A 658-W VCSEL-pumped rod laser module with 52.6%optical efficiency

Xue-Peng Li(李雪鹏) Jing Yang(杨晶) Meng-Shuo Zhang(张梦硕)Tian-Li Yang(杨天利) Xiao-Jun Wang(王小军) and Qin-Jun Peng(彭钦军)

1Key Laboratory of Solid State Laser,Technical Institute of Physics and Chemistry,Chinese Academy of Sciences,Beijing 100190,China

2Key Laboratory of Functional Crystal and Laser Technology,Technical Institute of Physics and Chemistry,Chinese Academy of Sciences,Beijing 100190,China

3Institute of Optical Physics and Engineering Technology,Qilu Zhongke,Jinan 250000,China

4University of Chinese Academy of Sciences,Beijing 100190,China

Keywords: rod laser,VCSEL-pumped,high-efficiency,temperature adaptability

1. Introduction

Vertical-cavity surface-emitting laser (VCSEL)has been proved as an excellent pump source for solid-state lasers for its remarkable low wavelength shift coefficient, all-directionsymmetrical beam profile and narrow beam divergence.[1–3]Especially the∼0.06 nm/K wavelength shift coefficient makes it an ideal candidate pump source for the space and field applications.[4,5]However, compared with commonly used edge-emitting laser diode (LD), VCSEL chip has large emission area and relative low electro-optical conversion efficiency. Therefore,the power scaling of VCSEL side-pumped rod laser module faces two major challenges. The first is the junction temperature control of VCSEL array(VCSELA)with low electro-optical efficiency under large thermal generation and heat flow. The second is the coupling efficiency of VCSEL chip with large emission area to the rod laser module.Consequently, most previous demonstrations on the VCSEL pumped rod lasers were only several Watts output power.[6,7]Based on the VCSEL face-pumped slab architecture, 400-W level laser module was reported.[8,9]However, the face cooling design used in the slab lasers module cannot be directly transplanted in side-pumped rod module.

In order to overcome the aforementioned obstacles, we carefully study and optimize the parameters of VCSEL sidepumped rod Nd:YAG laser. We utilize several new approaches to obtain power scaling. First, the substrate material of VCSEL chip with high thermal conductivity is selected to reduce its own thermal resistance. Second, a vascularized macrochannel heat sink[10]is used in the thermal management of the VCSELA and the heat sink structure is also simulated,including the shortest distance from the chip to the channel,the transverse spacing and the vertical depth of the channel,the channel number,the size and position of the inlet and outlet of the heat sink,to realize an excellent heat removal and control the pressure loss of heat sink. Third,a five-fold symmetric pump structure is chosen and the structural parameters is simulated,such as the size of the crystal rod,the center distance from the VCSEL chip to the crystal rod, the inner diameter of the diffuse reflective chamber,the number of pump arrays,the inner diameter and outer diameter of the glass tube, to enhance the pump uniformity and the pump absorption efficiency. Consequently,a record-high power of 658 W and an optical–optical(o–o) efficiency of 52.6% from the VCSEL side-pumped rod laser is obtained for the first time. To the best of our knowledge,this is the highest continuous-wave(CW)output power and the highest o–o efficiency for any VCSEL-pumped solid lasers.

Moreover,the output power stability has been tested,and the power fluctuations are±0.7%over 400 s and±3.1%in a temperature range from 16◦C to 26◦C. By inserting a telescopic module into the cavity and optimizing the fundamental mode volume, an average beam quality ofM2=1.34 is achieved under an output power of 102 W.Hopefully,the VCSEL pumped rod laser is a potential solution for the high average power applications in the complicated environment.

