Impact of extreme climate and train traffic loads on the performance of high-speed railway geotechnical infrastructures

Ying WU, Haoran FU, Xuecheng BIAN, Yunmin CHEN

Review

Impact of extreme climate and train traffic loads on the performance of high-speed railway geotechnical infrastructures

1MOE Key Laboratory of Soft Soils and Geoenvironmental Engineering, Zhejiang University, Hangzhou 310058, China2Department of Civil Engineering, Zhejiang University, Hangzhou 310058, China

High-speed railways are very important in global transportation. However, the railway subgrade is significantly affected by the environment due to its exposure to the atmosphere. At present, global warming is the primary trend in world climate change and seriously damages railway infrastructure. Owing to the coupling effect of extreme environmental and train loads, various subgrade problems tend to arise, such as settlement, ballast fouling, and mud pumping, thus inducing frequent railway accidents and reducing travel safety. Insights into the problems triggered by extreme climate and train loads are critical to the design and long-term operation of high-speed railway subgrades. This study therefore presents a detailed survey of recent advances in typical subgrade problems through analyzing the problem formation mechanisms and influences. Traditional and emerging detection/monitoring technologies in respect of subgrade problems are discussed in detail, as well as pre-accident and post-accident maintenance methods. Finally, according to the existing challenges in long-term subgrade shakedown assessment, an outlook on open opportunities is provided for future research.

High-speed railways; Subgrade performance; Train loads; Extreme climate

1 Introduction

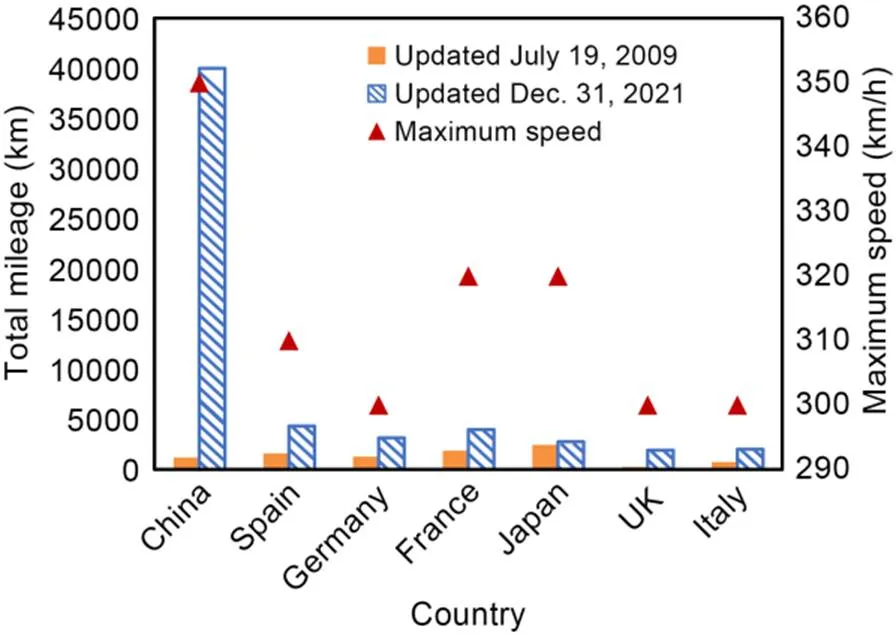

In recent years, as a form of fast and environmentally friendly mass transportation, high-speed railways have rapidly developed globally to meet the growing requirements for transport of freight and people. The total mileages of high-speed railways in China, Spain, Germany, etc., increased significantly from 2009 to 2021, with the maximum speed of traditional wheeled vehicles in daily operation varying from 300 to 350 km/h (Fig. 1). The operation of maglev trains is not considered here. It is noteworthy that trains can reach higher speeds in tests, e.g., the China high-speed train CRH380A exceeded 400 km/h in experiments (Zhai et al., 2015). However, such high speeds in long-term operation would decrease subgrade performance, thereby increasing railway accidents.

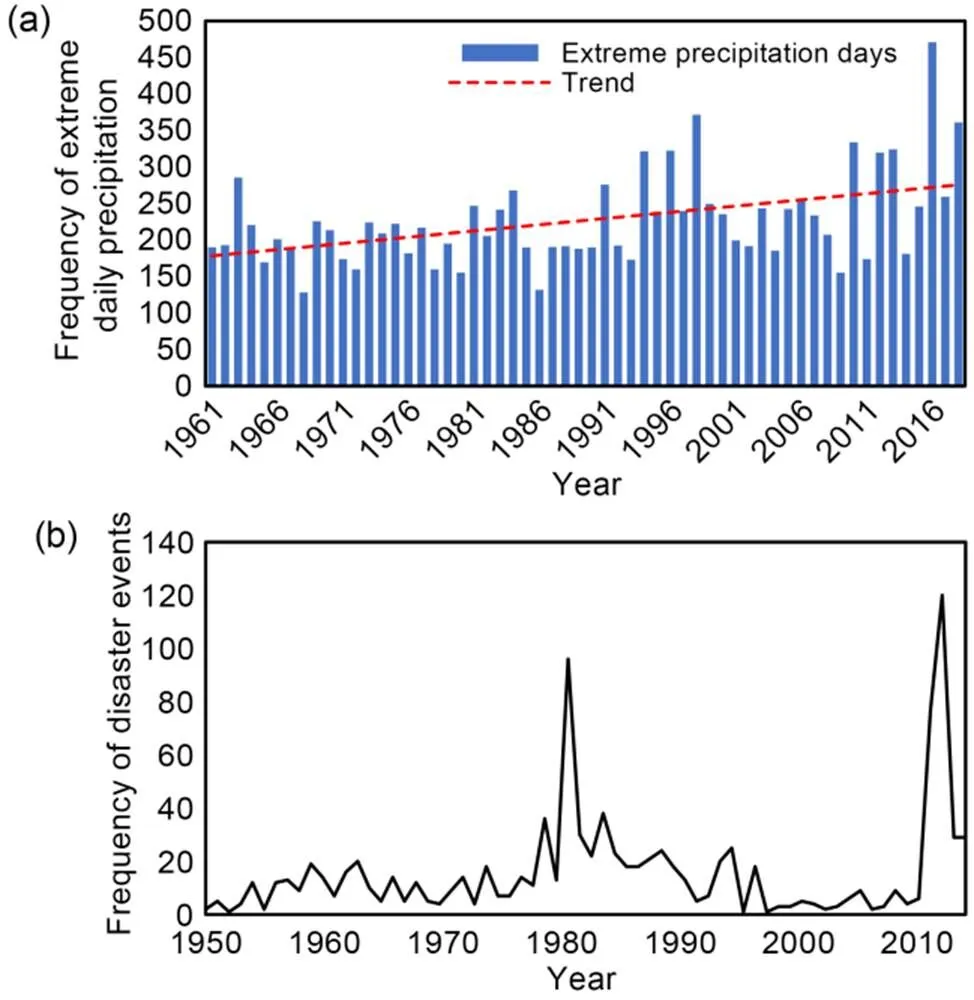

Climate change inevitably influences subgrade performance as the subgrade is exposed to the atmosphere. According to (WMO, 2019), global warming increases precipitation and extreme climate events. The delay times of train operation attributed to severe weather have grown by an average of 7200 min/a during 2014–2019 in the UK, with most being related to variations of precipitation and temperature (DeVinne et al., 2022). The trend of extreme precipitation in China is a generally increasing one and the peak frequency of railway accidents corresponds to the years with frequent precipitation (Figs. 2a and 2b). Specifically, the peak frequencies in 1981 and 2013 are attributed to flood and typhoon, respectively. Overall, subgrade problems, geological disasters, and infrastructural damage are critical factors that induce railway accidents (Hong et al., 2015; Lu and Cai, 2019). Here, subgrade problems refer to subgrade damage caused by excessive settlement, mud pumping, etc.; geological disasters are railway lines disrupted by landslide, flood, etc.; infrastructural damage refers to overhead lines destroyed by strong winds, lightning, etc. (DeVinne et al., 2022).

Fig. 1 Total mileages and the maximum speeds of high-speed railways

Fig. 2 Effect of extreme climate in China: (a) frequency of extreme daily precipitation from 1961 to 2019 from China Meteorological Administration; (b) frequency of railway accident events, reprinted from Cui and Guo (2018), Copyright 2018, with permission from Meteorological and Environmental Sciences

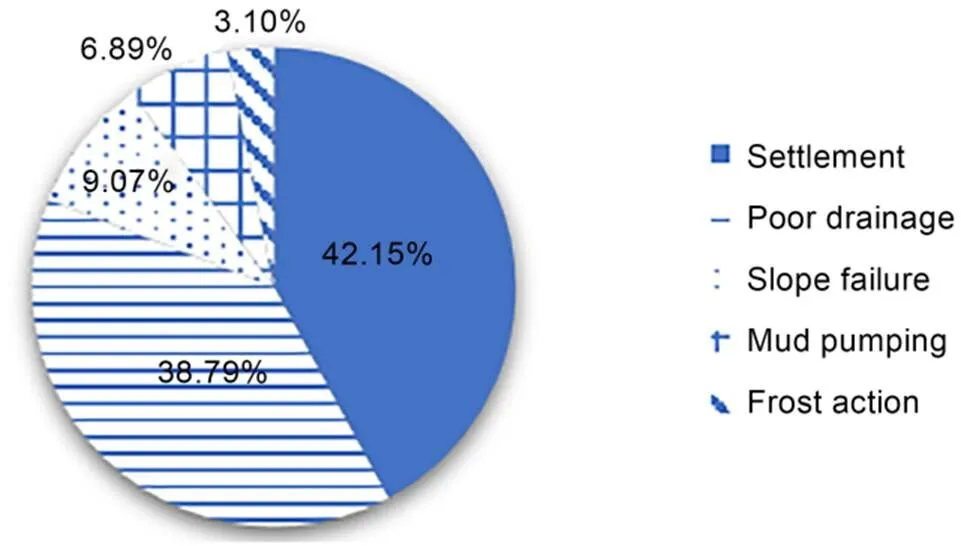

Subgrade problems such as earthwork failure and ballast fouling caused by the increase of extreme climate events directly induce railway accidents (DeVinne et al., 2022). Fig. 3 shows the proportion of subgrade problems in China, including settlement, poor drainage, and slope failure. Here, settlement and poor drainage are the most prominent, accounting for 42.15% and 38.79%, respectively, which significantly affect subgrade performance. Considerable efforts have been made in the investigation of subgrade problems, ranging from their formation mechanisms to their evolution trends and influencing factors, through theoretical modeling, numerical analysis, and field tests, so as to provide guidelines for the construction, monitoring, and maintenance of high-speed railways. In this paper, we present a detailed review of recent advances in these subgrade problems. We begin with the causes and characteristics of subgrade problems in Section 2, followed by brief descriptions of detection, monitoring, and maintenance in Sections 3 and 4. Finally, we summarize the current challenges and recommend opportunities for future research.

