高强汽车中锰钢的热压缩变形行为研究

校振华,冯亚磊,冯启生,罗志辉

高强汽车中锰钢的热压缩变形行为研究

校振华1,冯亚磊1,冯启生2,3,罗志辉3

(1.河南农业职业学院 机电工程学院,郑州 451450;2.河南科技大学 材料科学与工程学院,河南 洛阳 471000;3.洛阳中重铸锻有限责任公司,河南 洛阳 471000)

为第三代汽车中锰钢工业化生产的加工工艺制定提供参考。采用Gleeble-3800型热力模拟试验机对汽车用中锰钢进行了变形温度900~1 150 ℃、应变速率0.1~20 s−1的热压缩变形处理(变形量为50%),基于不同热压缩变形条件下的应力应变数据建立中锰钢的流变应力本构方程,并对本构方程进行应变补偿,验证考虑应变补偿的流变应力本构方程预测值与试验结果的一致性。应变速率不变时,中锰钢的峰值应力随着变形温度的升高逐渐减小;变形温度不变时,中锰钢的峰值应力随着应变速率的增大整体逐渐增大。在变形温度900~1 150 ℃、应变速率0.1~20 s−1的条件下,汽车用中锰钢考虑应变补偿的流变应力的散点预测值与实测值吻合较好;进行应变补偿处理后,汽车用中锰钢流变应力本构方程的相关系数为0.986,绝对平均误差3.36%,相较于未考虑应变补偿的流变应力本构方程,考虑应变补偿后相关系数变大,绝对平均误差变小。考虑应变补偿的流变应力本构方程可以对汽车用中锰钢热压缩变形过程中的流变行为进行准确预测。

中锰钢;变形温度;应变速率;本构方程;应变补偿

汽车工业的快速发展给汽车用材带来巨大发展机遇的同时,对汽车用钢的开发与应用提出了新的挑战,这主要是因为节能环保、低成本和高防撞安全性等需求的提高[1],已要求汽车用钢从轻量化和安全性指标很低、强塑积一般(约15 GPa·%)的第一代汽车用钢向逐渐升级到轻量化和安全性指标高、强塑积≥30 GPa·%的第三代汽车钢的方向发展[2-4]。其中,Fe-Mn-Al-C系中锰钢由于具有密度低、强度高、塑性好和生产成本低等特点而成为第三代汽车用钢的重要组成部分,科研工作者从成分设计、工艺设计、组织调控等角度已开发出了强塑积可以达到30 GPa·%以上的汽车中锰钢[5-7]。然而,目前汽车用中锰钢的研究主要还处于实验室阶段,仍然存在成形工艺复杂性和可控性等问题[8-9],需要进一步研究热变形过程中变形温度、变形速率等对汽车中锰钢热变形行为的影响规律,为具有良好强塑性的第三代高强汽车钢规模化工业生产过程中的加工工艺制定提供参考。

1 试验材料与方法

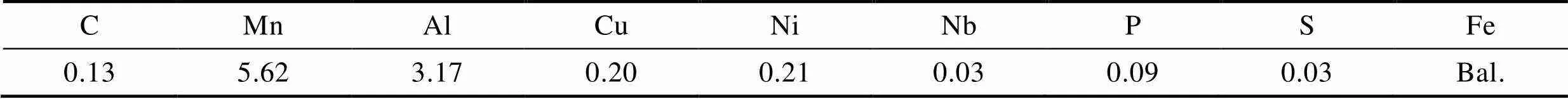

采用真空冶炼的方法制备自行设计的汽车用Fe-Mn-Al-C中锰钢锭,钢锭进行1 180 ℃保温2 h的均匀化热处理后,在1 140~900 ℃的高温至低温范围内将钢锭锻造成截面尺寸100 mm×150 mm的锻坯,空冷至室温。采用电感耦合等离子发射光谱法测得其主要元素含量,如表1所示。采用DIL805型热膨胀仪测得中锰钢的Ac1和Ac3分别为638、1 146 ℃。

采用线切割方法从锻坯上截取8 mm×12 mm棒状标准试样,在Gleeble–3800型热力模拟试验机上进行热压缩试验。棒状试样以8 ℃/s的速度从室温升高至1 200 ℃,保温3 min后以8 ℃/s速度冷却至设定热压缩温度(900、950、1 000、1 050、1 150 ℃),保温0.5 min后以设定应变速率(0.1、1、2.5、5、10、20 s−1)热压缩至50%变形量,水淬至室温。