2. Design of the module

2.1. Design of VCSEL side-pumped laser module

A VCSEL pumped laser module with a relatively larger size of the laser gain medium and a large-diameter reflective chamber is one of the potential solutions for a highly efficient and high power VCSEL side-pumped laser module.[11,12]Figure 1 shows the cross section of the laser module. In order to obtain a large mode field and reduce the heat flux density in the gain medium, a 0.6-%-doped Φ8 mm×190 mm Nd:YAG rod is adopted. The side surface of the rod is roughened and the end facets of the rod are antireflection coated at 1064 nm. The rod is placed inside a cooling sleeve of glass tube.The cooling liquid flows rapidly the gap between the crystal and the glass tube.The inner diameter of the tube isdo=11 mm.The length of the annular flow isL=160 mm. VCSEL is selected as the pump source due to its temperature insensitive property and narrow linewidth. Five linear VCSELA are arranged around the rod in five-fold symmetric directions with a total CW pump power of 1250 W at∼808 nm. Each linear VCSELA with a size of 130.7 mm×4.7 mm contains 15 chips. Each chip from Laserconn(CS5-15-808-20W)has a size of 4.7 mm×4.7 mm and the beam divergence is 14.7◦×14.7◦(full angle). To reduce thermal resistance of the VCSEL chip,the substrate material with high thermal conductivity is selected,which is similar to that of Ref.[8]. The Au-coated reflective chamber with a diameter of 44.4 mm has five slits that allow us to couple the emission of five linear VCSELA directly to the laser crystal rod,and the effective reflection area of this reflective chamber is more than 80%. Consequently, the reflective chamber distributes the pump beam uniformly through the crystal rod.The distance between the rod side-surface and the VCSEL emitting face of the pump source isl=26 mm.

To estimate the gain uniformity of this laser module, the absorbed pump power distribution is simulated by ray-tracing at a pump power of 1250 W, as shown in the inset of Fig. 1.It can be found that the side-pumped structure results in a uniform high-gain area with a diameter of 5 mm with respect to the center of the rod and the total pump absorption efficiencyηais around 85%.

Fig. 1. Pumping configuration of the laser module. Inset: the simulation of the absorbed pump power distribution in the middle cross section of the Φ8 mm rod with l=26 mm at total pump power of 1250 W.

