Study on the Preparation of "Oil-tea" Instant Tea from the Compound Extract of Green Tea and Ginger

RuhanHUANG DongdiXIE

Abstract[Objectives] This study was conducted to develop an "oil-tea" instant tea with traditional "oil-tea" flavor, easy preservation and transportation and good taste. [Methods]With green tea, ginger and peanuts as experimental materials, a compound extract was obtained by boiling, and the "oil-tea" instant tea was prepared by spray drying. The tea polyphenol content and soluble solid content of the extract (oil tea soup), the yield of finished solid product and sensory quality were comprehensively evaluated. [Results] The optimum instant tea technical parameters were determined as follows: the ratio of material to liquid 1∶15, the extraction time of boiling 60 min, the inlet air temperature of spray drying 180 ℃, the feeding speed 850 ml/h, the soluble solid content of the extract 13%, and the amount of maltodextrin added 12 mg/g. Under these conditions, the yield of the instant tea was high, and the instant tea had better sensory quality and good solubility. [Conclusions]This study provides a reference for the commercial development of "oil tea".

Key wordsGreen tea; Ginger; Extract; Oil tea; Instant tea

The "oil tea" is very popular in the northern and central regions of Guangxi. It is drunk freshly after being prepared, and has the functions of invigorating the stomach, helping digestion, and conditioning the whole body. The traditional craftsmanship of "oil tea" takes a long time and requires a lot of manpower and material resources, and the tea does not have a good storage period, and is inconvenient to carry. The instant tea is tea essence[1], which is a powdered or granular solid tea similar to instant coffee, prepared with finished tea as the raw material, which is subjected to extraction for tea juice, followed by steps of filtration, concentration and drying[2]. It is easy to carry and brew, and occupies a small area. It is also easy to transport and store, so it is a very promising beverage. In order to turn the traditional "oil tea" into commercialization and meet the needs of consumers, this study developed a "oil tea" instant tea with traditional "oil tea" flavor, which is easy to store, transport and brew and has a good taste. That is, we used green tea, ginger and peanuts as raw materials, obtained a compound extract by boiling, and prepared the solid powder instant tea by the spray drying process, in order to provide reference for the commercial development of "oil tea".

Materials and Methods

Experimental materials

Green tea; ginger; peanut; garlic; peanut oil; maltodextrin; ferrous sulfate; potassium sodium tartrate; sodium hydrogen phosphate dihydrate; potassium dihydrogen phosphate; phosphate buffer.

Main instruments and equipment

JP-250A-8 high-speed multifunctional pulverizer (Zhejiang Yongkang Jiupin Industry and Trade Co., Ltd.); Mar-80 large-capacity electric centrifuge (Jiangsu Jintan Huanyu Scientific Instrument Factory); SP-1500 spray dryer (Shanghai Shunyi Equipment Co., Ltd.); 722-visible spectrophotometer (Shanghai Spectrum Instrument Co., Ltd.); MC handheld digital saccharimeter (Guangzhou Atago Scientific Instrument Co., Ltd.); RE-311 vacuum rotary evaporator (yamato).

Experimental methods

Preparation method of oil-tea instant teaTea leaves were soaked with warm water. A certain amount of peanut oil was heated, and the tea leaves were fried until fragrant. Then, the set amount of ginger, peanuts and garlic cloves were added while heating and beating with a wooden hammer until juice seeped from the raw materials. Next, the materials were added with 80 ℃ hot water and boiled according to the set material-to-liquid ratio for a certain time, to obtain oil tea soup, which was filtered to obtain a composite extract. The extract was concentrated to a certain soluble solid concentration, which was spray-dried under certain conditions to obtain oil tea powder, and a certain amount of maltodextrin was added to obtain the finished product of "oil-tea" instant tea.

