Polyhexamethylene biguanide chemically modified cotton with desirable hemostatic,inflammation-reducing,intrinsic antibacterial property for infected wound healing

Chun Guo,Jie Zhng,Xiojun Feng,Zhenggui Du,∗,Yunzhng Jing,Yidong Shi,Gunghui Yng,Lin Tn,d,∗

a College of Biomass Science and Engineering,Key Laboratory of Leather Chemistry and Engineering of Ministry of Education,Sichuan University,Chengdu 610065,China

b Department of Breast Surgery,West China Hospital,Sichuan University,Chengdu 610041,China

c School of Materials and Environmental Engineering,Shenzhen Polytechnic,Shenzhen 518000,China

d State Key Laboratory of Polymer Materials Engineering,Sichuan University,Chengdu 610065,China

Keywords:Cotton dressing Polyhexamethylene biguanidine Antibacterial performance Blood clotting Infected wound healing

ABSTRACT Medical cotton dressing is cheap and widely used in diversified fields,but in the application of promoting wound healing,the continuous research of multifunctional medical cotton dressing is still of great significance.Here,we developed a fresh type of antibacterial cotton dressing through a succinct strategy based on chemically anchoring polyhexamethylene biguanide (PHMB).Intriguingly,after PHMB modification,the cotton dressing exhibited outstanding antibacterial performance which could maintain >99.99%antibacterial rate after several treatments,including washing 50 times,repeated use 10 times,UV irradiation for 7 days,cationic dyes dying,and conditioned under 90 °C water bath for 2 h.In addition,the water contact angle of cotton dressing increased dramatically from 0° to 111°,which could facilitate bacterial adhesion,thus further enhance the antibacterial efficiency,and easily remove the bacterial debris.Apart from that,the developed cotton dressing showed good cytocompatibility,promoted blood clotting and expression of platelets,and promoted the wound healing process in the infection intervened skin wound model.Taken together,this antibacterial cotton dressing with desirable blood clotting,sustained protection against bacterial infection and bacterial removal features shows the potential to be a candidate for infected skin wound healing.

Skin is the largest organ which mainly isolates the internal and external environment of human body,and thus achieves the protection against the physical,chemical and microbial invasion[1].However,skin is susceptible to various external factors,such as mechanical damage,surgical operation and pathological induction,to cause different types of wounds [2].One of the toughest problems of skin wounds is bacterial infection.Bacteria can easily grow and proliferate under the warm and humid environment of the wound beds [3,4].Besides,the adherent and growing bacterial colonies will quickly produce extracellular polymer matrix on the surface of the wound,thereby resisting the action of antibiotics and the host immune system,which may delay the healing rate,and eventually leads to serious consequences,such as amputation or death [5,6].Accordingly,it is crucial to timely kill bacteria and reduce their adhesion on the wound [7,8].In addition,uncontrollable bleeding on the wounds is another main problem which can cause death.Therefore,efficient hemostasis should be also promptly achieved [9,10].

In clinic,medical gauzes made of cotton fiber have been widely used to cover skin wounds in virtue of its softness,moisture absorption,safety and low cost.Nonetheless,the macro-porous structure and natural super-hydrophilicity of cotton provide a homelike environment for the growth of pathogenic bacteria,which may cause cross infection around the wound,delay wound healing and also plays as a threat to nursing personals [11].Regarding this issue,most wounds in hospitals are treated with 75% alcohol or iodophor disinfection,and then covered with medical cotton dressing [12].However,due to the lack of antibacterial properties of medical cotton dressing,cumbersome work and high cost are usually required because of the regular disinfection and dressing replacement [13].Recently,the researchers have made great efforts aiming at the ideal wound healing by developing antibacterial cotton dressings.Jun Xiang [11]et al.fixed the zwitterionic PCBDA@AgNPs on the amino-modified cotton yarn through covalent and non-covalent interactions,which improved the stability of AgNPs on the cotton yarn and promoted wound healing.Nevertheless,the continuous release of AgNPs would gradually reduce the antibacterial period,pollute the environment after use,and even cause drug resistance [14].Bonda Rama Rao [15]et al.modified the surface of cotton fabric with SNPNPs nanoparticles by dipping and long-term antibacterial properties were obtained.Yet,in animal models,AgNPs could be found in the skin tissue of mice,indicating that the extruded AgNPs may yield accumulated toxicity to living body.In addition,Wenyi Wang [16]et al.coated polyhexamethylene biguanide (PHMB) on cotton dressings by padding and curing,and the obtained antibacterial cotton dressing exhibited desirable antibacterial property,and good durability in simulating medical washing.However,the concerns on PHMB leakage cannot be avoided due to the physical binding interaction.Since PHMB is recognized as one of the safest and most efficient broadspectrum antibacterial agents with the characters of colorless and odorless,fast action and low minimum inhibitory concentration(MIC) [17],it may be a considerable way to use chemical bonds to bind PHMB on dressings’surface.Besides,the removal of colonized or deposited bacteria and their debris was commonly ignored which should be a concern to be addressed.The reason is that,after death and decomposition of bacteria,they will release endotoxins,which may enter the body to produce an immune response and lead to organ failure,septic shock,and even death [18].

