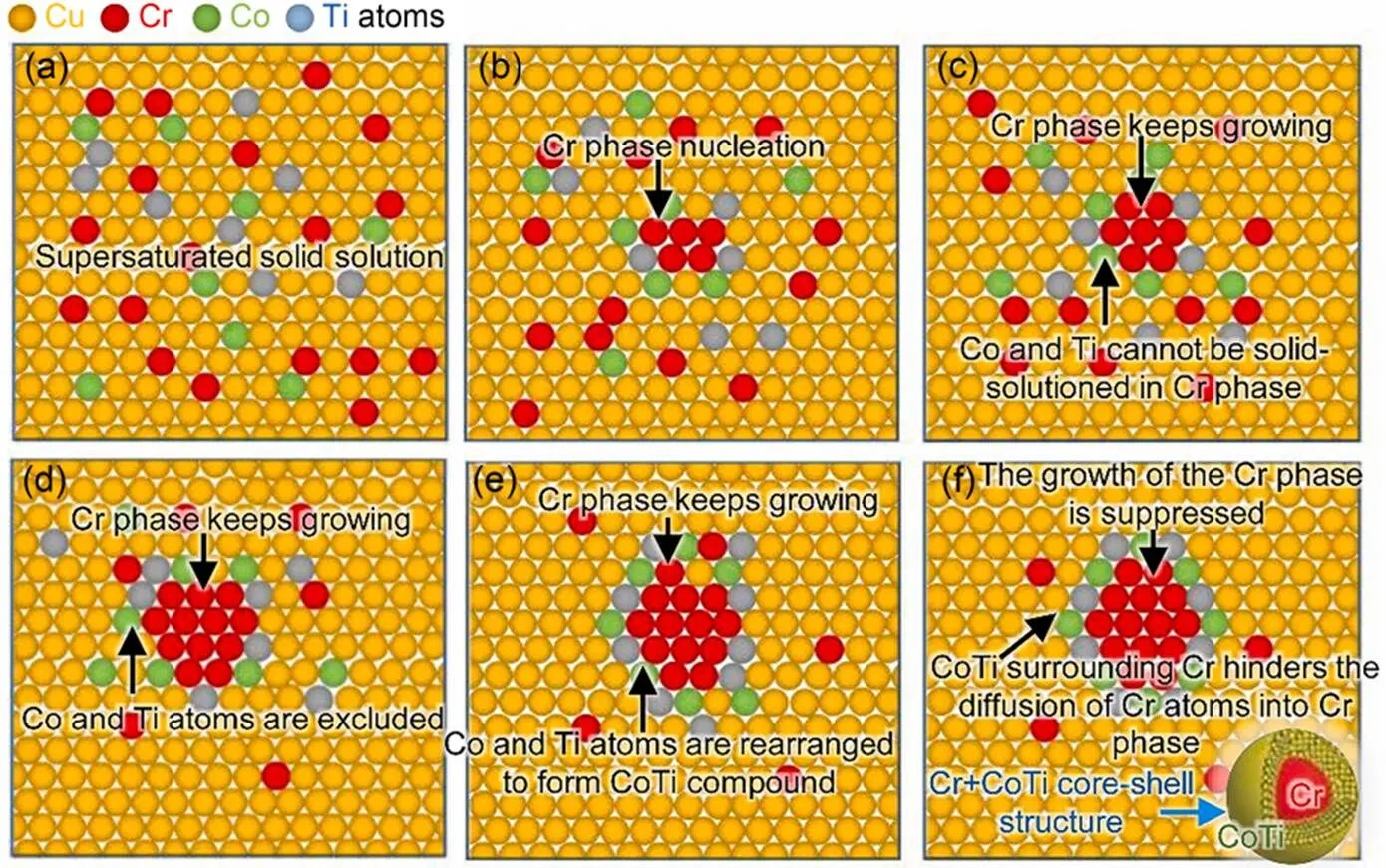

In addition, we studied the effect of adding Cr to Cu-Co-Ti alloy and discovered that a new mechanism improved the softening resistance of these alloys (Yang et al., 2022). As mentioned above, the growth of precipitates weakens the strengthening effect achieved. In Cu-Cr-Co-Ti alloy, the CoTi phase nucleated around the preferentially precipitated Cr phase, and finally formed the core-shell structure of CoTi/Cr (Fig. 20). The low diffusion rates of Co and Ti further inhibited the growth of precipitated phases. This study also provides a new idea for developing high-performance copper alloys: that the interaction of different precipitates can have a positive impact on alloy properties.

