退火温度对激光增材制造CoCrFeMnNi高熵合金耐点蚀性能的影响

贾玺泉,徐震霖,周生璇,何宜柱,杜晓洁

退火温度对激光增材制造CoCrFeMnNi高熵合金耐点蚀性能的影响

贾玺泉,徐震霖,周生璇,何宜柱,杜晓洁

(安徽工业大学 材料科学与工程学院,安徽 马鞍山 243002)

研究激光增材制造CoCrFeMnNi高熵合金经不同温度退火后,微观组织演变对其在NaCl溶液中的耐点蚀性能的影响规律。采用激光选区熔化(SLM)技术制备CoCrFeMnNi高熵合金,通过X射线衍射(XRD)、光学显微镜(OM)和扫描电子显微镜(SEM)研究其退火后的微观结构。利用动电位极化和电化学阻抗谱(EIS)测试研究SLM成形高熵合金的耐点蚀性能,并通过X射线光电子能谱(XPS)分析钝化膜成分。经过不同温度退火后,高熵合金相组成并未改变,均为单一的面心立方结构固溶体。然而高熵合金的微观组织发生了明显转变,退火前微观组织由熔池、柱状晶及胞状亚晶所组成。随着退火温度的升高,熔池边界与亚晶结构逐渐消失,晶粒逐渐长大。SLM成形高熵合金在3.5% NaCl溶液中的腐蚀类型主要为点蚀。随着退火温度从700 ℃提高至1 100 ℃,高熵合金的腐蚀电流密度先减小、后增加,700℃退火试样相较于打印态试样,腐蚀电流密度下降了97%。打印态和700 ℃退火试样的钝化膜中Co+Cr+Ni与Mn+Fe阳离子含量的比值分别为1.38和1.61,钝化膜中Cr本征氧化层厚度分别为5.43 nm和5.75 nm。高熵合金耐点蚀性能随退火温度的升高,先提升、后降低。胞状亚晶有利于阻碍点蚀坑的扩展,并促使形成稳定的钝化膜。高熵合金经700 ℃退火,在消除部分熔池边界的同时,保留了胞状亚晶,因此表现出最佳的耐点蚀性能。

激光选区熔化;增材制造;高熵合金;微观结构;点蚀;钝化膜

高熵合金一般指混合熵在1.61以上的合金,通常由5种或5种以上元素所组成[1-2]。高熵合金具有优异的力学性能,如高的强度、硬度[3-4],出色的耐磨性能[5-6],独特的蠕变性能[7],同时具有良好的耐蚀性能[8-11]。但由于大部分高熵合金成形性较差[12],通过传统制备方式难以得到合格的高熵合金结构件。激光选区熔化(SLM)是一种通过激光束逐层扫描熔化指定区域的金属增材制造技术,不仅可以直接制备出任意形状的复杂零件,还可得到独特的分级微观结构,包括熔池边界、柱状晶、胞状亚晶及纳米孪晶等,这些微观结构相互耦合对材料的腐蚀性能产生影响[13-14]。

CoCrFeMnNi高熵合金具有优异的力学性能[3],良好的抗辐照性能[15]和耐腐蚀性能[14],成为航空航天、核工业、极地科研等极端环境下极具应用潜力的新型结构材料之一。在工程应用中,腐蚀是结构材料的主要失效形式之一,因此高熵合金的设计及推广应用必须考虑其耐蚀性能。例如,在核反应堆中的结构材料,由于长期暴露于冷却剂中,对材料的耐蚀性能提出了更高的要求[16]。Pathak等[17]对铸态CoCrFeMnNi高熵合金在3.5% NaCl溶液的腐蚀行为进行了研究,结果表明,由于Ni、Mn元素在枝晶间的偏聚,点蚀更易发生于铸态高熵合金的枝晶间区域。笔者研究团队在之前的研究中发现,与铸态高熵合金相比,SLM成形CoCrFeMnNi高熵合金具有更均匀的成分和更细小的晶粒,有利于形成保护性更强的钝化膜,因此具有更优异的耐点蚀性能[18]。Wang等[19]对SLM成形CoCrFeMnNi高熵合金的腐蚀各向异性进行了研究,发现在3.5% NaCl溶液中,平面的耐点蚀性能优于平面,和平面之间的耐点蚀性能差异是由测试平面暴露的微观结构特征引起的。有研究表明,应变退火增加了CoCrFeMnNi高熵合金低ΣCSL晶界的比例,提高了高熵合金的抗点蚀能力[20]。Zhu等[21]对CoCrFeMnNi高熵合金于不同温度退火后在碱性土壤模拟溶液中的腐蚀行为进行了研究,结果表明,750 ℃退火样品的耐腐蚀性能最高,650 ℃退火试样的耐腐蚀性略高于850 ℃处理试样,而550 ℃制备的试样的耐腐蚀性能最差。

增材制造过程中,极高的冷却速度导致了非平衡组织的形成,常通过后续热处理调控组织,以获得满足不同力学性能要求的结构件。微观组织的演变同样会对材料的耐点蚀性能产生影响,但退火温度对CoCrFeMnNi高熵合金耐点蚀性能的影响仍缺少系统性研究。因此,本文研究了经不同温度退火后,SLM成形CoCrFeMnNi高熵合金微观组织的演变规律及其对高熵合金在NaCl溶液中耐点蚀性能的影响规律。