2.2. Stability of pumping wavelength

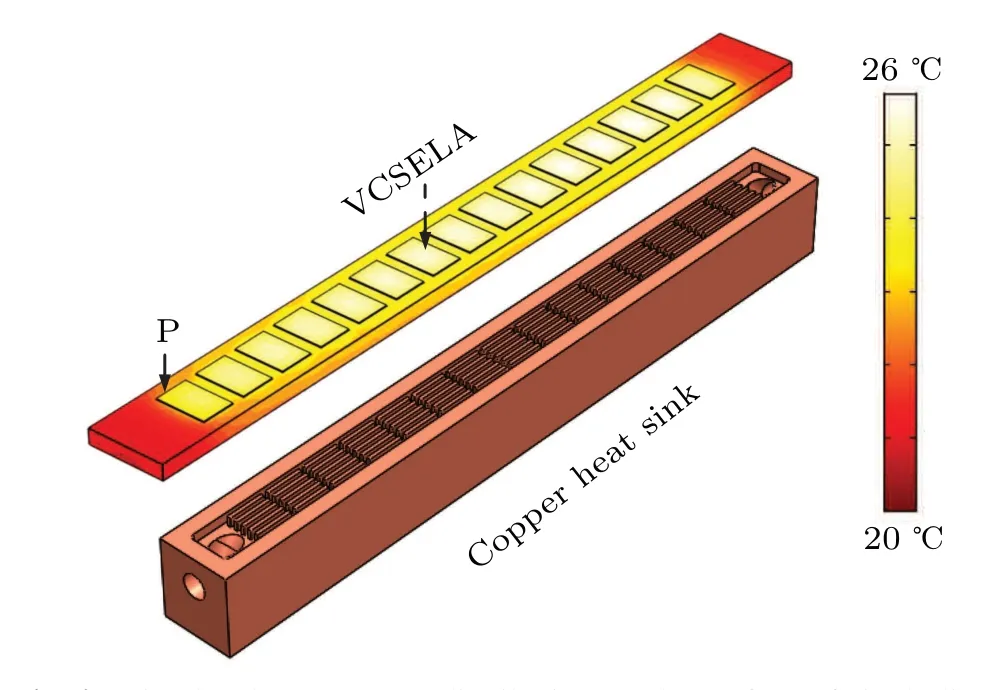

The wavelengths of VCSEL are chosen carefully to match the absorption peak of the laser gain medium. High output power requires that an efficient thermal management to the VCSEL, which is closely related to the wavelength stability and the electro-optical conversion efficiency of the pump source. Since the wavelength of the VCSEL is insensitive to temperature changes, we select a macro-channel structure to cool the VCSEL array. To make optimal cooling,the heat sink structure is also computational fluid dynamic simulated. The following parameters are used in our heat sink. Fifteen fin groups are inserted in the copper heat sink, corresponding to the welding VCSEL chips. Each fin group contains five fins,the size of each fin is 8 mm×4 mm×0.8 mm and the period of the fins is 1.6 mm. The shortest distance between the VCSEL chip to the edge of the macro-channel is 3 mm. The inlet and outlet of the heat sink with a diameter of 5 mm are distributed at both ends of the heat sink. The water is used as the coolant.We simulate the temperature distribution on the surface of a single linear VCSEL array under 250-W pump power to verify the heat exchange performance of the macro-channel heat sink. The flow rate is 5 L/min and the coolant temperature at the inlet of the heat sink is 20◦C. The simulation result is shown in Fig.2. It can be observed that the maximum temperature in the VCSELA is 26◦C and the minimum temperature at P near the inlet of heat sink is 24◦C.Thereby,the maximum temperature difference of VCSEL chips is 2◦C,which is only 0.12 nm for the corresponding wavelength drift on single linear VCSELA.This indicates that the macro-channel structure with fins has excellent heat removal performance and ensures the consistency of the output wavelength of the pump source.In our experiment, the pressure loss of this heat sink is less than 0.3 MPa at a flow rate of 5 L/min. Since it is macrochannel cooled VCSEL scheme, there is no longer need for a refined filter,deionized water and electric-conductivity control, which greatly reduces the complexity and maintenance cost of the thermal management system.

Fig. 2. Simulated temperature distribution on the surface of single linear VCSEL array with macro-channel heat sink for W =0.8 mm and water flow rate 5 L/min at 20 ◦C under a pump power of 250 W.

Based on the optimized macro-channel heat sink, the wavelength characterization of the VCSEL chips is tested by a spectrometer (HR 4000, Ocean Optics) under CW operation. The wavelength of a linear VCSELAversusthe water temperature at an output power 250 W is shown in Fig. 3.The shift of the central wavelength of the VCSELA is only 0.55 nm from 805.99 nm to 806.54 nm for the temperature spanning from 16◦C to 26◦C,corresponding to a wavelength shift coefficient of 0.055 nm/K, which is much smaller than 0.25 nm/K of the edge emitted laser diode (LD).[13]In addition, the wavelengths of five linear VCSELAs are measured at 20◦C. The central-wavelength change from 806.19 nm to 806.7 nm and the spectral full-width half-maximum(FWHM)range is 0.9 nm–1.4 nm. The normalized spectrum around 808 nm after the addition of the wavelengths of the five linear VCSELAs is sketched in the inset of Fig. 3. The center wavelength and FWHM of this added spectrum are 806.3 nm and 1.35 nm,respectively,suggesting that VCSEL with a center wavelength close to the absorption peak of the laser gain medium and a narrow linewidth is selected. The measured results show that the VCSEL is competent as a temperaturestable pump source for solid-state lasers.

The effective absorption efficiency of the Nd:YAG crystal is determined by the overlapping efficiencyηoverbetween the Nd:YAG absorption spectrum and the VCSEL emission spectrum:[14]

whereSpumpis a normalized emission spectral density of the VCSELA,Tis the crystal temperature,∆λandλ0refer to the bandwidth and the center wavelength, respectively. Based on the data presented in Fig. 3, then, the calculated overlapping efficienciesηoverare 82.6%,83%,and 83.5%at 16◦C,20◦C,and 26◦C,respectively.Hence the variation of the overlapping efficiency is less than±0.55%. The calculation results show that the VCSEL-pumped Nd:YAG crystal has high absorption efficiency and high temperature stability.

Fig.3.Central wavelength of a linear VCSELA versus the temperature from 16 ◦C to 26 ◦C of the water at a fixed flux of 5 L/min and an output power of 250 W. The inset is the normalized spectrum around 808 nm after the summation of the wavelengths of the five linear VCSELAs at 20 ◦C.