Fig. 3 Railway subgrade problems in China modified from Guo et al. (2019)

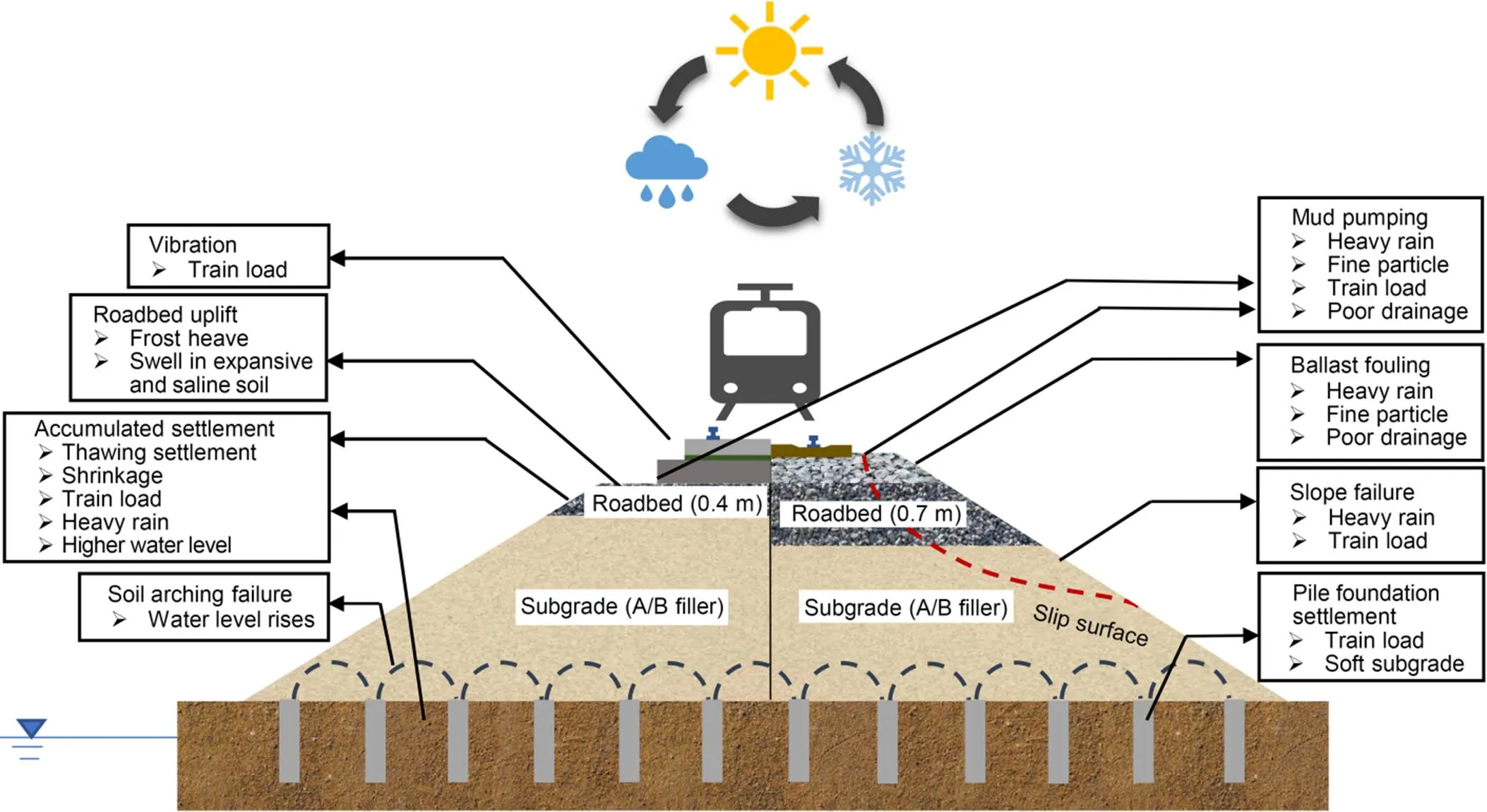

2 Subgrade problems under extreme climate and train loads

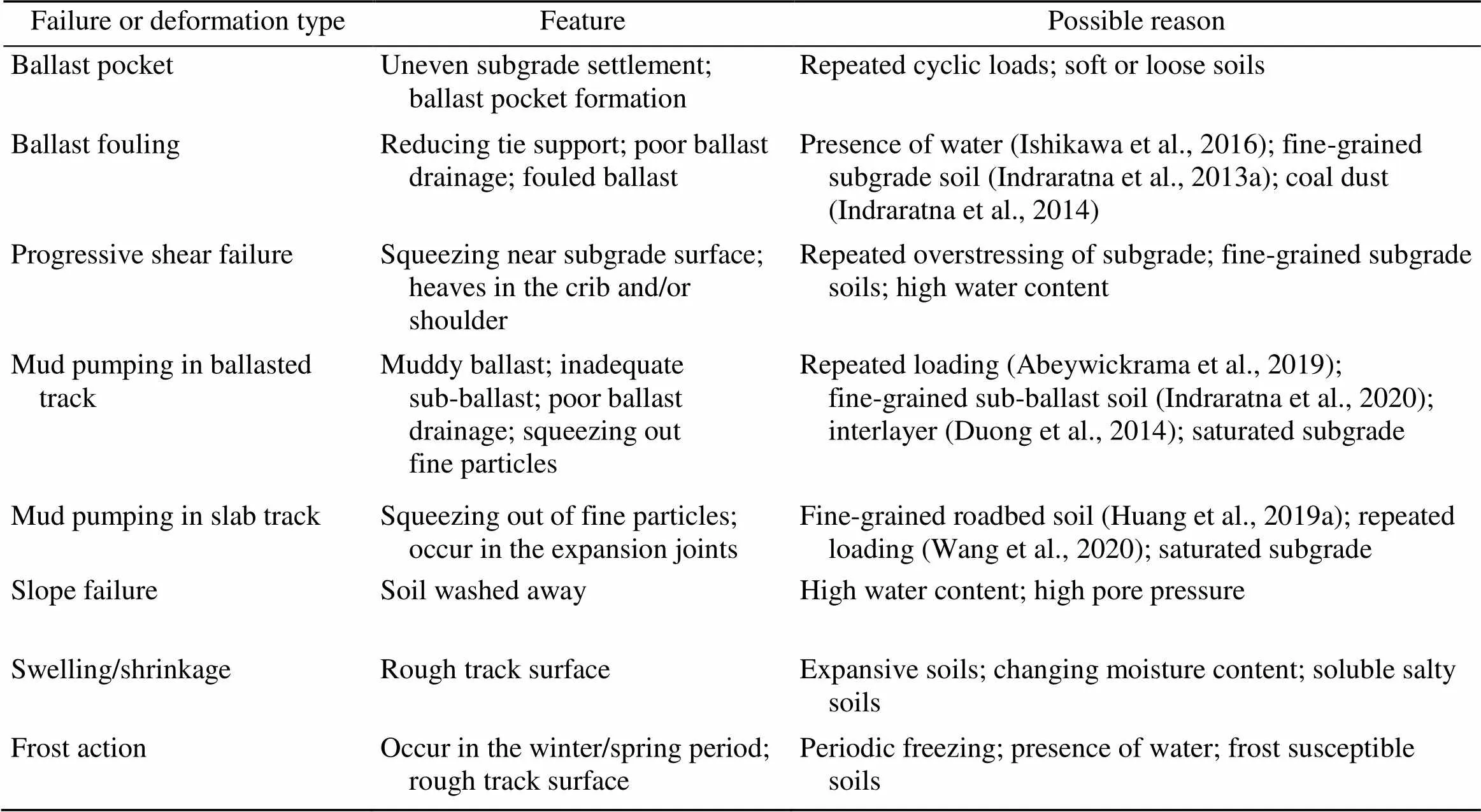

High-speed railways are mainly classified into two categories: those with ballasted tracks and those with ballastless tracks. Ballasted tracks, comprising rail, sleepers, ballast, sub-ballast, and subgrade, exhibit great advantages, such as easy maintenance, low cost, and convenient laying. Ballastless tracks have the advantages of high smoothness and comprise rails, slab, cement asphalt mortar layer, concrete base, roadbed, and subgrade. Fig. 4 shows the subgrade problems in the ballasted and ballastless tracks induced by extreme climate and train loads. Based on the research of Li and Selig (1995), various typical subgrade problems are further summarized (Table 1).

Fig. 4 Subgrade problems caused by extreme climate and train loads (Li and Selig, 1995; Bian et al., 2018)

2.1 Strong vibration and shock by high-speed train

When the train speed reaches a certain level (i.e., the critical speed), the track system resonates with the substructure. Under such circumstances, the subgrade dynamic response is strongly amplified. This phenomenon was originally observed in Ledsgard, where the maximum deflection of the track reached 15 mm at a train speed of 200 km/h (Holm et al., 2002). Therefore, this critical speed is the factor restricting train speed. Remarkable progress has been made in the theory of critical speed by frequency–wavenumber spectrum approaches (Madshus and Kaynia, 2000; Takemiya, 2003; Bian et al., 2008), dispersion curve strategies (Cao, 2006; Bian et al., 2016a), or dynamic amplified factor methods (Hu et al., 2016; Sayeed and Shahin, 2016; Hu and Bian, 2022). By the frequency– wavenumber spectrum approaches, Takemiya (2003) proposed that the amplified track response attributes to the interaction of track vibration and Rayleigh wave propagation when the train reaches the critical speed. Based on dispersion curve strategies, Costa et al. (2020) developed an experimental–analytical approach to assess critical speed. Firstly, they obtained the ground dispersion curve by the geophysical spectral analysis of surface waves (SASW) setup and then calculated the track dispersion curve by the analytical method. Then, the critical speed was obtained as the intersection of two curves. In this approach, the soil property uncertainties could be fully considered. Compared with the above approaches, dynamic amplified factor methods are time-consuming but straightforward, because multiple models are developed to derive the maximum vertical displacement of subgrade as a function of the train speed, with the critical speed corresponding to the largest displacement. Sheng et al. (2004a) exploited the dynamic amplified factor methods and concluded that a decrease in track mass could enhance the critical speed for the ballasted track.

Table 1 Types, causes, and characteristics of typical subgrade problems

The critical speed is related to the conditions of track, subgrade, and foundation (Connolly and Costa, 2020). The critical speed of the track–substructure system is close to the Rayleigh wave velocity of homogeneous subsoil (Zhou and Jiang, 2006). Additionally, increasing the track bending stiffness or adding a subgrade enhances the critical speed (Sheng et al., 2004b; Hu et al., 2019), and the stiffness ratio of the adjacent subsoil layers also affects it (Costa et al., 2015). Moreover, Bian et al. (2019b)and Gao et al. (2012) used a 2.5-dimensional (2.5D) finite element approach to investigate the critical speed in a saturated foundation. Numerical results showed that the excess pore pressure and dynamic responses were amplified when the train speed approached the Rayleigh wave velocity of the saturated subsoil.