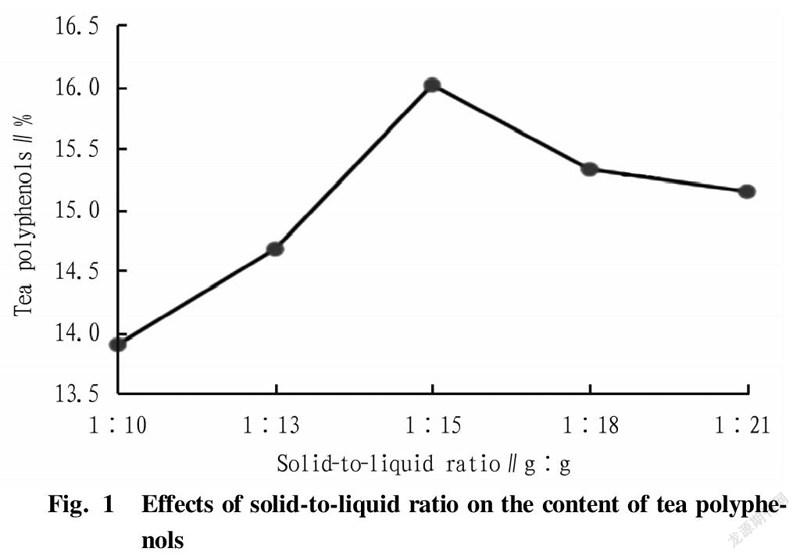

Determination of boiling extraction conditionsThrough pre-experiment, it was determined that the ratio of oil tea ingredients was green tea∶ginger∶peanut∶garlic clove∶peanut oil=2∶4∶2∶0.5∶0.5 (amount ratio), and different material-to-liquid ratios (1∶10, 1∶13, 1∶15, 1∶18, 1∶21) and different boiling and extraction time (20, 40, 60, 80, 100 min) were set. The quality of oil tea soup was judged by the content of tea polyphenols in the extract.

Determination of spray drying conditionsThe obtained extract was spray-dried. Specifically, the drying process conditions were fixed under the determined suitable material-to-liquid ratio and boiling extraction time: outlet temperature 75 ℃, inlet air temperature 180 ℃, feed rate 900 ml/h, and soluble solid material 12%, and the inlet air temperature (165, 170, 175, 180, 185 ℃), feed rate (750, 800, 850, 900, 950 ml/h) respectively ) and the soluble solids in the extract (10%, 11%, 12%, 13%, 14%) were set, respectively. The influencing factors of spray drying were investigated with product yield and product color as indexes.

Determination of the amount of maltodextrin addedUnder the conditions of determined solid-to-liquid ratio, boiling extraction time and corresponding spray drying parameters, the amount of maltodextrin added was set to 10, 12 and 14 mg/g, respectively. The effects of different amounts of maltodextrin added on the sensory quality of instant tea products were investigated.

Index measurement method

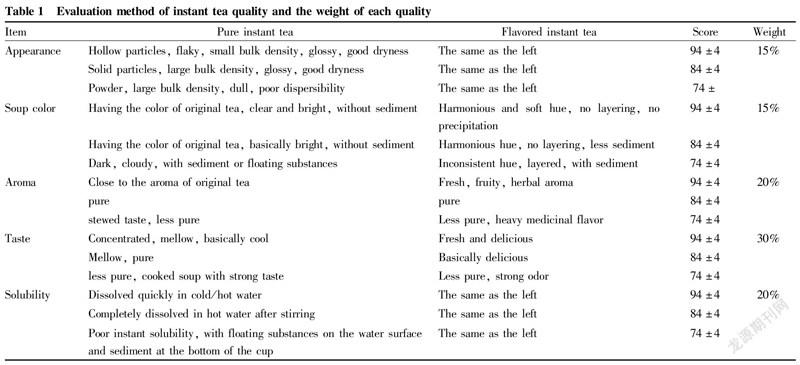

Tea polyphenols were determined by the ferrous tartrate colorimetric method[3]. The pink value (L value) of oil tea was determined by the HunerLab colorimetric method[4]. The yield of oil tea powder was calculated based on the mass percentage of oil tea powder to extract. The appearance, soup color, aroma, taste and instant solubility of the finished instant oil tea were evaluated by the sensory evaluation method[5] (Table 1).

