Evaluation and Analysis for Survey of Tea Production Quality Safety Management and Control

JingHUANG XiaoDU

Abstract[Objectives] This study was conducted to investigate and evaluate the quality safety of tea production in China. [Methods]With the production of famous and high-quality green tea in the western Sichuan tea areas as the investigation object, the practice survey and comprehensive evaluation analysis method were adopted to conduct research on tea production quality safety management and control, and a comprehensive evaluation was carried out in combination with the survey. [Results] Statistical analysis and scoring were carried out according to relevant indices, and the current situation of tea production quality safety was comprehensively evaluated. Four hazards were found, including pesticide residues, heavy metal residues, harmful microorganisms and non-tea impurities, and improvement measures were proposed. [Conclusions]This study provides a theoretical reference for improving the quality safety of tea production in China.

Key wordsTea quality safety; Base planting; Processing and production; Market circulation; Government supervision

Food safety is the foundation of people's health, and improving and ensuring food quality and safety is a research topic with great significance[1-8]. As an additivefree hea-lthy beverage, tea has attracted much attention for its quality safety, especially the potential safety hazards such as pesticide residues in tea[9-13] and heavy metals exceeding the standard[16-17], which have a negative impact on the development and export of tea in the domestic market. As a major country in tea production, consumption and export, China has the responsibility and obligation to do its best to ensure quality and safety. The occurrence of tea quality and safety problems has both subjective reasons and objective existence. Therefore, in this study, tea quality safety management and control was investigated by practical survey and comprehensive evaluation and analysis methods taking tea planting and tea processing as research clues.

Survey Methods

Objects of survey

The scope of the investigation was Ya'an, Chengdu and Leshan in Sichuan, the main producing areas of famous green tea in western Sichuan. Survey, research, comprehensive evaluation and result analysis were carried out for quality safety control in the two key links of tea planting and processing in production.

Survey and evaluation methods

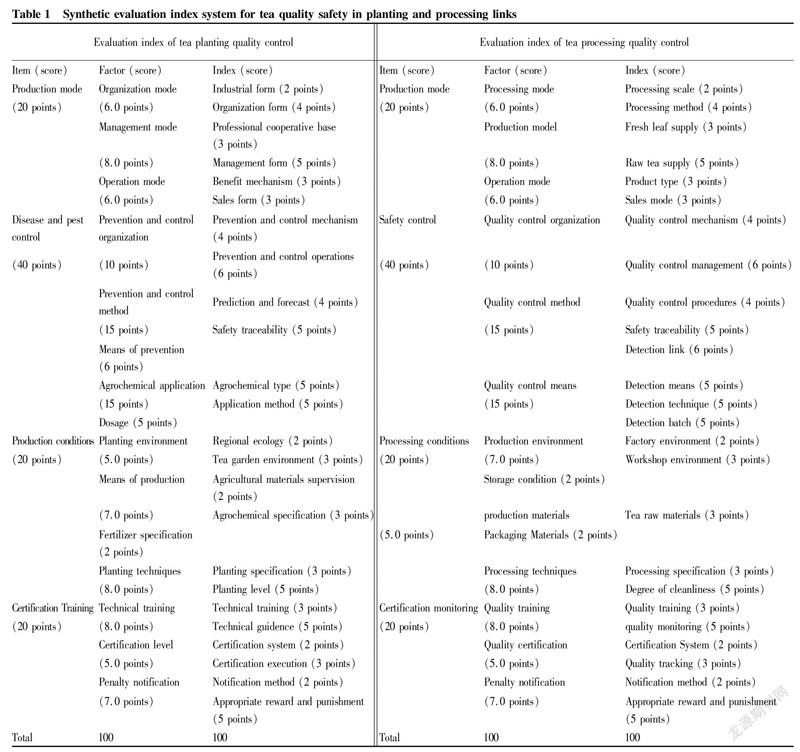

For the main tea planting bases and tea processing enterprises within the scope of the survey, field visits, observation and recording and questionnaire survey were carried out. A comprehensive evaluation index system of 4 major items, 9 factors and 30 indicators involving quality safety control in the two links of tea planting and tea processing was designed using the Analytic Hierarchy Process (AHP) (Table 1). Tea experts, tea technicians and quality supervisors were invited to divide the weights into 3 levels according to the items, factors and indicators and then score according to the three levels of excellent, good and medium combining with the actual research situation. According to the two links of planting and processing, the scores of various factors were counted to conduct a comprehensive evaluation of quality safety control.