3. Experimental investigation to the VCSEL side-pumped rod laser

In order to evaluate the lasing performance of the VCSEL side-pumped rod Nd:YAG laser module, a proof-of-principle experiment is implemented based on a short cavity multimode oscillator. The experiment setup is shown in Fig.4. The laser cavity is made up of a high-reflective (HR) plane mirror M1 at 1064 nm and a plane output coupler M2 with transmissionT=30%at 1064 nm.The laser module is placed in the middle of the cavity and the total cavity length is 284 mm. The output beam enters a power meter(6K-W-BB-200×200,OPHIR)via a 45◦HR mirror M3 at 1064 nm and an aperture for filtering stray light. Figure 5 depicts the evolution of the output power as a function of the incident pump power.It can be seen that the output power increases linearly with the incident pump power. At a pump power of 1250 W, a maximal laser output power of 658 W is generated, which is roughly two orders of magnitude higher than that in Ref.[7]. The corresponding o–o efficiency is 52.6%. Also visible in Fig.5 is that the output power does not show any saturation or roll-off effect up to the maximum incident power,which seems to indicate higher power that may be achieved with higher pump power.

The wavefront distribution of the output beam is also measured at full output power by a wavefront sensor(HASO3 128-GE2, Axiom optics), as displayed in the inset at lower right of Fig. 5, which is similar to the one described in Ref. [15]. It is found that the peak-to-valley (PV) value of the wavefront is 1.16 µm and the root mean square (RMS)is 0.26 µm after subtracting the defocus and tilt, since these low-order aberrations can be easily corrected by geometric optics.[16]It also can be seen from the measured result that the wavefront distortion is relatively small compared to Ref.[17].

Fig. 4. Schematic diagram of the VCSEL-side-pumped rod Nd:YAG laser with a short cavity. M1: high-reflective mirror at 1064 nm; M2: output coupler;M3: 45◦high-reflection mirror at 1064 nm.

Fig.5. Output power and o–o efficiency of the VCSEL-side-pumped 1064-nm rod Nd:YAG laser versus the pump power under CW operation. Lower right inset: measured wavefront distortion under VCSEL pump power of 1250 W.

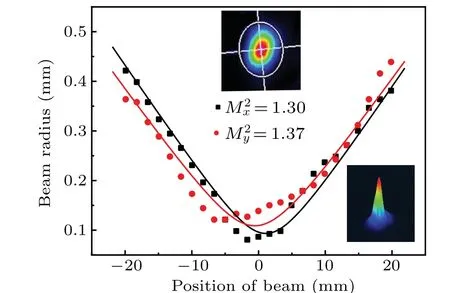

In our previous experiment, we use a short cavity as a laser resonator to obtain a high average output power. However,owing to the existence of multiple transverse modes,the beam quality is not good. Therefore, we insert a telescopic module,which is in the place of black dashed frame in Fig.4,and increase the length of the resonator, where the distances of each optical elementsl1,l2, andl3are optimized to make it work in the thermal-near-unstable region.[18,19]The beam quality is tested using a commercial beam analyzer (Gentec Electro–Optics, BEAMAGE-M2). Under an output power of 102 W, the measured beam quality factors areM2x=1.30 atxaxis andM2y=1.37 atyaxis, corresponding to an average value ofM2=1.34, as shown in Fig. 6. The details of this work will be presented elsewhere.