2 结果与分析

2.1 流变应力本构方程

图1为不同应变速率下汽车用中锰钢的真应力-真应变曲线。在不同应变速率和变形温度下,中锰钢的真应力随应变的整体变化趋势相同。在变形初始阶段,中锰钢的应力随着真应变的增加快速增长,这个阶段对应中锰钢中位错密度增大而产生相互缠结和交割,加工硬化作用下应力快速增大;随着真应变的增加,中锰钢逐渐进入第2个变形阶段,此时中锰钢中的位错通过滑移和攀移使得位错密度降低,回复软化抵消了部分加工硬化作用,真应力随应变增大的速率变小;继续增加真应变,中锰钢逐渐进入稳定变形阶段,中锰钢的变形储能增加使得材料发生动态再结晶,回复和再结晶软化作用与加工硬化作用基本达到平衡,此时应力变化幅度较小;在到达峰值应力后,软化作用逐渐占主导,真应力-真应变曲线逐渐呈现下降趋势。

表1 实验用中锰钢的化学成分

Tab.1 Chemical composition of medium manganese steel for experiment wt.%

图1 不同应变速率下汽车用中锰钢的真应力-真应变曲线

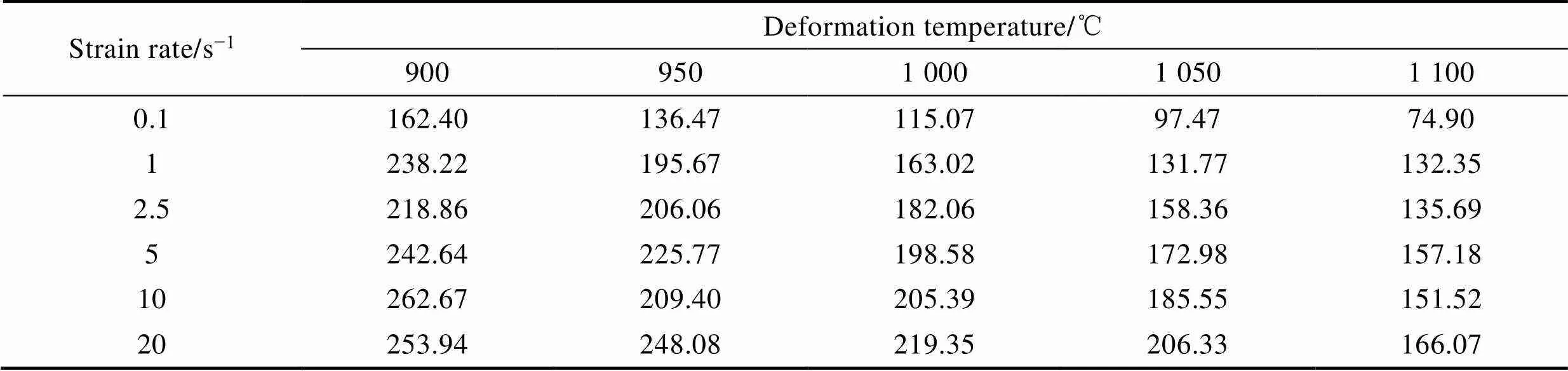

在变形温度900~1 150 ℃、应变速率0.1~20 s−1的条件下,汽车用中锰钢的峰值应力统计结果如表2所示。当应变速率固定不变时,随着变形温度从900 ℃上升至1 150 ℃,中锰钢的峰值应力逐渐减小,这主要是因为变形温度的升高会使得内部热激活能增大,材料的动态软化行为愈发显著而使得应力减小[10];当变形温度固定不变时,随着应变速率从0.1 s−1增大至20 s−1,中锰钢的峰值应力整体呈逐渐增大的趋势,这主要是因为在较高的应变速率下,中锰钢中的加工硬化作用愈发显著[11],相应地,流变应力会更大,但是在变形温度较低时(900、950 ℃),中锰钢仍然存在高应变速率下峰值应力较低的现象,这主要与中锰钢在高应变速率下的变形热来不及散失而造成温度升高有关[12]。