Results and Analysis

Effects of solid-to-liquid ratio on the quality of oil tea soup

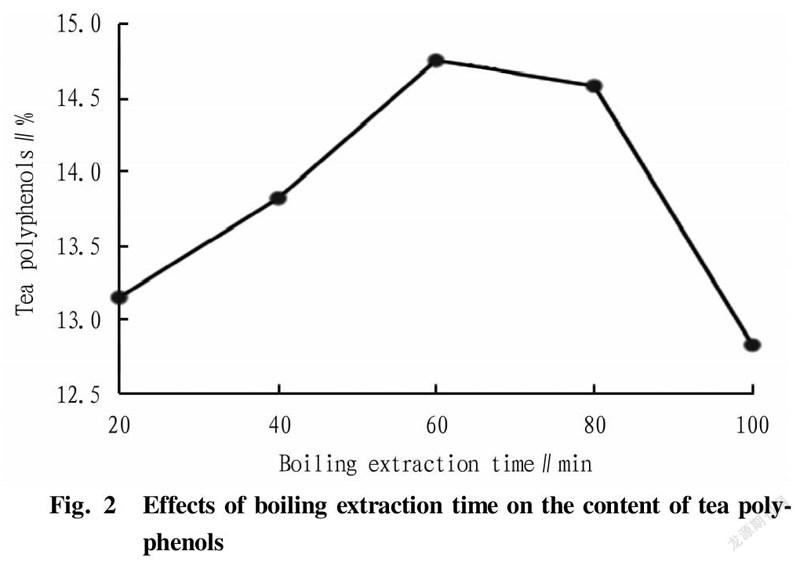

Boiling extraction can not only extract active ingredients in tea leaves, ginger and peanuts, but also improve the quality of oil tea soup. In a certain temperature range, the content of tea polyphenols is positively correlated with time. The longer the time is, the higher the extraction rate of tea polyphenols is. However, when a certain time is reached, according to the principle of osmotic balance, time has little effect on the extraction rate, and even causes the oxidation of tea polyphenols.

It can be seen from Fig. 1 that with the decrease of solid-to-liquid ratio, the content of tea polyphenols in oil tea soup first increased and then decreased. When the solid-to-liquid ratio was 1∶15, the content of tea polyphenols reached the maximum value of 16.03%. It showed that the extraction of tea polyphenols almost reached equilibrium at this time, and with the decrease of the ratio of solid to liquid, tea polyphenols showed a downward trend. Considering the cost and follow-up process comprehensively, a material-to-liquid ratio of 1∶15 was more appropriate.

Effects of boiling time on the quality of oil tea soup

As can be seen from Fig. 2, the content of tea polyphenols in oil tea soup showed a trend of first increasing and then decreasing with the increase of cooking time. It reached the maximum at 60 min, and then decreased rapidly with the increase of time, which might be due to the long-term high temperature extraction changed the forms of phenolic substances. Therefore, the cooking time of 60 min was more suitable.