4.3 Cu-Fe-Ti alloys

Both Fe and Ti contribute significantly to deterioration of the electrical conductivity of Cu. According to the Fe-Ti phase diagram, Fe and Ti can combine into FeTi and Fe2Ti compounds (Raghavan, 2009). Currently, not much research is focused on the ternary Cu-Fe-Ti alloy. It was found that the main precipitates in Cu-0.8Fe-0.4Ti (%, atom fraction) and Cu-0.4Fe-0.4Ti (%, atom fraction) alloys were Fe2Ti and FeTi phases, respectively (Mineau et al., 1993). Our preliminary studies (Yang et al., 2021b; Zhao et al., 2021) also proved the precipitation of Fe-Ti compounds, as shown in Fig. 21. We prepared Cu-0.44Fe-0.23Ti and Cu-0.74Fe-0.33Ti alloys (%, mass fraction) with solid-solution, cold rolling, and aging. The tensile strength and conductivity of the former were 488 MPa and 78% IACS, respectively. The latter alloy achieved a tensile strength of 590 MPa and conductivity of 69% IACS.

Fig. 19 Tensile test curves of the Cu-0.61Co-0.43Ti alloy in different states (a); softening temperature test results of the alloy (b). Reprinted from (Yang et al., 2021a), Copyright 2021, with permission from Elsevier. References to color refer to the online version of this figure

These three systems provide a new direction for balancing the trade-off between strength and conductivity, and also offer some superior properties compared to common alloys, such as the softening resistance of Cu-Fe-Ti alloys. They deserve to be further studied with a view to large-scale application.

Fig. 20 Schematic diagram of formation process of CoTi/Cr core-shell structure in alloys. Reprinted from (Yang et al., 2022), Copyright 2022, with permission from Elsevier. References to color refer to the online version of this figure

5 Conclusions and prospect

High-strength conductive Cu alloys have been widely used in many fields with high performance requirements, and precipitation-strengthened Cu alloys represent an essential segment of this market. An important aspect of this research is finding ways to control the properties of each system. One can regulate properties by adding alloying elements or changing the preparation process, and use characterization technology and simulation methods to provide an understanding of the mechanisms involved. By summarizing the contents of this review, the current prospects of high-strength conductive Cu alloy with nanoprecipitates become clear:

(1) It is through the addition of different elements that a variety of high-performance Cu alloy systems can be developed. For example, Cu-Ni-Co-Si alloy with better comprehensive properties is a promising replacement for Cu-Ni-Si alloy as the next generation lead-frame material. By studying the effects of various elements on precipitates and microstructure, it should also be possible to find exciting mechanisms in different systems, such as purification of the matrix and grain refinement with rare earth elements.

(2) Recent science and technology will help us achieve unexpected changes in precipitates and properties. Rapid cooling of the melt can help to eliminate micro-segregation in Cu alloys. Plastic deformation before aging can promote precipitation, but it is necessary to avoid the re-dissolving of alloy elements caused by excessive deformation.

(3) High-strength conductive Cu alloys have many aspects worthy of in-depth exploration. However, conventional blind attempts lead to increased costs and reduced research efficiency. In recent years, the rising big data processing technology (such as machine learning, federal learning, and data mining), theoretical calculation, and mathematical simulation have proved effective in solving this problem.

