Analysis of drilling difficulty of extended-reach wells based on drilling limit theory

Wen-Jun Huang ,De-Li Gao ,*

a MOE Key Laboratory of Petroleum Engineering,China University of Petroleum,Beijing,102249,China

b State Key Laboratory of Petroleum Resources and Prospecting,China University of Petroleum,Beijing,102249,China

Keywords:

ABSTRACT

1.Introduction

With the conditions of the exploration and development of oil and gas resources become more complex,the demand for extended-reach wells,especially for extended-reach horizontal wells and cluster extended-reach horizontal wells,is increasing,and the corresponding technical challenges are also increasing.To reasonably evaluate and reduce the engineering operation difficulty,a lot of studies have been carried out.These studies can be divided into two categories:drilling limit prediction and drilling risk evaluation.In this section,the research progresses on these two aspects are introduced,the challenges in drilling difficulty evaluation are discussed,and a new solution is given.

1.1.Extended-reach drilling limit

Any system in nature has its limits.For example,the speed at which a person runs,the height at which a bird flies,etc.,have their limit values.Similarly,under certain ground and down-hole constraint conditions,there is a limit value of well depth for any extended-reach well,which is called extended-reach drilling limit.

Extended-reach drilling limit refers to the maximum well depth that can be safely drilled under various ground and down-hole constraint conditions(Gao,2018).Studies of extended-reach drilling limit can be divided into two aspects:theoretical models and case studies.The preliminary research mainly focuses on the analysis and summary of engineering practice,namely case studies(Alfsen et al.,1995;Martins et al.,2004;Mason and Judzis,1998;Meader et al.,2000;Meertens and Kloss,1994;Rodman and Swietlik,1997;Suggett and Smith,2005).

In recent years,more theoretical research has been carried out.Wu and Juvkam-Wold(1995)deduced the slack off limit of tubing while considering the effect of tubular buckling.Rocha et al.(2003a,2003b)pointed out that the wellbore fracture pressure nearly remains unchanged,but the annulus pressure increases a lot in the extended-reach section,so there is a limit length for the open-hole section.Wang and Guo(2008)studied the extendedreach drilling limit while considering the constraints of drilling pumps,annulus pressure loss and cuttings bed height.Yan et al.(2010)studied the operation limit of drill strings under the constraints of friction force,tubular buckling,drilling rig and so on.In 2009,Gao et al.(2009)put forward the concept of extended-reach drilling limit for the first time,which is further divided into three sub-concepts:mechanical limit,hydraulic limit and open-hole limit,and the prediction models of these three types of drilling limits are built.(Chen and Gao,2018;Huang et al.,2018;Li et al.,2016,2019).At present,a theoretical system of extended-reach drilling limit theory has been established.

The prediction model of drilling limit can be used to evaluate the drilling difficulty of extended-reach wells.The main idea is that the predicted value of drilling limit is compared with the designed value to determine whether the designed well depth can be safely drilled.If the predicted value is larger than the designed value,the designed well depth can be reached;otherwise,cannot.However,the division of two levels including“can”and“cannot”is too rough,and this method cannot effectively evaluate the drilling difficulty of a well including several well sections.

1.2.Drilling risk evaluation

There have been many drilling risk evaluation methods,including difficulty matrix method(Sirous,2017),analytic hierarchy process(Jin et al.,2011),BP neural network(Sergey et al.,2020),fuzzy mathematics method(Skogdalen and Vinnem,2012;Zhang et al.,2009),event tree analysis method(Ramzali et al.,2015),bow-tie model(Abimbola,2014),Monte Carlo algorithm(Sheng et al.,2019),Bayesian method(Khakzad et al.,2013),and so on.These methods can be roughly divided into qualitative methods and quantitative methods.

The reliability of qualitative methods mainly depends on the skill levels of experts and whether they are familiar with the evaluation object.The evaluation results of different experts may be quite different.Qualitative methods can give the results of drilling risk levels,but the results are usually rough.Two different operations may be on the same risk level,but the specific risks of these two operations are usually different.Qualitative methods are usually adopted when there is no enough field data for quantitative risk evaluation.

Quantitative evaluation methods can be further divided into two categories:statistical models and physical models.Statistical models require a large amount of field data for the probability evaluation(Kato and Adams,1991).However,it is usually difficult to meet this condition.For the physical models,the physical causal mechanisms and expert evaluations are sufficiently combined(Andersen,1998).Fault tree analysis is one of the most commonly used physical models,in which probability evaluation problem is broken into the combination of smaller problems to find proper experts to make probability evaluation.In the decomposition process of the probability evaluation problem,the physical casual mechanism is fully considered.

The physical models of drilling risk evaluation are more applicable for risk evaluation of single accident phenomenon,such as blowout.The potential risks in extended-reach drilling include not only blowout,but also pipe sticking,tubular buckling and locking,wellbore collapse and other problems.However,it is difficult to use current methods to comprehensively evaluate these potential risks.

1.3.Main challenges and solutions

For an extended-reach well,the relevant parameters of different well sections are different,so the drilling challenges and main constraint factors are usually different.For a same well section,the drilling challenges and main constraint factors of various operating conditions are also different.Even for a same operating condition,kinds of factors are related to the operation safety,and which factor is the main constraint condition needs specific analysis.Therefore,the effects of multiple well sections,multiple operating conditions,and multiple influencing factors should be considered in the drilling difficulty evaluation of extended-reach wells.

The current method based on extended-reach drilling limit to evaluate drilling difficulty is rough and needs further improvement.The risk evaluation methods are also not suitable,because multiple kinds of casual mechanisms are coupled,and the probabilities of some problems are impossible to determine.Therefore,it is necessary to establish a more effective method of drilling difficulty evaluation.

To achieve this goal,the drilling limit model and expert evaluation are combined to build a new method of drilling difficulty evaluation.In the new method,the drilling difficulties on the levels of operation condition,well section and entire well are evaluated,and the main constraint conditions are identified.The evaluation results are more sophisticated than the results of drilling limit models and multiple kinds of casual mechanisms are also considered.