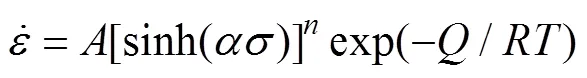

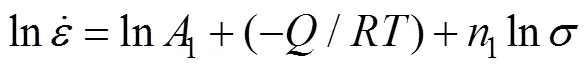

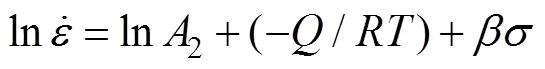

(2)

式中:结构因子(1、2、)和应力指数(1、)为与中锰钢有关的常数;为反映动态软化的应力水平参数(=1);为变形激活能,kJ/mol;为变形温度,K;为气体常数,8.314 J/(mol·K)。

在设定变形温度和应变速率的条件下,假定保持不变,对式(1)—(3)两边取对数,得到式(4)—(6)。

表2 汽车用中锰钢的峰值应力

Tab.2 Peak stress of medium manganese steel for automobile MPa

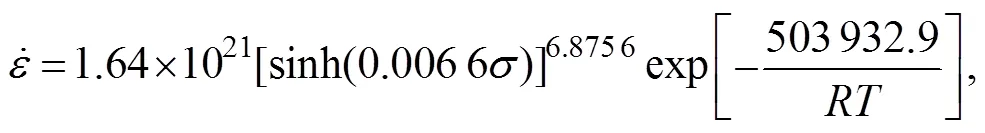

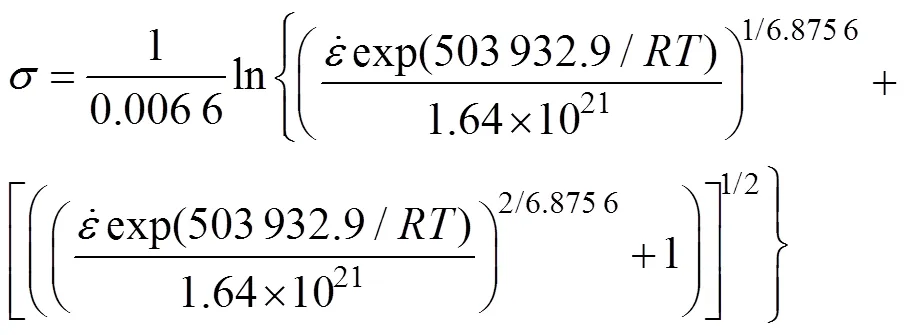

结合式(3)可得汽车用中锰钢的双曲正弦Arrhenius流变应力本构方程,见式(7)

由式(8)、式(9)结合式(7)可得汽车用中锰钢用参数表达的应力本构方程,见式(10)。

2.2 本构方程应变补偿

上述流变应力本构方程的建立主要考虑变形温度和应变速率对流变应力的影响,而未将对中锰钢的激活能有显著影响的应变考虑进去[16],因此,为了提高流变应力本构方程的准确性,有必要对本构方程进行应变补偿。将中锰钢的材料常数(和ln)看作是应变量的多项式函数,采用6阶多项式函数进行拟合[17-18],见式(11)—(14)。

(12)

图3 ln-ln[sinh(ασ)]和ln[sinh(ασ)]-1/T关系曲线

图4为中锰钢的材料常数与真应变的多项式拟合曲线,真应变范围为0.05~0.7。材料常数和ln的确定系数R2分别为0.940 3、0.995 3、0.975 4和0.957 3,而²的值越接近1,则表明回归曲线对观测值的拟合程度越好[19]。由此可见,考虑应变补偿的回归方程整体的拟合度较高。

图5为考虑应变补偿的汽车用中锰钢的应力-应变曲线。由图5可知,在变形温度900~1 150 ℃、应变速率0.1~20 s−1的条件下,汽车用中锰钢考虑应变补偿的流变应力的散点预测值与实测值吻合较好,表明考虑应变补偿的流变应力本构方程可以较好地对汽车用中锰钢的流变应力进行有效预测。

图4 中锰钢各材料常数与真应变的多项式拟合曲线

图5 考虑应变补偿的汽车用中锰钢的应力-应变曲线

进一步引入相关系数()和绝对平均误差(AARE)来评估流变应力本构方程的预测精度[20-21]。在未考虑应变补偿前,汽车用中锰钢流变应力本构方程的相关系数为0.965、绝对平均误差为4.97%,进行应变补偿处理后,相关系数为0.986、绝对平均误差3.36%。可见,相较于未考虑应变补偿的流变应力本构方程,考虑应变补偿后相关系数变大,绝对平均误差变小,这也说明考虑应变补偿可以更好地对汽车用中锰钢热压缩变形过程中的流变应力进行准确预测[22-25]。