1 试验

1.1 高熵合金制备

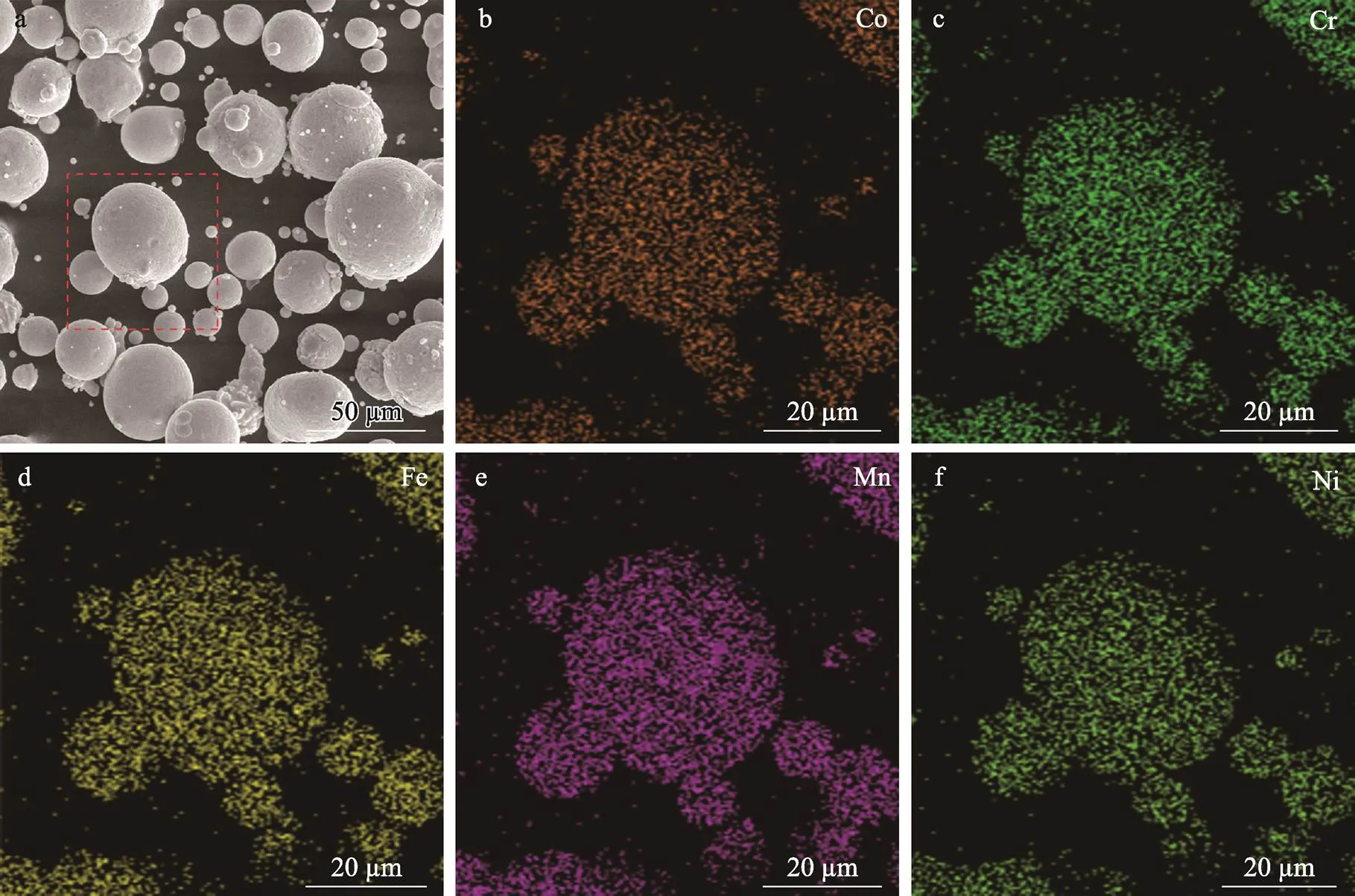

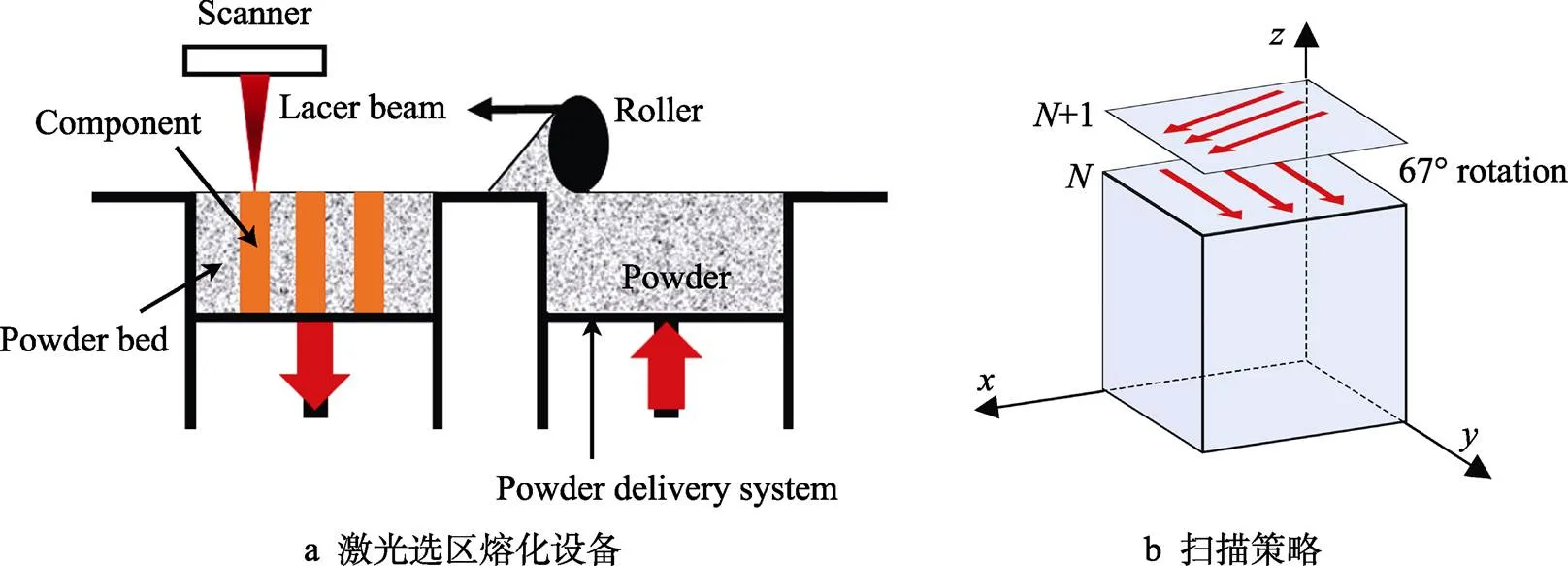

激光选区熔化成形采用由气雾法制备的等原子比CoCrFeMnNi高熵合金粉末,粉末呈球形,粉末尺寸为15~53 μm,平均粒径为34.5 μm。CoCrFeMnNi粉末的表面形貌及成分分析如图1所示,粉末未出现明显的成分偏析,这有利于提高SLM成形试样成分的均匀性。激光选区熔化设备与扫描策略如图2所示。在本次试验中,采用棋盘状激光扫描模式,每层与相邻层旋转67°,使用纯度为99.99 %氩气作为保护气体,打印过程中成型仓的氧含量低于100 mg/L。工艺参数:激光功率为180 W,扫描速度为670 mm/s,铺粉层厚为50 μm,扫描间距为70 μm。在此工艺下,激光能量密度为76.76 J/mm3。

1.2 组织观察及性能测试

2)本试验采用SA2-16-14TP真空热处理炉进行退火,为避免退火过程中试样表面的氧化,退火前通过真空泵将炉内气压降至3×10–3Pa。退火过程中试样随炉升温,到温后保温4 h,随炉冷却至室温。退火温度分别为700、900、1 100 ℃,打印态试样与各温度退火试样以下简称为SLMed、SLM-700、SLM-900和SLM-1100。

3)通过CHI760型电化学工作站对高熵合金试样进行动电位极化和电化学阻抗谱测试,测试中工作电极、参比电极和辅助电极分别为高熵合金试样、甘汞电极和铂电极。所有试验均在室温(25±1) ℃环境下进行。测试前,对试验体系测量1 h开路电位,确保试验体系稳定。电化学阻抗谱的测试频率为10 kHz~10 mHz,动电位极化曲线测试初始电位为–1.5 V,最终电位为1.5 V。