2.Prediction model of drilling difficulty

2.1.Prediction model of drilling limit

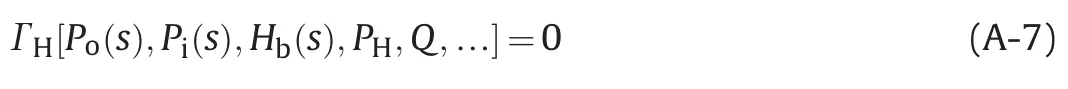

According to the type of constraint conditions,drilling limit is further divided into mechanical limit,hydraulic limit and openhole limit.The prediction model of these three types of drilling limits can be expressed in a unified form(Gao et al.,2009):

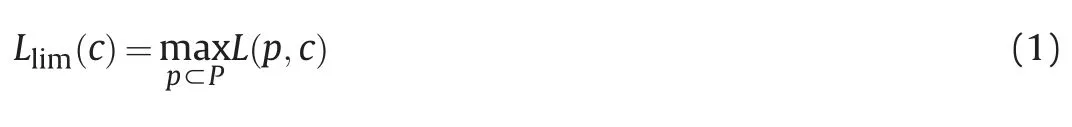

where Llimis the limit well depth,L is the well depth,p is the constraint condition,P is the allowable space of the parameter p and expressed as constraint condition,c is the operation condition.

Note that,Eq.(1)is just a simplified expression to facilitate understanding.The details about the calculations of mechanical limit,hydraulic limit and open-hole limit are given in Appendix A.

2.2.Definition of drilling difficulty index

Drilling difficulty is a concept used to indicate the technical difficulty of drilling a well.Low drilling difficulty means that it is easy to drill a well,while high difficulty means it is difficult.Drilling difficulty depends not only on the complexity of drilling conditions,and but also the level of drilling equipment and the quality of operation team.

Drilling difficulty index is proposed for quantitative evaluation of drilling difficulty.The larger the drilling difficulty index,the higher the drilling difficulty;otherwise,the lower.The difficulty index is defined as

where R is the drilling difficulty index,Llimis the limit well depth,Ldsgis the designed well depth.

The value of difficulty index ranges from 0 to 1.When Llim≫Ldsg,R tends to 0 and the designed well depth can be easily reached.When Llim≪Ldsg,R tends to 1 and the designed well depth cannot be achieved.

2.3.Calculation of drilling difficulty index

A well is usually composed by several well sections,and there are multiple operation conditions in drilling every well section.The more specific expression of drilling limit Llimis

where i is the sequential number of well sections,j is the sequential number of operation conditions in drilling the i-th well section,k represents the type of constraint condition.

The drilling difficulty index corresponding to Eq.(3)is expressed by

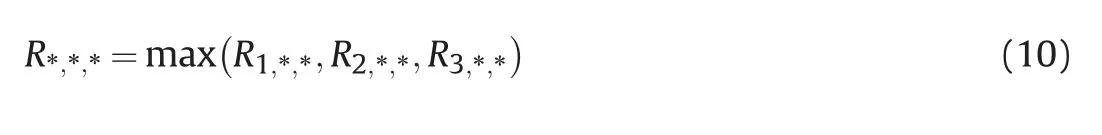

Table 1 shows kinds of difficulty indexes for an entire well.The well sections,including 171/2-in.,121/4-in.and 81/2-in.sections,respectively correspond to the subscript i=1,2 and 3 in Ri,j,k.There are 10 kinds of operation conditions for one well section including sliding drilling,sliding slack off,sliding pick up,rotary drilling,rotary slack off,rotary pick up,sliding running in,sliding running out,rotary running in and rotary running out,which respectively correspond to the subscript j=1 to 10.There are 3 kinds of constraint conditions including mechanical,hydraulic and openhole constraint conditions,which respectively correspond to the subscript k=1,2 and 3.

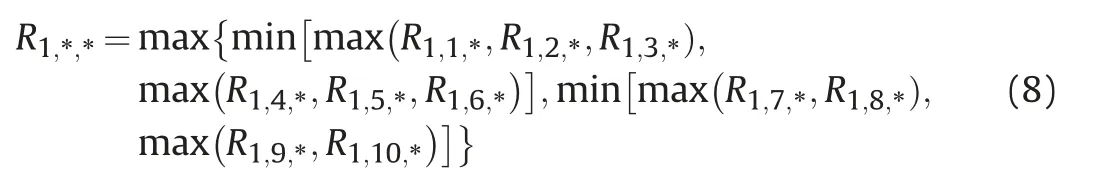

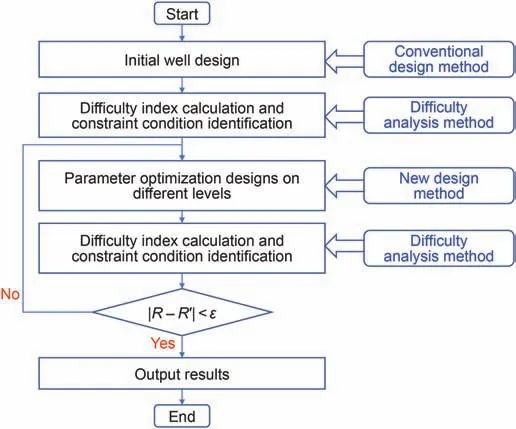

After the values in Table 1 are obtained,the difficulty indexes for all operation conditions,well sections and entire well can be determined.The calculation procedure of difficulty indexes is shown in Fig.1.

Table1 Difficulty indexes for a well.