3 结论

1)汽车用中锰钢的流变应力本构方程为

2)在变形温度900~1 150 ℃、应变速率0.1~20 s−1的条件下,汽车用中锰钢考虑应变补偿的流变应力的散点预测值与实测值吻合较好;进行应变补偿处理后,汽车用中锰钢流变应力本构方程的相关系数为0.986、绝对平均误差3.36%,相较于未考虑应变补偿的流变应力本构方程,考虑应变补偿后相关系数变大,绝对平均误差变小。考虑应变补偿可以更好地对汽车用中锰钢热压缩变形过程中的流变行为进行准确预测。

[1] 赵征志, 陈伟健, 高鹏飞, 等. 先进高强度汽车用钢研究进展及展望[J]. 钢铁研究学报, 2020, 32(12): 1059-1076.

ZHAO Zheng-zhi, CHEN Wei-jian, GAO Peng-fei, et al. Progress and Perspective of Advanced High Strength Automotive Steel[J]. Journal of Iron and Steel Research, 2020, 32(12): 1059-1076.

[2] 陈明昕, 杨晓江, 孟庆勇. 中锰钢高温热塑性研究[J]. 钢铁研究学报, 2020, 32(6): 519-524.

CHEN Ming-xin, YANG Xiao-jiang, MENG Qing-yong. Study on High Temperature Thermoplasticity of Medium Manganese Steel[J]. Journal of Iron and Steel Research, 2020, 32(6): 519-524.

[3] 宋仁伯, 霍巍丰, 周乃鹏, 等. Fe-Mn-Al-C系中锰钢的研究现状与发展前景[J]. 工程科学学报, 2020, 42(7): 814-828.

SONG Ren-bo, HUO Wei-feng, ZHOU Nai-peng, et al. Research Progress and Prospect of Fe-Mn-Al-C Medium Mn Steels[J]. Chinese Journal of Engineering, 2020, 42(7): 814-828.

[4] 赵明杰, 黄亮, 李昌民, 等. 300M钢的热变形行为及热锻成形工艺研究现状[J]. 精密成形工程, 2020, 12(6): 16-27.

ZHAO Ming-jie, HUANG Liang, LI Chang-min, et al. Research Status of the Hot Deformation Behaviors and Hot Forging Process of 300M Steel[J]. Journal of Netshape Forming Engineering, 2020, 12(6): 16-27.

[5] 何春雨, 余伟, 程知松, 等. 高强耐蚀车体用钢热变形行为及本构方程的研究[J]. 材料导报, 2021, 35(18): 18153-18162.

HE Chun-yu, YU Wei, CHENG Zhi-song, et al. Study on Thermal Deformation Behavior and Constitutive Equation of High Strength Corrosion-Resistant Car Body Steel[J]. Materials Reports, 2021, 35(18): 18153- 18162.

[6] CAI Z M, JI H C, PEI W C, et al. Hot Workability, Constitutive Model and Processing Map of 3Cr23Ni8Mn3N Heat Resistant Steel[J]. Vacuum, 2019, 165: 324-336.

[7] 杨大伟, 李伟, 林莺莺, 等. PH13-8Mo钢热变形行为及本构模型[J]. 锻压技术, 2021, 46(5): 234-239.

YANG Da-wei, LI Wei, LIN Ying-ying, et al. Hot Deformation Behavior and Constitutive Model for PH13-8Mo Steel[J]. Forging & Stamping Technology, 2021, 46(5): 234-239.

[8] 霍存龙, 霍元明, 何涛, 等. 40CrNiMo钢高温低速压缩变形行为及微观组织演变[J]. 材料热处理学报, 2021, 42(8): 84-90.

HUO Cun-long, HUO Yuan-ming, HE Tao, et al. Deformation Behavior and Microstructure Evolution of 40CrNiMo Steel during High Temperature and Low Speed Compression[J]. Transactions of Materials and Heat Treatment, 2021, 42(8): 84-90.

[9] KISHOR B, CHAUDHARI G P, NATH S K. Hot Deformation Characteristics of 13Cr-4Ni Stainless Steel Using Constitutive Equation and Processing Map[J]. Journal of Materials Engineering and Performance, 2016, 25(7): 2651-2660.