(4) It is an open question how the co-existence of multiple precipitates in the Cu matrix affects the properties of an alloy. Research should be done to pinpoint positive interactions that improve the comprehensive properties over past experiments. For example, the Cu5Zr phase and Cr phase in the Cu matrix work together to produce a Cu-Cr-Zr alloy. The CoTi phase inhibits the growth of the Cr phase, thereby providing the Cu-Cr-Co-Ti alloy with excellent softening resistance. Positive interactions between different precipitates may be a promising way to improve the properties of Cu alloys.

This work is supported by the National Natural Science Foundation of China (Nos. 92266202, 51827810, and 51977193).

Jian YU wrote the first draft of the manuscript. Feng ZHAO and Huiya YANG helped supplement the content of Section 4. Feng ZHAO, Huiya YANG, and Jiabin LIU helped organize the manuscript. Youtong FANG and Jien MA helped revise the manuscript. Jiabin LIU revised and edited the final version.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Atapek ŞH, Pantelakis S, Polat Ş, et al., 2020. Fatigue behavior of precipitation strengthened Cu-Ni-Si alloy modified by Cr and Zr addition., 11(6):861-873. https://doi.org/10.1108/IJSI-11-2018-0080

Batawi E, Morris DG, Morris MA, 1990. Effect of small alloying additions on behaviour of rapidly solidified Cu-Cr alloys., 6(9):892-899. https://doi.org/10.1179/mst.1990.6.9.892

Batra IS, Laik A, Kale GB, et al., 2005. Microstructure and properties of a Cu-Ti-Co alloy., 402(1-2):118-125. https://doi.org/10.1016/j.msea.2005.04.015

Caldatto Dalan F, de Lima Andreani GF, Travessa DN, et al., 2022. Effect of ECAP processing on distribution of second phase particles, hardness and electrical conductivity of Cu-0.81Cr-0.07Zr alloy., 32(1):217-232. https://doi.org/10.1016/S1003-6326(21)65789-8

Cao GM, Zhang S, Chen J, et al., 2021. Microstructure and precipitate evolution in Cu-3.2Ni-0.75Si alloy processed by twin-roll strip casting., 30(2):1318-1329. https://doi.org/10.1007/s11665-020-05371-y

Chbihi A, Sauvage X, Blavette D, 2011. Atomic scale investigation of Cr precipitation in Cu and related mechanical properties., 172-174:291-296. https://doi.org/10.4028/www.scientific.net/SSP.172-174.291

Chen JQ, Su YH, Li Q, et al., 2021. Recent progress and perspective on copper alloy contact wire for high-speed electrified railways., 1(5):11-16 (in Chinese). https://doi.org/10.3969/j.issn.2097-017X.2021.05.003

Chen W, Hu XN, Guo W, et al., 2019. Effects of C addition on the microstructures of As-cast Cu-Fe-P alloys., 12(17):2772. https://doi.org/10.3390/ma12172772

Cheng TL, Wen YH, 2021. Phase-field model of precipitation processes with coherency loss., 7(1):36. https://doi.org/10.1038/s41524-021-00503-x

Donoso E, Zúñiga A, Diánez MJ, et al., 2010. Nonisothermal calorimetric study of the precipitation processes in a Cu-1Co-0.5Ti alloy., 100(3):975-980. https://doi.org/10.1007/s10973-009-0642-y

Du YB, Zhou YJ, Song KX, et al., 2020. Investigation of the retained austenite orientation in iron precipitates of martensitic transformation., 280:128556. https://doi.org/10.1016/j.matlet.2020.128556

Du YB, Zhou YJ, Song KX, et al., 2021. Zr-containing precipitate evolution and its effect on the mechanical properties of Cu-Cr-Zr alloys., 14:1451-1458. https://doi.org/10.1016/j.jmrt.2021.07.020

Faizova SN, Aksenov DA, Faizov IA, et al., 2021. Unusual kinetics of strain-induced diffusional phase transformations in Cu-Cr-Zr alloy., 11(2):218-222. https://doi.org/10.22226/2410-3535-2021-2-218-222

Feng GB, Yu FX, Cheng JY, et al., 2019. Re-aging behaviour and precipitated phase characteristics of high-performance Cu-Ni-Co-Si alloy., 40(8):76-83 (in Chinese). https://doi.org/10.13289/j.issn.1009-6264.2019-0122