图1 CoCrFeMnNi高熵合金粉末形貌(a)与成分(b—f)

图2 激光选区熔化设备与扫描策略

4)为研究钝化膜对腐蚀性能的影响,将退火前后的高熵合金试样浸泡在3.5% NaCl溶液中7 d,使其形成稳定的钝化膜。使用X射线光电子能谱仪(XPS)对钝化膜成分进行分析,XPS结果通过C(C1s, 284.8 eV)进行校正。

2 结果及分析

2.1 相组成的分析

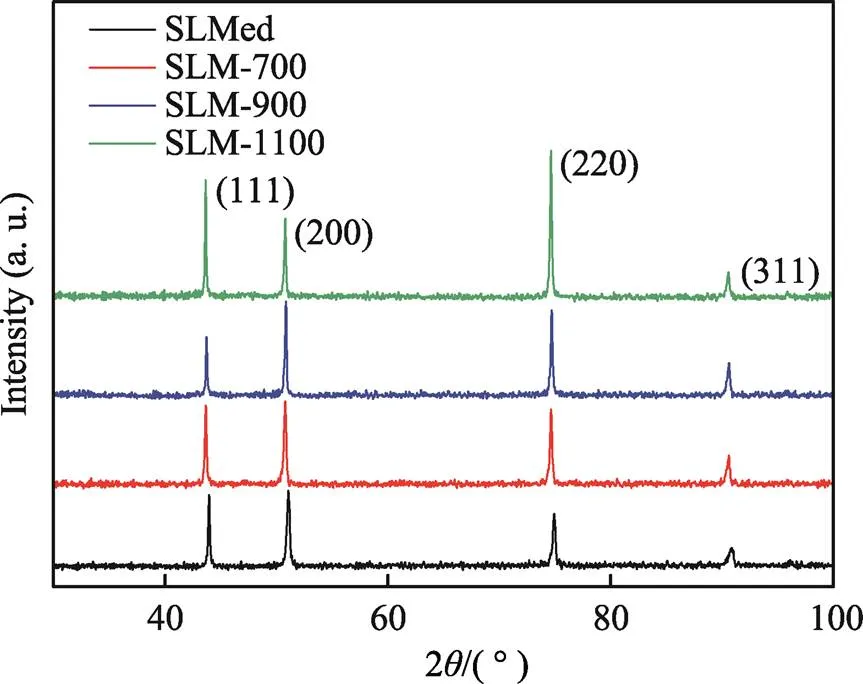

退火前后CoCrFeMnNi高熵合金的XRD图谱如图3所示。由于CoCrFeMnNi高熵合金中的5种元素具有相近的原子半径,化学相容性较好,有利于生成单相。通过XRD分析发现,在经过退火后,合金均为单一的面心立方(FCC)结构固溶体。经过不同温度退火后,相较于SLMed试样,衍射峰向左偏移。这说明经过退火后,晶面间距和晶格参数略有增加,位错密度有所下降[22]。

2.2 微观组织分析

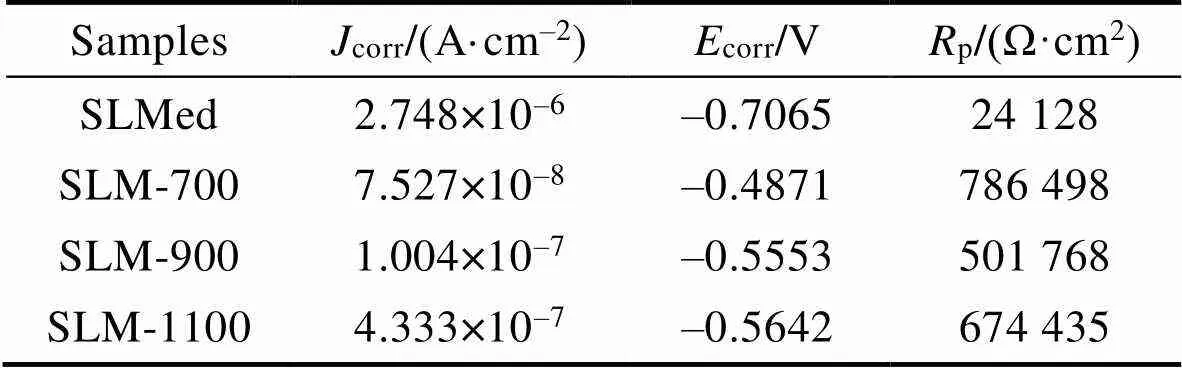

退火前后CoCrFeMnNi高熵合金的微观组织如图4所示。退火前,微观组织主要由熔池及跨越熔池生长的柱状晶所组成;700 ℃退火后,消除了部分熔池边界(MPB),柱状晶有所长大;900、1 100 ℃退火后,熔池边界全部消失,柱状晶进一步长大。熔池边界分为“层–层”和“轨道–轨道”2种类型,有报道称“轨道–轨道”熔池边界所形成的尖锐区域不利于合金的力学性能[23],但不同熔池边界类型对腐蚀行为的影响较小[24]。通过测量SLMed试样中的熔池形态,发现大部分熔池宽度为100~200 μm,深度为70~150 μm。为表示熔池间结合情况,采用几何结合因子作为指标[25],当﹥1时,才能得到致密的金属试样,其计算方法见式(1)。

图3 退火前后高熵合金的XRD图谱

图4 退火前后高熵合金微观组织的金相图片

式中:为熔池宽度;为熔池下侧交点的距离;为铺粉层厚。本研究在最优工艺下的几何结合因子=1.02,说明在连续扫描过程中,较大比例的单个熔池被重熔,因此得到了高致密度的试样(相对密度为99.4 %)。

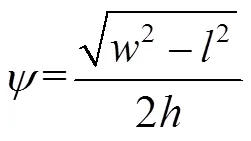

退火前后CoCrFeMnNi高熵合金微观组织的SEM形貌如图5所示。由图5a可以看出,SLMed试样的柱状晶内包含着大量的胞状亚晶结构,平均尺寸小于1 μm。由于打印时采用棋盘式扫描策略,晶粒生长时,散热方向不断发生转变,胞状亚晶呈现出不同的生长方向。经700 ℃退火后,大部分熔池边界消失,但胞状亚晶仍然存在(见图5b)。经900、1 100 ℃退火后,SLM-900试样和SLM-1100试样中的熔池边界全部消失,转变为晶界,亚晶界也全部消失(见图5c、d)。金属材料冷却凝固时,微观结构取决于温度梯度()和晶体生长速率()。SLM成形过程中,金属熔池凝固前沿的冷却速度高达103K/s以上,/值较高,会产生大量亚稳态胞状亚晶[26-27]。此外,Prashanth等[28]认为经典凝固理论不足以解释胞状亚晶的形成机制,除了热力学和动力学,还要考虑物理学方面的因素,如表面张力导致的溶质/杂质扩散。研究表明,SLM成形所产生的胞状亚晶由位错环组成,在热力学上处于亚稳态,高温退火后,胞状亚晶逐渐消失[18,29-30]。退火导致胞状亚晶的消失,一方面,由于在退火过程中位错获得足够的能量产生运动,运动过程中异号位错相互抵消,从而使位错环所组成的胞状亚晶逐渐消失;另一方面,由于高温退火促使合金产生再结晶,形成无畸变的晶粒,在此过程中,胞状亚晶逐渐消失[29-31]。同时在本文研究工作中,经过700 ℃下4 h退火后,SLM-700试样部分胞状亚晶消失,900、1 100 ℃退火后,胞状亚晶完全消失。这是由于具有高畸变能的位错在高温退火过程中容易转变为具有低能态的规则晶格结构,表明了胞状亚晶为非平衡组织,具有热力学亚稳态性质。