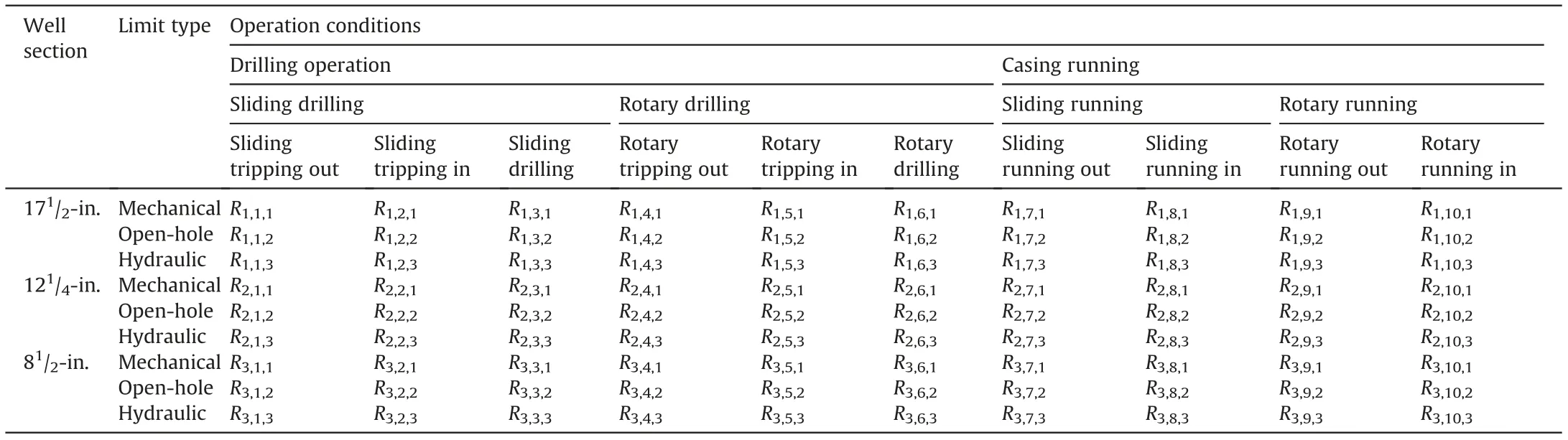

The drilling difficulty index for the j-th operation condition in the i-th well section is calculated by,

where Ri,j,*is the maximum value of the mechanical,hydraulic and open-hole drilling difficulty indexes.

For example,the drilling difficulty index for the sliding tripping out operation in 171/2-in.section is calculated by The drilling difficulty index for the i-th well section is determined by the difficulty indexes of all operations in this well section,and calculated by

whereНis the function containing a serious of maximum and minimum operations.

For example,the drilling difficulty index for 121/4-in.section is calculated by

The drilling difficulty index of the entire well is the maximum value of difficulty indexes of all well sections,and calculated by,

For example,the drilling difficulty index of this well is calculated by

3.Drilling difficulty evaluation and optimization design

3.1.Classification of drilling difficulty levels

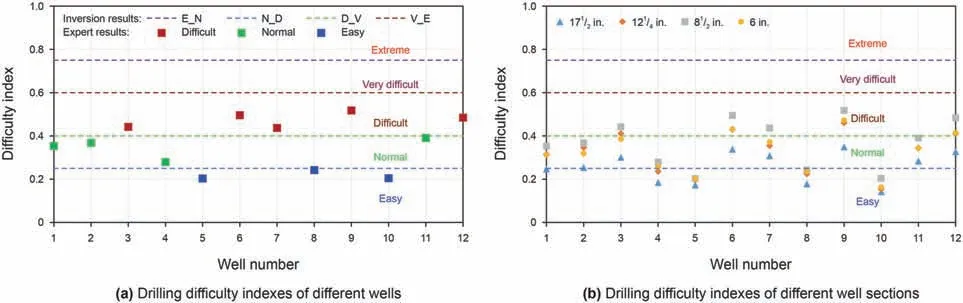

According to drilling practice,drilling difficulty can be divided into five levels,including“extreme”,“very difficult”,“difficult”,“normal”,and“easy”.The relationship between the levels and indexes of drilling difficulties are determined with expert evaluation results.This relationship can be built by following the steps below:

Firstly,drilling data in a certain oilfield is collected.Secondly,the drilling difficulty index of each well is calculated.Thirdly,the difficulty level of each well is determined through expert evaluation.At last,the results of difficulty indexes and difficulty levels are compared,and the interval of drilling difficulty index corresponding to each difficulty level is determined.

The meanings of these five difficulty levels are as follows:

(1)“Extreme”means that drilling complications and accidents occur frequent,the drilling efficiency is rather low,and it is impossible to reach the designed well depth.

Fig.1.Calculation procedure of difficulty indexes on operation condition,well section and entire well levels.

(2)“Very difficult”means that drilling complications and accidents are probable to occur,which obviously affect the overall drilling efficiency,and it is very difficult to reach the designed well depth.

(3)“Difficult”means drilling complications and accidents possibly happen,the impact on the overall drilling efficiency is obvious,and it is difficult to reach the designed well depth.

(4)“Normal”means complications and accidents happened occasionally,the impact on the overall operation efficiency is limited and the difficulty to reach the designed well depth is moderate.

(5)“Easy”means complications and accidents generally do not occur,the impact on the overall drilling efficiency is small and it is easy to reach the designed well depth.

Generally,the drilling difficulty should be controlled on or below the“normal”level.It is not recommended to drill on“difficult”level or“very difficult”level.If it is on the“difficult”level,it requires a detailed plan to deal with potential complicated problems in advance.

3.2.Optimization design method

The optimization design problem with drilling difficulty index as the objective function is expressed as

where R means the drilling difficulty index,R*is the minimum value of difficulty index,d is the design parameter,D is the allowable space of the parameter d and expressed as design space.

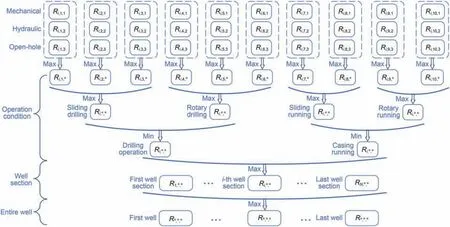

In the above optimization design problem,the objective function can be defined on the levels of entire well,well section and operation condition.Therefore,there are three levels of optimization designs.