Fine ME, Isheim D, 2005. Origin of copper precipitation strengthening in steel revisited., 53(1):115-118. https://doi.org/10.1016/j.scriptamat.2005.02.034

Gao LQ, Yang X, Zhang XF, et al., 2019. Aging behavior and phase transformation of the Cu-0.2 wt%Zr-0.15 wt%Y alloy., 159:367-373. https://doi.org/10.1016/j.vacuum.2018.10.054

Geng YF, Li X, Zhou HL, et al., 2020a. Effect of Ti addition on microstructure evolution and precipitation in Cu-Co-Si alloy during hot deformation., 821:153518. https://doi.org/10.1016/j.jallcom.2019.153518

Geng YF, Ban YJ, Wang BJ, et al., 2020b. A review of microstructure and texture evolution with nanoscale precipitates for copper alloys., 9(5):11918-11934. https://doi.org/10.1016/j.jmrt.2020.08.055

Goto M, Han SZ, Yakushiji T, et al., 2008., 30:1333-1344. https://doi.org/10.1016/j.ijfatigue.2007.11.001

Goto M, Yamamoto T, Han SZ, et al., 2019. Microstructure-dependent fatigue behavior of aged Cu-6Ni-1.5Si alloy with discontinuous/cellular precipitates., 747:63-72. https://doi.org/10.1016/j.msea.2019.01.057

Goto M, Yamamoto T, Han SZ, et al., 2021. Simultaneous increase in electrical conductivity and fatigue strength of Cu-Ni-Si alloy by utilizing discontinuous precipitates., 288:129353. https://doi.org/10.1016/j.matlet.2021.129353

Han LT, Liu JW, Tang HG, et al., 2019. Preparation and properties of ultra-fine-grained and nanostructured copper alloy with the addition of P., 221:322-331. https://doi.org/10.1016/j.matchemphys.2018.09.048

Han SZ, Ahn JH, You YS, et al., 2018. Discontinuous precipitation at the deformation band in copper alloy., 24(1):23-27. https://doi.org/10.1007/s12540-017-6626-8

Hatakeyama M, Toyama T, Nagai Y, et al., 2008. Nanostructural evolution of Cr-rich precipitates in a Cu-Cr-Zr alloy during heat treatment studied by 3 dimensional atom probe., 49(3):518-521. https://doi.org/10.2320/matertrans.MBW200736

Hatakeyama M, Toyama T, Yang J, et al., 2009. 3D-AP and positron annihilation study of precipitation behavior in Cu-Cr-Zr alloy., 386-388:852-855. https://doi.org/10.1016/j.jnucmat.2008.12.266

Hocker S, Rapp D, Schmauder S, 2017. Molecular dynamics simulations of strengthening due to silver precipitates in copper matrix., 254(5):1600479. https://doi.org/10.1002/pssb.201600479

Holzwarth U, Stamm H, 2000. The precipitation behaviour of ITER-grade Cu-Cr-Zr alloy after simulating the thermal cycle of hot isostatic pressing., 279(1):31-45. https://doi.org/10.1016/S0022-3115(99)00285-8

Hu T, Chen JH, Liu JZ, et al., 2013. The crystallographic and morphological evolution of the strengthening precipitates in Cu-Ni-Si alloys., 61(4):1210-1219. https://doi.org/10.1016/j.actamat.2012.10.031

Izawa K, Ozawa A, Kita K, et al., 2014. Influence of Co on strength and microstructure of Cu-Ni-Co-Si alloy.,, 63(5):401-408 (in Japanese). https://doi.org/10.2472/jsms.63.401

Jha K, Neogy S, Kumar S, et al., 2021. Correlation between microstructure and mechanical properties in the age-hardenable Cu-Cr-Zr alloy., 546:152775. https://doi.org/10.1016/j.jnucmat.2020.152775

Jia SG, Liu P, Ren FZ, et al., 2007. Sliding wear behavior of copper alloy contact wire against copper-based strip for high-speed electrified railways., 262(7-8):772-777. https://doi.org/10.1016/j.wear.2006.08.020

Jiang L, Fu HD, Wang CS, et al., 2020. Enhanced mechanical and electrical properties of a Cu-Ni-Si alloy by thermo-mechanical processing., 51(1):331-341. https://doi.org/10.1007/s11661-019-05507-3

Kawakatsu I, Suzuki H, Kitano H, 1967. Properties of high Zr, Cu-Zr-Cr alloys and the phase diagram at the Cu-rich corner., 31:1253-1257.