In present study,with the purpose on constructing a cotton dressing with safe and effective antibacterial properties,fast blood coagulation,and bacterial debris removal,we chemically modified PHMB on cotton dressingviaa green finishing method without toxic solvents (Fig.1),the antibacterial performance of resultant antibacterial cotton dressing displayed extraordinary durability to washing,UV irradiation,high temperature conditioning.Notably,the transition of surface wettability from hydrophilic to hydrophobic rendered the cotton dressing with enhanced antibacterial efficiency,bacteria adsorption and their bacterial debris removal,larger fluids absorption capacity,as well as blood coagulation.Through the animal infected skin wound model,the developed cotton dressing exhibited the potential to promote the healing rate and quality.

Compared with raw cotton,the characteristic signals appearing at 1748 cm−1and 1190 cm−1in Fig.2A are ascribed to the absorption peaks of-COOH and C-O-C groups,respectively,indicating that chloroacetic acid was successfully modified cotton dressing.In addition,after PHMB modification,the peak at 1748 cm−1disappeared,and two new strong bands of PHMB (1666 cm−1and 1561 cm−1) appeared [19],which could verify the reaction between PHMB and Cotton-CAA,and the successful preparation of PHMB modified cotton (Cotton-CAA-PHMB).

The thermal degradation curves of cotton dressings are presented in Figs.2B and C.The maximum thermal decomposition temperature (Td) of raw cotton dressing was recorded as 336.8◦C,which was slightly lower than that of Cotton-CAA (337.9◦C).However,Tdof Cotton-CAA-PHMB increased dramatically to 351.4◦C with the aid of PHMB,which was in accordance with previous report,and the reason could be attributed to the formation of tighter polymeric chains induced by the hydrogen bonds between PHMB and cellulose [20].The enhanced thermal stability of Cotton-CAAPHMB might also indirectly imply the successful chemical anchoring of PHMB on cotton surface.

Compared with the smooth surface of raw cotton dressing,the surface of Cotton-CAA presents “damaged” morphologies (Fig.2D),indicating that the hydroxyl groups were activated,and the active cotton dressing underwent the acidization process.Subsequently,after the amidation reaction with PHMB,the rough morphologies became more regular.The phenomenon could be explained in a similar way that PHMB,as a long-chain molecule,chemically deposited on the cotton surface and the entanglement among the polymeric chains became tighter due to the large number of hydrogen bonds.These results indicated the completion of two modification steps,which was also consistent with the results of FTIR characterization.Moreover,the mechanical property of cotton dressing improved significantly.The tensile strength of cotton increased from 184.33±8.73 N to 284±8.83 N,and the elongation at break increased from 6.55% ± 0.21% to 13.59% ± 1.66% (Fig.S1 in Supporting information).Such improvement could also be explained by the enhancement of intermolecular interaction which rendered the cotton to be more tenacious.

After the complete modification,the surface elements of raw cotton,Cotton-CAA,Cotton-CAA-PHMB were determined by EDS and the results,raw cotton (C 1s: 53.4%,O 1s: 46.6%,N 1s: 0%),Cotton-CAA (C 1s: 50.3%,O 1s: 49.7%,N 1s: 0%),and Cotton-CAAPHMB (C 1s: 50.9%,O 1s: 48.5%,N 1s: 0.6%),are shown in Fig.2E.Compared with the raw cotton dressing,the wt% of oxygen increased in Cotton-CAA,while that of carbon decreased.Besides,the energy spectrum peaks of sodium and nitrogen appear at 1.041 keV and 0.392 keV,respectively,indicating again that chloroacetic acid was grafted on cotton,and followed by the grafting of PHMB.According to the result of elemental analysis,the grafting ratio of PHMB was calculated as 4.76%.In addition,the grafting ratios calculated by conductivity titration method [21]and absorbance of dissolving cellulose method [22]were 6.34% and 4.06%,respectively (Fig.S3 in Supporting information).