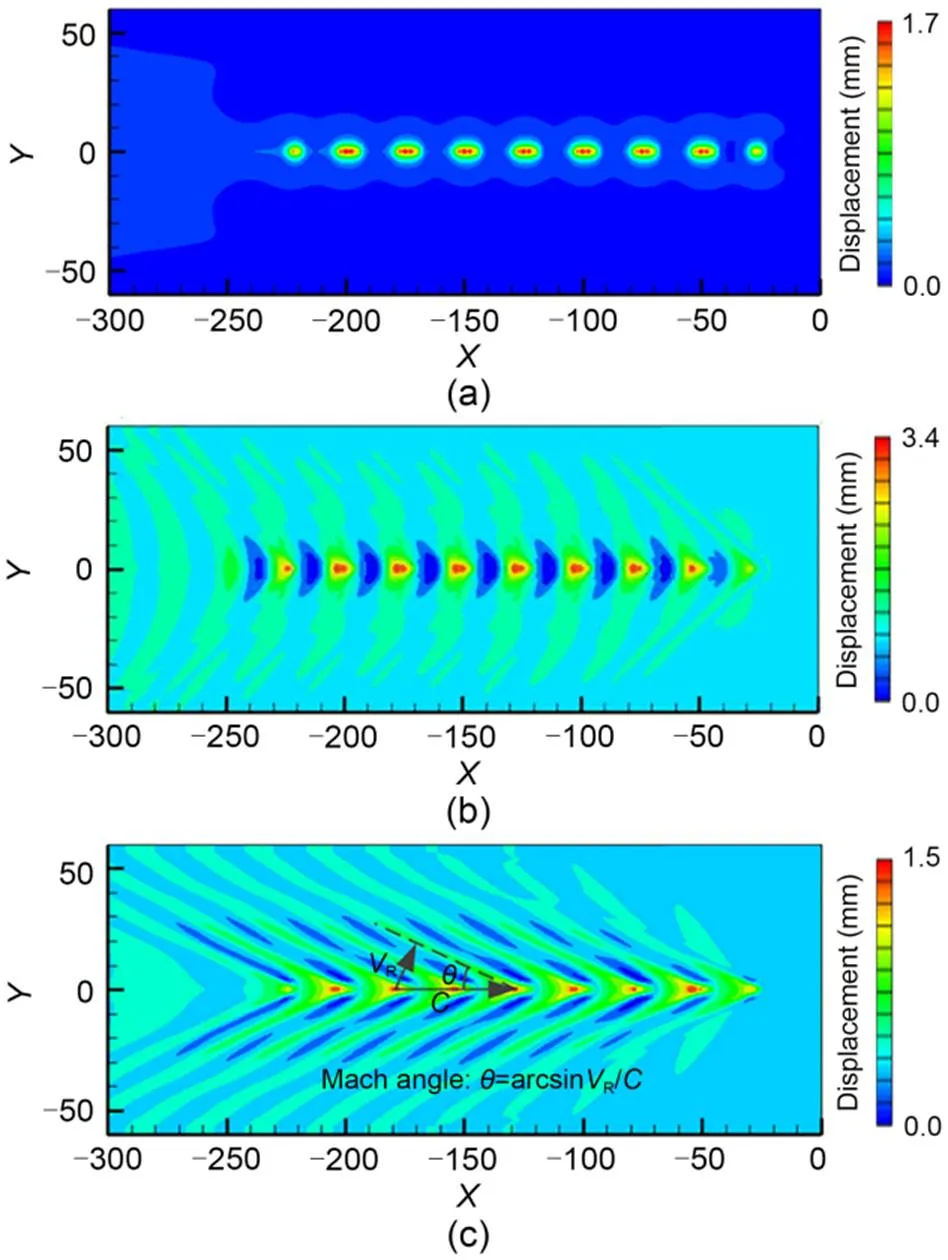

Briefly, critical speed is a critical factor in subgrade dynamic response. As shown in Fig. 5, at a low train speed, the subgrade dynamic response is quasi-static. The vertical deformation is induced near the axle position (Fig. 5a). With increasing train speed, the dynamic response first increases to the maximum (Fig. 5b) and then decreases after the train exceeds the critical speed (Fig. 5c) (Bian et al., 2014). In the meantime, the surrounding ground also deforms vertically, indicating that the wave propagates to far field. A shockwave also can be observed in Figs. 5b and 5c which is known as the Mach cone. Consequently, academic opinions are that the train speed should be limited to 70% of the critical speed, as it is a critical point for an intense increase in dynamic response (Woldringh and New, 1999; Mezher et al., 2016; Sayeed and Shahin, 2016). In daily operation, the maximum allowable speed is affected by various factors such as track geometry, train design, and subgrade stability (Zicha, 1989). In terms of track geometry, the directional curvature of the railway limits the train speed to ensure sufficient centripetal force (Hodas, 2014). Also, the geometric deterioration of turnouts decreases train average speed (Sadeghi et al., 2016). Furthermore, the aerodynamic drag increases dramatically with increasing train speed, so the maximum allowable speed is also limited by aerodynamic design (Ding et al., 2016). Additionally, the subgrade dynamic response is amplified when the train reaches the critical speed, increasing the risk of derailment.

Fig. 5 Vertical displacement response of ground at different train speeds: (a) below the critical speed; (b) close to the critical speed; (c) exceeding the critical speed. Adapted from (Bian et al., 2016a), Copyright 2014, with permission from Springer Nature

2.2 Subgrade settlement

Settlement is a serious subgrade problem that reduces subgrade stability and driving safety. Both theoretical and experimental studies have shown that the settlement of ballasted tracks is mostly attributable to the ballast layer, with ballast breakage and movement (Abadi et al., 2018), accounting for about 50%–70% of the total settlement (Selig and Maters, 1994; Mishra et al., 2014, 2017; Li et al., 2018). Furthermore, the settlement of ballastless tracks mainly involve the accumulated settlement of subgrades and foundations (Liu et al., 2022). Under heavy rain and train loads, pore pressure accumulates, and the effective stress in the soil decreases, thereby inducing settlement (Chen XX et al., 2021). Moisture content affects settlement through variation in resilient modulus (Khan et al., 2011). As the moisture content decreases, the resilient modulus increases because high matric suction reduces lubrication between the soil particles and limits particle movement (Chen et al., 2020), thereby decreasing settlement (Liu XL et al., 2019; Blackmore et al., 2020). Jiang et al. (2015, 2016) and Bian et al. (2016b) established a full-scale physical model to study the impact of water levels on subgrade settlement. When the water table is at the subsoil surface, excess pore pressure increases gradually and settlement quickly accumulates due to incomplete drainage. When the water table rises to the subgrade surface, the accumulative settlement evolves dramatically. After 700000 cyclic loadings at a train speed of 360 km/h, the accumulative settlement approaches 76 mm and exceeds the control limit of 15 mm in the criterion. After the water table recedes to the subsoil surface, the accumulative settlement still rises as the load cycles increase.

2.3 Ballast fouling

As the ballast is pushed into the subgrade due to uneven dynamic stress, the underlying subgrade forms a pocket-like structure in which ballast and water are held. The broken ballast is pressed down, and the underlying soil becomes soft under repeated train loads. Meanwhile, plastic deformation in the subgrade accumulates. Thus, the cavity deepens and forms a large water-filled pocket (i.e., the ballast pocket). Furthermore, the ballast becomes fouled owing to the subgrade particles and outside fines. Additionally, the overstressed soft subgrade soil is progressively squee zed sideways and upward under train loads, inducing progressive shear failure (i.e., cess heave).

Most ballast degradation is attributed to abrasion rather than bulk fracture, and usually arises beneath the sleeper (McDowell et al., 2005). Moreover, the increase of train speed and axle load intensifies ballast abrasion and breakage, especially the ballast in platy, bladed, and elongated shapes, rendering the particles smooth in surface and round in shape (Bian et al., 2021a; Xu et al., 2021; Gu et al., 2022). To investigate the micro-mechanical behavior of ballast, some researchers developed discrete element method (DEM) models considering realistic particle shape and inertia, as well as the friction and abrasion between ballast aggregates; the predicted ballast settlement agrees well with the field test results (Lu and McDowell, 2006; Ferellec and McDowell, 2010; de Bono et al., 2020; Suhr et al., 2020).

Broken ballast or external fines mixing with water results in ballast fouling. Kashani et al. (2018) carried out triaxial tests and found that ballast degradation is mainly caused by water content. As the water infiltrates continuously, the resulting filler in the pocket reduces the interlocking and frictional resistance between the ballast particles, thereby decreasing the subgrade shear strength (Danesh et al., 2018). Additionally, an approximately 3% increase in water content can triple the track's elastic deformation in moderately or highly fouled ballast (Kashani et al., 2017), and reduce shear strength by approximately 50% in dry fouled ballast (Qian et al., 2016). Moreover, the fouled materials also reduce the shear strength of ballast particles. Huang et al. (2009) found that coal dust decreases the shear strength most among various fouling agents such as plastic clayey soil and mineral filler. Furthermore, Budiono et al. (2004) stated that the resiliency of coal-fouled ballast reduces as the fouling level increases. Through triaxial tests, Touqan et al. (2020) found that the axial strain rate in fouled ballast increases with increasing loading frequency. Combined with laboratory experiments, DEM can be used to investigate the mechanical properties of the ballast layer. Xu et al. (2015) and Chen J et al. (2021) showed that small-size fouling materials have more detrimental effect on the shear strength of ballast aggregates. Besides, fouled ballast reduces the track's lateral resistance by more than 50%, and increases the risk of track bulking (Xu et al., 2016; Ngamkhanong et al., 2021). To increase the stability of the ballast layer, geogrid is utilized to constrain particle movement and to provide interlocking between ballast aggregates, thereby increasing the shear strength of fouled ballast. However, that enhancement declines with increasing fouling levels (Indraratna et al., 2011, 2013b).

2.4 Mud pumping

Fines, excess water infiltration, and repeated train loads significantly influence mud pumping formation (Duong et al., 2016; Bian et al., 2022; Wan et al., 2022). Based on the statistical analysis of on-site soil samples, mud pumping incidents usually occur in fine soil with a low-to-moderate plastic index (Bian et al., 2022).

For the ballasted track, the fine particles from the ballast breakage, subgrade, and the external environment (i.e., the coal dropped from freight trains or the dust transported by wind) form slurry by water infiltration in the ballast layer and then are pumped up to the track surface due to the train loads. Based on physical model tests, Duong et al. (2014) stated that the dissipation of excess pore pressure enables fine particles to migrate upward only in saturated situations. Additionally, the suction-driven model proposed by Takatoshi (1997) is acknowledged in this area. In this model, the suction from the sleeper bottom drives the migration of fine particles under repeated train loads.

However, for the ballastless track, mud pumping usually occurs in the expansion gaps between adjacent concrete bases and extends to both ends of the gaps. Through X-ray diffraction tests, Bian et al. (2022) revealed that fine particles mostly came from the roadbed instead of the underlying subgrade. Moreover, field tests indicated that the strong vibration at the end of the concrete base induced a whipping effect, thereby prompting detachments between the concrete base and the roadbed (Wan et al., 2022). Furthermore, under heavy rain and train loads, the slurry from the mixture of rain and fines is pumped out to the track surface by a nonuniform hydraulic gradient and then reduces the contact pressure between concrete base and roadbed. Thus, the subgrade bearing capability decreases and the settlement increases (Huang et al., 2019a; Bian et al., 2022).

