Tongmuling Site:An Archaeological Breakthrough in China’s Mining and Metallurgy

by Zhou Chenliang

Guiyang, located in western Chenzhou City, Hunan Province, is rich in mineral resources and has developed a prosperous smelting industry since ancient times.

According to historical records, a “gold official” and an “iron official” were named in Guiyang in the Western Han Dynasty (202 B.C.-8 A.D.) and the Eastern Han Dynasty(25-220), respectively. A department for mining and mintage was established in Guiyang during the late Tang Dynasty (618-907), continuing into the Song Dynasty(960-1279). It has been reputed as the “Millennial Capital of Mining and Metallurgy.” Zinc and brass were widely used to make coins in the Ming (1368-1644) and Qing(1644-1911) dynasties. Guiyang is a major zinc producer in China, so it is also known as the “capital of coinage material.”

In September 2015, the School of Archaeology and Museology of Peking University and the Hunan Provincial Institute of Cultural Relics and Archaeology formed a joint investigation team and headed to the Tongmuling mining and metallurgy site in Guiyang.

Restoring the Site

The Tongmuling site covers an area of about 110,000 square meters. A mountain of melting slag is stacked at the core of the site. By de-obscuring the mountain platform, a roasting unit and two smelting units in a triangular form were discovered as components of a complete smelting system.

“This is how we restored the functional structural layout of the smelting site,” explained Mo Linheng, head of the archaeological project in Guiyang and associate research fellow at the Hunan Provincial Institute of Cultural Relics and Archaeology.“It is of vital reference for studying functional partition, processing, production scale, life of workers, and productivity of ancient metallurgical workshops.”

Reviving Ancient Smelting Techniques

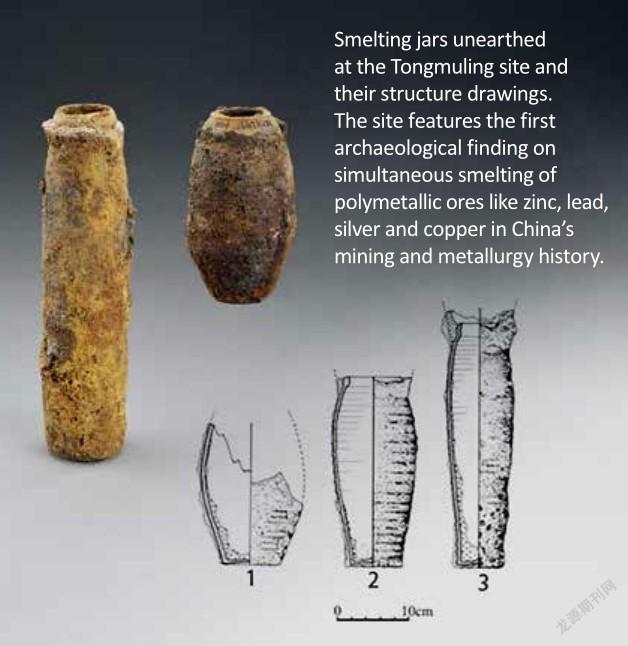

Smelting tools were also unearthed at the Tongmuling site including crucibles, condensers, and shovels, as well as blue and white porcelain, pottery, coins, and other daily utensils. Relics with a high content of copper, lead, and silver were found in the area. Based on overall inspection and analyses, it can be inferred that this polymetallic smelting site mainly engaged in zinc smelting, along with lead, copper, and silver. Preliminary speculation of the unearthed relics suggested the site was built in the late Ming Dynasty or the early Qing Dynasty and abandoned in the mid or late Qing Dynasty.

The excavation site covers more than two hectares. Footings of smelting workshops were laid out neatly at the site, with more workshops sitting on the roadways extending in all directions. Hundreds of ceramic smelting pots and several thousand tons of polymetallic slag remains were discovered as well. All of these inspired an imagination of the spectacular furnaces with rolling smoke and flames back then.

Zhou Wenli, an associate researcher with the Institute for the History of Natural Sciences at the Chinese Academy of Sciences, also participated in the excavation. She explained that usually three to four workers operated a trough-shaped furnace, so dozens of trough furnaces required hundreds of operators. Roasters, crushers, and concentrators were also necessary, testifying to the scale of the smelter site.

“The best part of this archaeological excavation has been the interdisciplinary integration and synchronous archaeological research, which greatly improved research quality and efficiency,”said Mo Linheng. “Through joint efforts, we have restored the ancient process of desulfurization for zinc smelting for the first time.”

China was one of the first countries to master the zinc smelting technique. Chen Jianli, professor at Peking Universitys School of Archaeology and Museology, is among those suggesting the Tongmuling site shows the most advanced zinc smelting techniques of the era. Although it is difficult to reduce zinc directly with sulfide ore found at the site, the problem was solved neatly by first converting zinc sulfide into zinc oxide. This skill, a major technological advance in zinc smelting history, was discovered in China at the earliest date. Other metal smelting activities with lead, silver, and copper were also found at the site. It is the first record of simultaneous smelting of polymetallic ore in Chinas mining and metallurgy history. It testifies to higher-level utilization of ore and highlights ancient Chinas advanced science and technology.