Kermajani M, Raygan S, Hanayi K, et al., 2013. Influence of thermomechanical treatment on microstructure and properties of electroslag remelted Cu-Cr-Zr alloy., 51:688-694. https://doi.org/10.1016/j.matdes.2013.04.062

Kim Y, Lee K, Cho YH, et al., 2016. Fatigue safety evaluation of newly developed contact wire for eco-friendly high speed electric railway system considering wear., 3(4):353-358. https://doi.org/10.1007/s40684-016-0044-0

Krupińska B, Rdzawski Z, Krupiński M, et al., 2020. Precipitation strengthening of Cu-Ni-Si alloy., 13(5):1182. https://doi.org/10.3390/ma13051182

Lai ZM, Mai YJ, Song HY, et al., 2022. Heterogeneous microstructure enables a synergy of strength, ductility and electrical conductivity in copper alloys., 902:163646. https://doi.org/10.1016/j.jallcom.2022.163646

Lei CH, Yang HY, Zhao F, et al., 2021. Effect of Co addition on hardness and electrical conductivity of Cu-Si alloys., 56(26):14821-14831. https://doi.org/10.1007/s10853-021-06251-z

Li J, Huang GJ, Mi XJ, et al., 2019. Influence of the Ni/Co mass ratio on the microstructure and properties of quaternary Cu-Ni-Co-Si alloys., 12(18):2855. https://doi.org/10.3390/ma12182855

Liu Y, Liu XL, Tian BH, 2011. Residual stresses distribution calculation of the Cu-Cr-Zr alloy contact wire used in high-speed electrical railway., 189-193:2076-2080. https://doi.org/10.4028/www.scientific.net/AMR.189-193. 2076

Liu YL, Zhou P, Liu SH, et al., 2017. Experimental investigation and thermodynamic description of the Cu-Cr-Zr system., 59:1-11. https://doi.org/10.1016/j.calphad.2017.07.002

Lockyer SA, Noble FW, 1994. Precipitate structure in a Cu-Ni-Si alloy., 29(1):218-226. https://doi.org/10.1007/BF00356596

Long YQ, Liu P, Liu Y, et al., 2011. First-principle investigation of the structural stability and electronic property of precipitates on the Cu-rich side of Cu-Ni-Si alloys., 16(3):266-271. https://doi.org/10.1007/s12204-011-1141-4

Lou MYW, Grant NJ, 1984. Identification of CuSu5Zr phase in Cu-Zr alloys., 15(7):1491-1493. https://doi.org/10.1007/BF02648579

Mineau L, Hamar-Thibault SJ, Allibert CH, 1993. Precipitation in Cu-rich Cu-Fe-Ti ternary alloys—a continuous process?, 137(1):87-100. https://doi.org/10.1002/pssa.2211370106

Nagai T, Henmi Z, Sakamoto T, et al., 1973. Effect of precipitates on recrystallisation temperature in Cu-Cr, Cu-Zr and Cu-Zr-Cr alloys., 14(6):462-469. https://doi.org/10.2320/matertrans1960.14.462

Nagarjuna S, Balasubramanian K, Sarma DS, 1997. Effect of prior cold work on mechanical properties and structure of an age-hardened Cu-1.5wt% Ti alloy., 32(13):3375-3385. https://doi.org/10.1023/A:1018608430443

Nagarjuna S, Balasubramanian K, Sarma DS, 1999. Effect of prior cold work on mechanical properties, electrical conductivity and microstructure of aged Cu-Ti alloys., 34(12):2929-2942. https://doi.org/10.1023/A:1004603906359