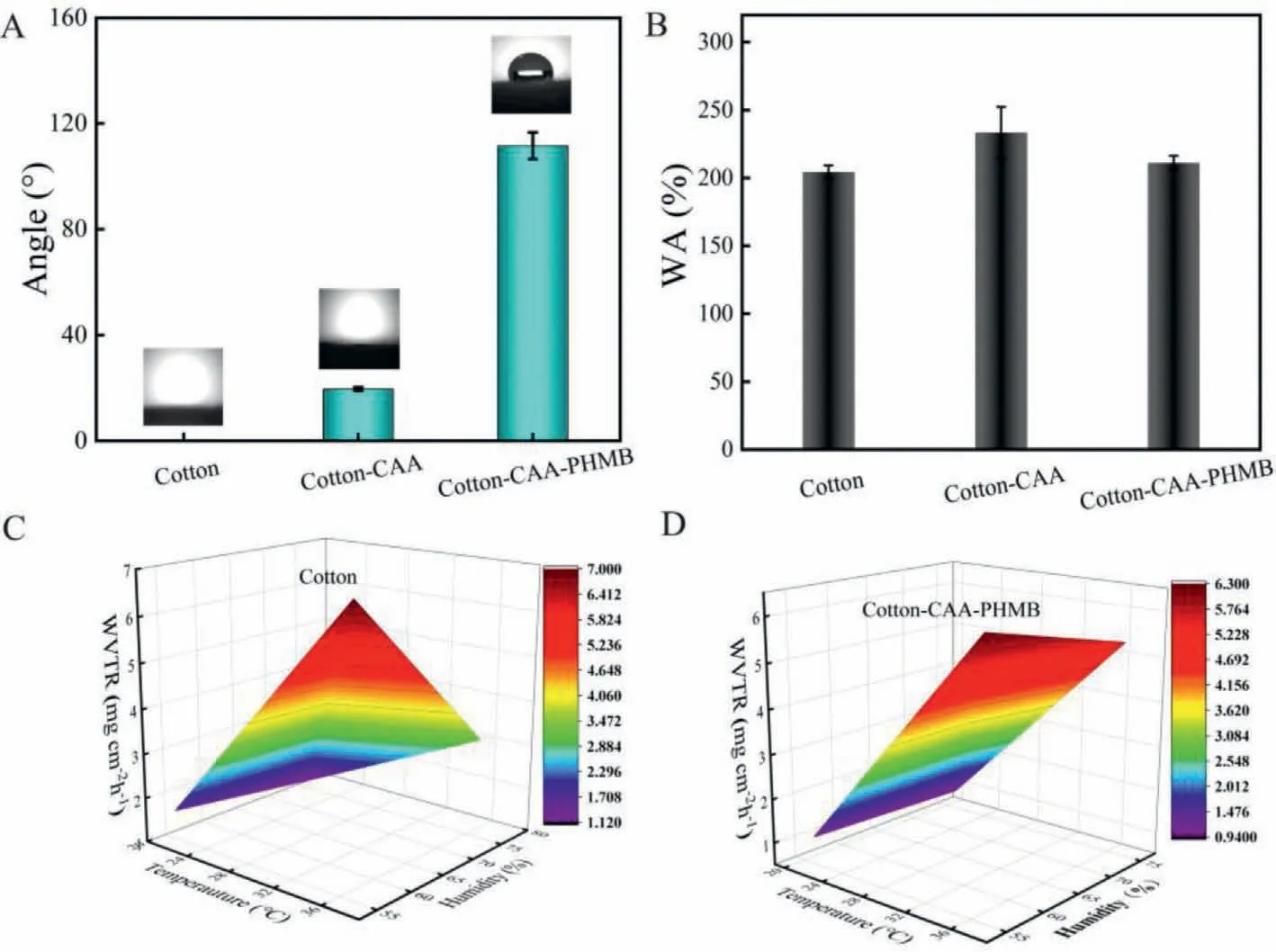

In Fig.3A,raw cotton exhibits excellent hydrophilic properties since the water droplet was absorbed immediately once touching the cotton surface,and WCA could be regarded as ∼0°.However,after modification with chloroacetic acid,the surface temporally became less hydrophilic and the WCA value was 15.56° ± 0.69°.Furthermore,after the subsequent PHMB modification,and the WCA value was recorded as 111.58° ± 5.05°,which meant the long hydrophobic chain from PHMB further enhanced the hydrophobicity of cotton dressing [23,24].Therefore,the introduction of PHMB enabled the cotton dressing a certain waterproof function in addition to the antibacterial property.Additionally,water absorption K(%) values of raw cotton,Cotton-CAA and Cotton-CAA-PHMB were recorded as 204.37% ± 4.77%,233.33% ± 18.90% and 211.11% ±5.90%,respectively (Fig.3B),implying the modification had little effect on the water absorption capacity.

Both liquid absorption capacity and WVTR are important factors affecting wound healing.The former can reflect the removal and retention capacity of exudates from wound bed,while WVTR will influence the dehydration of the wound or the accumulation of exudate.By adjusting the liquid absorption and WVTR,an ideal moist micro-environment around the wound could be established.Whatever it is normal skin or injured skin,body fluids usually evaporate through the pores of the skin,and the vapor evaporation rate of injured skin is higher than that of normal skin.Therefore,a wound dressing with suitable WVTR would promote wound healing.As shown in Figs.3C and D,Cotton-CAA-PHMB exhibited better WVTR than raw cotton under the same environment.For example,under the condition of 37◦C,55% humidity,the water vapor transmittance of raw cotton was recorded as 6.3 mg cm−2h−1,while that of Cotton-CAA-PHMB was 7.0 mg