2.3 电化学腐蚀性能分析

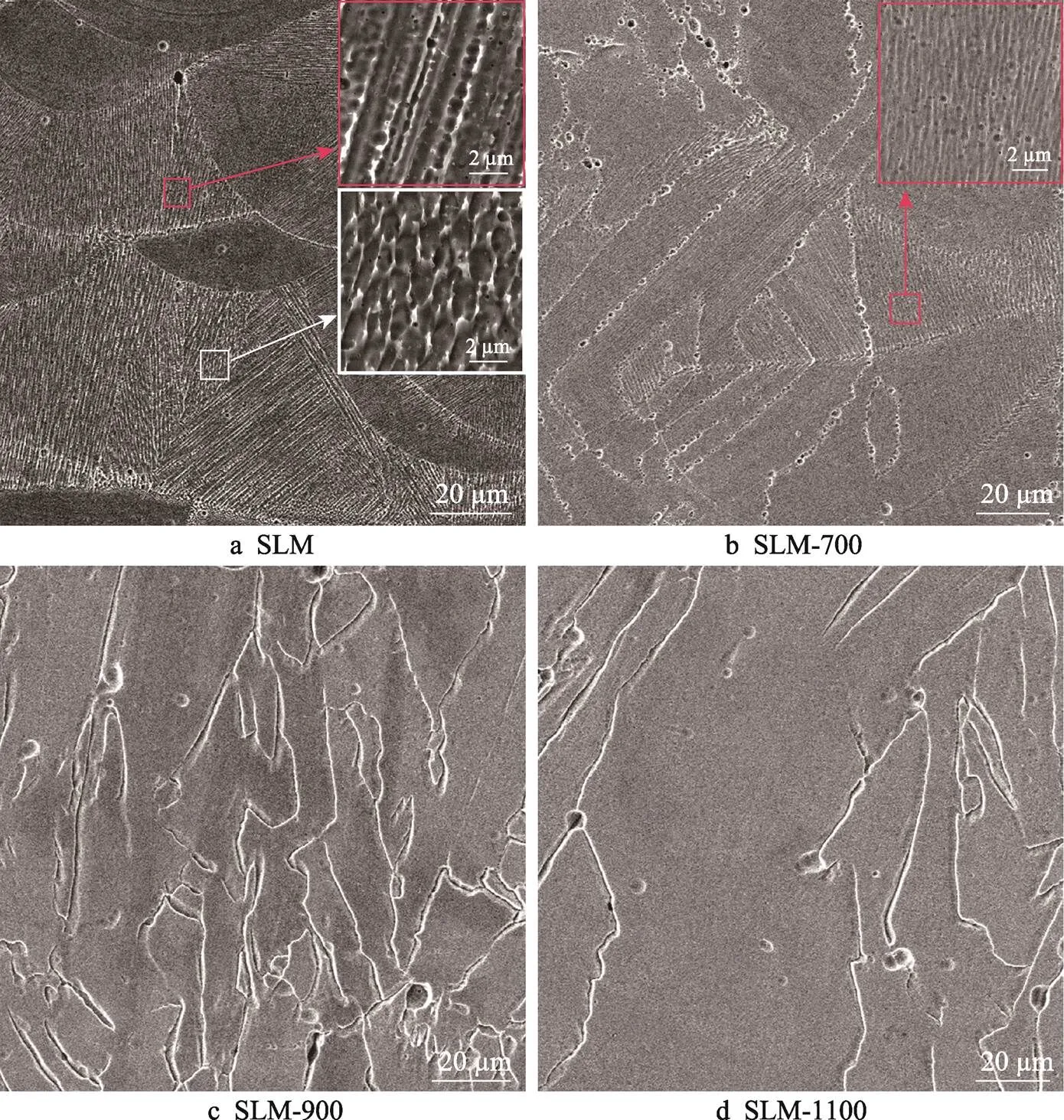

退火前后CoCrFeMnNi高熵合金在3.5% NaCl溶液中的动电位极化曲线如图6所示,从图6中可知,SLMed试样的腐蚀电流密度(corr)最大,腐蚀电位(corr)最低,耐点蚀性能最差,退火后试样的耐点蚀性能整体要优于SLMed试样。通过Tafel外推法对动电位极化曲线进行分析,结果见表1。其中,corr为腐蚀电流密度;corr为腐蚀电位;p为极化电阻。结果表明,随着退火温度的提高,CoCrFeMnNi高熵合金的耐点蚀性能先增加、后减小。SLM-700试样表现出最佳的耐点蚀性能,SLM-900与SLM-1100试样的耐点蚀性能相似。SLM-700试样相较于SLMed试样,腐蚀电流密度下降了97.3%,腐蚀电位提高了31.5%,极化电阻提高了32.6倍。与他人[18-20,24,29]对CoCrFeMnNi高熵合金和316L不锈钢耐蚀性的研究工作进行对比,发现高熵合金与316L不锈钢的耐点蚀性能相近,SLM成形CoCrFeMnNi高熵合金的耐点蚀性能略优于铸态CoCrFeMnNi高熵合金。

图5 退火前后高熵合金微观组织的SEM形貌

图6 高熵合金的动电位极化曲线及与他人工作对比

表1 高熵合金在3.5% NaCl中的动电位极化测试结果

Tab.1 Results of dynamic potential polarization test of HEA in 3.5% NaCl

CoCrFeMnNi高熵合金在3.5% NaCl溶液中的Nyquist图、Bode图及等效电路如图7所示。4组试样的Nyquist图均表现为不完整的半圆状(见图7a),表明在腐蚀过程中主要受电荷转移控制,在Nyquist图中的电容弧直径越大,表面的钝化膜越稳定,样品的耐腐蚀性就越高[32]。图7c为等效电路模型(EEC),由溶液电阻(e)、极化电阻(1)和恒相位元件(CPE)组成。等效电路中1与CPE并联,e与1和CPE串联。由于金属/溶液界面的非理想电容行为,在EEC模型中使用CPE代替纯电容[18],高熵合金在3.5% NaCl溶液中的EIS等效电路拟合参数见表2。与其他状态试样相比,SLM-700试样具有更高的1值和更小的CPE值,表明在SLM-700试样上形成的钝化膜具有更稳定和更强的保护性能,缺陷更少[19]。