On the basis of the comprehensive evaluation, combined with the actual survey situation, key factors were found out through Hazard Analysis and Critical Control Points (HACCP). The reasons were analyzed, and the level of tea production quality safety management and control was evaluated.

Results and Discussion

Evaluation results of quality safety management and control in tea planting

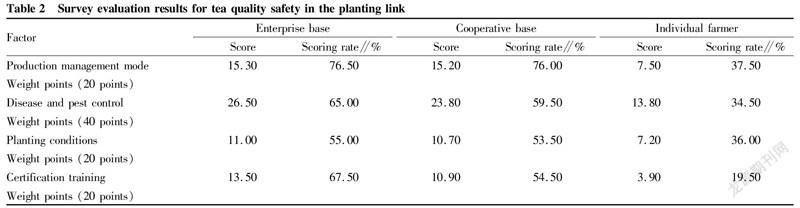

Tea planting involves production methods, pest control, planting conditions and training services, etc., and is the basic link of tea quality safety[21-27]. At present, the tea planting models in the survey area mainly include the "enterprise+base" production model (about 10.8%), the "cooperative+base" management model (about 26.7%), and the "individual farmer" management model (about 62.5%), and about 58.7% of the latter farmers intend to participate in the cooperative model. Regarding the tea quality and safety management and control, according to the survey results and comprehensive evaluation, it was shown that the priority of the production mode was the enterprise base mode (76.5%) ≈ the cooperative base mode (76.0%) > the individual farmer (37.5%), and the former two had far higher scores than the latter, which was due to the orderly organization, the proper management and the sound benefit mechanism of the base models. Similarly, the priority order of pest control was the enterprise base model (65.0%) > the cooperative base model (59.5%) > the individual farmer model (34.5%), and the former two had far higher scores than the latter, which was due to the fact that all base models implemented "unified prevention and control" (accounting for 95%) and green prevention and control were in place (accounting for 85%), while 66% of farmers apply pesticides themselves, and chemical pesticides account for 62.5%. The priority order of planting conditions was also the enterprise base model (55.0%) ≈ the cooperative base model (53.5%) > the individual farmer model (36.0%), and the former two had far higher scores than the latter, which was due to the excellent planting environment of the base models, in which alpine tea gardens accounted for 43.25% and hilly areas account for 50.24%. In terms of certification of monitoring, the priority order was also the enterprise base model (67.5%) > the cooperative base model (54.5%) > the individual farmer model (19.5%). Green (pollution-free) certification reached 93.1% for the enterprise tea gardens and 83.18% for the cooperative base model, while farmers' tea gardens rarely got certified. 92.0% of company employees participated in quality and safety training, 78.7% of cooperatives participated in training, while only 23.50% of farmers participated. On the whole, the enterprise base model and the cooperative model are both highly recognized management models, while the recognition of farmers' self-management is low. The details are shown in Table 2.