cm−2h−1.In addition,the lowest value of WVTR of Cotton-CAA-PHMB was recorded as 1.16 mg cm−2h−1.However,the lowest value of WVTR of raw cotton was 0.94 mg cm−2h−1(Figs.3C and D).That meant the penetration of water vapor was enhanced after the introduction of PHMB.Generally,for normal skin,the WVTR is about 0.85 mg cm−2h−1,and for injured skin,the value is between 1.16–21.41 mg cm−2h−1,thus this novel antibacterial cotton dressing can meet the requirements of being a qualified wound dressing for liquid control [25].

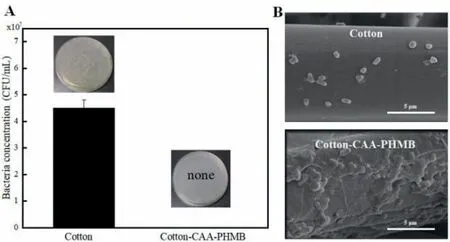

As shown in Figs.4A and B,compared with normal cotton fabric,Cotton-CAA-PHMB dressing adheres more bacteria,and no residual live bacteria existed in the residual solution.There were two reasons for this phenomenon,the first was that the surface of Cotton-CAA-PHMB dressing was positively charged which yielded the mutual attraction with negatively charged surface of bacteria due to the presence of phospholipids and lipopolysaccharides or teichoic acids;the second was that bacteria tended to adhere to moderate wet-table surfaces because of the hydrogen bonding and hydrophobicity between the surface of the bacterial membrane and the surface of cotton-CAA-PHMB [26].Collectively,Cotton-CAAPHMB dressing could initially kill the contacted or adjacent bacteria,and subsequently remove the killed bacteria and their debris,and such feature was highly helpful to avoid the formation of bacterial biofilm and accelerate the wound healing speed.

Fig.3.(A) WCA and (B) water absorption testing results of raw cotton,Cotton-CAA and Cotton-CAA-PHMB.(C) WVTR distribution of raw cotton and (D) Cotton-CAA-PHMB dressings.

Fig.4.(A) The solution after co-culture with bacteria is counted on the agar coating plate.(B) Distribution of bacteria on cotton and antibacterial cotton under scanning electron microscope.