表2 等效电路参数拟合结果

Tab.2 Fitting results of equivalent circuit parameters

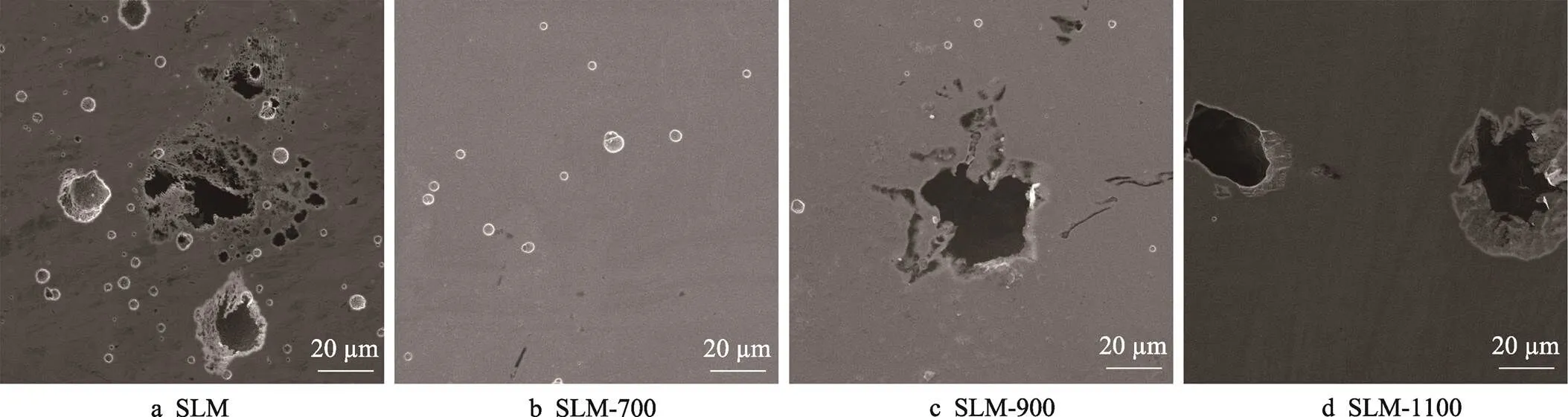

经动电位极化后的腐蚀形貌如图8所示。由图8可以看出,点蚀是高熵合金在3.5% NaCl溶液中的主要腐蚀形式。原始试样中存在较深的点蚀坑与密集的小点蚀坑,同样在900、1 100 ℃退火试样中也发现了较深的点蚀坑,但在700 ℃退火后,腐蚀形貌中仅观察到小点蚀坑。导致SLM成形高熵合金产生点蚀与阻碍点蚀的主要因素是界面、熔池边界和晶界[29],微观结构演变影响SLM成形高熵合金的耐点蚀性能。熔池边界相较于晶界是更加容易被腐蚀的区域,在SLMed试样中存在大量易被腐蚀的熔池边界,因此SLMed试样在盐溶液中耐点蚀性能最差。在经过700 ℃退火后,高熵合金中消除了大部分熔池边界,减少了点蚀发生区域[24],保留了细小的胞状亚晶。细小的晶粒可以降低亚稳态点蚀坑的形成速率,使点蚀坑由亚稳态转变为稳态阻碍点蚀坑的继续长大,提高合金的耐腐蚀性能[33],因此在700 ℃退火后,高熵合金表现出最佳的耐点蚀性能。在经过900、1 100 ℃退火后,胞状亚晶消失,晶粒显著长大,导致其耐点蚀性能有所下降[34]。