2.5 Subgrade problems in special geological areas

In saline soil areas, track deteriorations and subgrade sinkage are likely to occur because of salt expansion and collapsibility (Tan et al., 2011). In karst areas, the subgrade tends to be washed and submerged by abundant groundwater, leading to water bursts, slope collapses, subgrade subsidence, etc. (Jiang, 2001). In expansive soil areas, the reciprocating swelling–shrinkage behavior of the expansive soil induces nonuniform settlement. As the ballastless track is sensitive to substructure deformation (Duan et al., 2020; Wang et al., 2021b), it should be constructed beyond a reasonable subgrade height (Jiang et al., 2018). In frozen soil areas, temperature, water, and soil properties are critical to freeze–thaw behaviors (Niu et al., 2017). In winter, the water becomes ice and the volume expands, and thus the subgrade is prone to frost-heave; conversely, in summer, the water from melting ice migrates upwards, and thaw settlement in the subgrade surface arises (Li et al., 2018). Some research has focused on the relationship between water content, frost-heave, and settlement. Niu et al. (2020) found, by field measurement, that most frost-heave happened in the gravel layer (0–0.5 m). Even though this layer is composed of "non-frost susceptible" materials and well graded, the frost-heave in this layer, accounts for 66% of the total deformation. A feasible explanation is that the water comes into the gravel layer downwards through the track cracks and then accumulates in the top layer. Furthermore, Sheng et al. (2014) proposed a pump-enhanced frost-heave theory to investigate the interaction between train loads and frost-heave. In their model, the excess pore pressure is assumed to increase under cyclic train loads, and hence "pumps" up the water table to the frost front and turns water into an ice lens in the subgrade. Thus, the maximum frost-heave arises in the railway centerline. Moreover, Teng et al. (2022) took a series of laboratory experiments of frost-heave and developed a frost-heave model considering vapor flow. They pointed out that vapor flow is a critical factor for frost-heave in coarse-grained soils.

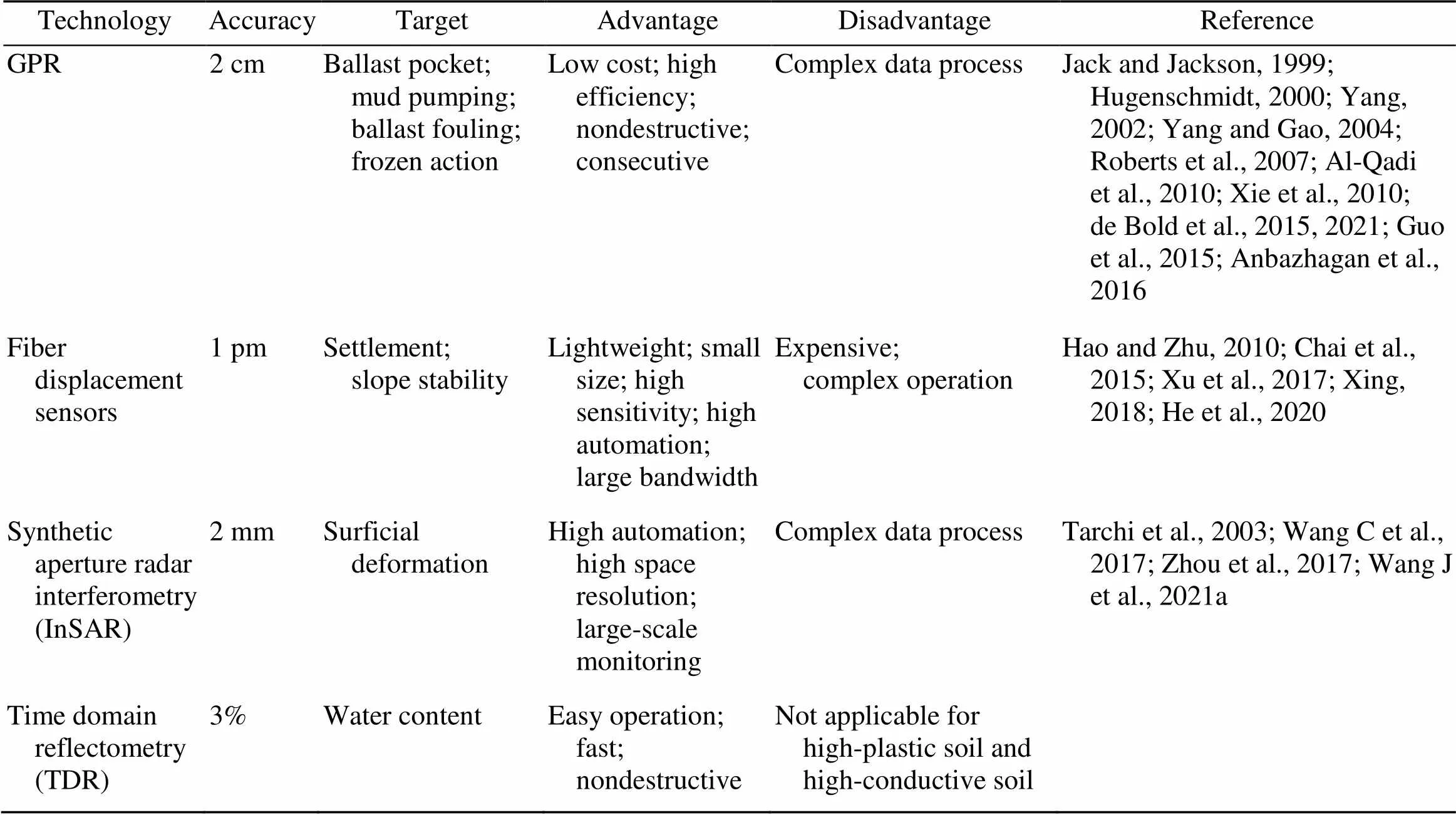

3 Subgrade detection and monitoring technologies

Settlement monitoring is an important part of long-term subgrade monitoring. Traditional monitoring technologies of subgrade settlement (i.e., the settlement plate, observation pile, and settlement meter) are interfered by the environment, but they are still frequently used because of their convenient operation and low cost (Wang, 2008; Hua, 2014). Besides, the detection of subgrade problems is necessary along with long-term monitoring. Detection is usually conducted during the skylight period; thus, the time for operation is short. Moreover, a large-span, high-speed railway is exposed to the atmosphere, and its geological conditions vary along the lines. Consequently, the equipment for detection and monitoring must be durable and strong. In traditional methods, sensors are usually embedded in a problematic location to measure the mechanical properties of the soil and analyze the cause of subgrade problems. However, these methods damage the subgrade and have poor efficiency. Therefore, emerging monitoring and detection techniques can compensate for the shortcomings of traditional technologies (Table 2).

Ground penetrating radar (GPR) relies on the reflection signal generated in the interface of media with different electromagnetic properties, by launching a signal into the soil. It is utilized for initially detecting soil distribution (Hugenschmidt, 2000); the subgrade settlement profile can then be obtained by analyzing the change in the soil interface (Gallagher et al., 1999; Jack and Jackson, 1999; Sussmann et al., 2003; Xie et al., 2010; Popov et al., 2022). Additionally, GPR can also locate the aquifer approximately (Liu et al., 2020). Therefore, GPR is widely used in the detection of subgrade problems, such as ballast fouling (Roberts et al., 2007; Al-Qadi et al., 2010; de Bold et al., 2015, 2021; Anbazhagan et al., 2016), mud pumping (Yang, 2002; Yang and Gao, 2004), and frozen subgrade (Guo et al., 2015).

Compared with traditional deformation measuring instruments, such as the displacement meter, dial indicator, and extensometer (Dunnicliff, 1993), fiber sensors are durable and capable of continuous large-scale measuring. They launch light into the soil and then receive its reflection. As the wavelength and phase of the reflected light change with temperature and strain, the physical parameters of the soil can be obtained using a fiber-grating demodulator. Moreover, the fiber sensor can be combined with a clinometer and settlement plate to monitor the subgrade settlement (Hao and Zhu, 2010; Xing, 2018). Additionally, Xu et al. (2017) and He et al. (2020) developed a distributed optical fiber strain-vibration joint system to measure sinkhole collapse. Furthermore, Huang et al. (2012) fabricated a piezometer system by integrating a pressure sensor with an optical fiber Bragg grating (FBG) to monitor the long-term pore pressure of the subgrade slope. The lateral displacement of ballast and the tensile force distribution of the geogrid can also be measured by integrating fiber sensors with the geogrid (Hussaini et al., 2015).

InSAR can obtain surficial deformation according to the phase difference of the echo received by a satellite or aircraft. This technology can monitor large areas and the deformation of complex terrains such as deserts, mountains, and glaciers, at millimeter-level accuracy and has great advantages on long-span high-speed railway monitoring (El Kamali et al., 2020). At present, InSAR is used to monitor surficial deformation along railway lines (Zhou et al., 2017). In addition, seasonal settlements due to the sunny–shady slope effect and frozen soil distribution are being monitored along the Qinghai–Tibet railway (Wang C et al., 2017; Wang J et al., 2021a).

Table 2 Subgrade detection and monitoring technologies

As mentioned above, water is closely related to subgrade problems, so the measurement of water content is important. TDR obtains the water content based on variations in permittivity and it fulfills the accuracy requirement of common subgrade fillers. However, a large discrepancy arises in the test for highly plastic soil. Peng (2011) solved the deviation of TDR in the red clay subgrade by laboratory calibration tests and field applications. In addition, Yu et al. (2012) introduced a new TDR sensor to monitor the freezing–thawing status of subgrade and determined the freezing–thawing degree by developing an empirical analysis algorithm.

4 Subgrade maintenance

Based on China's high-speed railway design code (TB10621–2014) (NRA, 2015), while the rate of wheel load reduction is limited to below 60% to ensure driving safety, vehicle vibration acceleration is limited to below 1.3 m/s2to ensure passenger comfort. Additionally, settlement is a comprehensive indicator of subgrade performance, and the post-construction settlement is specified in the design code. Moreover, water infiltrates the subgrade by surface running and water level rising, thereby affecting subgrade performance. Therefore, the high-speed railway substructure requires external and internal drainage. The drainage requirements in the criteria are shown in Table 3. The key to ballasted track drainage is to remove contained water in the ballast layer, whereas for the ballastless track, it is to discharge surface runoff. Considering the factors above, maintenances such as foundation treatment, drainage optimization, and material improvement have been proposed in engineering and research to ensure subgrade performance.