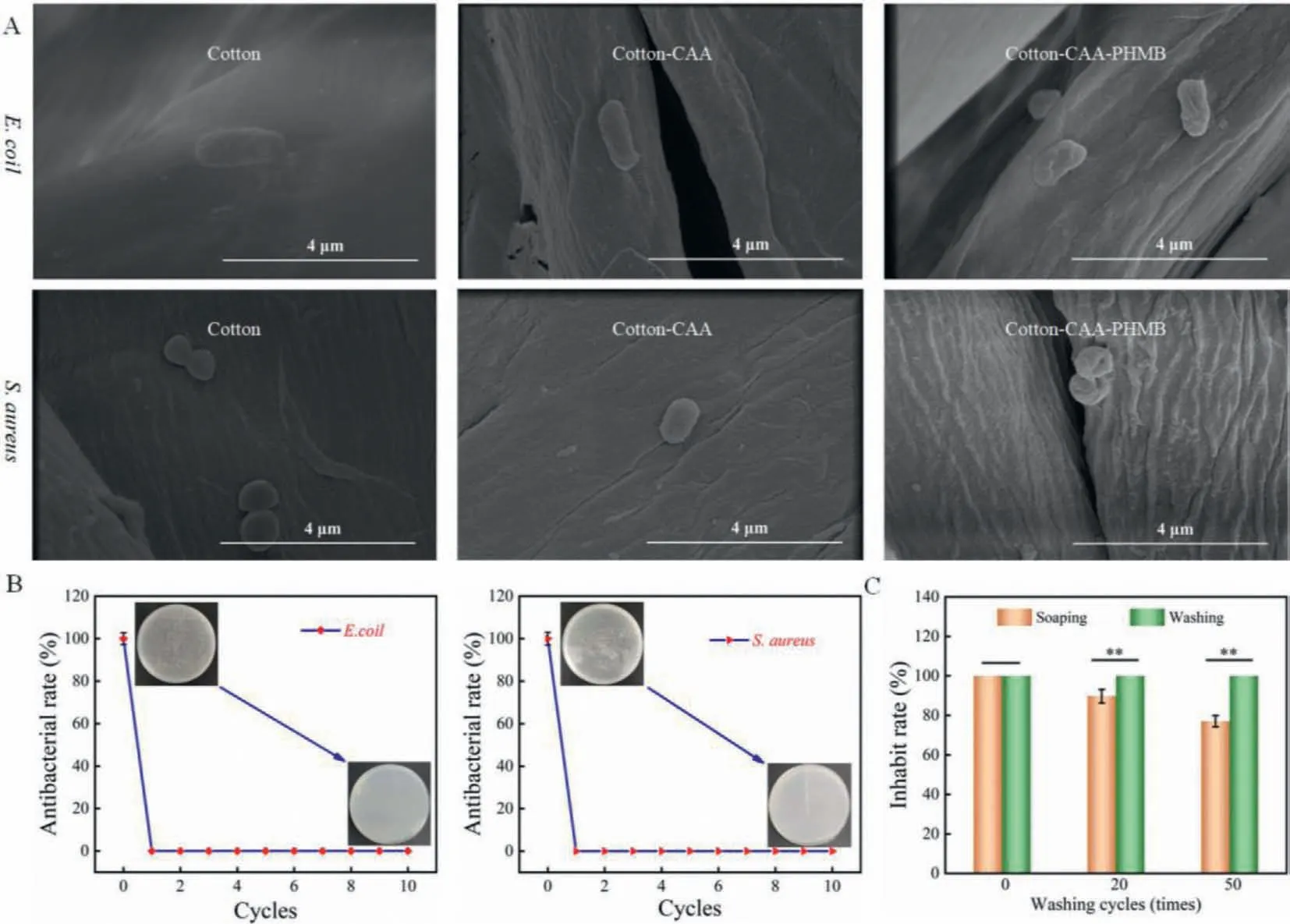

The morphologies of bacteria contacting different dressings were observed by SEM.Obviously,the bacteria in natural appearances,spherical shape forE.coliand rod shape forS.aureus,were observed after contact with raw cotton and Cotton-CAA dressings,while those on Cotton-CAA-PHMB surface are in collapse state with holes,indicating the bacteria were seriously damaged during the process of being killed (Fig.5A).Therefore,the results revealed that cotton dressing and Cotton-CAA had no killing effect on bacteria,but Cotton-CAA-PHMB destroyed the bacterial cell and then killed them.The killing effect might be due to the electrostatic action between anchored cation segments of PHMB and the negatively charged bacterial cell,and the damage and decomposition happened and finally led to the death of bacteria [27–29].