Nagarjuna S, Sharma KK, Sudhakar I, et al., 2001. Age hardening studies in a Cu-4.5Ti-0.5Co alloy., 313(1-2):251-260. https://doi.org/10.1016/S0921-5093(00)01834-7

Okamoto H, 2012. Cu-Zr (copper-zirconium)., 33(5):417-418. https://doi.org/10.1007/s11669-012-0077-1

Pan XX, Jiang HC, Feng H, et al., 2021. Evolution of precipitated phases in high strength and high electrical conductivity Cu-Cr-Zr alloy during aging., 46(7):7-12 (in Chinese). https://doi.org/10.13251/j.issn.0254-6051.2021.07.002

Papaefthymiou S, Bouzouni M, Gavalas E, 2018. Theoretical study of particle dissolution during homogenization in Cu-Fe-P alloy., 8(6):455. https://doi.org/10.3390/met8060455

Peng HC, Xie WB, Chen HM, et al., 2021. Effect of micro-alloying element Ti on mechanical properties of Cu-Cr alloy., 852:157004. https://doi.org/10.1016/j.jallcom.2020.157004

Peng LJ, Mi XJ, Xiong BQ, et al., 2015a. Microstructure of phases in a Cu-Zr alloy., 34(10):706-709. https://doi.org/10.1007/s12598-014-0324-1

Peng LJ, Xie HF, Huang GJ, et al., 2015b. The phase transformation and its effects on properties of a Cu-0.12wt% Zr alloy., 633:28-34. https://doi.org/10.1016/j.msea.2015.02.077

Raghavan V, 1998. Cu-Fe-P (Copper-Iron-Phosphorus)., 19(3):283-284. https://doi.org/10.1361/105497198770342454

Raghavan V, 2009. Fe-Ti-Y (iron-titanium-yttrium)., 30(4):397. https://doi.org/10.1007/s11669-009-9554-6

Salvan C, Briottet L, Baffie T, et al., 2021. CuCrZr alloy produced by laser powder bed fusion: microstructure, nanoscale strengthening mechanisms, electrical and mechanical properties., 826:141915. https://doi.org/10.1016/j.msea.2021.141915

Sarin VK, Grant NJ, 1979. Effect of thermomechanical treatments on powder metallurgy Cu-Zr and Cu-Zr-Cr alloys., 11(4):153-157.

Semboshi S, Sato S, Iwase A, et al., 2016. Discontinuous precipitates in age-hardening Cu-Ni-Si alloys., 115:39-45. https://doi.org/10.1016/j.matchar.2016.03.017

Shangina DV, Bochvar NR, Morozova AI, et al., 2017. Effect of chromium and zirconium content on structure, strength and electrical conductivity of Cu-Cr-Zr alloys after high pressure torsion., 199:46-49. https://doi.org/10.1016/j.matlet.2017.04.039

Szajewski BA, Crone JC, Knap J, 2020. Analytic model for the Orowan dislocation-precipitate bypass mechanism., 11:100671. https://doi.org/10.1016/j.mtla.2020.100671

Szajewski BA, Crone JC, Knap J, 2021. Dislocation precipitate bypass through elastically mismatched precipitates., 29(2):025005. https://doi.org/10.1088/1361-651X/abd015

van der Straten PJM, Bastin GF, van Loo FJJ, et al., 1976. Phase equilibria and interdiffusion in the cobalt-titanium system/phasengleichgewichte und diffusion im system kobalt-titan., 67(3):152-157. https://doi.org/10.1515/ijmr-1976-670303

Vinogradov A, Patlan V, Suzuki Y, et al., 2002. Structure and properties of ultra-fine grain Cu-Cr-Zr alloy produced by equal-channel angular pressing., 50(7):1639-1651. https://doi.org/10.1016/S1359-6454(01)00437-2

Wang JF, Chen JS, Guo CJ, et al., 2020. Low cycle fatigue behavior of precipitation-strengthened Cu-Cr-Zr contact wires., 137:105642. https://doi.org/10.1016/j.ijfatigue.2020.105642

Wang L, Martin D, Chen WY, et al., 2021. Effect of sink strength on coherency loss of precipitates in dilute Cu-base alloys during in situ ion irradiation., 210:116812. https://doi.org/10.1016/j.actamat.2021.116812

Wang QJ, Liu F, Du ZZ, et al., 2013. Hot-compression deformation behavior of Cu-Cr-Zr alloy., 37(5):687-694 (in Chinese).