There are also three kinds of design parameters corresponding to the levels of entire well,well section and operation condition.The design parameters on operation condition level can be easily changed;the design parameters on well section level are usually determined before well section operation;the design parameters on entire well level are determined before drilling.Some common design parameters on these three levels are shown in Table 2.

Table2 Classification of design parameters.

The drilling optimization design can be taken as the combination of optimization designs on these three levels.These three levels of designs are not equal,but in a mother-child relationship,so the entire design problem can be regarded as a longitudinal design problem.Conventional drilling design can be regarded as a horizontal design problem,in which the sub-designs are relatively equal and on the same level.Horizontal design can fully consider various categories of drilling parameters and it is mainly used for initial drilling design.Longitudinal design can be conducted on different levels,and it is more applicable for deep optimization.

The entire design process is divided into two steps as shown in Fig.2.Firstly,the initial design solutions are obtained with conventional design method.The initial design solutions include well trajectory,well structure,drill strings,casing strings,drilling parameters and so on.Next,the optimal design solutions are obtained in the continuous iteration process,and the design parameters are optimized until the difference between the objective functions in two adjacent iterations is very small.In each iteration,the drilling difficulty indexes are calculated,the most difficult operation condition and main constraint condition are identified,and the design parameters according to the main constraint condition are optimized.

The selection of design parameters is mixed with some engineering experience and knowledge,which is a combination of technology and art.When the selection of design parameters and the determination of design parameter values are reasonable,the design calculations will be greatly reduced.Generally,it only takes a few iterations to get the optimal solutions.

The above design process only provides a basic framework.In the actual design process,some adjustments must be made according to the characteristics of the problem to obtain the optimal solutions as fast as possible.

Fig.2.Procedures of drilling optimization design.

4.Case study of extended-reach wells in the South China Sea

4.1.Technical challenges

Over the past 20 years,a total of more than 100 extended-reach wells have been drilled in the eastern South China Sea,and a technology system of extended-reach drilling with the characteristics of the eastern South China Sea has been formed.To ensure continuous increase in production,it is necessary to develop marginal oilfields and adjust old oilfields,and thus drill more extendedreach wells of larger horizontal displacements and larger horizontal-to-vertical ratios.Therefore,the important technical challenge facing the oil & gas development of the eastern South China Sea is how to drill these extended-reach wells safely.

This paper takes the Liuhua oilfield as example,which is in the eastern South China Sea with an average water depth of 310 m.There are many complex problems in this field including large water depth,shallow burial depth of reservoir,harsh environmental conditions,high crude oil viscosity and so on.At present,more than 10 extended-reach wells have been drilled in this oilfield,most of which horizontal-to-vertical ratios are larger than 3,several wells are larger than 5.With the further increase of horizontal displacements of subsequent extended-reach wells,the drilling difficulties become higher,which brings serious threats to drilling safety.Then,it is urgent to answer several questions:

(1)What is the current level of drilling difficulty?What are the main constraint conditions?How far can it be safely drilled under the current technology and equipment level?

(2)If the technology and equipment are upgraded,what is the level of drilling difficulty?Then,how far can it be safely drilled?

In this section,the extended-reach drilling difficulties are quantitatively evaluated,and the above questions are answered.

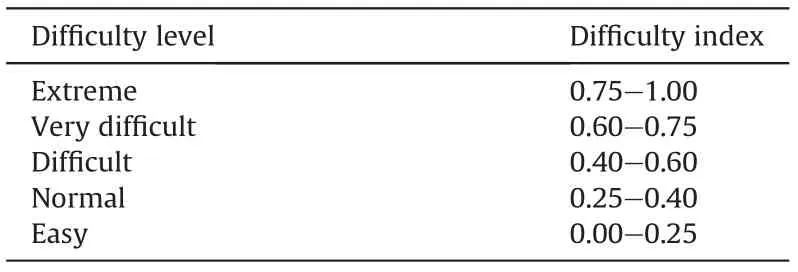

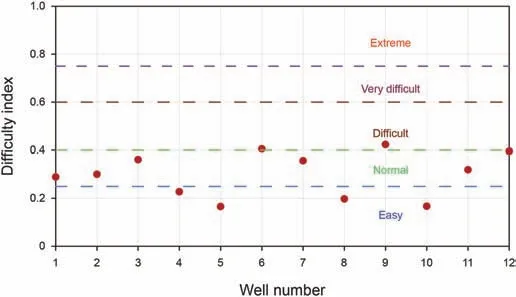

4.2.Model validation

A total of 12 wells were selected from the Liuhua oilfield,and the relevant data of these wells were sent to experts for drilling difficulty level evaluation.Fig.3 shows the expert evaluation results and model calculation results,in which the dash lines are the dividing lines of difficulty levels based on the expert evaluation results.The dividing lines decomposes the entire plane into five intervals,namely five difficulty levels.The expert evaluation results are accurately distributed in these five intervals,which verifies the accuracy of the difficulty evaluation model.The relationship between difficulty level and difficulty index is given in Table 3.

Table3 The relationship between difficulty level and difficulty index.

Fig.3(a)shows that the drilling difficulty indexes of wells in the Liuhua oilfield range from 0.25 to 0.50,in which five wells are on“difficult”level,four wells on“normal”level and three wells on“easy”level.The average drilling difficulty index is 0.37,indicating the average drilling operations in this field are on“normal”level.

Fig.3(b)shows that most of well sections are on“normal”or“difficult”level.The drilling operations on 81/2-in.section are the most difficult,that on 121/4-in.and 6-in.sections are the second.However,the difference of difficulty indexes for these three well sections are small,and thus all these three sections should be considered in drilling optimization design.

4.3.Drilling difficulty analysis

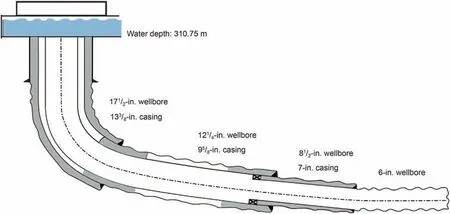

Well X is an extended-reach well which sidetracks from another well.The vertical depth including water depth is 1233.6 m,horizontal displacement is 6052.6 m,and the horizontal-to-vertical ratio is about 4.9.

