Carbon dots enhanced gelatin/chitosan bio-nanocomposite packaging film for perishable foods

Bofi Fu,Qioling Liu,Minghun Liu,Xiofng Chn,Htong Lin,Zongping Zhng,Junqiu Zhu,Congji Di,Xiohn Dong,D-Png Yng,,*

a Key Laboratory of Chemical Materials and Green Nanotechnology,College of Chemical Engineering and Materials Science,Quanzhou Normal University,Quanzhou 362000,China

b Department of Clinical Laboratory,The Second Affiliated Hospital of Fujian Medical University,Quanzhou 362000,China

c Fujian Province Key Laboratory for Preparation and Function Development of Active Substances from Marine Algae,College of Oceanology and Food Science,Quanzhou Normal University,Quanzhou 362000,China

d College of Food Science,Fujian Agriculture and Forestry University,Fuzhou 350002,China

e School of Physical and Mathematical Sciences,Nanjing Tech University,Nanjing 211800,China

Keywords:Carbon dots Bio-nanocomposite Gelatin UV shielding Intelligent packaging

ABSTRACT Carbon dots (CDs) with intriguing fluorescent property,good biocompatibility,high stability,easy interaction with substrates,are burgeoning carbon nanoparticles with large potential in various applications.Incorporating CDs into the polymer matrix is becoming a popular strategy to endow the complex with new functions.Herein,the green-synthesized CDs was integrated into the mixture of gelatin(derived from waste fish scale) and chitosan,and a multifunctional bio-nanocomposite (defined as Gelatin/Chitosan/CDs) film was developed,which showed the excellent antibacterial,antioxidant,pHsensitivity,UV shielding,and blue-emission properties.The effects of different concentrations of CDs on the physical,mechanical,structural,and functional activity of bio-nanocomposite film were tested.Compared with the Gelatin/Chitosan film,the Gelatin/Chitosan/CDs film with an optimum addition of 20%CDs showed the enhanced antibacterial,antioxidant as well as UV shielding activities.More importantly,it was used as an effective packaging material for fish meat preservation,reducing the loss of nutritional quality consumption,extending the shelf life of food.Besides,the bio-nanocomposite films also possessed the anti-counterfeiting and pH-responsive properties due to the strong fluorescent emission of CDs,and had the great potential in developing the intelligent packaging materials.Our work shed new light on the new application of CDs and the synthesis of bio-nanocomposite film in food industry.

In recent years,edible films have been highly concerned due to their eco-friendly,sustainable,and bio-degradable characters by using natural resources.In order to develop this kind of film,some biological macromolecules such as lipids,proteins and polysaccharides are widely explored as the recognized safe materials [1].Among them,gelatin is a partially hydrolyzed product of collagen,which exhibits outstanding performances in the field of food packaging and is often combined with other functional materials to form composite film with enhanced functions [2,3].For example,Guoet al.combined the gelatin produced by waste leather with gallic acid to prepare a biodegradable film [4].Fanet al.integrated gelatin and zein into a composite film,and the mechanical strength of the film was increasing humidity [5].However,gelatin like the most proteins do not possess the antibacterial,antioxidant,as well as UV-shielding properties,which are extremely important to food preservation.Thus,some necessary treatment methods need be used to modify the polymer network of gelatin by cross-linking other components to enhance its functions for food preservation[6].

With the rapid development of nanotechnology,adding functional nanoparticles into polymer matrix (gelatin) might be an alternative strategy to achieve the purpose.For example,Ejazet al.combined ZnO nanoparticles and gelatin to form a film,which showed superior antibacterial activity againstListeriaandSalmonella typhimurium[7].Ezatiet al.proved that adding CuO nanoparticles into the carrageenan could improve the antibacterial properties,mechanical strength,and water vapor barrier properties of the resulting film [8].However,these inorganic compounds containing metal ions in the film will inevitably penetrate into the food,posing a potential threat to human health.Therefore,it is very important to replace these inorganic nanoparticles with natural nontoxic antibacterial agents,such as curcumin,chitosan,cinnamon-polycaprolactone [9].Among them,chitosan has attracted much attention due to its excellent antibacterial activity,nontoxic character,biodegradation,and biocompatibility [10].Besides,since gelatin and chitosan are hydrophilic with excellent intimacy and compatibility,both could form composite films with good properties.Therefore,integrating chitosan into gelatin will play important role in keeping good antibacterial activity of the film.