Status quo of tea quality safety in production and processing

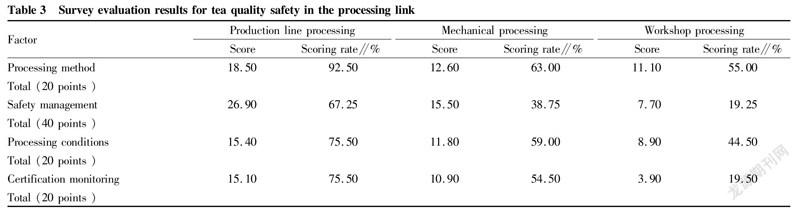

According to the processing methods and processing conditions of tea, the survey objects mainly focused on the production line processing during which the products are on the line all the time, artificially-assisted mechanical processing using unit operations, and small-scale workshop processing using small machinery combined with manual operation. In this link, the results of the survey area showed that the production line processing method (92.5%) had the highest quality safety recognition, much higher than that of machinery processing (63.0%) and small tea factories (55.0%), which was because the processing scale (73.12%) and the processing method (69.53%) of the production line processing method were much higher than the latter two, and the supply of raw materials (93.15%) and the supply of raw tea (89.68%) were strictly controlled. In terms of production safety management, the priority order was production line processing (67.25%) > mechanical processing (38.75%) > small tea factory (19.25%), which was because the quality control organization (96.81%), quality control methods (97.32%), and specific quality control methods (97.15%) around product quality safety management were strictly in place, and records could be traced. In terms of processing conditions, the priority order was small production line processing (75.5%) > mechanical processing (59.00%) > small tea factories (44.50%). The survey data showed that the production environment (86.72%), processing technology (73.18%) and production materials (85.63%) of large production line processing enterprises had a high degree of recognition, which was because many large-scale enterprises introduced intelligent equipment, by which the whole process from raw materials entering the factories to finished products was stably monitored, and the product quality was stable. From the perspectives of training and certification, it showed a priority order of production line processing (75.50%) > mechanical processing (54.50%) > small tea factories (19.50%), which was due to the fact that production line processing enterprises implemented quality training (75.28%), quality certification (73.86%), and notification of punishment (78.15%) at rates much higher than the latter two. The details are shown in Table 3.

Analysis of quality safety hazardous factors and critical control points

The priority of specific factors was determined using Hazard Analysis and Critical Control Points (HACCP). Solving problems based on their main factors can achieve strong pertinence, and the problems can thus be effectively solved.

Analysis of quality safety hazardous factors

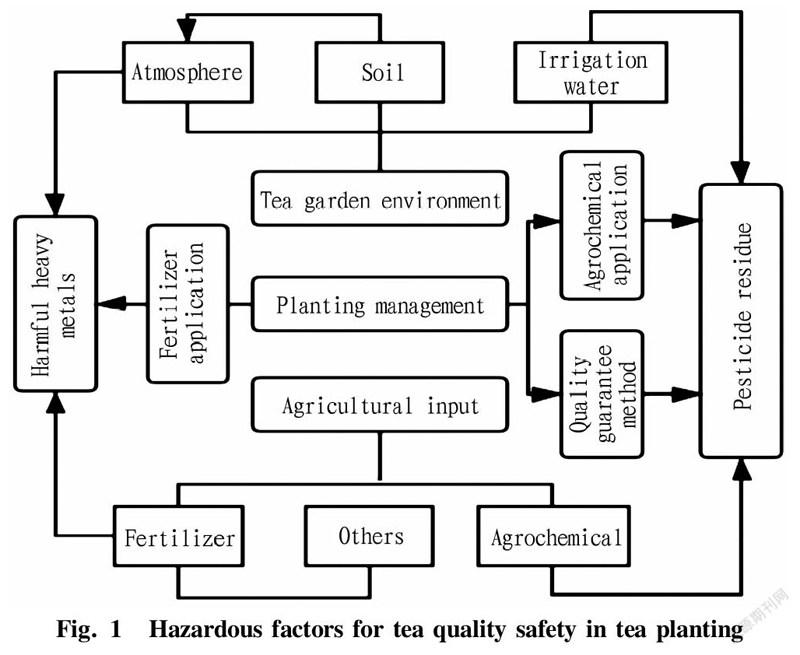

Hazard analysis for base plantingIn tea planting and production, pesticide residues and harmful heavy metals were the two major hazard factors for quality safety. The main sources of factors involved the tea garden environment, planting management and agricultural inputs. Specifically, the introduction of atmospheric drift, the soil itself, and irrigation water were the mainstream factors affecting the tea garden environment. Agricultural inputs in planting management, such as chemical fertilizers, pesticide application methods (93.8%) and plant protection methods (65.2%), were the key factors related to the growth quality characteristics of tea trees. If the quality of fertilizer is not up to standard, it will cause heavy metal pollution. The use of prohibited chemical pesticides in the prevention and control of pests and diseases in tea gardens was the main source of pesticide residues in tea, and it accounted for 91.26% in the survey. The use of chemical agents in plant protection management was also an indirect factor that caused pesticide residues in tea trees, and it accounted for 76.13% in the survey. Secondly, the heavy metal content in the soil itself was high, and it accounted for 53.21% in the survey. The results are shown in Fig. 1.