[10] 邱宇, 袁飞, 曾元松, 等. 4Cr5MoSiV1热作模具钢的热变形行为与热加工图[J]. 机械工程材料, 2021, 45(2): 71-77.

QIU Yu, YUAN Fei, ZENG Yuan-song, et al. Hot Deformation Behavior and Hot Processing Maps of 4Cr5MoSiV1 Hot Working Die Steel[J]. Materials for Mechanical Engineering, 2021, 45(2): 71-77.

[11] 王庆娟, 王钦仁, 杜忠泽, 等. 40Cr10Si2Mo钢的热变形模型及动态再结晶行为[J]. 钢铁, 2021, 56(11): 112-121.

WANG Qing-juan, WANG Qin-ren, DU Zhong-ze, et al. Hot Deformation Model and Dynamic Recrystallization Behavior of 40Cr10Si2Mo Steel[J]. Iron & Steel, 2021, 56(11): 112-121.

[12] 任劲宇, 陈飞, 张晓峰, 等. 铸态ER8车轮钢的热变形行为及本构模型研究[J]. 锻压技术, 2021, 46(1): 202-207.

REN Jin-yu, CHEN Fei, ZHANG Xiao-feng, et al. Study on Hot Deformation Behavior and Constitutive Model of As-Cast ER8 Wheel Steel[J]. Forging & Stamping Technology, 2021, 46(1): 202-207.

[13] ZHANG H M, CHEN G, CHEN Q, et al. A Physically-Based Constitutive Modelling of a High Strength Aluminum Alloy at Hot Working Conditions[J]. Journal of Alloys and Compounds, 2018, 743: 283-293.

[14] 杨鹏, 宁静, 苏杰, 等. 新型低成本超高强度钢热变形行为研究[J]. 塑性工程学报, 2020, 27(7): 150-157.

YANG Peng, NING Jing, SU Jie, et al. Investigation on Hot Deformation Behavior of New Low Cost Ultra-High Strength Steel[J]. Journal of Plasticity Engineering, 2020, 27(7): 150-157.

[15] 张丽凤. 汽车用6061铝合金热压缩变形行为研究[J]. 塑性工程学报, 2020, 27(11): 174-181.

ZHANG Li-feng. Study on Hot Compression Deformation Behavior of 6061 Aluminum Alloy for Automobile[J]. Journal of Plasticity Engineering, 2020, 27(11): 174-181.

[16] WEN D X, LIN Y C, ZHOU Y. A New Dynamic Recrystallization Kinetics Model for a Nb Containing Ni-Fe-Cr-Base Superalloy Considering Influences of Initial δ Phase[J]. Vacuum, 2017, 141: 316-327.

[17] 张学忠, 刘建生, 何文武, 等. 12%Cr超超临界转子钢热变形行为及高温塑性本构方程[J]. 锻压技术, 2020, 45(8): 184-189.

ZHANG Xue-zhong, LIU Jian-sheng, HE Wen-wu, et al. Hot Deformation Behavior and High Temperature Plastic Constitutive Equation for 12%Cr Ultra-Supercritical Rotor Steel[J]. Forging & Stamping Technology, 2020, 45(8): 184-189.

[18] SHAHRIARI B, VAFAEI R, SHARIFI E M, et al. Modeling Deformation Flow Curves and Dynamic Recrystallization of BA-160 Steel during Hot Compression[J]. Metals and Materials International, 2018, 24(5): 955-969.

[19] 张伟, 闫志杰, 王睿, 等. Fe–1.3C–5Cr–0.4Mo–0.4V超高碳钢的热变形行为与再结晶组织研究[J]. 机械工程学报, 2020, 56(12): 116-123.

ZHANG Wei, YAN Zhi-jie, WANG Rui, et al. Hot Deformation Behavior and Recrystallization Structure of Fe-1.3C-5Cr-0.4Mo-0.4V Ultra High Carbon Steel[J]. Journal of Mechanical Engineering, 2020, 56(12): 116-123.

[20] XIA Y N, ZHANG C, ZHANG L W, et al. A Comparative Study of Constitutive Models for Flow Stress Behavior of Medium Carbon Cr-Ni-Mo Alloyed Steel at Elevated Temperature[J]. Journal of Materials Research, 2017, 32(20): 3875-3884.