Table 3 Drainage requirement of ballasted and ballastless tracks

Table 4 Technologies of foundation treatment (Raju and Daramalinggam, 2012)

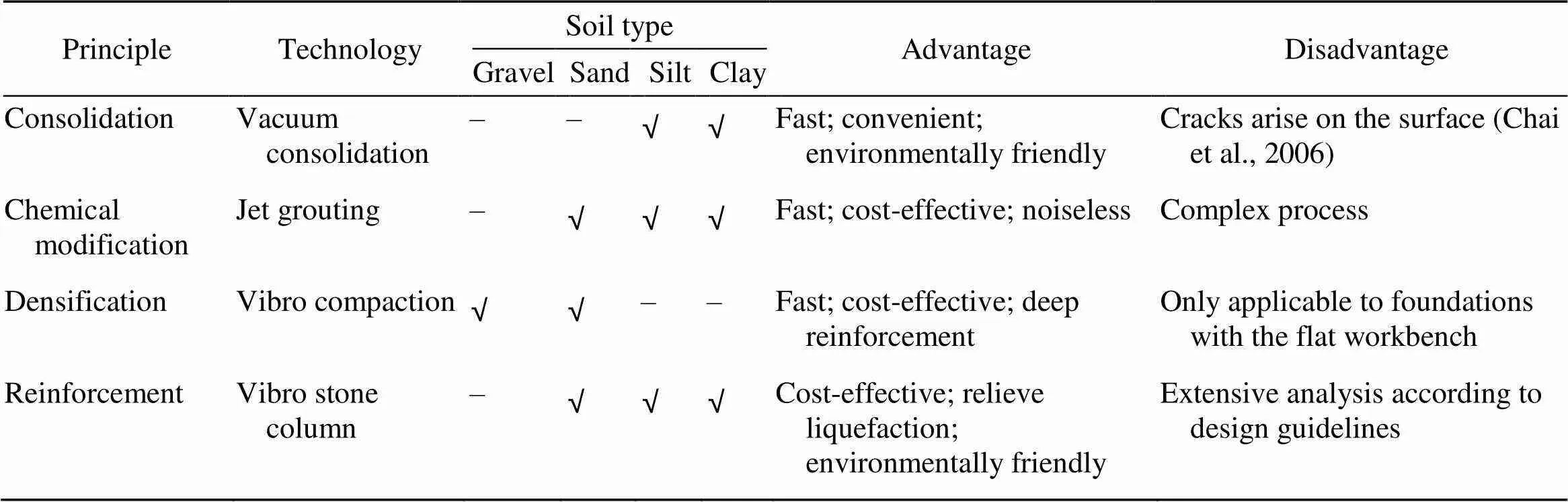

4.1 Foundation treatment

Geological conditions should first be investigated in the design stage of the high-speed railway, and the foundations can then be treated to reduce the subgrade settlement from repeated train loads. Common technologies of foundation treatment are shown in Table 4. Notably, building a pile-supported embankment to reinforce the foundation is widely used in high-speed railway construction.

4.2 Drainage optimization

Fabricating new drainage materials and optimizing drainage design can reduce the water retained in the subgrade. The subgrade is prone to mud comprising fine particles with high water content, so the drainage system requires good drainability, corrosion resistance, and non-clogging. Based on the above considerations, Tasalloti et al. (2020) developed a geocellular system installed between sleepers to remove water and fine particles in the ballast layer. Guo et al. (2018) developed a new polyvinyl chloride (PVC) pipe by exploiting a capillary permeable belt. For the ballastless track, a polyurethane-improved waterproof layer can be used on roadbed surfaces to reduce water infiltration (Huang et al., 2019b). Additionally, drainage facilities should bear frost-heave stress in frozen soil areas. Thus, Tian et al. (2019) embedded a coarse-grained transition layer and impermeable geotextile into drainage facilities to ensure thermal insulation and impermeability. Moreover, the drainage layout should be adjusted to local conditions. Liu MS et al. (2019) proposed a drainage design method called the permeable subgrade shoulder, providing guidelines for mud pumping prevention of the ballastless track.

4.3 New improved and repaired materials

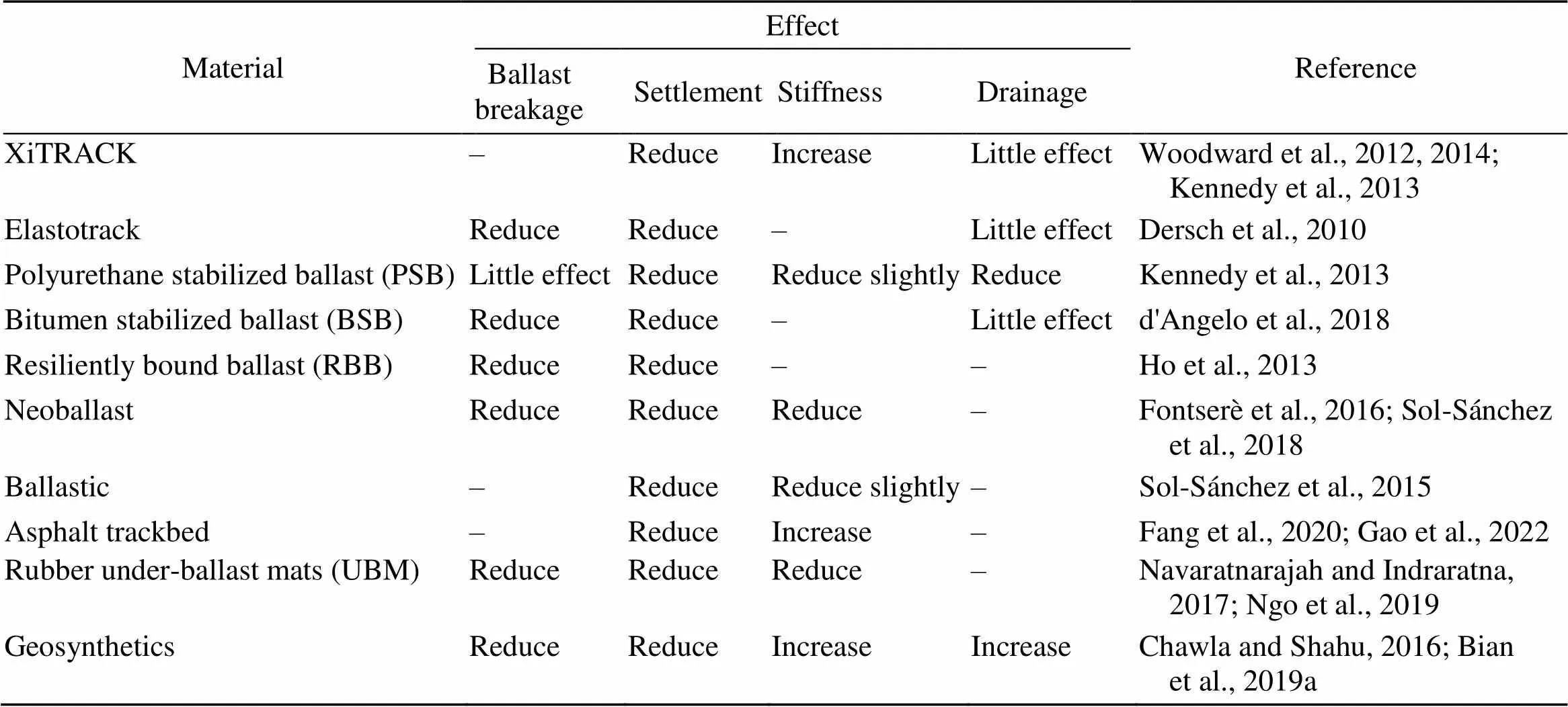

Subgrade problems of the ballasted track increase mostly owing to ballast breakage and water infiltration. These problems can be solved by replacing with clean ballast. However, this method is inefficient. Therefore, new materials have been developed to improve ballast integrity (Sol-Sánchez and d'Angelo, 2017; Gundavaram and Hussaini, 2019; Jing et al., 2019). In addition, rubber cushions can be embedded in the ballast layer to increase the elasticity of ballasted tracks (Navaratnarajah and Indraratna, 2017; Kumar et al., 2019; Ngo et al., 2019). Table 5 shows the improved materials and their effects. As the aim of ballastless track repairment is subgrade, Bian et al. (2014, 2021b), Liu et al. (2015), and Wan et al. (2020) proposed polyurethane chemical injection and chemical glue injection, respectively, to repair subgrade settlement and mud pumping.

5 Conclusions and future work

The service life of a railway is 100 a, including safe operations, performance degradation, and unsafe service periods. In the early stage of a newly-built railway, the subgrade becomes stabilized under self-weight and train loads, indicating that the subgrade is in a shakedown and the railway is in a safe operation period. However, the subgrade is exposed to the atmosphere and subjected to both train and environmental loads, such as rainfall infiltration, and seasonal dry–wet and freezing–thawing cycles. Thereafter, the railway performance decays because the subgrade shakedown decreases. At present, high-speed railways in China have been operating for more than 10 a and have gradually entered the decayed performance period. As a result, studying the change in subgrade performance under train and environmental loads is necessary.

Table 5 Improved materials of ballasted track

However, the development of subgrade shakedown takes a few decades and is difficult to observe by field tests and reproduce by physical modeling. Therefore, mechanisms and laws cannot be obtained. With advances in China's Western Development Policy and the Belt and Road Initiative, the mileage of high-speed railways is about to reach another record high, but subgrade performance degradation threatens railway driving safety. Consequently, the maintenance and improvement of subgrade shakedown under train and environmental loads have become an urgent technical challenge.

The gravels in the ballast layer and roadbed are broken under long-term train loads, reducing the interlocking between particles and the subgrade bearing capacity, thereby causing progressive accumulated settlement. Meanwhile, fine particles due to gravel breakage reduce the permeability of the ballast layer and subgrade, resulting in poor drainage. Moreover, coupled with environmental loads, the subgrade and foundation are fluidized, which is an important reason for subgrade degradation, inducing various subgrade problems such as mud pumping, subgrade sinkage, and even subgrade collapse. In addition, it is a complicated phenomenon, including phase transition and fluidization, and is hard to explain by existing soil mechanical models. At present, many studies on mud pumping have been carried out through field tests and laboratory experiments, and considerable progress has been achieved in establishing the formation mechanism and the influencing factors. However, quantitative models and theories for mud pumping are still few and immature, and criteria for railway subgrade design and construction considering mud pumping have not yet been established.

The annual rainfall along the Sichuan–Tibet railway reaches 2000 mm, and the temperature changes greatly, reaching 40 ℃ in summer and -20 ℃ in winter. The special climate and complicated geological conditions require a higher subgrade shakedown. Therefore, studying the subgrade failure mechanism under train loads alongside dry–wet and freezing–thawing cycles is imperative. However, most of the current studies only consider the effect of train loads or freezing–thawing individually and the failure mechanism of subgrade under the combination of these two effects remains unclear. Moreover, the present hydro-thermal-mechanical theories on freeze–thaw mostly focus on hydro-thermal coupling. Although the stress distribution in the subgrade can affect the pore ratio, pore pressure, and water–ice phase-transition temperature, these influences are neglected in current models. Additionally, the rules for water source and migration remain unclear currently, so precautionary methods for mud pumping and frost-heave have not yet been developed. Regarding technological development, establishing a functional system, including reinforcement, waterproof, and shakedown sensing, is necessary to ensure the subgrade's long-term performance. For example, an intelligent sensing geogrid can be devised to monitor the temperature and water content of the subgrade, and to report on the soil freezing– thawing status and water infiltration. Meanwhile, limiting particle movement controls the settlement according to the geogrid. Additionally, a new polymer-reinforced ballasted track could be developed to reduce vibration and ballast degradation while preventing water infiltration to avoid freeze–thaw and mud pumping.

Reproducing and observing the development of subgrade performance over the decades is a critical challenge in recent research on subgrade shakedown. The advantage of the centrifuge tests is that they reduce the model size and time, providing a unique method to solve the problem. The dry–wet and freezing–thawing cycles due to climate change can recur in centrifuge tests. Furthermore, train loads can be applied by self-developed high-speed railway loading devices. Therefore, the coupled hydraulic-thermal-mechanical catastrophic mechanism of the subgrade under train and environmental loads can be reproduced promptly. Finally, the water migration rules, mechanism of subgrade fluidization, mud pumping, and subgrade-foundation system failure can be obtained to establish laws of subgrade shakedown.

This work is supported by the National Natural Science Foundation of China (Nos. 52125803 and 51988101).