Analysis of hazardous factors in tea processingProcessing quality control of tea products is the premise of quality safety assurance, and is also a key link in management. At present, there are four main quality and safety hazards in tea processing: pesticide residues, heavy metal residues, harmful microorganisms and pollution from non-tea impurities. According to the survey results, these hazard factors were mainly caused by the acceptance inspection of fresh leaves (95.27%), processing (87.28%) and packaging and transportation (60.45%). In the fresh leaf acceptance link, the source control of fresh leaves was mainly to prevent the harm of pesticide residues in products, and the hygiene monitoring mainly controlled the mixing of non-tea inclusions and harmful heavy metals. In the process of processing management, the control was mainly in three aspects: technical control (accounting for 90.26%), equipment maintenance (accounting for 85.18%) and site and personnel hygiene (accounting for 89.56%), among which technical control mainly monitors harmful heavy metals exceeding the standard, equipment maintenance prevents the mixing of metal debris, and hygiene control mainly prevents people, animals and workers from mixing in non-tea inclusions. In terms of packaging and transportation, transportation methods (88.76%), product storage (93.25%) and packaging materials (73.12%) were the main sources of quality problems. They mainly caused non-tea inclusions and harmful metal debris to be mixed in. The specific analysis idea is shown in Fig. 2.

Analysis on critical control points of quality safety

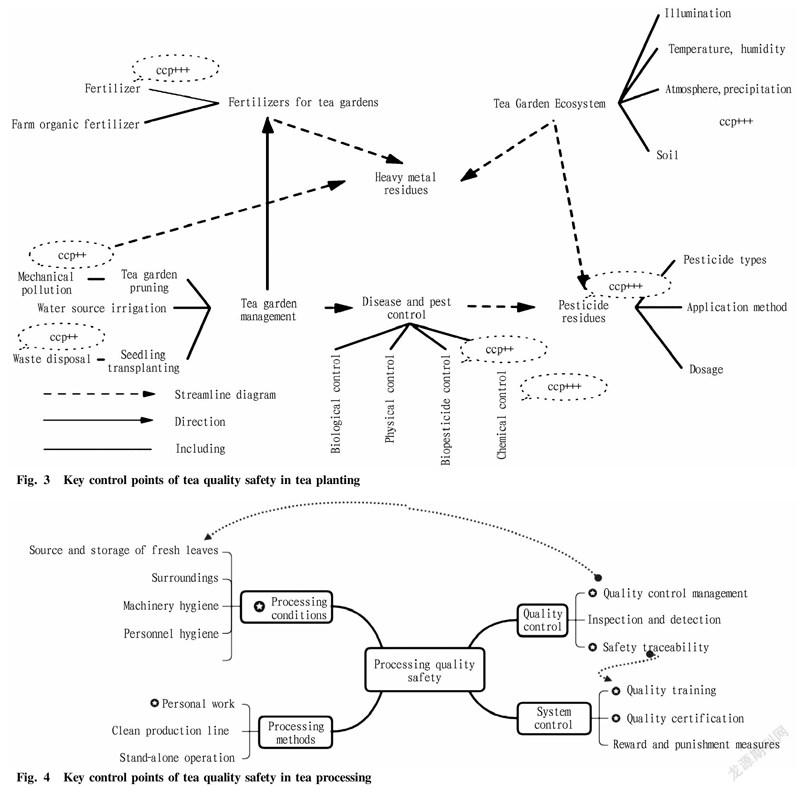

Analysis on key control points for base plantingBased on the analysis of the survey results, the critical control points were determined. The factors that lead to the problem of pesticide residues and heavy metal pollution in fresh tea leaves are subjective and objective. The objective aspects are the ecological environments where tea gardens are located, including temperature, humidity, light, atmospheric drift and precipitation, the soil itself, and water source irrigation. The survey data showed that atmospheric drift, precipitation (63.18%) and the soil itself (67.18%) were the key points. Atmospheric drift and precipitation mainly bring foreign pollution sources into tea gardens through high-altitude wind and cloud transmission. In terms of tea garden management, tea seedling selection, tea garden pruning, fertilization, irrigation and pest control were involved. If tea gardens are not well managed, there will be hidden dangers of introducing pollution sources. Specifically, chemical control in disease and pest control (98.56%), chemical fertilizers adopted in tea garden fertilization (92.16%), and water source pollution in irrigation water (91.08%) were important factors causing the problem of pesticide residues and harmful heavy metals in fresh leaves. The details are shown in Fig. 3.