图7 高熵合金在3.5% NaCl溶液中的电化学阻抗谱与等效电路

图8 高熵合金在3.5% NaCl溶液中的腐蚀形貌

2.4 钝化膜组成分析

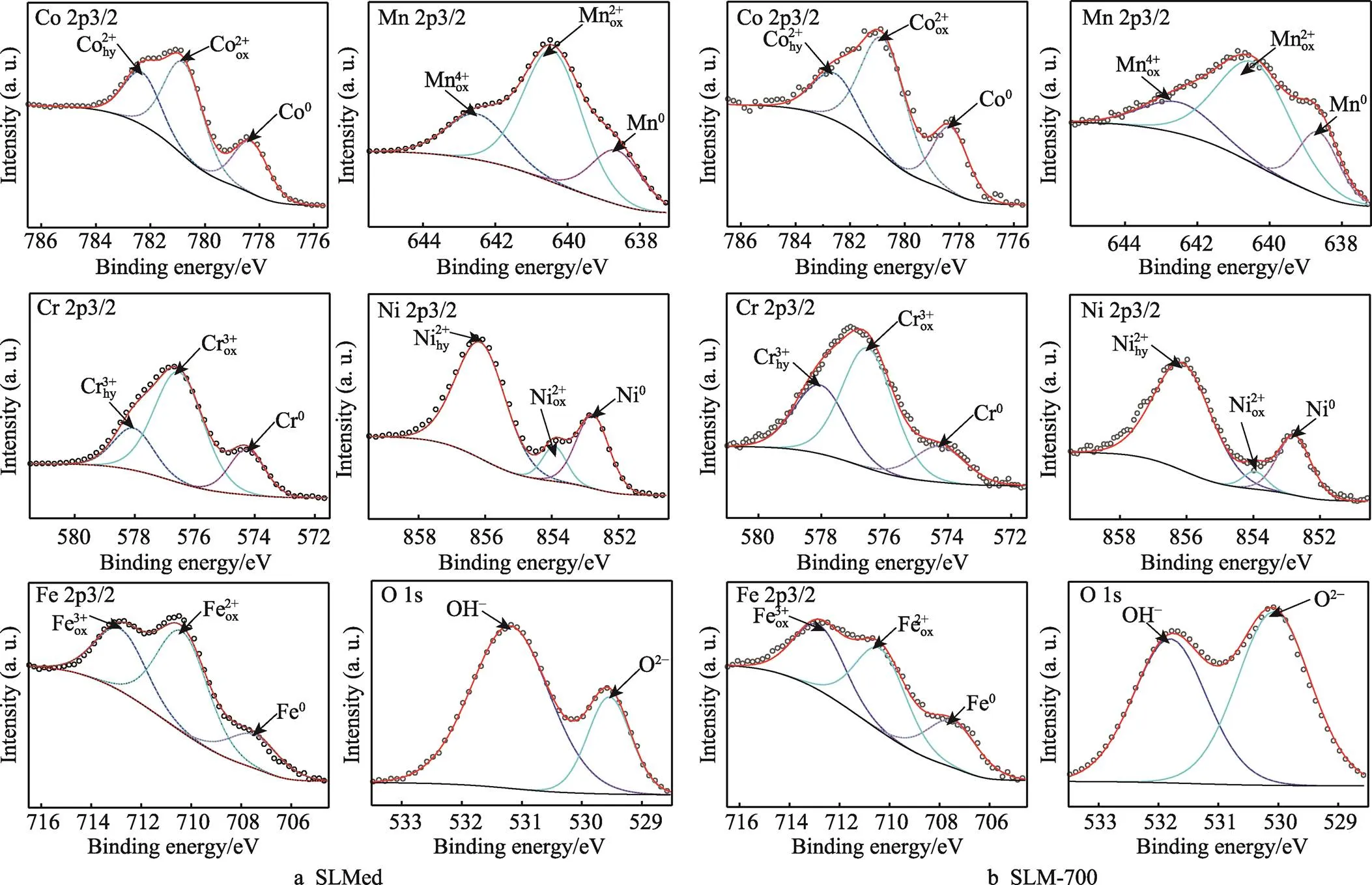

腐蚀过程中,钝化膜可以起到阻碍腐蚀继续进行的作用,提高耐点蚀性能。因此,本节通过XPS对CoCrFeMnNi高熵合金在3.5% NaCl溶液中所形成的钝化膜进行分析。将SLMed和SLM-700试样在3.5% NaCl溶液中浸泡7 d,选择未发生点蚀的区域进行XPS分析,结果如图9所示。

结合XPS手册及相关文献[35-37],对试验结果进行分峰拟合,钝化膜的成分主要由氧化物与氢氧化物组成。Co 2p3/2出现3个峰,分别对应金属态Co(778.1 eV)、Coo2x+(780.9 eV)和Coh2y+(782.1 eV)。Cr 2p3/2发生电离均形成3个组成峰,分别对于金属态Cr(574.1 eV)、Cro3x+(576.8 eV)和Crh3y+(578.4 eV)。Fe 2p3/2发生电离形成3个组成峰,分别对应于金属态Fe(707.1 eV)、Feo2x+(709.9 eV)、Feox3+(711.6 eV)。Ni 2p3/2的XPS光谱有3个组成峰,分别对应于金属Ni(852.8 eV)、Nio2x+(854.0 eV)、Nih2y+(856.0 eV)。O 1s对应2个峰,一个为金属氧化物所对应的O2–(530.1 eV),另一个峰为金属氢氧化物所对应的OH–(531.8 eV)。

图9 高熵合金在3.5% NaCl溶液中浸泡7 d后的XPS图谱

基于XPS检测,对氧化膜的成分进行半定量分析,各元素离子比例(C)的计算见式(2)[18]。

式中:I为各元素的峰面积;S为原子的灵敏度因子。各元素离子比例计算结果如图10所示,结果表明,SLMed与SLM-700的成分组成基本相同,但金属离子比例有所不同。研究表明,对于CoCrFeMnNi高熵合金,Cr、Co和Ni可以形成具有保护能力的致密钝化膜,这3种元素在钝化膜中含量越高,合金的耐点蚀性能越强,即Co+Cr+Ni与Mn+Fe阳离子含量的比值越高,耐点蚀性能越强[18,38]。通过计算,2组试样中Co+Cr+Ni与Mn+Fe阳离子含量的比值分别为1.38和1.83,表明700 ℃退火后耐点蚀性能有所提升。

Cr元素所形成的氧化层是钝化膜中重要的组成部分之一,因此通过计算Cr氧化层厚度可以推测试样的耐点蚀性能。Cr元素的本征氧化层厚度的计算见式(3)[39-40]。

式中:dfilm为本征氧化层厚度;λ为Cr元素光电子的介质自由程长度,λ=1.7 nm;为XPS分析中Cr氧化物的积分强度;为XPS分析中Cr金属态的积分强度。经过计算,2组试样的dfilm分别为5.75 nm与5.43 nm。700 ℃退火后,钝化膜中保护性成分增加,钝化膜保护性增强。

3 结论

1)SLM成形CoCrFeMnNi高熵合金在退火前后均为单一的FCC结构,随着退火温度的升高,熔池边界与亚晶结构逐渐消失。

2)在3.5% NaCl溶液中,高熵合金的耐点蚀性能随退火温度的升高先提升、后降低,经过700 ℃退火后,高熵合金的抗点蚀能力最佳。相较于打印态试样,700 ℃退火试样的腐蚀电流密度下降了97.3%,腐蚀电位提高了31.5%,极化电阻提高了32.6倍。

3)在3.5% NaCl溶液中浸泡7 d后,高熵合金钝化膜主要由金属离子的氧化物与氢氧化物所组成,打印态试样和700 ℃退火试样钝化膜中,Co+Cr+Ni与Mn+Fe阳离子含量的比值分别为1.38和1.61,本征氧化层厚度分别为5.43 nm与5.75 nm。700 ℃退火后,高熵合金在NaCl溶液中所形成钝化膜的抗点蚀能力更强。

[1] YEH J W, CHEN S K, LIN S J, et al. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes[J]. Advanced Engineering Materials, 2004, 6(5): 299-303.

[2] MIRACLE D B, SENKOV O N. A Critical Review of High Entropy Alloys and Related Concepts[J]. Acta Materialia, 2017, 122: 448-511.

[3] GLUDOVATZ B, HOHENWARTER A, CATOOR D, et al. A Fracture-Resistant High-Entropy Alloy for Cryogenic Applications[J]. Science, 2014, 345(6201): 1153- 1158.

[4] 王洪伟, 何竹风, 贾楠. 非均匀组织FeMnCoCr高熵合金的微观结构和力学性能[J]. 金属学报, 2021, 57(5): 632-640.

WANG Hong-wei, HE Zhu-feng, JIA Nan. Microstructure and Mechanical Properties of a FeMnCoCr High-Entropy Alloy with Heterogeneous Structure[J]. Acta Metallurgica Sinica, 2021, 57(5): 632-640.

[5] 刘一帆, 常涛, 刘秀波, 等. 高熵合金涂层的摩擦学性能研究进展[J]. 表面技术, 2021, 50(8): 156-169.

LIU Yi-fan, CHANG Tao, LIU Xiu-bo, et al. Research Progress on Tribological Properties of High-Entropy Alloy Coatings[J]. Surface Technology, 2021, 50(8): 156-169.

[6] SHITTU J, SADEGHILARIDJANI M, POLE M, et al. Tribo-Corrosion Response of Additively Manufactured High-Entropy Alloy[J]. Npj Materials Degradation, 2021, 5: 31.

[7] XU, ZHANG H, LI W, et al. Microstructure and Nanoindentation Creep Behavior of CoCrFeMnNi High- Entropy Alloy Fabricated by Selective Laser Melting[J]. Additive Manufacturing, 2019, 28: 766-771.

[8] SHUANG S, DING Z Y, CHUNG D, et al. Corrosion Resistant Nanostructured Eutectic High Entropy Alloy[J]. Corrosion Science, 2020, 164: 108315.

[9] WU P, GAN K, YAN D, et al. A Non-Equiatomic FeNiCoCr High-Entropy Alloy with Excellent Anti- Corrosion Performance and Strength-Ductility Synergy [J]. Corrosion Science, 2021, 183: 109341.