The well structure of well X is shown in Fig.4.It plans to cut and pull out 133/8-in.casing and 95/8-in.casing and plug back with cement.Next,it plans to drill four sections including 171/2-in.section from 410 to 1005 m,121/4-in.to 4205 m,81/2-in.to 5777 m and 6-in.to 6687 m.To be specific,firstly,51/2-in.drill strings are used to drill 171/2-in.section and 133/8-in.casing is running to 1000 m.Secondly,51/2-in.drill strings are used to drill 121/4-in.section and 95/8-in.casing is running to 4200 m.Next,51/2-in.drill strings are used to drill 81/2-in.section,wellbore is enlarged to 91/4-in.,and 7-in.linear is running to 5772 m.At last,4-in.and 51/2-in.drill strings are used to drill 6-in.section and open-hole completion is adopted.

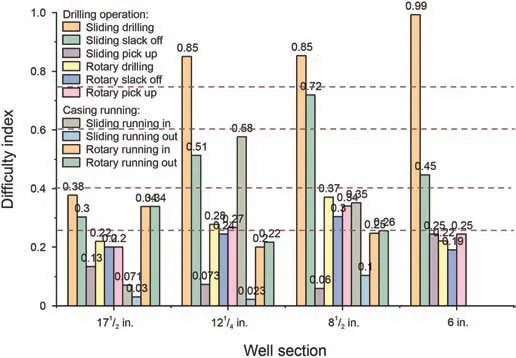

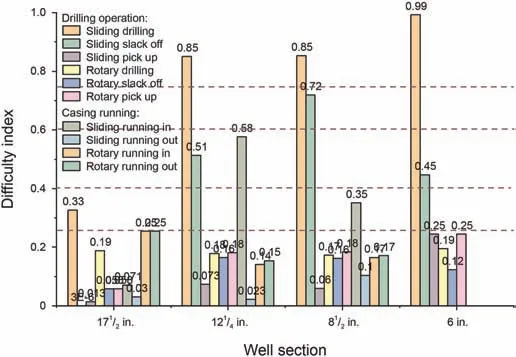

For 171/2-in.,121/4-in.and 81/2-in.sections,there are 10 kinds of operation conditions for every section,and there are 6 kinds of operation conditions for 6-in.section.Therefore,there are 36 kinds of operation conditions in the drilling design.There are 3 kinds of difficulty indexes for every operation condition including mechanical,hydraulic and open-hole difficulty indexes.In sum,there are 108 kinds of difficulty indexes in the drilling design.

Fig.3.Comparison of the calculated results and expert evaluation results.(E_N means the critical condition between“easy”and“normal”levels,N_D means that between“normal”and“difficult”levels,“D_V”means that between“difficult”and“very difficult”levels,and“V_E”means that between“very difficult”and“extreme”levels).

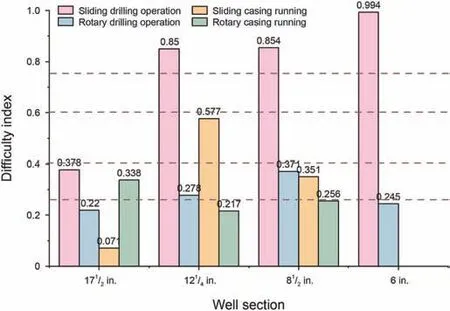

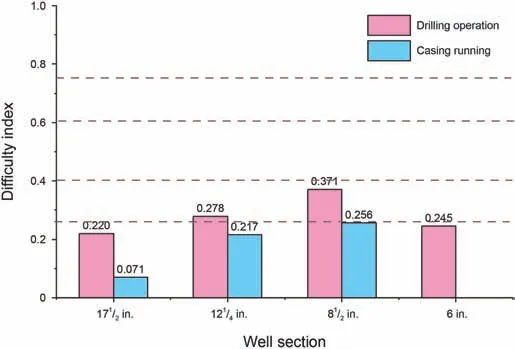

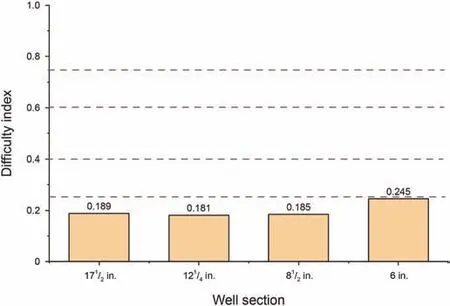

The values of drilling difficulty indexes for all operation conditions and well sections are given in Figs.5-8.Sliding drilling operation in Fig.6 is the combination of sliding drilling,sliding slack off and sliding pick up in Fig.5;rotary drilling operation is the combination of rotary drilling,rotary slack off and rotary pick up;sliding casing running is the combination of sliding running in and sliding running out;rotary casing running is the combination of rotary running in and rotary running out.Drilling operation in Fig.7 is the combination of sliding drilling operation and rotary drilling operation in Fig.6,casing running is the combination of sliding casing running and rotary casing running.

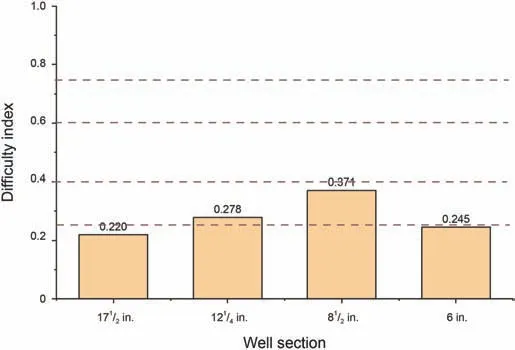

According to the results in Figs.5-8,sliding drilling operations in 6-in.,81/2-in.and 121/4-in.sections are on“extreme”level.Therefore,sliding drilling should be replaced by rotary drilling,and then drilling difficulty decrease to“normal”level.Casing sliding running in 121/4-in.section is on“difficult”level,and thus rotary running on“normal”level is adopted.The above adjustments are in consistent with oilfield practice.The drilling difficulty index for the entire well is 0.371,indicating that the entire well is on“normal”level.