Analysis on key control points in tea processingThe control of quality safety in tea processing mainly starts from the main aspects of processing conditions, processing methods, quality control supervision, and processing management systems. The processing conditions include the surrounding environment inside and outside processing plants, such as cleanliness, including mechanical cleanliness and worker hygiene, control of the sources of fresh leaves and storage conditions.

It was concluded from the survey data that processing conditions were key control points, including the source of fresh leaves (95.15%), the surrounding environment (93.16%), mechanical hygiene (96.18%) and personnel hygiene (95.22%). The analysis showed that volatile toxic and harmful gases, rodents and pests around processing enterprises, the sanitation of the processing sites inside the enterprises, the cleanliness of processing machinery, and the personal hygiene of workers were the main factors causing pollution. Among the three processing modes, small tea factories showed the lowest evaluation level and the highest risk, and it was the key point. According to the survey data, the surrounding sanitary conditions of small tea factories were not up to standard (90.13%), and had the problems of outdated production equipment (98.12%), not thorough cleaning of tea making (93.15%), substandard health and hygiene of personnel (81.16%), etc. In terms of quality control and system control, product quality traceability system (85.17%), personnel quality training (93.25%) and enterprise quality certification (96.16%) were the key points, especially the traceability of product quality and personnel's quality and safety awareness, such as quality and safety training. The analysis idea is shown in Fig. 4.

Construction of Tea Quality Safety Management Organization

Planting organization chart

The supervision of fresh leaf production bases is actually the interaction between base producers and government departments to realize accepting supervision during the production process of fresh tea leaves, fulfilling the government's guidelines and policies, and implementing the technical achievements of technical experts into production. The organizational chart is planned to establish a comprehensive tea management office and a comprehensive management team of tea bases in the form of region in the province (city) led by the Agricultural Bureau with the assistance of the Market Supervision Bureau and the Environmental Protection Bureau and the guidance of experts. The department purchases agricultural materials in a unified manner, and implements unified scientific prevention and control. Secondly, the management of weeding, fertilization, and pruning in tea gardens shall be scientifically guided according to local conditions. Meanwhile, the tea garden management office conducts regular and centralized training on the scientific management of tea gardens to the base cooperatives, enterprises and farmers, so as to improve the quality safety knowledge of the staff of tea garden bases. Meanwhile, the municipal supervision department focuses on the supervision of retail tea gardens, and implements irregular sampling and sampling inspection. Only with the quality report of the Municipal Supervision Bureau can the tea be sold, and the raw materials that fail the sampling inspection are not allowed to be sold, so that the hidden dangers of tea quality safety from the source can be minimized. The details are shown in Fig. 5.

Processing management organization chart

The idea of constructing the organizational structure of tea processing management is that the tea comprehensive management office cooperates with tea technical experts and cooperates with relevant government functional departments to implement a series of management and service work for tea processing and production. Specifically, the Agricultural Bureau provides certain technical guidance on the control of the sources of raw materials and the processing equipment of enterprises. The Environmental Protection Bureau checks whether the environment around enterprises and factory areas meets relevant standards. The municipal supervision departments conduct random inspections on products, and regularly check the equipment conditions and the implementation of the product traceability system. The tea management office focuses on providing corresponding technical guidance and training on quality safety production to enterprises. When quality problems occur in enterprises, they coordinate with various administrative departments to assist them in timely rectification to ensure standardized production of enterprises. The details are shown in Fig. 6.

Conclusions

Tea is a green and healthy sunrise industry. The area of tea gardens in China ranks first in the world. There are many kinds of tea products, especially high-end teas, which are basically from China. However, China's tea products are basically in the current situation of high-end domestic sales and low-end export. Therefore, it is necessary to improve the production quality safety of tea, start scientific management in the production field, control and improve the quality safety of tea from sources, and promote the quality of tea products. Laying a solid foundation for the quality safety of tea products can let more high-end tea from China go abroad, and let foreign friends know about Chinese tea and love Chinese tea.

References

[1] WU JZ. Analysis of tea quality and safety management mode[J]. South China Agriculture, 2018, 12(15): 133-135. (in Chinese).

[2] ZHANG BL. Practical discussion on the management mode of tea quality and safety[J]. Agricultural Quality & Standards, 2013(1): 66-68. (in Chinese).

[3] HAN MH. Tea quality and safety problems and solutions[J]. China Food Safety Magazine, 2021(25): 21-22. (in Chinese).