[21] PU E X, ZHENG W J, SONG Z G, et al. Characterization of Hot Deformation Behavior of a Fe-Cr-Ni-Mo-N Superaustenitic Stainless Steel Using Dynamic Materials Modeling[J]. Journal of Materials Engineering and Performance, 2017, 26(3): 1424-1432.

[22] CHEN F L, QU H T, WU W, et al. A Physical-Based Plane Stress Constitutive Model for High Strength AA7075 under Hot Forming Conditions[J]. Metals, 2021, 11(2): 314-319.

[23] 张佩佩, 隋大山, 齐珂, 等. 316LN钢高温流动应力与动态再结晶模型[J]. 塑性工程学报, 2014, 21(1): 44-51.

ZHANG P P, SUI D S, QI K, et al. Modeling of Flow Stress and Dynamic Recrystallization for 316LN Steel during Hot Deformation[J]. Journal of Plasticity Engineering, 2014, 21(1):44-51.

[24] LI N, HUANG Y, HAN R H, et al. Constitutive Modeling and Dynamic Recrystallization Mechanisms of an Ultralow-Carbon Microalloyed Steel during Hot Compression Tests[J]. Journal of Wuhan University of Technology-Mater Sci Ed, 2020, 35(5): 946-957.

[25] WU C F, CAI M H, YANG P R, et al. Physically-Based Modeling and Characterization of Hot Flow Behavior in an Interphase-Precipitated Ti-Mo Microalloyed Steel[J]. Metals, 2018, 8(4): 243.

Hot Compression Deformation Behavior of High Strength Medium Manganese Steel for Automobile

XIAO Zhen-hua1, FENG Ya-lei1, FENG Qi-sheng2,3, LUO Zhi-hui3

(1. College of Mechanical and Electrical Engineering, Henan Vocational College of Agriculture, Zhengzhou 451450, China; 2. School of Materials Science and Engineering, Henan University of Science and Technology, Henan Luoyang 471000, China; 3. Luoyang Zhongzhong Casting and Forging Co., Ltd., Henan Luoyang 471000, China)

The work aims to provide reference for the formulation of processing technology in industrial production of the third generation medium manganese steel for automobile. Gleeble-3800 thermal simulation testing machine was used to carry out the thermal compression treatment of medium manganese steel for automobile with deformation temperature of 900-1 150 ℃ and strain rate of 0.1-20 s−1(The deformation amount was 50%). Based on the stress and strain data under different hot compression deformation conditions, the flow stress constitutive equation of medium manganese steel was established, and the constitutive equation was strain compensated. The consistency between the predicted values of the rheological stress constitutive equation considering strain compensation and the experimental results was verified. The results showed that when the strain rate was constant, the peak stress of medium manganese steel decreased gradually with the increase of deformation temperature; when the deformation temperature remained unchanged, the peak stress of medium manganese steel increased gradually with the increase of strain rate. At deformation temperature of 900-1 150 ℃ and strain rate of 0.1~20 s−1, the scattered prediction value of flow stress considering strain compensation for medium manganese steel for automobile was in good agreement with the measured value; after strain compensation treatment, the correlation coefficient of the flow stress constitutive equation of medium manganese steel for automobile was 0.986, and the absolute average error was 3.36%. Compared with the flow stress constitutive equation without considering strain compensation, the correlation coefficient became larger and the absolute average error became smaller after considering strain compensation. The rheological stress constitutive equation considering strain compensation can accurately predict the rheological behavior of medium manganese steel for automobile during hot compression deformation.

medium manganese steel; deformation temperature; strain rate; constitutive equation; strain compensation

10.3969/j.issn.1674-6457.2023.02.015

TG142.1

A

1674-6457(2023)02-0125-07

2022‒02‒05

2022-02-05

河南省杰出人才创新基金(182102610014)

Henan Provincial Innovation Fund for Distinguished Talents (182102610014)

校振华(1984—),男,硕士,副教授,主要研究方向为汽车材料开发与应用。

XIAO Zhen-hua (1984-), Male, Master, Associate professor, Research focus: development and application of automobile materials.

校振华, 冯亚磊, 冯启生, 等. 高强汽车中锰钢的热压缩变形行为研究[J]. 精密成形工程, 2023, 15(2): 125-131.

XIAO Zhen-hua, FENG Ya-lei, FENG Qi-sheng, et al. Hot Compression Deformation Behavior of High Strength Medium Manganese Steel for Automobile [J]. Journal of Netshape Forming Engineering, 2023, 15(2): 125-131.