The results in Fig.8 indicate that 81/2-in.section is the most difficult well section,and rotary drilling is the most difficult operation condition for this section.Therefore,rotary drilling in 81/2-in.section is the most difficult operation condition for the entire well.The main constraint condition corresponding to the most difficult operation is excessive ground torque,indicating that rated torque of drilling rig constraints the rotary pick up operation.121/4-in.section is the second difficult section,rotary drilling is the most difficult operation condition and the main constraint condition is excessive ground torque.6-in.section is the third difficult section,rotary pick up is the most difficult operation condition and the main constraint condition is well collapse due to swabbing pressure.

Practice has shown that rotary drilling in 81/2-in.and 121/4-in.sections is the most difficult operation condition in this field,and a problem called periodic sticking is an important constraint condition.The mechanical mechanism of periodic pipe sticking and measures to alleviate this problem have been studied in our previous paper(Huang and Gao,2020).Field practice also indicated that the drilling rig performance is the main factor that limits the development radius of offshore platform.

4.4.Parameter optimization

Fig.4.Schematic of well structure of well X.

Fig.5.Difficulty indexes of all operation conditions.

Fig.6.Difficulty indexes of four kinds of operation conditions.

Fig.7.Difficulty indexes of drilling operation and casing running.

Under current technology and equipment level,it is impossible to significantly decrease drilling difficulty index in this field.Thus,it is necessary to upgrade the drilling rig.Here,the well X is taken as example in the following optimization design.

The rated torque of drilling rig is upgraded from 47.75 to 67.75 kN m,rated drilling pump pressure from 42.5 to 54.3 MPa,and the well structure is slightly adjusted.

Fig.8.Difficulty indexes of different well sections.

After the above optimizations,the drilling difficulty index of this well is decreased from 0.371 to 0.245,and 6-in.section becomes the most difficult well section.The values of difficulty indexes of operation conditions and well sections are given in Fig.9 and Fig.10.For 6-in.section,wellbore leakage due to high ECD in rotary drilling operation is the main constraint factor.For 81/2-in.and 121/4-in.sections,excessive ground torque in rotary pick up operation is the main constraint factor.For 171/2-in.section,hole uncleaning due to high cutting bed is the main constraint condition.

Fig.11 shows the values of drilling difficulty indexes of 12 wells in the Liuhua field after parameter optimization.The drilling difficulty indexes of these wells range from 0.15 to 0.42,in which only one well is on“difficult”level,seven wells are on“normal”level and four wells on“easy”level.

By comparing the results in Figs.3(a)and Fig.11,the drilling difficulty indexes are obviously decreased through drilling rig upgradation.The main constraint conditions are excessive torque and high friction before technology upgradation,and transform to one of excessive torque,hole uncleaning,wellbore instability and so on after technology upgradation.Which is the main constraint condition in the end requires specific analyses under certain drilling parameters and technology level.

Fig.9.Difficulty indexes of all operation conditions.

Fig.10.Difficulty indexes of different well sections.

Fig.11.Drilling difficulty indexes of different wells.

4.5.Limit well depths

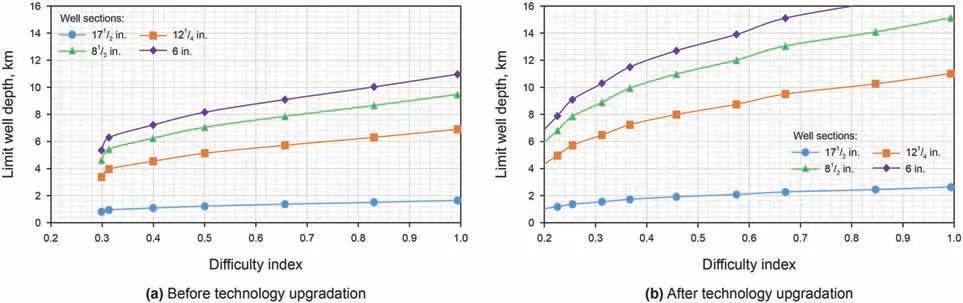

In the above analyses,the total well depth is set to a constant value.In fact,it is necessary to increase the total well depth as much as possible to increase the development control area of the well.Naturally,there is a question:what is the limit well depth on a certain difficulty level?

The limit depths of all well sections on different difficulty levels are calculated,and the relationships between limit well depths and difficulty indexes after and before technology upgradation are shown in Fig.12.The results show that the limit depths of all well sections increase with the increase in difficulty indexes.Given a certain difficulty index,the optimal design solution of well structure and the maximum well depth can be obtained with Fig.12.

Here,we assume that the drilling difficulty level is not higher than“difficult”,namely the difficulty index is not larger than 0.6.At current technology level,the limit depth of 171/2-in.section is 1.3 km,that of 121/4-in.section is 5.6 km,that of 81/2-in.section is 7.8 km,and that of 6-in.section is 8.8 m.After technology upgradation,the limit depth of 171/2-in.section is 2.0 km,that of 121/4-in.section is 8.8 km,that of 81/2-in.section is 12.4 m,and that of 6-in.section is 14.4 m.Then,the limit well depth is increased by about 5.6 km through technology upgradation.The limit well depths after technology upgradation are about 1.6 times in average that before technology upgradation.

4.6.Development control radii

Engineers usually use horizontal-to-vertical ratio or horizontal displacement to estimate the drilling difficulty of extended-reach wells.However,the relationship between horizontal-to-vertical ratio or horizontal displacement and drilling difficulty is mostly based on experience,and these has no a quantitative method to build this relationship.