In addition,the antibacterial performance of Cotton-CAA-PHMB was further demonstrated.The bacteria with a concentration of∼106CFU/mL were in contact with cotton and Cotton-CAA-PHMB for 10 min.After that,the bacteria on the sample were eluted with PBS and spread on the agar plate.The experiment results showed that no live bacteria were observed after the contact with Cotton-CAA-PHMB (Fig.S4 in Supporting information).Furthermore,considering that the long-lasting antibacterial property may render the dressings with reduced cross-infection during the process of nursing and after use,while this point was normally ignored.Hence,circulating antibacterial tests were applied.As shown in Fig.5B,Cotton-CAA-PHMB dressing could still completely killS.aureusandE.coliafter 10 times’repeated use,which undoubtedly reflected that the antibacterial performance of Cotton-CAA-PHMB was worthy to be highly commendable.

Apart from above,standard washing and soaping experiments were employed to test the durability of antibacterial property.As shown in Fig.5C,Cotton-CAA-PHMB dressing maintained a highlevel antibacterial rate (>99.99%) after 50 times’washing with water.However,after 20 times’washing with soap,the antibacterial rate slightly weakened (89.80% ± 3.42%),and which decreased to 77.09% ± 2.83% after 50 times’washing with soap.The reason for the decrease of antibacterial rate after soaping may be attributed to the possible cleavage of amide bond and the partial shielding of cationic characteristic derived from PHMB under the intense alkaline condition.However,under the condition of neutral water washing,the amide bonds were stable,which would not influence the antibacterial rate.Besides,Cotton-CAA-PHMB exhibited desirable antibacterial performance under other harsh conditions.For example,after being heated in a high-temperature water bath,irradiated with ultraviolet for 24 h,48 h and 7 d,or even dyeing with cationic dyes,the antibacterial rate still maintained more than 99.99% (Figs.S5-S7 in Supporting information).