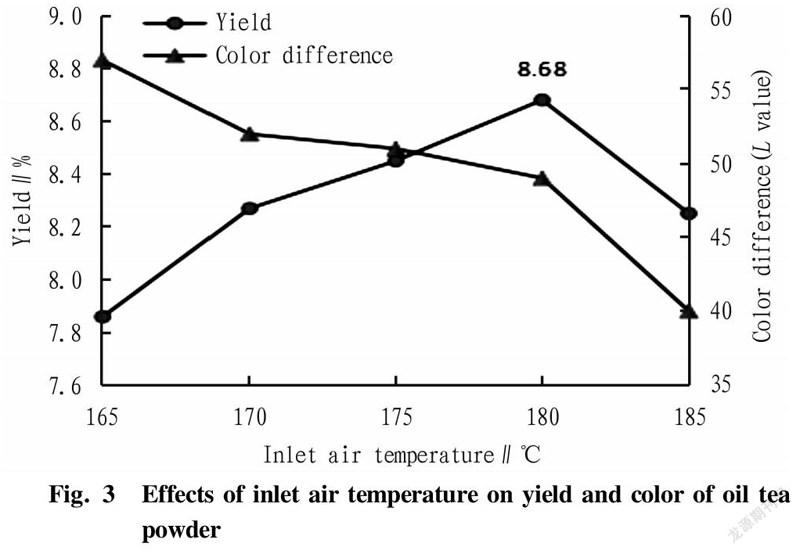

Effects of inlet air temperature on yield and color of oil tea powder

It can be seen from Fig. 3 that with the increase of the inlet air temperature, the yield of oil tea powder showed a trend of first increasing and then decreasing, and the yield was the highest at 180 ℃. However, as the temperature increased, the aromatic substances in the oil tea soup were reduced during the drying process, and replaced by a burnt taste. Moreover, with the increase of the inlet air temperature, the L value of tea powder showed a downward trend, and the decline was relatively slow in the stage from 165 to 180 ℃. In addition, considering the consumption of energy, the reduction of steam pressure, the reduction of production costs and improvement of economic benefits, the inlet air temperature of 180 ℃ was more suitable.

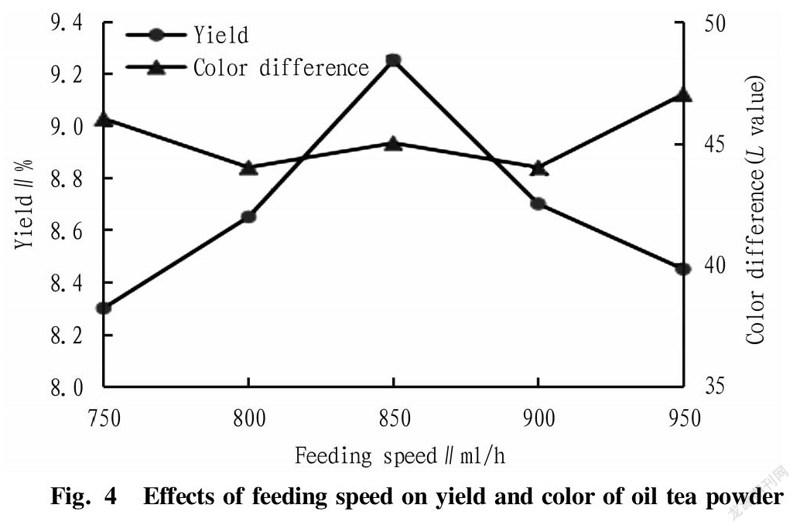

Effects of feeding speed on yield and color of oil tea powder

It can be seen from Fig. 4 that with the increase of the feeding speed, the product yield showed a trend of first increasing and then decreasing, but little effect was produced on the color. When the feed rate reached 850 ml/h, the product yield was high, but decreased then. With a too-slow feeding speed, the droplets sprayed by the atomizer were too small and too light, which reduced the efficiency of spray drying. When the feed rate was too fast, the droplets become larger, and could not be completely dried and adhered to the inner wall of the drying chamber, which also reduced the drying efficiency. Therefore, from the perspective of energy saving and other aspects, the feeding rate of 850 ml/h was a more reasonable choice.