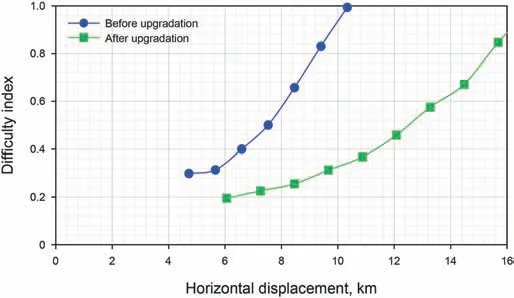

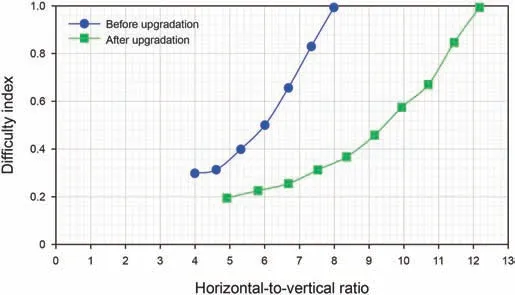

Here,we use the drilling difficulty evaluation model to draw the difficulty distribution charts,in which the relationships between horizontal-to-vertical ratio or horizontal displacement and drilling difficulty are revealed.The difficulty indexes under different horizontal displacements are shown in Fig.13,and that under different horizontal-to-vertical ratios are shown in Fig.14.Here,the horizontal displacement also means the development control radius from the platform.

The results indicate that the drilling difficulty index increases with the increase of development control radius or horizontal-tovertical ratio.Under the same difficulty index,the development control radius or horizontal-to-vertical ratio is increased a lot through technology upgradation.In another word,the difficulty index is decreased a lot under the same development control radius or horizontal-to-vertical ratio through technology upgradation.

Fig.12.Limit depths of different well sections.

Fig.13.Difficulty indexes under different horizontal displacements.

Fig.14.Difficulty indexes under different horizontal-to-vertical ratios.

For the“very difficult”level,the development control radius ranges from 8.2 to 9.0 km and the horizontal-to-vertical ratio ranges from 6.5 to 7.1 at current technology level.Until now,no wells in the South China Sea are in this range,and the highest record of horizontal displacement is smaller than 8.2 km.There have been several wells in Sakhalin,Wytch Farm and other oilfields are in this range.After technology upgradation,the development control radius ranges from 13.6 to 15.2 km and the horizontal-tovertical ratio ranges from 10.1 to 11.1.Until now,only one well in Sakhalin oilfield is in this range of which the horizontal displacement reaches more than 14 km.

For the“difficult”level,the development control radius ranges from 6.6 to 8.2 km and the horizontal-to-vertical ratio ranges from 5.3 to 6.5 at current technology level.Several extended-reach wells in the South China Sea are in this range.After technology upgradation,the development control radius ranges from 11.4 to 13.6 km and the horizontal-to-vertical ratio ranges from 8.7 to 10.1.

For the“normal”level,the development control radius is smaller than 6.6 km and the horizontal-to-vertical ratio is smaller than 5.3 at current technology level.Practice has shown that it is not difficult to drill extended-reach wells on this level in the South China Sea.After technology upgradation,the maximum development control radius reaches 11.4 km and the maximum horizontalto-vertical ratio is 8.7.

The next work in the South China Sea is to drill adjustment wells in old oilfields and develop new marginal oilfields,which require extended-reach wells of larger horizontal displacements and higher horizontal-to-vertical ratios.It is necessary to further improve the level of drilling technology to increase the development control radius.Then,the drilling difficulty curves in Figs.13 and 14 will shift to the right along the x-axis,and the increase rate in drilling difficulty decreases.Therefore,technology upgradation,especially drilling rig upgradation,is the most important development direction for extended-reach drilling in the South China Sea.

5.Conclusions and outlooks

Based on the above studies,we obtain the following conclusions:

(1)A drilling difficulty evaluation model is built by combing drilling limit model and expert evaluation.This method can obtain the difficulty levels of operation conditions,well sections and entire well,and reveal the main constraint conditions.Therefore,it provides an important basis for difficulty evaluation and optimization design in extendedreach drilling.

(2)Under current technology level,the drilling difficulty indexes of extended-reach wells in the Liuhua oilfield range from 0.25 to 0.50.Rotary drilling in 81/2-in.section is the most difficult compared with other well sections,and the main constraint conditions are excessive torque and high friction.After technology upgradation,drilling difficulty indexes range from 0.15 to 0.42,and the main constraint condition transforms to one of excessive torque,hole cleaning,wellbore instability and so on.Which is the main constraint condition in the end requires specific analyses under certain drilling parameters and technology level.

(3)If the drilling difficulty is controlled not higher than“normal”level,the development control radius reaches 6.6 km and the horizontal-to-vertical ratio achieves 5.3 at current technology level.After technology upgradation,the development control radius reaches 11.4 km and the horizontal-to-vertical ratio achieves 8.7.Considering that the lateral displacements of some development wells in marginal oilfields and adjustment wells in old oilfields are inevitably larger than 6.6 km,drilling rig upgradation is necessary.

(4)Drilling difficulty is a complicated problem,and it is still a vague concept in drilling engineering.This article mainly carried out a preliminary study of drilling difficulty evaluation from the technical point of view.It is recommended that the next step is to reveal the connotation of this concept more comprehensively and build a more reasonable evaluation method to guide safe and efficient extended-reach drilling.

(5)In actual drilling process,drilling parameters are changing with time and different from that in drilling design stage,which leads to deviations of drilling difficulties in actual drilling and pre-drilling design stages.Therefore,the next step is to carry out research on dynamic difficulty evaluation while drilling.

Acknowledgments

The authors gratefully acknowledge the financial support from the Natural Science Foundation of China(Grant Nos.51904317 and 51821092),Science Foundation of China University of Petroleum,Beijing(Grant No.ZX20180414),and other projects(ZLZX2020-01-07-01).