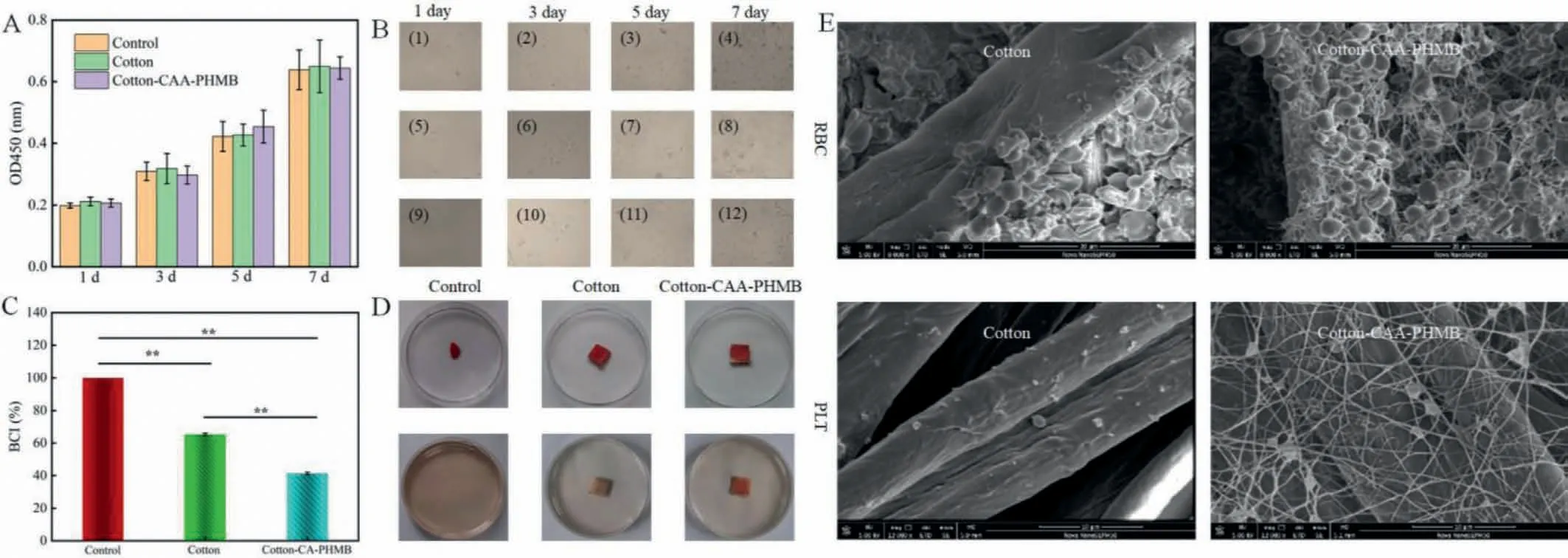

The active antibacterial strategy is a common method to prepare antibacterial wound dressings.However,the release of active antibacterial agent from the antibacterial wound dressings will danger the growth and proliferation of normal cells during the performing of antibacterial action,and the sub-concentration of antibacterial agent will induce the resistance.Regarding the developed Cotton-CAA-PHMB dressing,its extracts were examined in terms of cytotoxicity.The results (Figs.6A and B) showed that the number of cells increased gradually with the increase of culture days,and the cell proliferation performed in a desirable manner.Compared with the blank group,the cells cultured in cotton and Cotton-CAA-PHMB extracts grew well,and the proliferation rate was almost the same,indicating that Cotton-CAA-PHMB had no cytotoxicity to L929 cells.

Fig.5.(A) Morphologies of E.coli and S.aureus after contact with raw cotton,Cotton-CAA and Cotton-CAA-PHMB.(B) Antibacterial results of 10 cycles of Cotton-CAA-PHMB.(C) Antibacterial rate of cotton dressing after 20 and 50 times of washing and soaping.

Fig.6.(A,B) Cell viability of L929 cells cultured with different extracts of dressings (cotton (1–4),Cotton-CAA-PHMB (5–8),Blank (9–12) on day 1,3,5,and 7.(C) Coagulation appearances.(D) Blood coagulation index.(E) Micro-morphologies of red blood cells and platelets during coagulation.

Promoting blood coagulation is another important property of this new type of antibacterial cotton dressing.As shown in Fig.6C,The BCI value of raw cotton dressing is 65.38% ± 0.73%,but the BCI of Cotton-CAA-PHMB reduces to 41.38% ± 0.74%,thereby implying enhanced blood coagulation capacity after PHMB modification.As shown in Fig.6D,compared with control group and raw cotton dressing,obvious blood clotting can be observed in Cotton-CAAPHMB group.What is more,the blood clotting function of Cotton-CAA-PHMB could be demonstrated more intuitively according to the blood coagulation index (BCI).As shown in Fig.6E,platelets on raw cotton dressing present in normal disc-shape,platelets and blood cells scatter and accumulate on the surface of dressings,while platelets on the surface of Cotton-CAA-PHMB dressing are deformed,pseudopodia are prominent,and a large number of networks appear which can wrap the blood cells.In detail,it is well accepted that protein adsorption is the first event once blood encounters exogenous dressing materials,and hydrophobic interactions play an important role during protein adsorption [30–32].In the case of a hydrophobic surface,proteins are likely to adsorb on the surface through hydrophobic interactions and followed by the adsorption of proteins,such as fibrinogen,which can induce the activation of the coagulation system and the activation of platelets[33].Overall,Cotton-CAA-PHMB could activate the platelets and accelerate the coagulation process partially benefitting from the hydrophobic surface compared with raw cotton.