On the other hand,oxidation is another major cause of food spoilage,and it will adversely affect the sensory quality (flavor,color,freshness,etc.) [11].The current popular research strategy is to extract natural antioxidants (such as tea polyphenols,anthocyanins,flavonoids) and combine them with edible films.However,these natural antioxidants not only have the complicated extraction process,but also show only single anti-oxidation function,which is unable to meet the requirements of food preservation.

Therefore,we need to look for a novel multifunctional and safe material for food preservation.Carbon dots (CDs) as a new class of carbon nanomaterials with size below 10 nm,has the advantages of antioxidant,antibacterial,non-toxicity,good biocompatibility,low cost,UV shielding and simple synthesis [12,13].Owing to theses excellent properties,they were widely applied in the field of chemical/biological sensing,bioimaging and nanomedicine [14].For example,Purkayasthaet al.reported that CDs prepared from oilseed pressed cakes had superior antioxidant activity and blood compatibility,and can effectively prevent oxidative degradation of oil [15].In recent research,Barmanet al.reported that CDs had the UV and blue light shielding functions [16].Interestingly,Wanget al.reported that CDs could be used as a sensor for the determination of pH [17].Based on these,it seems that CDs can be an ideal additive for the preparation of bio-composite film with multi-functions (antibacterial,antioxidant,UV-shielding,pH-sensing),which inspires us to explore their potential application in the field of food preservation.

Herein,we firstly prepared and characterized the fluorescent CDs by hydrothermal method using chitosan as precursor [18].And then,the green synthesized CDs were added to gelatin and chitosan mixed solution to form the bio-nanocomposite film.The mechanical strength,antioxidant activities,antibacterial properties,pH sensitivity,morphological characteristics,water vapor transmission rate,as well as water contact angle of the Gelatin/Chitosan/CDs composite films were measured.Meanwhile,the quality changes and lipid oxidation during inhibition of fresh fish fillets wrapped with Gelatin/Chitosan coating,Gelatin/Chitosan/CDs coating and the untreated group were investigated and compared.Moreover,the Gelatin/Chitosan/CDs film also serves as a pH sensitive indicator for intelligent packaging system,which can be used to monitor the freshness of the fish meat.

The CDs can show multicolor emissions,which is a huge advantage to make them apart from most labeling agents [19].Based on this,this function can be used in anti-counterfeiting and smart packaging [20].The photoluminescence studies of the as-prepared CDs (Fig.1a) with the different excitation wavelengths showed that the broad blue emission strength had a highest peak (λmax~420 nm) under exposure to excitation wavelength at 340-360 nm;a small change from 450 nm to 480 nm in fluorescence peak was followed when the excitation wavelength changed from 380 nm to 440 nm;the emission spectra of CDs ranging from 500 nm to 540 nm under the excitation wavelength was changed from 460 nm to 480 nm.The short shift of the fluorescence peak indicated that the particle size distribution was narrow and resulted in lower energy paths for emission [21].As shown in Fig.1b,the UV-vis absorption spectrum of the CDs showed strong absorption at 235 nm and below 324 nm,the strong absorption peak at 235 nm mostly was due toπ-π*transitions of C=C bonds,the consumingly absorption at 324 nm mainly was fromn-π*transitions of C-N and C=O bonds,the CDs can soak up ultraviolet rays due to the existence of these peaks [16].If this function was applied to the packaging film,it can effectively prevent food from decay and deterioration caused by ultraviolet radiation in the environment.The maximal excitation and emission wavelengths of the CDs were recorded at 339 nm and 419 nm (Fig.1b),respectively.As shown in Fig.1c,the 3D excitation and emission mapping indicated that CDs could emit blue light (420 nm) when they were excited by UV light,while cyan light to green light (540 nm) appeared upon the excitation (380-440 nm).What is more,the QY of CDs was calculated by referring to quinine sulfate to be 28.32%.