[10] 郝文俊, 孙荣禄, 牛伟, 等. 激光熔覆CoCrFeNiSix高熵合金涂层组织及耐蚀性能研究[J]. 表面技术, 2021, 50(8): 343-348.

HAO Wen-jun, SUN Rong-lu, NIU Wei, et al. Study on Microstructure and Corrosion Resistance of CoCrFeNiSixHigh-Entropy Alloy Coating by Laser Cladding[J]. Surface Technology, 2021, 50(8): 343-348.

[11] 张冲, 吴旭晖, 戴品强. FeCoCr0.5NiBSi高熵合金涂层的高温冲蚀磨损性能[J]. 表面技术, 2019, 48(2): 166- 172.

ZHANG Chong, WU Xu-hui, DAI Pin-qiang. Erosive Wear Properties of FeCoCr0.5NiBSiHigh-Entropy Alloy Coating at High Temperature[J]. Surface Technology, 2019, 48(2): 166-172.

[12] LI Rui-di, NIU Peng-da, YUAN Tie-chui, et al. Selective Laser Melting of an Equiatomic CoCrFeMnNi High- Entropy Alloy: Processability, Non-Equilibrium Microstructure and Mechanical Property[J]. Journal of Alloys and Compounds, 2018, 746: 125-134.

[13] 赖莉, 徐震霖, 何宜柱. 热处理对SLM 18Ni300马氏体时效钢组织及腐蚀性能的影响[J]. 表面技术, 2019, 48(12): 328-335.

LAI Li, XU Zhen-lin, HE Yi-zhu. Effect of Heat Treatment on Microstructure and Corrosion Properties of SLM 18Ni300 Maraging Steel[J]. Surface Technology, 2019, 48(12): 328-335.

[14] ZHU Z G, NGUYEN Q B, NG F L, et al. Hierarchical Microstructure and Strengthening Mechanisms of a CoCrFeNiMn High Entropy Alloy Additively Manufactured by Selective Laser Melting[J]. Scripta Materialia, 2018, 154: 20-24.

[15] HUANG S, GUAN H, ZHONG Z, et al. Effect of He on the Irradiation Resistance of Equiatomic CoCrFeMnNi High-Entropy Alloy[J]. Journal of Nuclear Materials, 2022, 561: 153525.

[16] JIANG G, XU D, FENG P, et al. Corrosion of FeCrAl Alloys Used as Fuel Cladding in Nuclear Reactors[J]. Journal of Alloys and Compounds, 2021, 869: 159235.

[17] PATHAK S, KUMAR N, MISHRA R S, et al. Aqueous Corrosion Behavior of Cast CoCrFeMnNi Alloy[J]. Journal of Materials Engineering and Performance, 2019, 28(10): 5970-5977.

[18] XU Z, ZHANG H, DU X, et al. Corrosion Resistance Enhancement of CoCrFeMnNi High-Entropy Alloy Fabricated by Additive Manufacturing[J]. Corrosion Science, 2020, 177: 108954.

[19] WANG Bo-wen, SUN Miao, LI Bo-bo, et al. Anisotropic Response of CoCrFeMnNi High-Entropy Alloy Fabricated by Selective Laser Melting[J]. Materials (Basel, Switzerland), 2020, 13(24): 5687.

[20] THOTA H, JEYARAAM R, BAIRI L R, et al. Grain Boundary Engineering and Its Implications on Corrosion Behavior of Equiatomic CoCrFeMnNi High Entropy Alloy[J]. Journal of Alloys and Compounds, 2021, 888: 161500.

[21] ZHU M, ZHAO B, YUAN Y, et al. Effect of Annealing Temperature on Microstructure and Corrosion Behavior of CoCrFeMnNi High-Entropy Alloy in Alkaline Soil Simulation Solution[J]. Materials Chemistry and Physics, 2022, 279: 125725.

[22] TONG Z P, REN X D, JIAO J F, et al. Laser Additive Manufacturing of FeCrCoMnNi High-Entropy Alloy: Effect of Heat Treatment on Microstructure, Residual Stress and Mechanical Property[J]. Journal of Alloys and Compounds, 2019, 785: 1144-1159.

[23] WEN S F, LI S, WEI Q S, et al. Effect of Molten Pool Boundaries on the Mechanical Properties of Selective Laser Melting Parts[J]. Journal of Materials Processing Technology, 2014, 214(11): 2660-2667.

[24] ZHAO C, BAI Y, ZHANG Y, et al. Influence of Scanning Strategy and Building Direction on Microstructure and Corrosion Behaviour of Selective Laser Melted 316L Stainless Steel[J]. Materials & Design, 2021, 209: 109999.

[25] LIU Z, ZHAO D, WANG P, et al Additive Manufacturing of Metals: Microstructure Evolution and Multistage Control[J]. Journal of Materials Science & Technology, 2022, 100: 224-236.

[26] KENEL C, GROLIMUND D, LI X, et al. In Situ Investigation of Phase Transformations in Ti-6Al-4V under Additive Manufacturing Conditions Combining Laser Melting and High-Speed Micro-X-Ray Diffraction[J]. Scientific Reports, 2017, 7: 16358.

[27] CHEN Z W, PHAN M L, DARVISH K. Grain Growth during Selective Laser Melting of a Co-Cr-Mo Alloy[J]. Journal of Materials Science, 2017, 52(12): 7415-7427.

[28] PRASHANTH K G, ECKERT J. Formation of Metastable Cellular Microstructures in Selective Laser Melted Alloys[J]. Journal of Alloys and Compounds, 2017, 707: 27-34.

[29] ZHOU Cheng-shuang, HU Shi-yin, SHI Qiao-ying, et al. Improvement of Corrosion Resistance of SS316L Manufactured by Selective Laser Melting through Subcritical Annealing[J]. Corrosion Science, 2020, 164: 108353.

[30] KONG De-cheng, DONG Chao-fang, WEI Shao-lou, et al. About Metastable Cellular Structure in Additively Manufactured Austenitic Stainless Steels[J]. Additive Manufacturing, 2021, 38: 101804.

[31] FU Z, YANG B, GAN K, et al. Improving the Hydrogen Embrittlement Resistance of a Selective Laser Melted High-Entropy Alloy via Modifying the Cellular Structures[J]. Corrosion Science, 2021, 190: 109695.

[32] KUMAR N, FUSCO M, KOMARASAMY M, et al. Understanding Effect of 3.5 wt.% NaCl on the Corrosion of Al0.1CoCrFeNi High-Entropy Alloy[J]. Journal of Nuclear Materials, 2017, 495: 154-163.

[33] MAN C, DUAN Z, CUI Z, et al. The Effect of Sub-Grain Structure on Intergranular Corrosion of 316L Stainless Steel Fabricated via Selective Laser Melting[J]. Materials Letters, 2019, 243: 157-160.