Yunmin CHEN and Xuecheng BIAN designed the research. Ying WU wrote the first draft of the manuscript and processed the corresponding data. Xuecheng BIAN and Haoran FU helped to organize the manuscript. Ying WU and Haoran FU revised and edited the final version.

Ying WU, Haoran FU, Xuecheng BIAN, and Yunmin CHEN declare that they have no conflict of interest.

Abadi T, Pen LL, Zervos A, et al., 2018. Improving the performance of railway tracks through ballast interventions., 232(2):337-355. https://doi.org/10.1177/0954409716671545

Abeywickrama A, Indraratna B, Rujikiatkamjorn C, 2019. Excess pore-water pressure generation and mud pumping in railways under cyclic loading.: Sundaram R, Shahu JT, Havanagi V (Eds.), Geotechnics for Transportation Infrastructure. Springer, Singapore, p.371-383. https://doi.org/10.1007/978-981-13-6701-4_24

Al-Qadi I, Xie W, Roberts R, 2010. Optimization of antenna configuration in multiple-frequency ground penetrating radar system for railroad substructure assessment., 43(1):20-28. https://doi.org/10.1016/j.ndteint.2009.08.006

Anbazhagan P, Dixit PSN, Bharatha TP, 2016. Identification of type and degree of railway ballast fouling using ground coupled GPR antennas., 126:183-190. https://doi.org/10.1016/j.jappgeo.2016.01.018

Bian XC, Chen YM, Hu T, 2008. Numerical simulation of high-speed train induced ground vibrations using 2.5D finite element approach., 51(6):632-650. https://doi.org/10.1007/s11433-008-0060-3

Bian XC, Cheng C, Wang FM, et al., 2014. Experimental study on dynamic performance and long-term durability of high-speed railway subgrade rehabilitated by polymer injection technology., 36(3):562-568 (in Chinese).

Bian XC, Cheng C, Jiang JG, et al., 2016a. Numerical analysis of soil vibrations due to trains moving at critical speed., 11(2):281-294. https://doi.org/10.1007/s11440-014-0323-2

Bian XC, Jiang HG, Chen YM, 2016b. Preliminary testing on high-speed railway substructure due to water level changes., 143:769-781. https://doi.org/10.1016/j.proeng.2016.06.124

Bian XC, Li W, Hu J, et al., 2018. Geodynamics of high-speed railway., 17:69-76. https://doi.org/10.1016/j.trgeo.2018.09.007

Bian XC, Chen HH, He B, et al., 2019a. Experimental study on accumulated settlement of ballasted trackbed reinforced with geogrid under cyclic loading., 52(8):120-128 (in Chinese). https://doi.org/10.15951/j.tmgcxb.2019.08.011

Bian XC, Hu J, Thompson D, et al., 2019b. Pore pressure generation in a poro-elastic soil under moving train loads., 125:105711. https://doi.org/10.1016/j.soildyn.2019.105711

Bian XC, Shi KH, Li W, et al., 2021a. Quantification of railway ballast degradation by abrasion testing and computer-aided morphology analysis., 33(1):04020411. https://doi.org/10.1061/(asce)mt.1943-5533.0003519

Bian XC, Duan X, Li W, et al., 2021b. Track settlement restoration of ballastless high-speed railway using polyurethane grouting: full-scale model testing., 26:100381. https://doi.org/10.1016/j.trgeo.2020.100381

Bian XC, Wan ZB, Zhao C, et al., 2022. Mud pumping in the roadbed of ballastless high-speed railway., in press. https://doi.org/10.1680/jgeot.21.00135

Blackmore L, Clayton CRI, Powrie W, et al., 2020. Saturation and its effect on the resilient modulus of a pavement formation material., 70(4):292-302. https://doi.org/10.1680/jgeot.18.P.053

Budiono D, McSweeney T, Gurung N, et al., 2004. The effect of coal dust fouling on the cyclic behaviour of railway ballast. Proceedings of the 2004 International Conference on Cyclic Behaviour of Soils and Liquefaction Phenomena, p.627-632.

Cao YM, 2006. The Theoretical Analysis and Experiments of the Train-induced Free-field and Building Vibrations. PhD Thesis, Beijing Jiaotong University, Beijing, China (in Chinese).

Chai J, Yuan Q, Li Y, et al., 2015. Application analysis on method of physical model test with optical fiber sensing technique., 23(6):1100-1108 (in Chinese). https://doi.org/10.13544/j.cnki.jeg.2015.06.010

Chai JC, Carter JP, Hayashi S, 2006. Vacuum consolidation and its combination with embankment loading., 43(10):985-996. https://doi.org/10.1139/t06-056

Chawla S, Shahu JT, 2016. Reinforcement and mud-pumping benefits of geosynthetics in railway tracks: model tests., 44(3):366-380. https://doi.org/10.1016/j.geotexmem.2016.01.005

Chen J, Gao R, Liu YZP, et al., 2021. Numerical exploration of the behavior of coal-fouled ballast subjected to direct shear test., 273:121927. https://doi.org/10.1016/j.conbuildmat.2020.121927

Chen WB, Feng WQ, Yin JH, 2020. Effects of water content on resilient modulus of a granular material with high fines content., 236:117542. https://doi.org/10.1016/j.conbuildmat.2019.117542

Chen XX, Nie RS, Li YF, et al., 2021. Resilient modulus of fine-grained subgrade soil considering load interval: an experimental study., 142:106558. https://doi.org/10.1016/j.soildyn.2020.106558

Climate Change Center, 2019. China’s Climate Change White Paper 2019. Technical Report, China Meteorological Administration, China (in Chinese).

Connolly DP, Costa PA, 2020. Geodynamics of very high speed transport systems., 130:105982. https://doi.org/10.1016/j.soildyn.2019.105982

Costa PA, Colaço A, Calçada R, et al., 2015. Critical speed of railway tracks. Detailed and simplified approaches, 2:30-46. https://doi.org/10.1016/j.trgeo.2014.09.003

Costa PA, Soares P, Colaço A, et al., 2020. Railway critical speed assessment: a simple experimental-analytical approach., 134:106156. https://doi.org/10.1016/j.soildyn.2020.106156

Cui XQ, Guo XM, 2018. Feature analysis of meteorological and derivative disasters in China railway during 1950–2015., 41(2):98-104 (in Chinese). https://doi.org/10.16765/j.cnki.1673-7148.2018.02.014

Danesh A, Palassi M, Mirghasemi AA, 2018. Effect of sand and clay fouling on the shear strength of railway ballast for different ballast gradations., 20(3):51. https://doi.org/10.1007/s10035-018-0824-z

d'Angelo G, Sol-Sánchez M, Moreno-Navarro F, et al., 2018. Use of bitumen-stabilised ballast for improving railway trackbed conventional maintenance., 68(6):518-527. https://doi.org/10.1680/jgeot.17.P.022

de Bold R, O’Connor G, Morrissey JP, et al., 2015. Benchmarking large scale GPR experiments on railway ballast., 92:31-42. https://doi.org/10.1016/j.conbuildmat.2014.09.036

de Bold R, Connolly DP, Patience S, et al., 2021. Using impulse response testing to examine ballast fouling of a railway trackbed., 274:121888. https://doi.org/10.1016/j.conbuildmat.2020.121888

de Bono J, Li HQ, McDowell G, 2020. A new abrasive wear model for railway ballast., 60(3):714-721. https://doi.org/10.1016/j.sandf.2020.05.001

Dersch MS, Tutumluer E, Peeler CT, et al., 2010. Polyurethane coating of railroad ballast aggregate for improved performance. The Joint Rail Conference, p.337-342. https://doi.org/10.1115/JRC2010-36215

DeVinne N, DeBold R, Forde MC, et al., 2022. Impact of climate change on railway construction, maintenance and safety in the United Kingdom.: Hoff I, Mork H, Saba R (Eds.), Eleventh International Conference on the Bearing Capacity of Roads, Railways and Airfields, Volume 2. CRC Press, London, UK, p.62-80. https://doi.org/10.1201/9781003222897

Ding SS, Li Q, Tian AQ, et al., 2016. Aerodynamic design on high-speed trains., 32(2):215-232. https://doi.org/10.1007/s10409-015-0546-y

Duan JY, Yang GL, Hu M, et al., 2020. Heave performance of a ballastless track subgrade of double line high-speed railway filled with micro-expansive andesite under water immersion., 252:119087. https://doi.org/10.1016/j.conbuildmat.2020.119087

Dunnicliff J, 1993. Geotechnical Instrumentation for Monitoring Field Performance. Wiley, New York, USA.

Duong TV, Cui YJ, Tang AM, et al., 2014. Investigating the mud pumping and interlayer creation phenomena in railway sub-structure., 171:45-58. https://doi.org/10.1016/j.enggeo.2013.12.016

Duong TV, Cui YJ, Tang AM, et al., 2016. Effects of water and fines contents on the resilient modulus of the interlayer soil of railway substructure., 11(1):51-59. https://doi.org/10.1007/s11440-014-0341-0

El Kamali M, Abuelgasim A, Papoutsis I, et al., 2020. A reasoned bibliography on SAR interferometry applications and outlook on big interferometric data processing., 19:100358. https://doi.org/10.1016/j.rsase.2020.100358

Fang MJ, Hu T, Rose JG, 2020. Geometric composition, structural behavior and material design for asphalt trackbed: a review., 262:120755. https://doi.org/10.1016/j.conbuildmat.2020.120755

Ferellec JF, McDowell GR, 2010. A method to model realistic particle shape and inertia in DEM., 12(5):459-467. https://doi.org/10.1007/s10035-010-0205-8

Fontserè V, Pita AL, Manzo N, et al., 2016. Neoballast: new high-performance and long-lasting ballast for sustainable railway infrastructures., 14:1847-1854. https://doi.org/10.1016/j.trpro.2016.05.151

Gallagher GP, Leiper Q, Williamson R, et al., 1999. The application of time domain ground penetrating radar to evaluate railway track ballast., 32(8):463-468. https://doi.org/10.1016/S0963-8695(99)00025-0

Gao GY, Chen QS, He JF, et al., 2012. Investigation of ground vibration due to trains moving on saturated multi-layered ground by 2.5D finite element method., 40:87-98. https://doi.org/10.1016/j.soildyn.2011.12.003

Gao ZL, Luo X, Cai DG, et al., 2022. Cyclic settlement of ballast layer due to train passages at high speed and its reduction by asphalt trackbed., 318:125956. https://doi.org/10.1016/j.conbuildmat.2021.125956

Gu QS, Zhao C, Bian XC, et al., 2022. Trackbed settlement and associated ballast degradation due to repeated train moving loads., 153:107109. https://doi.org/10.1016/j.soildyn.2021.107109

Gundavaram D, Hussaini SKK, 2019. Polyurethane-based stabilization of railroad ballast–a critical review., 7(3):219-240. https://doi.org/10.1080/23248378.2019.1570477

Guo LH, Chen F, Li ZG, et al., 2019. Investigation and analysis of served state for high speed railway subgrade., 59(3):64-68 (in Chinese). https://doi.org/10.3969/j.issn.1003-1995.2019.03.16

Guo YP, Leng WM, Nie RS, et al., 2018. Laboratory evaluation of a new device for water drainage in roadside slope along railway systems., 46(6):897-903. https://doi.org/10.1016/j.geotexmem.2018.08.005

Guo ZW, Dong HF, Xiao JP, 2015. Retracted: detection of permafrost subgrade using GPR: a case examination on Qinghai-Tibet plateau., 3(5):35-47. https://doi.org/10.4236/gep.2015.35005

Hao JY, Zhu SJ, 2010. Discussion on schemes for monitoring post-construction subsidence of subgrade of Zhengzhou–Xi’an passenger dedicated line., 27(3):33-36 (in Chinese). https://doi.org/10.3969/j.issn.1006-2106.2010.03.008

He JP, Xue Y, Xu J, et al., 2020. Whole-process monitoring of sinkhole collapse based on distributed optical fiber strain-vibration joint system and its case study in railway subgrade., 60:102380. https://doi.org/10.1016/j.yofte.2020.102380

Ho CL, Humphrey D, Hyslip JP, et al., 2013. Use of recycled tire rubber to modify track–substructure interaction., 2374(1):119-125. https://doi.org/10.3141/2374-14

Hodas S, 2014. Design of railway track for speed and high-speed railways., 91:256-261. https://doi.org/10.1016/j.proeng.2014.12.056

Holm G, Andréasson B, Bengtsson PE, et al., 2002. Mitigation of Track and Ground Vibrations by High Speed Trains at Ledsgård, Sweden. Report 10, Swedish Deep Stabilization Research Centre, Linkoping, Sweden.