The XRD patterns of CDs showed (Fig.1d) a broad diffraction peak at 2θvalues of 20.8°,which revealed a graphite structure of CDs [22].The functional groups of CDs were further identified by FTIR and XPS.The FTIR spectroscopy (Fig.1e) showed the presence of O-H stretching vibrations of amine and hydroxyl groups at 3209 cm-1[23];The broad peaks at 2982 cm-1indicated different types of C-H stretching vibrations [16].The stretching vibrations at 1666 cm-1and 1562 cm-1matched up to the C=O and amide II (N-H bending vibration and C-N stretching vibration) [24],respectively.In addition,the vibration peaks at 1404 cm-1and 1200 cm-1corresponded to O=C-OH and C-O stretching,respectively [25].The XPS survey scan (Fig.S1 in Supporting information) of CDs showed three typical peaks of C 1s,N 1s and O 1s,the corresponding contents of C,N and O were calculated to be around 54.7%,3.7% and 39.6%,respectively.The deconvolutions of the C 1s spectrum exhibited four peaks at 284.3 eV,285.1 eV,286.2 eV and 288.9.3 eV,which were assigned to the groups of C-C/C=C,C-N,C-O and O-C=O,respectively [26].The N 1s spectra revealed three peaks at 399.5 eV,400.4 eV and 401.6 eV,which were assigned to pyridinic N,pyrrolic N and graphitic N,respectively [27,28].In addition,the O 1s spectra mainly consisted of two peaks at 531.9 eV and 533.1 eV,which were assigned to C=O and C-OH/C-O-C,respectively.The results pointed to that the CDs had plentiful functional groups on their surface,which were conducive to the formation of stable hydrogen bonds with chitosan and fish scale gelatin,leading to a more stable film.In addition,the surface of CDs has reductive electron-donating groups (-OH,O=C-OH,-O-C=O,-O-R),which can directly react with free radicals and play an antioxidant role.

Prior to adding CDs into the edible film,safety and edibility are primary.Therefore,we evaluate the cell toxicity of the CDs throughin vitrostudies on human skin fibroblasts.A series of different concentrations of CDs (0.5 mg/L to 5 mg/L) were incubated with the cells for 24 h.It can be seen from Fig.1f,the results showed no cytotoxic effect of the synthesized CDs at 0.5-5 mg/L concentration as no significant decline in the percentage of human skin fibroblasts survived viability.The experiments indicated that the synthesized CDs were biocompatible and low cytotoxicity for further food packaging applications.Theoretically,the result is also predictable,because the original materials (chitosan and citric acid) used in the experiment are all naturally occurring in nature without chemical reaction,and their ingredients are safe and effective for human health.

In addition,we unexpectedly discovered that the CDs had antibacterial properties,which could enhance the antibacterial activity of the packaging film.The antibacterial activity of the CDs was examined usingE.coliandS.aureusby the agar diffusion method [29].Figs.1g and h show the typical inhibitory zones of CDs againstE.coliandS.aureus.Some researchers pointed out that the CDs exhibited an antibacterial effect by destroying the cell membrane protein structure of bacterial [30-33].Herein,the antibacterial activities could be attributed to two points.On one side,the chitosan-derived CDs were positively charged (9.53 mV of Fig.1i),which can be bond to peptidoglycan,proteins and porins through electrostatic interactions and accumulated largely on the surfaces,resulting in a synergistic destabilization and impairment of the cytomembrane [34].On the other hand,a large number of-NH3+groups on the CDs surface enhanced their antibacterial activity [35].

In order to understand the microscopic structure of CDs,we used HR-TEM to investigate the particle size and morphology of CDs.As shown in Fig.S2a (Supporting information),the TEM image clearly showed that the as-prepared CDs were almost spherical and well-dispersed,the size mainly distributed between 1.0 nm to 3.0 nm (insert of Fig.S2a) with the average diameter of about 2.09 nm.The HR-TEM image of CDs showed the well-resolved lattice fringes spacing of 0.22 nm (Fig.S2b in Supporting information),which were close to the (001) diffraction facets of graphite [36].