[34] ABBASI AGHUY A, ZAKERI M, MOAYED M H, et al. Effect of Grain Size on Pitting Corrosion of 304L Austenitic Stainless Steel[J]. Corrosion Science, 2015, 94: 368-376.

[35] BIESINGER M C, PAYNE B P, GROSVENOR A P, et al. Resolving Surface Chemical States in XPS Analysis of First Row Transition Metals, Oxides and Hydroxides: Cr, Mn, Fe, Co and Ni[J]. Applied Surface Science, 2011, 257(7): 2717-2730.

[36] LIU C, WU J. Influence of pH on the Passivation Behavior of 254SMO Stainless Steel in 3.5% NaCl Solution[J]. Corrosion Science, 2007, 49(5): 2198-2209.

[37] WATTS J F. The Use of X-ray Photoelectron Spectroscopy for the Analysis of Organic Coating Systems[M]// Wilson AD, Nicholson JW, Prosser HJ. Surface Coatings— 1. Dordrecht: Springer, 1987: 137-187.

[38] LUO H, ZOU S, CHEN Y H, et al. Influence of Carbon on the Corrosion Behaviour of Interstitial Equiatomic CoCrFeMnNi High-Entropy Alloys in a Chlorinated Concrete Solution[J]. Corrosion Science, 2020, 163: 108287.

[39] REYNIER I, BENNY W, FRANCESCO A, et al. EIS Comparative Study and Critical Equivalent Electrical Circuit (EEC) Analysis of the Native Oxide Layer of Additive Manufactured and Wrought 316L Stainless Steel[J]. Corrosion Science, 2020, 167: 108480.

[40] WALLINDER D, PAN J, LEYGRAF C, et al. Eis and XPS Study of Surface Modification of 316LVM Stainless Steel after Passivation[J]. Corrosion Science, 1998, 41(2): 275-289.

Effect of Annealing Temperature on Pitting Resistance of CoCrFeMnNi High-entropy Alloy Fabricated by Laser Additive Manufacturing

,,

(School of Materials Science and Engineering, Anhui University of Technology, Anhui Maanshan 243002, China)

Equiatomic CoCrFeMnNi high-entropy alloy (HEA) has good corrosion resistance and radiation resistance, and possesses high strength and excellent toughness at cryogenic temperature, which makes it a potential application material for advanced nuclear reactors. As one of the most widely applied additive manufacturing (AM) technologies, selective laser melting (SLM) provides a new idea for the green preparation of HEA, reducing the production cycle and the manufacturing cost. However, the corrosion resistance of the CoCrFeMnNi HEA prepared by laser additive manufacturing still lacks systematic study. The work aims to investigate the effect laws of microstructure evolution on the pitting resistance of the SLMed CoCrFeMnNi high-entropy alloy in NaCl solution after annealing at various temperature.

Spherical CoCrFeMnNi HEA powder with an average diameter of 26.0 μm fabricated by gas-atomized was used in this study. The high-density CoCrFeMnNi HEA with a relative density of 99.4 % was fabricated by a SLM machine (Hanbang HBD-150D) under pure argon gas protection. The manufacturing process was set as: checkerboard scanning strategy, laser power of 180 W, scanning speed of 670 mm/s, hatching space of 70 μm and layer thickness of 50 μm. Then, the SLMed specimens were subject to annealing for 4 hours at 700 ℃, 900 ℃ and 1 100 ℃ respectively, followed by cooling in a furnace in an argon atmosphere. The phase of the HEA before and after annealing was analyzed by X-ray diffraction (XRD, Japanese Rigaku D/max2500pc). The microstructure was examined by optical microscopy (OM, Zeiss Axiovert 40MAT) and scanning electron microscopy (SEM, Tescan MIRA3 XMU). The pitting resistance of the SLMed HEA in 3.5 wt.% NaCl solution was analyzed by kinetic potential polarization and electrochemical impedance spectroscopy (EIS). The composition of the passivation film of the HEA formed in the NaCl solution was investigated by X-ray photoelectron spectroscopy (XPS, Thermo Scientific K-Alpha).

The phase of the CoCrFeMnNi HEA before and after annealing was single-phase face-centered cubic, which indicated that the HEA had good phase stability at elevated temperature. However, the microstructure of the HEAs had undergone a significant transformation after annealing. The microstructure of the SLMed HEA consisted of melt pools, columnar crystals, and cellular subgrains due to the rapid heating and cooling in the manufacturing process. As the annealing temperature increased, the melt pool boundary and subgrain structure gradually disappeared and the grains gradually grew. Annealing treatment significantly affected the pitting resistance of the HEAs. With the increase of annealing temperature from 700 ℃ to 1 100 ℃, the corrosion current density of the HEAs decreased firstly and then increased. The corrosion current density of the sample annealed at 700 ℃ decreased by 97 % compared with that of the as-built sample. The HEA passive film mainly consisted of metal oxides and hydroxides. The cation ratios of the Co+Cr+Ni to Mn+Fe in the passivation film of the samples prepared by SLM and annealed at 700 ℃were 1.38 and 1.61, respectively, and the thickness of the Cr intrinsic oxide layer in the passivation film was 5.43 nm and 5.75 nm, respectively. The sample annealed at 700 ℃ has the best pitting resistance. With the increase of annealing temperature, the pitting resistance of high-entropy alloy firstly increases and then decreases. Cellular subgrain is beneficial to hindering the expansion of pitting and promoting the formation of stable passivation film. The annealing at 700 °℃ provides the best pitting resistance by removing part of the melt pool boundary while maintaining the cellular subgrains, preventing further pitting pit expansion and improving the protection ability of passivation film.

selective laser melting; additive manufacturing; high-entropy alloy; microstructure; pitting corrosion; passivation film

TG156.2

A

1001-3660(2023)02-0272-10

10.16490/j.cnki.issn.1001-3660.2023.02.025

2022–01–22;

2022–04–11

2022-01-22;

2022-04-11

国家自然科学基金(51971001);山西省科技重大专项(20181101016)

The National Natural Science Foundation of China (51971001); The Science and Technology Major Special Project of Shanxi Province (20181101016)

贾玺泉(1997—),男,硕士研究生,主要研究方向为金属增材制造。

JIA Xi-quan (1997-), Male, Postgraduate, Research focus: metal additive manufacturing.

何宜柱(1962—),男,硕士,教授,主要研究方向为高性能金属结构材料及增材制造。

HE Yi-zhu (1962-), Male, Master, Professor, Research focus: advanced structural metallic materials and additive manufacturing.

贾玺泉, 徐震霖, 周生璇, 等. 退火温度对激光增材制造CoCrFeMnNi高熵合金耐点蚀性能的影响[J]. 表面技术, 2023, 52(2): 272-281.

JIA Xi-quan, XU Zhen-lin, ZHOU Sheng-xuan, et al. Effect of Annealing Temperature on Pitting Resistance of CoCrFeMnNi High-entropy Alloy Fabricated by Laser Additive Manufacturing[J]. Surface Technology, 2023, 52(2): 272-281.

责任编辑:刘世忠