Wang W, Guo EY, Chen ZN, et al., 2018. Correlation between microstructures and mechanical properties of cryorolled CuNiSi alloys with Cr and Zr alloying., 144:532-546. https://doi.org/10.1016/j.matchar.2018.08.003

Wang YP, Fu RD, Li YJ, et al., 2019. A high strength and high electrical conductivity Cu-Cr-Zr alloy fabricated by cryogenic friction stir processing and subsequent annealing treatment., 755:166-169. https://doi.org/10.1016/j.msea.2019.04.004

Watanabe C, Monzen R, Tazaki K, 2008. Mechanical properties of Cu-Cr system alloys with and without Zr and Ag., 43(3):813-819. https://doi.org/10.1007/s10853-007-2159-8

Wegener T, Koopmann J, Richter J, et al., 2021. CuCrZr processed by laser powder bed fusion—processability and influence of heat treatment on electrical conductivity, microstructure and mechanical properties., 44(9):2570-2590. https://doi.org/10.1111/ffe.13527

Xiao JH, Yan ZQ, Shi J, et al., 2022. Effects of wheel-rail impact on the fatigue performance of fastening clips in rail joint area of high-speed railway., 26(1):120-130. https://doi.org/10.1007/s12205-021-1905-9

Xiao XP, Xu H, Chen JS, et al., 2019. Coarsening behavior of (Ni, Co)2Si particles in Cu-Ni-Co-Si alloy during aging treatment., 38(11):1062-1069. https://doi.org/10.1007/s12598-018-1169-9

Xie H, Jia L, Tao SP, et al., 2020. Regulation of Ni–Si intermetallics in Cu-Ni-Si alloys and its influence on electrical breakdown properties., 31(4):3137-3145. https://doi.org/10.1007/s10854-020-02860-7

Yan M, Wu YC, Chen JC, et al., 2011. Microstructure evolution in preparation of Cu-Sn contact wire for high-speed railway., 415-417:446-451. https://doi.org/10.4028/www.scientific.net/AMR.415-417. 446

Yang HY, Ma ZC, Lei CH, et al., 2020. High strength and high conductivity Cu alloys: a review., 63(12):2505-2517. https://doi.org/10.1007/s11431-020-1633-8

Yang HY, Bu YQ, Wu JM, et al., 2021a. CoTi precipitates: the key to high strength, high conductivity and good softening resistance in Cu-Co-Ti alloy., 176:111099. https://doi.org/10.1016/j.matchar.2021.111099

Yang HY, Li KQ, Bu YQ, et al., 2021b. Nanoprecipitates induced dislocation pinning and multiplication strategy for designing high strength, plasticity and conductivity Cu alloys., 195:113741. https://doi.org/10.1016/j.scriptamat.2021.113741

Yang HY, Bu YQ, Wu JM, et al., 2022. Nanocompound-induced anti-softening mechanisms: application to CuCr alloys., 841:143038. https://doi.org/10.1016/j.msea.2022.143038

Yang Y, Wang L, Snead L, et al., 2018. Development of novel Cu-Cr-Nb-Zr alloys with the aid of computational thermodynamics., 156:370-380. https://doi.org/10.1016/j.matdes.2018.07.003

Zaitsev AI, Zaitseva NE, Alexeeva JP, et al., 2003. Thermodynamics and amorphization of the copper–zirconium alloys., 5(19):4185-4196. https://doi.org/10.1039/B305089K