The pH sensitivity of the CDs was evaluated at various pH and the results were shown in Figs.S3a and b (Supporting information).The resultant CDs were very sensitive to pH values,fluorescence intensity rapidly decreased as pH increased from 6 to 9.It could be attributed to the two various functional groups (-NH2and-COOH) on surface of CDs.On one hand,the amine was promoted to ammonium salt (-NH3+) at pH 6 with the protonation,and on the other hand,it may be corresponding to deprotonation of the carboxyl groups by the pH value from acidic to alkaline[17].This phenomenon further confirmed that the carboxyl and amine groups were present on the surface of CDs [37].Although this mechanism was not fully understood,this optical sensitivity to pH could be made into smart packaging to monitor the freshness of fish [17,38].

CDs and Gelatin/Chitosan film were organically fused,as shown in Fig.S4 (Supporting information),the pure Gelatin/Chitosan film and Gelatin/Chitosan/CDs composite films were flexible and homogeneous in appearance.However,they became yellow with the increase of CDs contents under the sunlight.Under the UV light(λ=365 nm),as the CDs content increases,its fluorescence brightness also increases,and the film without CDs shows no fluorescence.The color of the films was important for appearance because they directly influence product appeal and consumer acceptance.Meanwhile,the microstructure of Gelatin/Chitosan/CDs (20%CDs,v/v) film was investigatedviaSEM (Fig.S5 in Supporting information).The surface morphology of film exhibits a rough and compact texture (Figs.S5a and b),but still looks like regular and uniform,this can be proved by EDX,which in the elements of C,O,N are uniformly distributed.In addition,the cross-sectional SEM of the nanocomposite withca.40 μm is shown in Fig.S5c,which also has a smooth and dense structure.SEM observation shows that our film is good fabricated and there are no bubbles.On the other hand,it also indicates that the CDs were well dispersed in the gelatin and chitosan mixed solution.

The excellent mechanical properties of the film guarantee the meat to have a good protective effect during storage,transportation,and sales.Thus,the mechanical properties of the Gelatin/Chitosan/CDs film were tested and compared.The TS and EB of the films containing different CDs (0%,10%,15%,20%) were shown in Table S1 (Supporting information).The results indicated that the TS and EB of films were changed by adding different concentration of CDs.TS increased with the increase of CDs concentration,and EB first increased and then decreased with CDs concentration.The highest values of TS (7.34±0.33 MPa) were related to the film with 20% of CDs,but the EB (80.84% ± 0.72%) was related to 15% of CDs.Therefore,the strength and flexibility of the film could be improved by increasing CDs content.This is because the surface of the CDs has some functional groups that form hydrogen and covalent bonds with amino and hydroxyl groups of polypeptides in fish scale gelatin and chitosan,which would weaken the protein-protein interactions to stabilize the protein network [39].

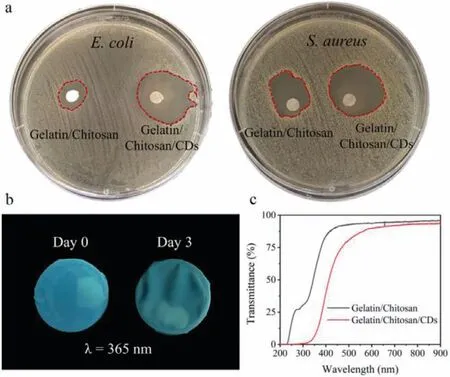

Fig.2.(a) Antibacterial activity of Gelatin/Chitosan film and Gelatin/Chitosan/CDs film against Escherichia coli (left) and Staphylococcus aureus (right).(b) Monitoring the freshness of fish meat (stored at 25 °C) under the smart indicator of the film (Gelatin/Chitosan/CDs film).(c) UV transmittance spectra of different films(Gelatin/Chitosan film and Gelatin/Chitosan/CDs film).