[4] LI FL. Study on the quality and safety of tea in China: A case study of Beijing Maliandao[D]. Beijing: Beijing Jiaotong University, 2017: 1-2. (in Chinese).

[5] DUAN TJ. Analysis of China's tea supply chain quality status of safety supervision[D]. Harbin: Harbin University of Commerce, 2015: 1-2. (in Chinese).

[6] XU L. Analysis and improvement of tea quality and safety in China[D]. Lin'an: Zhejiang A&F University, 2018: 1-2. (in Chinese).

[7] XU Q. Tea quality safety traceable supervision system construction status and countermeasures and suggestions: A case study on Wuyi Mountain, Fujian[D]. Fuzhou: Fujian Agriculture and Forestry University, 2019: 1-6. (in Chinese).

[8] TONG XL, ZHANG ZG. The status analysis of management standardization of Chinese tea quality safety[J]. Journal of Inspection and Quarantine, 2011, 21(6): 72-76. (in Chinese).

[9] CHEN YW, CHEN CC, ZHUANG MZ, et al. Research progress of the degradation of pesticide residues in tea leaves[J]. Tea Science and Technology, 2020, 61(1): 20-23. (in Chinese).

[10] YI YUN, YANG M, NIE Y, et al. Monitoring and risk assessment of 30 kinds of pesticide residues in tea samples[J]. Modern Food Science & Technology, 2019, 35(4): 250-257. (in Chinese).

[11] WANG JX. Analysis of the current situation and countermeasures of pesticide residues in tea based on the information on unqualified tea notified by the EU official website[J]. China Tea, 2018, 40(1): 39-39. (in Chinese).

[12] LIU Y. Pesticide residue limits in tea: More than 400 items in the EU VS 28 items in China[J]. China Food Safety Magazine, 2016(33): 80-82. (in Chinese).

[13] LIAO Q. Sampling detection and analysis of 666 and DDT residues in tea[D]. Ya'an: Sichuan Agricultural University, 2016: 3-10. (in Chinese).

[14] YAO FZ, GAO HR, LIU C, et al. Analysis and hazard evaluation of aluminium, lead, arsenic, mercury, chromium and cadmium content in tea[J]. China Food Safety Magazine, 2021, 12(0): 291-297. (in Chinese).

[15] LIU CL, ZHANG J, PENG YS, et al. Contents and health risks assessment of heavy metals in soil and tea in Leishan, Guizhou Province[J]. Acta Agriculturae Zhejiangensis, 2020, 32(6): 1049-1059. (in Chinese).

[16] WANG HF, XIAO ZP, ZHANG H, et al. Effect of ball milling on heavy metal pollution of ultrafine green tea powder[J]. Journal of Tea Business, 2020, 42(1): 21-24. (in Chinese).

[17] WANG HJ, MAO YX, CHEN X, et al. Evaluation of heavy metal pollution of tea garden in Hubei[J]. Gansu Agricultural Science and Technology, 2017, 12(25): 12-14. (in Chinese).

[18] XIANG YX, LI H, LIU XF. Analysis on the status quo and problems of China's tea export trade[J]. Rural Economy and Science-Technology, 2021, 32(14): 94-96. (in Chinese).

[19] YANG XR, DUAN H. Problems and countermeasures of Hubei tea export under the background of "one belt and one road"[J]. Tea Communication, 2020, 47(1): 135-139. (in Chinese).

[20] XU TH. China's tea exports face problems and countermeasures[J]. Tea Communication, 2016, 43(4): 55-58. (in Chinese).

[21] DAI J. Study of problems for exporting tea to the new silk economic belt based on the grounded theory[J]. Business & Economy, 2017(2): 1-3. (in Chinese).

Editor: Yingzhi GUANG Proofreader: Xinxiu ZHU

- 农业生物技术(英文版)的其它文章

- Report on the Breeding of Dahen 799 Broilers

- Study on the Preparation of "Oil-tea" Instant Tea from the Compound Extract of Green Tea and Ginger

- Research Progress on Chemical Constituents and Pharmacological Effects of Zhuang Medicine Cocculus laurifolius DC.

- Study on Quality Standard of Lujing Yiqi Shengxue Pills

- Research on the Development of Guangxi Zhuang and Yao Ethnic Medicine Industry

- Study on Leaching Conditions of Miao Medicine Xiange Zuyu Powder