Zeng KJ, Hämäläinen M, 1995. A theoretical study of the phase equilibria in the Cu-Cr-Zr system., 220(1-2):53-61. https://doi.org/10.1016/0925-8388(94)06029-0

Zhang JL, Lu ZL, Jia L, et al., 2019. Hot deformation behavior of Cu-Ni-Si alloy at elevated temperature., 6(8):086590. https://doi.org/10.1088/2053-1591/ab1fb9

Zhang Y, Lu MM, Hu YY, et al., 2014. Development and study of Cu-Ni-Si alloy for lead frame., 35(4):177-182 (in Chinese). https://doi.org/10.13258/j.cnki.snm.2014.04.009

Zhang Y, Sun HL, Volinsky AA, et al., 2017. Small Y addition effects on hot deformation behavior of copper-matrix alloys., 19(12):1700197. https://doi.org/10.1002/adem.201700197

Zhang ZC, Wang RC, Peng CQ, et al., 2021. Effect of elevated-temperature annealing on microstructureand properties of Cu-0.15Zr alloy., 31(12):3772-3784. https://doi.org/10.1016/S1003-6326(21)65763-1

Zhao DM, Dong QM, Liu P, et al., 2003a. Aging behavior of Cu-Ni-Si alloy., 361(1-2):93-99. https://doi.org/10.1016/S0921-5093(03)00496-9

Zhao DM, Dong QM, Liu P, et al., 2003b. Structure and strength of the age hardened Cu-Ni-Si alloy., 79(1):81-86. https://doi.org/10.1016/S0254-0584(02)00451-0

Zhao F, Lei CH, Zhao QK, et al., 2022. Predicting the property contour-map and optimum composition of Cu-Co-Si alloys via machine learning., 30:103138. https://doi.org/10.1016/j.mtcomm.2022.103138

Zhao QK, Yang HY, Liu JB, et al., 2021. Machine learning-assisted discovery of strong and conductive Cu alloys: data mining from discarded experiments and physical features., 197:109248. https://doi.org/10.1016/j.matdes.2020.109248

Zhao Z, Zhang Y, Tian BH, et al., 2019. Co effects on Cu-Ni-Si alloys microstructure and physical properties., 797:1327-1337. https://doi.org/10.1016/j.jallcom.2019.05.135

Zhou M, Peng YH, An L, 2022. Technical advances, innovation and challenges of developing high-speed rail in China., 175(2):79-86. https://doi.org/10.1680/jcien.21.00149

Zhou SH, Napolitano RE, 2010. Phase stability for the Cu-Zr system: first-principles, experiments and solution-based modeling., 58(6):2186-2196. https://doi.org/10.1016/j.actamat.2009.12.004

Zhu J, Lin Y, Liu S, et al., 2021. Electropulsing aging treatment of Cu-Ni-Si sheet for microforming., 23(8):2100249. https://doi.org/10.1002/adem.202100249

Zou J, Lu L, Lu DP, et al., 2016. Effect of boron and cerium on corrosion resistance of Cu-Fe-P alloy., 25(3):1062-1067. https://doi.org/10.1007/s11665-016-1918-6

Jien MA, majien@zju.edu.cn

Jien MA, https://orcid.org/0000-0001-9080-8668

Aug. 20, 2022;

Revision accepted Sept. 14, 2022;

Crosschecked Feb. 8, 2023

© Zhejiang University Press 2023

Journal of Zhejiang University-Science A(Applied Physics & Engineering)2023年3期

Journal of Zhejiang University-Science A(Applied Physics & Engineering)2023年3期

- Journal of Zhejiang University-Science A(Applied Physics & Engineering)的其它文章

- High-speed railway transport technology

- Recent advances in traction drive technology for rail transit

- Impact of extreme climate and train traffic loads on the performance of high-speed railway geotechnical infrastructures

- Adaptive cropping shallow attention network for defect detection of bridge girder steel using unmanned aerial vehicle images

- Adaptive fault-tolerant control of high-speed maglev train suspension system with partial actuator failure: design and experiments

- Effect of low operating temperature on the aerodynamic characteristics of a high-speed train