Antioxidant film is a major kind of active packaging and a prospective technique for extension food product shelf life.As shown in Table 1,the impact of CDs on the antioxidant properties of Gelatin/Chitosan films was explored by measuring their ability to scavenge the free radicals of DPPH·and ABTS·+,as well as Fe3+reducing power.The experimental results showed that the antioxidant activity of the film increased significantly (P<0.05) as the CDs content increased,It is because the surface of CDs has reductive electron-donating groups (-OH,O=C-OH,-O-C=O,-O-R),which can directly react with free radicals and play an antioxidant role.Generally,our research showed that the antioxidant activity of the Gelatin-based film greatly improved after enriching with CDs,which might be of benefit for commercial uses,such as packaging of food products that have high sensitivity to oxidant.

Fish meat often rots due to microbial infections,which seriously affects its edible value and shelf life.Here,we usedE.coli(Gramnegative) andS.aureus(Gram-positive) to evaluate the antibacterial assessment.As shown in Fig.2a,the Gelatin/Chitosan and Gelatin/Chitosan/CDs show a positive result when contactE.coliandS.aureus.But when CDs were added to the Gelatin/Chitosan,there were significant increments in inhibition zone for the Gelatin/Chitosan/CDs.The increase in inhibition zone indicates the antibacterial activity of CDs against the pathogens.This result has been proved in the characterization of CDs (Figs.1g and h).

The proteolysis decomposition and microbial degradation were responsible for the spoilage of most fish products.The deterioration of fish meat will cause the TVB-N value to rise,which in turn will cause the pH value to rise.According to this principle,the Gelatin/Chitosan/CDs film was used to monitor fish freshness as an intelligent indicator.The fish meat sample of the color parameters of the film during the storage at 23 °C are shown in Fig.2b.On day 0,the indicator film brightness (λ=365 nm),because the protein had not been degraded by microorganisms.With the increase in storage time,the pH value of the fish meat increased,and the brightness of the indicator film was significantly lower than that of day 0.The smart indicator of the film (Gelatin/Chitosan/CDs film)responded well to the pH change of the fish depending on the fish spoilage.At the same time,the film has hydrophilic properties (Fig.S6 in Supporting information).The main component of the volatile base nitrogen is ammonia,which can be absorbed by the film through the water vapor in the environment,so that the brightness of the film is reduced.The results are in good agreement with those of Parya,who developed an intelligent indicator using alizarin to detect fish spoilage at room temperature [40].

In addition to antioxidation properties,antibacterial properties,and pH indicator properties,the bio-nanocomposite film also has anti-ultraviolet properties.Fig.2c shows the light blocking performance of Gelatin/Chitosan film and bio-nanocomposite film with wavelengths ranging from 200 nm to 900 nm.The bionanocomposite film (red line) shows an improved UV shielding property than the Gelatin/Chitosan film (black line).The UV shielding efficiency of bio-nanocomposite film at 200-400 nm is 94.18% (the average light transmittance is only 5.82%),while the Gelatin/Chitosan film has only 65.13% (the average light transmittance is 34.87%).This effectiveness in shielding of UV radiation is ascribed to the high UV absorbance of the CDs nanoparticles (Fig.1b) on the film.This UV shielding performance is very valuable when the film was used for food preservation,because ultraviolet rays will cause the food to oxidize and deteriorate.