Hong L, Ouyang M, Peeta S, et al., 2015. Vulnerability assessment and mitigation for the Chinese railway system under floods., 137:58-68. https://doi.org/10.1016/j.ress.2014.12.013

Hu J, Bian XC, 2022. Analysis of dynamic stresses in ballasted railway track due to train passages at high speeds., 23(6):443-457. https://doi.org/10.1631/jzus.A2100305

Hu J, Bian XC, Jiang JQ, 2016. Critical velocity of high-speed train running on soft soil and induced dynamic soil response., 143:1034-1042. https://doi.org/10.1016/j.proeng.2016.06.102

Hu J, Bian XC, Xu WC, et al., 2019. Investigation into the critical speed of ballastless track., 18:142-148. https://doi.org/10.1016/j.trgeo.2018.12.004

Hua M, 2014. A brief analysis of the commonly used settlement monitoring methods for high-speed railway subgrades., 58(S1):122-125 (in Chinese). https://doi.org/10.13238/j.issn.1004-2954.2014.S.036

Huang AB, Lee JT, Ho YT, et al., 2012. Stability monitoring of rainfall-induced deep landslides through pore pressure profile measurements., 52(4):737-747. https://doi.org/10.1016/j.sandf.2012.07.013

Huang H, Tutumluer E, Dombrow W, 2009. Laboratory characterization of fouled railroad ballast behavior., 2117(1):93-101. https://doi.org/10.3141/2117-12

Huang JJ, Su Q, Wang W, et al., 2019a. Field investigation and full-scale model testing of mud pumping and its effect on the dynamic properties of the slab track–subgrade interface., 233(8):802-816. https://doi.org/10.1177/0954409718810262

Huang JJ, Su Q, Cheng YM, et al., 2019b. Improved performance of the subgrade bed under the slab track of high-speed railway using polyurethane adhesive., 208:710-722. https://doi.org/10.1016/j.conbuildmat.2019.03.020

Hugenschmidt J, 2000. Railway track inspection using GPR., 43(2-4):147-155. https://doi.org/10.1016/S0926-9851(99)00054-3

Hussaini SKK, Indraratna B, Vinod JS, 2015. Application of optical-fiber Bragg grating sensors in monitoring the rail track deformations., 38(4):387-396. https://doi.org/10.1520/GTJ20140123

Indraratna B, Ngo NT, Rujikiatkamjorn C, 2011. Behavior of geogrid-reinforced ballast under various levels of fouling., 29(3):313-322. https://doi.org/10.1016/j.geotexmem.2011.01.015

Indraratna B, Tennakoon N, Nimbalkar S, et al., 2013a. Behaviour of clay-fouled ballast under drained triaxial testing., 63(5):410-419. https://doi.org/10.1680/geot.11.P.086

Indraratna B, Ngo NT, Rujikiatkamjorn C, 2013b. Deformation of coal fouled ballast stabilized with geogrid under cyclic load., 139(8):1275-1289. https://doi.org/10.1061/(asce)gt.1943-5606.0000864

Indraratna B, Nimbalkar S, Coop M, et al., 2014. A constitutive model for coal-fouled ballast capturing the effects of particle degradation., 61:96-107. https://doi.org/10.1016/j.compgeo.2014.05.003

Indraratna B, Singh M, Nguyen TT, 2020. The mechanism and effects of subgrade fluidisation under ballasted railway tracks., 28(2):113-128. https://doi.org/10.1007/s40534-020-00210-1

Ishikawa T, Fuku S, Nakamura T, et al., 2016. Influence of water content on shear behavior of unsaturated fouled ballast., 143:268-275. https://doi.org/10.1016/j.proeng.2016.06.034

Jack R, Jackson P, 1999. Imaging attributes of railway track formation and ballast using ground probing radar., 32(8):457-462. https://doi.org/10.1016/S0963-8695(99)00023-7

Jiang GL, Chen WZ, Liu XF, et al., 2018. Field study on swelling-shrinkage response of an expansive soil foundation under high-speed railway embankment loads., 58(6):1538-1552. https://doi.org/10.1016/j.sandf.2018.09.008

Jiang HG, Bian XC, Chen YM, et al., 2015. Impact of water level rise on the behaviors of railway track structure and substructure., 2476(1):15-22. https://doi.org/10.3141/2476-03

Jiang HG, Bian XC, Jiang JQ, et al., 2016. Dynamic performance of high-speed railway formation with the rise of water table., 206:18-32. https://doi.org/10.1016/j.enggeo.2016.03.002

Jiang ZX, 2001. Geological hazards and control in Nanning–Kunming railway., (1):83-88 (in Chinese). https://doi.org/10.3969/j.issn.1006-2106.2001.01.023

Jing GQ, Qie LC, Markine V, et al., 2019. Polyurethane reinforced ballasted track: review, innovation and challenge., 208:734-748. https://doi.org/10.1016/j.conbuildmat.2019.03.031

Kashani HF, Hyslip JP, Ho CL, 2017. Laboratory evaluation of railroad ballast behavior under heavy axle load and high traffic conditions., 11:69-81. https://doi.org/10.1016/j.trgeo.2017.04.002

Kashani HF, Ho CL, Hyslip JP, 2018. Fouling and water content influence on the ballast deformation properties., 190:881-895. https://doi.org/10.1016/j.conbuildmat.2018.09.058

Kennedy J, Woodward PK, Medero G, et al., 2013. Reducing railway track settlement using three-dimensional polyurethane polymer reinforcement of the ballast., 44:615-625. https://doi.org/10.1016/j.conbuildmat.2013.03.002

Khan Z, El Naggar MH, Cascante G, 2011. Frequency dependent dynamic properties from resonant column and cyclic triaxial tests., 348(7):1363-1376. https://doi.org/10.1016/j.jfranklin.2010.04.003

Kumar N, Suhr B, Marschnig S, et al., 2019. Micro-mechanical investigation of railway ballast behavior under cyclic loading in a box test using DEM: effects of elastic layers and ballast types., 21(4):106. https://doi.org/10.1007/s10035-019-0956-9

Li D, Selig ET, 1995. Evaluation of railway subgrade problems., 1489:17-25.

Li W, Bian XC, Duan X, et al., 2018. Full-scale model testing on ballasted high-speed railway: dynamic responses and accumulated settlements., 2672(10):125-135. https://doi.org/10.1177/0361198118784379

Liu HM, Jiang HG, Zhao C, et al., 2022. Long-term responses of high-speed railway subjected to extreme precipitation events., 37:100852. https://doi.org/10.1016/j.trgeo.2022.100852

Liu MS, Luo Q, Guo JH, et al., 2019. Mechanism of frost boiling and optimization of drainage design in ballastless track subgrade bed., 43(3):16-25 (in Chinese). https://doi.org/10.11860/j.issn.1673-0291.20180143

Liu SX, Lu Q, Li HQ, et al., 2020. Estimation of moisture content in railway subgrade by ground penetrating radar., 12(18):2912. https://doi.org/10.3390/rs12182912

Liu T, Su Q, Zhao WH, et al., 2015. Study on injection–repaired and reinforcement effects of subgrade frost boiling under ballastless track., 37(12):88-95 (in Chinese). https://doi.org/10.3969/j.issn.1001-8360.2015.12.014

Liu XL, Zhang XM, Wang H, et al., 2019. Laboratory testing and analysis of dynamic and static resilient modulus of subgrade soil under various influencing factors., 195:178-186. https://doi.org/10.1016/j.conbuildmat.2018.11.061

Lu CF, Cai CX, 2019. Challenges and countermeasures for construction safety during the Sichuan–Tibet railway project., 5(5):833-838. https://doi.org/10.1016/j.eng.2019.06.007

Lu M, McDowell GR, 2006. Discrete element modelling of ballast abrasion., 56(9):651-655. https://doi.org/10.1680/geot.2006.56.9.651

Madshus C, Kaynia AM, 2000. High-speed railway lines on soft ground: dynamic behaviour at critical train speed., 231(3):689-701. https://doi.org/10.1006/jsvi.1999.2647

McDowell GR, Lim WL, Collop AC, et al., 2005. Laboratory simulation of train loading and tamping on ballast., 158(2):89-95. https://doi.org/10.1680/tran.2005.158.2.89

Mezher SB, Connolly DP, Woodward PK, et al., 2016. Railway critical velocity–analytical prediction and analysis., 6:84-96. https://doi.org/10.1016/j.trgeo.2015.09.002

Mishra D, Tutumluer E, Boler H, et al., 2014. Railroad track transitions with multidepth deflectometers and strain gauges., 2448(1):105-114. https://doi.org/10.3141/2448-13

Mishra D, Boler H, Tutumluer E, et al., 2017. Deformation and dynamic load amplification trends at railroad bridge approaches: effects caused by high-speed passenger trains., 2607(1):43-53. https://doi.org/10.3141/2607-07

Navaratnarajah SK, Indraratna B, 2017. Use of rubber mats to improve the deformation and degradation behavior of rail ballast under cyclic loading., 143(6):04017015. https://doi.org/10.1061/(asce)gt.1943-5606.0001669

Ngamkhanong C, Feng B, Tutumluer E, et al., 2021. Evaluation of lateral stability of railway tracks due to ballast degradation., 278:122342. https://doi.org/10.1016/j.conbuildmat.2021.122342

Ngo TN, Indraratna B, Rujikiatkamjorn C, 2019. Improved performance of ballasted tracks under impact loading by recycled rubber mats., 20:100239. https://doi.org/10.1016/j.trgeo.2019.04.002

Niu FJ, Li AY, Luo J, et al., 2017. Soil moisture, ground temperatures, and deformation of a high-speed railway embankment in Northeast China., 133:7-14. https://doi.org/10.1016/j.coldregions.2016.10.007

Niu FJ, Zheng H, Li AY, 2020. The study of frost heave mechanism of high-speed railway foundation by field-monitored data and indoor verification experiment., 15(3):581-593. https://doi.org/10.1007/s11440-018-0740-8

NRA (National Railway Administration of the People’s Republic of China), 2015. Code for Design of High Speed Railway, TB 10621-2014. National Standards of the People’s Republic of China (in Chinese).