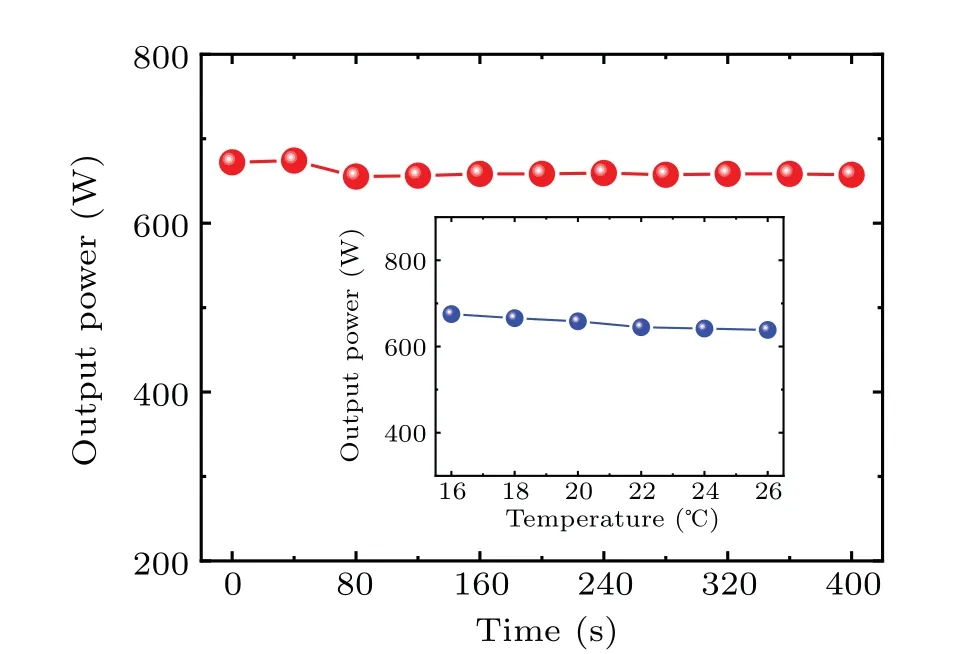

The power-stability of the output power for this laser is experimentally investigated, as shown in Fig. 7. It is found that,at a coolant temperature of 20◦C,the output power variation is only±0.7% over 400 s; The inset of Fig. 7 plots the output powerversusthe temperature. When the temperature changes from 16◦C to 26◦C, the variation of the output power is less than±3.1%. The results indicate the precise temperature control device to the coolant is no longer needed, while the conventional diode-pumped lasers require a specific coolant temperature and the temperature fluctuation has to be strictly controlled within±0.1◦C. As our previous report,[9]the excellent stability of the output power of the VCSEL-pumped Nd:YAG laser in a wide temperature range is result from the low wavelength shift of the VCSELAversusthe temperature and the smaller change of the overlapping efficiency between the emission spectra of VCSELA and the absorption spectrum of the Nd:YAG crystal at different temperatures. Consequently,such a stable high-power laser module is very suitable for field applications even if harsh environmental conditions.

Fig.6. Measured beam quality factors of the thermally near-unstable cavity with telescopic oscillator at an output power of 102 W. Upper inset: twodimensional(2D)beam spatial profile. Lower right inset:three-dimensional(3D)beam spatial profile.

Fig.7. Power-stability test at the highest output power over 400 s at 20 ◦C.Inset is the output power versus the temperature from 16 ◦C to 26 ◦C.

Moreover,in order to obtain higher pump power,diamond can be used as the substrate material of VCSEL chip to further reduce thermal resistance. For an application that needs to be operated in a low temperature environment, the coolant can be replaced with other fluid such as glycol and its solution and invar baseplate could be used to make the optical path stable. The lower temperature of the coolant indicates a lower junction temperature of a laser diode,which also means higher electro-optical efficiency.In this way,the VCSEL-pumped rod laser module with kW-class output capacity can be realized.

4. Conclusion

In summary,a temperature stable VCSELA side-pumped rod Nd:YAG laser with multi-hundred-Watt output power is designed and investigated for the first time. The output power and efficiency of the laser are greatly improved due to the optimization of the laser module structure and cavity parameters.As a result, a maximum CW output power of 658 W and a maximum o–o efficiency of 52.6% are obtained. To the best of our knowledge,this is the highest CW output power and the highest o–o efficiency for any VCSEL-pumped solid lasers.Meanwhile, the variations of the output power are measured to be less than±0.7% over 400 s and±3.1% over the temperature range from 16◦C to 26◦C.The experimental results reveal that the VCSEL side-pumped rod laser is appropriate for field applications and other scenarios which require a large temperature tolerance. Based on the laser gain module and telescopic resonator design,a laser oscillator with an average beam quality factor ofM2=1.34 is realized at an output power of 102 W and this work is in progress.

Acknowledgement

The authors would like to thank Prof. Da-Fu Cui for his helpful discussion in the manuscript modification.

- Chinese Physics B的其它文章

- Direct measurement of two-qubit phononic entangled states via optomechanical interactions

- Inertial focusing and rotating characteristics of elliptical and rectangular particle pairs in channel flow

- Achieving ultracold Bose–Fermi mixture of 87Rb and 40K with dual dark magnetic-optical-trap

- New experimental measurement of natSe(n,γ)cross section between 1 eV to 1 keV at the CSNS Back-n facility

- Oscillation properties of matter–wave bright solitons in harmonic potentials

- Synchronously scrambled diffuse image encryption method based on a new cosine chaotic map