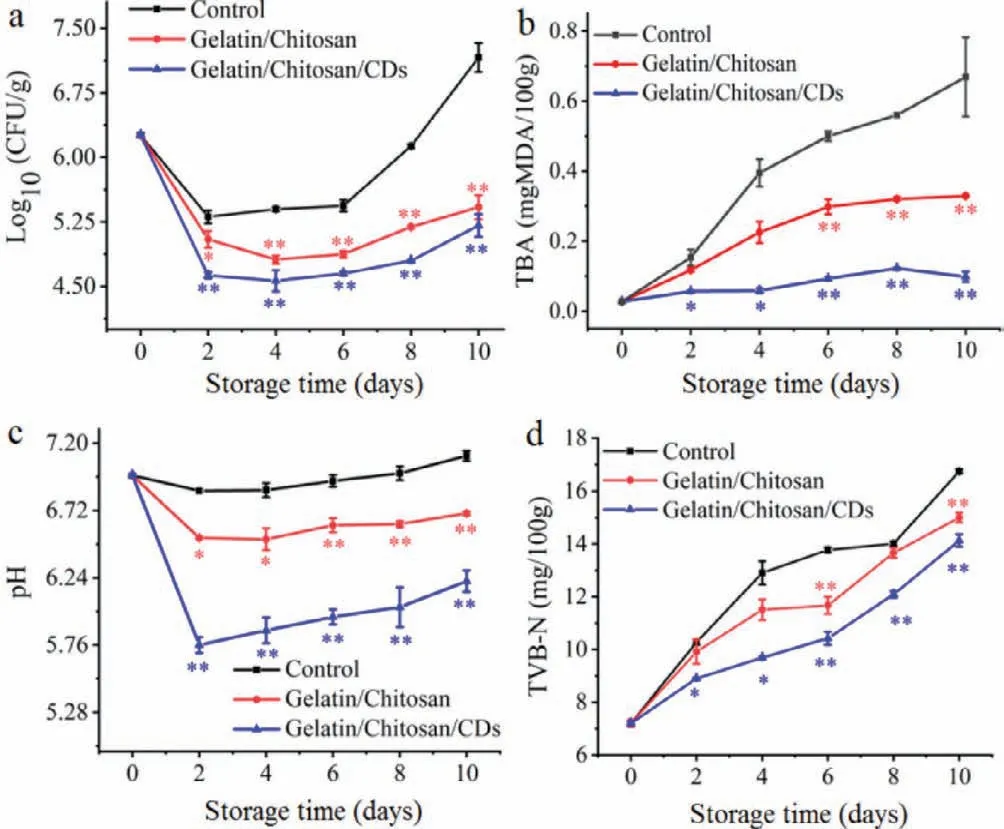

In vitroantibacterial and antioxidant properties were tested from the Gelatin/Chitosan/CDs films.The next step was to evaluate their function in the preservation of grass carp slices.As shown in Fig.3,the total bacteria,TBA index,TVB-N and pH of the product were assessed.

Recent studies have reported that the chitosan is known for its antibacterial activity,because the presence of the positively charged amino groups which interact with negatively charged macromolecules on the bacterial cell surface,leading to the leakage of intracellular constituents of the microorganisms [6].The CDs due to the positive charge on the surface on the surface,also have antibacterial activity properties (Figs.1g and h).Therefore,when chitosan and CDs were combined,the antibacterial activity of Gelatin/Chitosan/CDs was higher than that of Gelatin/Chitosan(Fig.2a).

Variations in the value of total bacteriological counts (TBC)during storage are presented in Fig.3a.The initial TBC was around 6.26 ± 0.02 log10(CFU/g).The reason is that the grass carp is cut by the owner of the vegetable market,which makes the number of microorganisms too large.On the second day of the storage,the TBC in the three groups decreased.Furthermore,the TBC of the different treatment groups (Gelatin/Chitosan and Gelatin/Chitosan/CDs) increased by varying degrees during the storage time.The growth pattern of TBC showed an increasing in the different treatments during the storage time.Control groups increased the value of 5.44 ± 0.03 log10(CFU/g) for TBC on the 6thday of storage,while Gelatin/Chitosan (TBC = 5.42 ± 0.07 log10(CFU/g)) and Gelatin/Chitosan/CDs (TBC = 5.22 ± 0.07 log10(CFU/g) groups did not reach this value until 10 days of storage.At the end of the storage period,the TBC of the control group was 7.16 ± 0.08 log10(CFU/g),which is higher than the maximal recommended limit of 7 log10(CFU/g).

Fig.3.(a) Change of total bacteriological counts of fish meat during storage time.(b) Change of TBA value of fish meat during the storage time.(c) Change of pH value of fish meat during the storage time.(d) Change of TVB-N value of fish meat during the storage time.The symbol * and ** shows significant differences according to the independent sample t-test (P<0.05 and P<0.01,respectively) for each time point.