Peng JL, 2011. Study on water content monitoring method of red clay subgrade based on the principle of TDR., 36(3):141-144 (in Chinese). https://doi.org/10.3969/j.issn.1674-0610.2011.03.036

Popov K, de Bold R, Chai HK, et al., 2022. Big-data driven assessment of railway track and maintenance efficiency using artificial neural networks., 349:128786. https://doi.org/10.1016/j.conbuildmat.2022.128786

Qian Y, Mishra D, Tutumluer E, et al., 2016. Moisture effects on degraded ballast shear strength behavior. Proceedings of the Joint Rail Conference. https://doi.org/10.1115/jrc2016-5840

Raju VR, Daramalinggam J, 2012. Ground improvement: principles and applications in Asia., 165(2):65-76. https://doi.org/10.1680/grim.10.00033

Roberts R, Schutz A, Al-Qadi I, et al., 2007. Characterizing railroad ballast using GPR: recent experiences in the United States. Proceedings of the 4th International Workshop on Advanced Ground Penetrating Radar, p.295-299. https://doi.org/10.1109/AGPR.2007.386570

Sadeghi J, Masnabadi A, Mazraeh A, 2016. Correlations among railway turnout geometry, safety and speeds., 169(4):219-229. https://doi.org/10.1680/jtran.15.00059

Sayeed A, Shahin MA, 2016. Three-dimensional numerical modelling of ballasted railway track foundations for high-speed trains with special reference to critical speed., 6:55-65. https://doi.org/10.1016/j.trgeo.2016.01.003

Selig ET, Maters JM, 1994. Track Geotechnology and Substructure Management. Thomas Telford, London, UK.

Sheng D, Zhang S, Niu F, et al., 2014. A potential new frost heave mechanism in high-speed railway embankments., 64(2):144-154. https://doi.org/10.1680/geot.13.p.042

Sheng X, Jones CJC, Thompson DJ, 2004a. A theoretical study on the influence of the track on train-induced ground vibration., 272(3-5):909-936. https://doi.org/10.1016/s0022-460x(03)00781-8

Sheng X, Jones CJC, Thompson DJ, 2004b. A theoretical model for ground vibration from trains generated by vertical track irregularities., 272(3-5):937-965. https://doi.org/10.1016/s0022-460x(03)00782-x

Sol-Sánchez M, d’Angelo G, 2017. Review of the design and maintenance technologies used to decelerate the deterioration of ballasted railway tracks., 157:402-415. https://doi.org/10.1016/j.conbuildmat.2017.09.007

Sol-Sánchez M, Thom NH, Moreno-Navarro F, et al., 2015. A study into the use of crumb rubber in railway ballast., 75:19-24. https://doi.org/10.1016/j.conbuildmat.2014.10.045

Sol-Sánchez M, Moreno-Navarro F, Rubio-Gámez MC, et al., 2018. Full-scale study of Neoballast section for its application in railway tracks: optimization of track design., 51(2):43. https://doi.org/10.1617/s11527-018-1167-2

Suhr B, Butcher TA, Lewis R, et al., 2020. Friction and wear in railway ballast stone interfaces., 151:106498. https://doi.org/10.1016/j.triboint.2020.106498

Sussmann TR, Selig ET, Hyslip JP, 2003. Railway track condition indicators from ground penetrating radar., 36(3):157-167. https://doi.org/10.1016/s0963-8695(02)00054-3

Takatoshi I, 1997. Measure for the Stabilization of Railway Earth Structure. Japan Railway Technical Service, Tokyo, Japan.

Takemiya H, 2003. Simulation of track–ground vibrations due to a high-speed train: the case of X-2000 at Ledsgard., 261(3):503-526. https://doi.org/10.1016/s0022-460x(02)01007-6

Tan DS, Sun YM, Hu LX, et al., 2011. Salt expansion properties and mechanism of saline soil in Xinjiang section of Lanzhou–Xinjiang railway and preventive measures., 33(9):83-88 (in Chinese). https://doi.org/10.3969/j.issn.1001-8360.2011.09.015

Tarchi D, Casagli N, Fanti R, et al., 2003. Landslide monitoring by using ground-based SAR interferometry: an example of application to the Tessina landslide in Italy., 68(1-2):15-30. https://doi.org/10.1016/s0013-7952(02)00196-5

Tasalloti A, Marshall AM, Heron CM, et al., 2020. Geocellular railway drainage systems: physical and numerical modelling., 22:100299. https://doi.org/10.1016/j.trgeo.2019.100299

Teng JD, Liu JL, Zhang S, et al., 2022. Frost heave in coarse-grained soils: experimental evidence and numerical modelling., in press. https://doi.org/10.1680/jgeot.21.00182

Tian YH, Yang ZJ, Tai BW, et al., 2019. Damage and mitigation of railway embankment drainage trench in warm permafrost: a case study., 261:105276. https://doi.org/10.1016/j.enggeo.2019.105276

Touqan M, Ahmed A, El Naggar H, et al., 2020. Static and cyclic characterization of fouled railroad sub-ballast layer behaviour., 137:106293. https://doi.org/10.1016/j.soildyn.2020.106293

Wan ZB, Bian XC, Li SH, et al., 2020. Remediation of mud pumping in ballastless high-speed railway using polyurethane chemical injection., 259:120401. https://doi.org/10.1016/j.conbuildmat.2020.120401

Wan ZB, Xu WC, Zhang ZY, et al., 2022. In-situ investigation on mud pumping in ballastless high-speed railway and development of remediation method., 33:100713. https://doi.org/10.1016/j.trgeo.2021.100713

Wang C, Zhang ZJ, Zhang H, et al., 2017. Seasonal deformation features on Qinghai-Tibet railway observed using time-series InSAR technique with high-resolution TerraSAR-X images., 8(1):1-10. https://doi.org/10.1080/2150704x.2016.1225170

Wang DH, 2008. Technologies for Wuhan–Guangzhou railway passenger dedicated line settlement observation and prediction of settlement deformation., 5(3):60-64 (in Chinese). https://doi.org/10.19713/j.cnki.43-1423/u.2008.03.013

Wang J, Wang C, Zhang H, et al., 2021a. Freeze-thaw deformation cycles and temporal-spatial distribution of permafrost along the Qinghai-Tibet railway using multitrack InSAR processing., 13(23):4744. https://doi.org/10.3390/rs13234744

Wang R, Cheng JJ, Gao L, et al., 2021b. Research on the swelling mechanism of high-speed railway subgrade and the induced railway heave of ballastless tracks., 27:100470. https://doi.org/10.1016/j.trgeo.2020.100470

Wang TF, Luo Q, Liu MS, et al., 2020. Physical modeling of train-induced mud pumping in substructure beneath ballastless slab track., 23:100332. https://doi.org/10.1016/j.trgeo.2020.100332

WMO (World Meteorological Organization), 2019. The Global Climate in 2015–2019. Technical Report.

Woldringh RF, New BM, 1999. Embankment design for high speed trains on soft soils. Proceedings of the Twelfth European Conference on Soil Mechanics and Geotechnical Engineering, p.1703-1712.

Woodward PK, El Kacimi A, Laghrouche O, et al., 2012. Application of polyurethane geocomposites to help maintain track geometry for high-speed ballasted railway tracks., 13(11):836-849. https://doi.org/10.1631/jzus.A12ISGT3

Woodward PK, Kennedy J, Laghrouche O, et al., 2014. Study of railway track stiffness modification by polyurethane reinforcement of the ballast., 1(4):214-224. https://doi.org/10.1016/j.trgeo.2014.06.005

Xie YY, Liao HJ, Zan YW, 2010. Two-dimensional forward simulation of railway roadbed disease based on ground penetrating radar technique., 44(10):1907-1911 (in Chinese). https://doi.org/10.3785/j.issn.1008-973X.2010.10.011

Xing HJ, 2018. Experimental study on railway slope sliding monitoring with optical fiber grating sensing technology., 58(2):85-88 (in Chinese). https://doi.org/10.3969/j.issn.1003-1995.2018.02.22

Xu J, He JP, Zhang L, 2017. Collapse prediction of karst sinkhole via distributed Brillouin optical fiber sensor., 100:68-71. https://doi.org/10.1016/j.measurement.2016.12.046

Xu Y, Gao L, Jing GQ, et al., 2015. Shear behavior analysis of fouled railroad ballast by DEM and its evaluation index., 32(8):96-102 (in Chinese). https://doi.org/10.6052/j.issn.1000-4750.2014.01.0051

Xu Y, Gao L, Zhang YR, et al., 2016. Discrete element method analysis of lateral resistance of fouled ballast bed., 23(9):2373-2381. https://doi.org/10.1007/s11771-016-3296-5

Xu Y, Yu WY, Qie LC, et al., 2021. Analysis of influence of ballast shape on abrasion resistance using discrete element method., 273:121708. https://doi.org/10.1016/j.conbuildmat.2020.121708

Yang XA, 2002. Railroad substructure and problem of Yuntaishan tunnel inspection using GPR., 21(4):86-88 (in Chinese). https://doi.org/10.3969/j.issn.1000-7849.2002.04.018

Yang XA, Gao YL, 2004. GPR inspection for Shanghai–Nanjing railway trackbed., 23(1):116-119 (in Chinese). https://doi.org/10.3321/j.issn:1000-6915.2004.01.022

Yu XB, Liu Y, Gonzalez J, et al., 2012. A new TDR sensor for accurate freeze–thaw measurement., 13(6):523-534. https://doi.org/10.1080/10298436.2011.626412

Zhai WM, Wei K, Song XL, et al., 2015. Experimental investigation into ground vibrations induced by very high speed trains on a non-ballasted track., 72:24-36. https://doi.org/10.1016/j.soildyn.2015.02.002

Zhou HF, Jiang JQ, 2006. Ground-borne vibration induced by high-speed trains., 28(12):2104-2110 (in Chinese). https://doi.org/10.3321/j.issn:1000-4548.2006.12.011

Zhou YY, Chen M, Gong HL, et al., 2017. The subsidence monitoring of Beijing–Tianjin high-speed railway based on PS-InSAR., 19(10):1393-1403 (in Chinese). https://doi.org/10.3724/SP.J.1047.2017.01393

Zicha JH, 1989. High-speed rail track design., 115(1):68-83. https://doi.org/10.1061/(ASCE)0733-947X(1989)115:1(68)

Haoran FU, https://orcid.org/0000-0002-5400-3042

July 8, 2022;

Revision accepted Nov. 18, 2022;

Crosschecked Feb. 8, 2023

© Zhejiang University Press 2023

Journal of Zhejiang University-Science A(Applied Physics & Engineering)2023年3期

Journal of Zhejiang University-Science A(Applied Physics & Engineering)2023年3期

- Journal of Zhejiang University-Science A(Applied Physics & Engineering)的其它文章

- High-speed railway transport technology

- Recent advances in traction drive technology for rail transit

- Adaptive cropping shallow attention network for defect detection of bridge girder steel using unmanned aerial vehicle images

- Adaptive fault-tolerant control of high-speed maglev train suspension system with partial actuator failure: design and experiments

- Effect of low operating temperature on the aerodynamic characteristics of a high-speed train

- Progress in research on nanoprecipitates in high-strength conductive copper alloys: a review