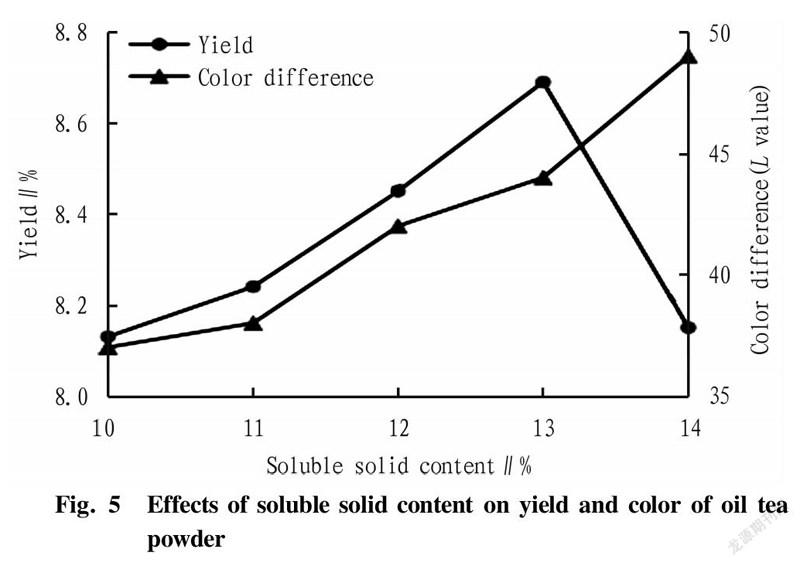

Effects of soluble solid content in extract on yield and color of oil tea powder

The concentration of tea extract is very low, containing only a few percent solids. If the solids of the extract are concentrated to a certain concentration, the drying efficiency can be improved, and the particle diameter of the product can be increased. It can be seen from Fig. 5 that with the increase of the soluble solid content of the extract, the yield of oil tea powder increased, and reached the maximum when the soluble solid content was 13%. With the increase of the soluble solid content of the extract, the L value of the dried oil tea powder also continued to increase, and a higher soluble solid content of the feed liquid was more conducive to the formation of large particles during the drying process, which facilitated the realization of the purpose of increasing the instant solubility of the product. Therefore, based on the above, the extract with a soluble solid content of 13% for spray drying was more reasonable.

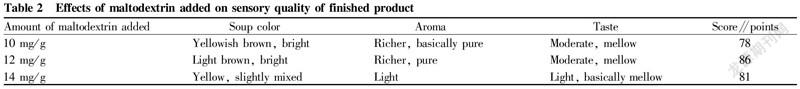

Effects of maltodextrin added on sensory quality of finished instant tea

The sensory qualities of instant tea, such as appearance, soup color, aroma, taste and instant solubility, are better. It is necessary to add substances that promote dissolution to the dried oil tea powder to enhance the appreciation and instant solubility of the product. It can be seen from Table 2 that when the amount of maltodextrin added was 12 mg/g (soluble solids), the sensory quality of oil tea powder was the best, and closest to the quality of crude tea soup. When the addition amount was 10 mg/g, the color of the tea soup was darker; and when the addition amount was 14 mg/g, the color of the tea soup was lighter, and the aroma was lighter,and the tea soup was not bright enough. Therefore, the addition amount of 12 mg/g of maltodextrin had a good influence on the sensory quality of the product. Meanwhile, considering the product yield, adding a certain amount of maltodextrin could also improve the product yield, so the value of adding maltodextrin was 12 mg/g.

Conclusions and Discussion

The optimal process parameters of "oil tea" instant tea were obtained. Specifically, to obtain the "extract" of oil tea soup, the ratio of material-to-liquid could be 1∶15, and the boiling time could be 60 min. To obtain "oil tea" instant tea, the best conditions were as follows: the spray drying temperature 180 ℃, the feeding rate 850 ml/h, the soluble solid content of the extract 13%, and the amount of maltodextrin added 12 mg/g. With these conditions, the yield of instant tea was better, and the finished product had better sensory quality and stronger solubility.References

[1] ZHUANG XD. Discussion on extraction technology of instant tea[J]. Acta Tea Sinica, 1999(2): 7-10. (in Chinese).

[2] KANG ML, XUE XC, LUO YP, et al. Advances in instant tea research[J]. Journal of Tea, 2006(1): 55-57. (in Chinese).

[3] HE PH, ZHANG YS, CHEN HD, et al. Tea evaluation guidelines[M]. Beijing: China Agricultural University Press, 1999. (in Chinese).

[4] LIU ZQ. A Humble Opinion on the quality standard of instant tea products[J]. Tea in Fujian, 1999(4): 27-28. (in Chinese).

[5] CUI JL. Study on the best technical route and process parameters for industrial production of instant tea powder[D]. Chongqing: Southwest University, 2011. (in Chinese).

Editor: Yingzhi GUANG Proofreader: Xinxiu ZHU

- 农业生物技术(英文版)的其它文章

- Report on the Breeding of Dahen 799 Broilers

- Evaluation and Analysis for Survey of Tea Production Quality Safety Management and Control

- Research Progress on Chemical Constituents and Pharmacological Effects of Zhuang Medicine Cocculus laurifolius DC.

- Study on Quality Standard of Lujing Yiqi Shengxue Pills

- Research on the Development of Guangxi Zhuang and Yao Ethnic Medicine Industry

- Study on Leaching Conditions of Miao Medicine Xiange Zuyu Powder