TBA value is index of lipid oxidation,which is caused by the accumulation of lipid peroxides and corresponding secondary metabolites [39,41].As shown in Fig.3b,the initial TBA value was 0.03 mg MDA/kg.From the four days of the storage,the value of Gelatin/Chitosan group and Gelatin/Chitosan/CDs group were observably lower than that of the control group.During the late storage,the TBA value of the control group (0.67 mg MDA/kg)was markedly higher than of the other groups.It is worth noting that during the entire storage period,the TBA value of the Gelatin/Chitosan/CDs group only increased slightly,which was significantly lower than the other two groups (Control group and Gelatin/Chitosan group).This result is consistent with CDs that have strong free radical scavenging capability,which can reduce the degree of oxidation [15].

The trend of the pH values falling first and then rising in all samples (Fig.3c).The initial pH (day 0) of grass carp slices was 6.97 ± 0.01.This value increased during the cold storage of the product.These values are like 6.81 ± 0.10 reported by other paper [39].During the early cold storage at 0-2 days,the pH values were decreased which could be owing to the glycolysis of grass carp slices,which led to the accumulation of lactic acid and the degradation of adenosine triphosphate (ATP) to release inorganic phosphate.With the increase of storage time at 2-10 days,the degradation of fish protein and the formation of alkaline compounds caused by the action of microorganisms has been shown to cause pH to rise [42].Compared with the control group,the Gelatin/Chitosan film and Gelatin/Chitosan/CDs film group rose slowly of the pH values during the storage period.It is because that inhibitory effect of the Chitosan and CDs on the microorganisms of fish meat.

The TVB-N measurement is directly reflective of the fish spoilage,it is related to the growth of microorganisms and the endogenous enzymes in fish [43,44].As shown in Fig.3d,compared with the control group,the Gelatin/Chitosan film and Gelatin/Chitosan/CDs film group rose solely of the TVBN values during the storage period.The results show that the Gelatin/Chitosan/CDs film could reduce the TVB-N value of grass carp meat,and the effect is better than Gelatin/Chitosan freshkeeping film.

In this present study,we have synthesized the fluorescent CDs with multifunctional properties (antibacterial,antioxidant,pH-sensitive and UV shielding behavior) by a facile one-step hydrothermal method by using chitosan as precursor.At the same time,the bio-nanocomposite film based on Gelatin/Chitosan incorporated with CDs was developed.The as-prepared bionanocomposite film showed considerable antibacterial,antioxidant,pH-sensitive as well as UV shielding properties.Meanwhile,the bio-nanocomposite film was applied for fish meat preservation.Results indicated the Gelatin/Chitosan/CDs composite film possessed the best protective effect on fish meat quality,maintaining a low TBC and pH values,the changes in TVB-N and TBA showed that the degree of lipid oxidation of fish meat decreased during the storage.Meanwhile,due to the pH sensitive property of CDs,the bio-nanocomposite film based on Gelatin/Chitosan with CDs were fabricated,which was applied to an indicator of fish meat freshness by showing fluorescence brightness change under the UV light(λ= 365 nm) as the pH of the packaged fish changed.It was therefore suggested that the prepared bio-nanocomposite film not only improves the quality and shelf life of fish meat,but also could indicate the freshness of fish meat.Thus,the combination of superior performances “green” carbon nanoparticles with natural biological macromolecules could endow this novel film great potential as a multifunctional packaging material in food industry.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

The authors are very grateful for the support from the Fujian Provincial Department of Science and Technology (Nos.2019H0023,2020J01218,2020J01774),the Quanzhou City Science&Technology Program (No.2018CT004).

Supplementary materials

Supplementary material associated with this article can be found,in the online version,at doi:10.1016/j.cclet.2022.03.048.

Chinese Chemical Letters2022年10期

Chinese Chemical Letters2022年10期

- Chinese Chemical Letters的其它文章

- An odyssey of lithium metal anode in liquid lithium-sulfur batteries

- Recent progress on preparation and applications of layered double hydroxides

- Two-dimensional transition metal chalcogenide nanomaterials for cancer diagnosis and treatment

- Emerging nanomedicine and prodrug delivery strategies for the treatment of inflammatory bowel disease

- Recent advances in persulfate-based advanced oxidation processes for organic wastewater treatment

- Recent advance of fluorescent probes for detection of drug-induced liver injury markers