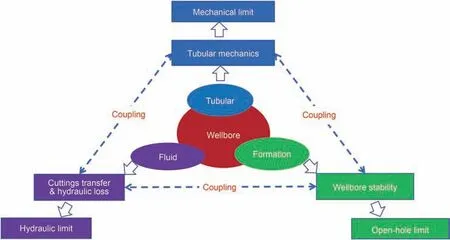

Appendix A.Prediction models of drilling limits

Fig.A1 shows the framework of extended-reach drilling limit theory.Tubular string,drilling fluid and near-wellbore formation are three kinds of key components of the wellbore,and tubular mechanical model,cuttings transfer & hydraulic pressure model and safety pressure window model are respectively built by taking these factors as research objects.Based on these models,three kinds of prediction models of drilling limits,including mechanical limit,hydraulic limit and open-hole limit,are respectively built.Therefore,extended-reach drilling theory is a further development of conventional drilling engineering theory.

Fig.A1.Framework of extended-reach drilling theory

(1)Mechanical limit

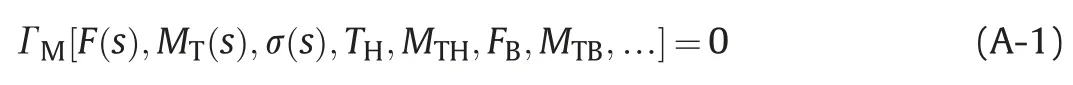

Mechanical limit refers to the maximum well depth that the drilling system can drill under mechanical constraint conditions.Mechanical limit is closely related to steerable drilling mode,tubular strength,friction force,drilling rig performance,etc.In the calculation of mechanical limit,the key is tubular mechanic model,namely

whereΓMis the tubular mechanical model which mainly refers to the axial force&torque model,F is the axial force on the drill string,MTis torque on the drill string,σis the equivalent stress,s is the well depth,THis the weight on hook,MTHis the torque on the ground,FBis the weight on bit,MTBis the torque on bit,…represents other factors.

There are several kinds of mechanical constraint conditions.Weight on hook is not larger than the rated pick up force of the drilling rig and not smaller than the minimum slack off force of the drilling rig,namely

where Triguis the rated pick up force of the drilling rig,Triglis the minimum slack off force of the drilling rig and usually taken as 0.

Torque on ground is not larger than the rated torque of the drilling rig,namely where MTriguis the rated torque of the drilling rig.

In the drilling process,weight on bit and torque on bit must be not smaller than the threshold values,namely

where Fthsland MTthslare the threshold weight on bit and torque on bit for rock breaking.

The equivalent stress of the tubular string is not larger than the allowable stress,namely where[σ]is the allowable stress of the tubular string.

(2)Hydraulic limit

Hydraulic limit refers to the maximum well depth that can be drilled under normal fluid circulation and wellbore cleaning and it depends on the drilling pump,hydraulic parameters and rate of penetration,etc.In the calculation of hydraulic limit,the key is cuttings transfer and hydraulic pressure model,namely

whereΓHis the cuttings transfer and hydraulic pressure model,Pois the annular pressure,Piis the pressure in the drill string,Hbis the cuttings bed thickness,PHis the pressure on ground,Q is the pump displacement.

The pressure on ground is not larger than the rated pressure of drilling pump,namely

where Priguis the rated pressure of drilling pump.

The cutting bed thickness should be no larger than the threshold value to ensure wellbore cleaning,namely

where Hbthsuis the threshold value of cutting bed thickness.

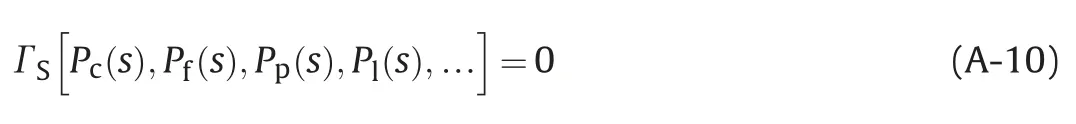

(3)Open-hole limit

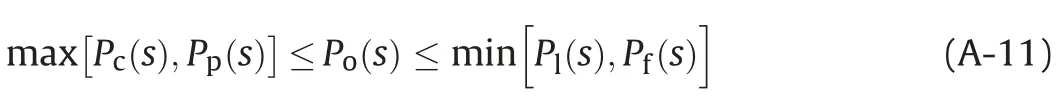

Open-hole limit refers to the maximum well depth that can be drilled under wellbore stability on the open-hole section and it depends on the safe drilling pressure window of the formation,the circulating pressure loss in the drill string and the annulus,etc.In the calculation of open-hole limit,the key is the safety pressure window model,namely

whereΓSis the safety pressure window model,Pcis the wellbore collapse pressure,Pfis the wellbore fracture pressure,Ppis the pore pressure of the formation,Plis the wellbore leakage pressure.

The annulus pressure should be larger than the collapse pressure and pore pressure and smaller than the leakage pressure and fracture pressure,namely In the calculation of drilling limit,a series of different well depths are set to obtain the mechanical behavior of the drill string,pressures in the drill string and the annulus,cutting bed thickness,safety pressure windows and so on,and determine whether the constraint conditions are satisfied.There is a critical well depth,the above constraint conditions are all satisfied when the well depth is less than the critical value and a certain constraint condition starts to be dissatisfied when the well depth exceeds the critical value.The critical value is the drilling limit,and the constraint condition is the main factor limiting wellbore extension.The value of drilling limit can be calculated with iteration method.

- Petroleum Science的其它文章

- Sedimentary characteristics and implications for hydrocarbon exploration in a retrograding shallow-water delta:An example from the fourth member of the Cretaceous Quantou Formation in the Sanzhao depression,Songliao Basin,NE China

- Study of the gas sources of the Ordovician gas reservoir in the Central-Eastern Ordos Basin

- A novel hybrid thermodynamic model for pore size distribution characterisation for shale

- Microstructural analysis of organic matter in shale by SAXS and WAXS methods

- Investigation of oil and water migrations in lacustrine oil shales using 20 MHz 2D NMR relaxometry techniques

- Fast least-squares prestack time migration via accelerating the explicit calculation of Hessian matrix with dip-angle Fresnel zone