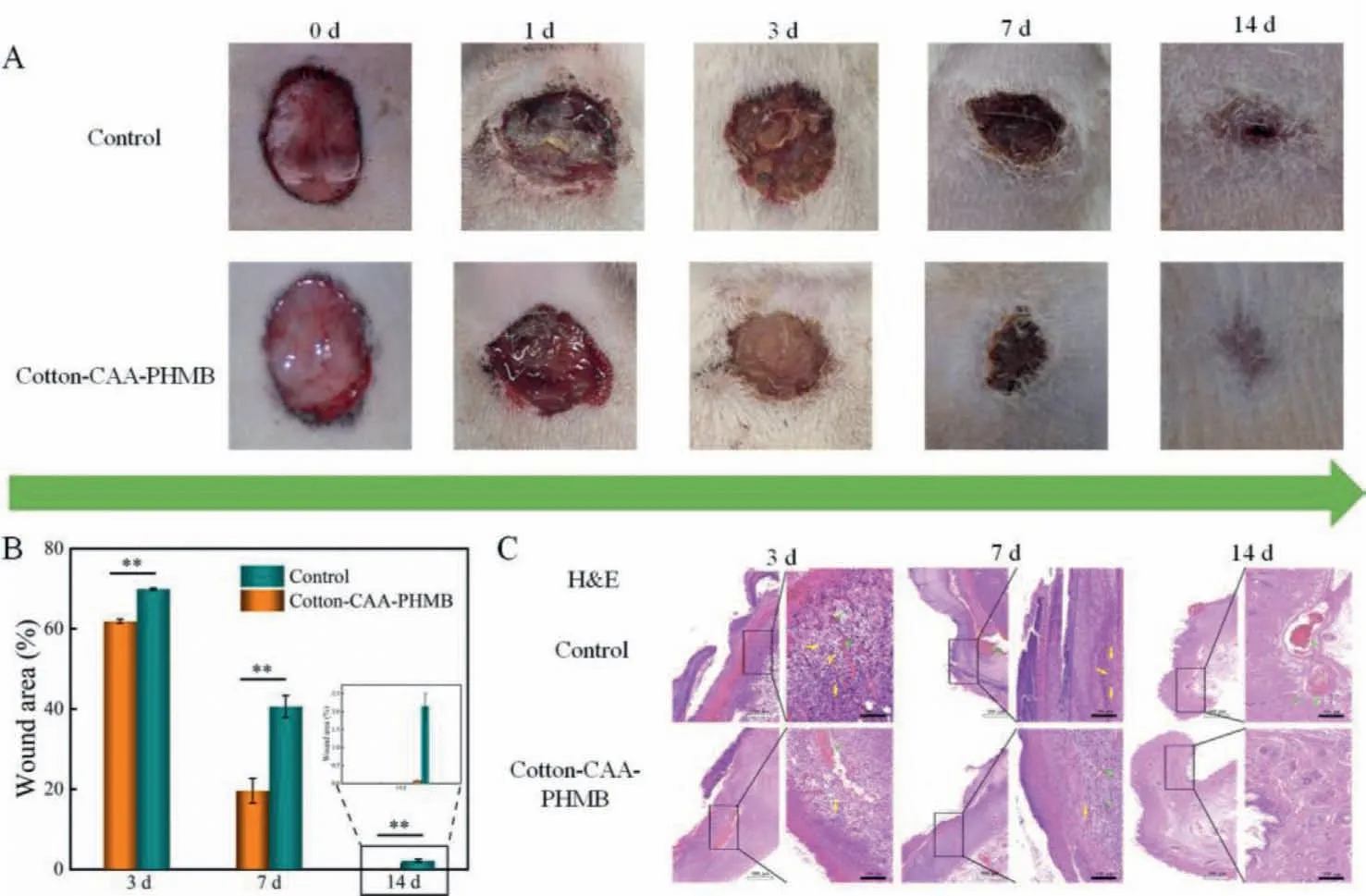

Fig.7.(A) Images of post-surgery at different time points.(B) Statistics of the wound area during the healing process.(C) H&E staining of wound tissue from both groups on day 3,7 and 14 after surgery (scale bar 500 μm and 100 μm).

All procedures for animal study were approved by the Institutional review committee of Sichuan University,School of Medicine and the National Institutes of Health (Chengdu,China).After thein vitroand blood coagulation cell study,the wound-healing efficiency of Cotton-CAA-PHMB was demonstrated by creating full thickness infected skin wounds on the back of rats in anin vivoexperiment.Fig.7A shows the optical images of the wound appearances at 0,3,7,and 14 days after treatment with Cotton-CAAPHMB.The wounds with ordinary medical gauze dressings were used as control,and the wound area was measured at several predetermined time points to determine the reduction in rate.According to the pixel statistics of the wound images,the size of the wound tends to decrease after treatment in all groups (Fig.7B).At each observed time point (3,7 and 14 days),the wound area of the experimental group (Cotton-CAA-PHMB) was smaller than that of the control group.Especially on the 7thday,the wound healing rate of the experimental group was 80.4% ± 3.06%,while that of the control group was only 59.37% ± 2.74%.After 14 days (Fig.7B),the wound healing rate of the experimental group reached to 99.92% ± 0.01%,and the wound healing rate of the control group was 97.84% ± 0.37%.Therefore,the experimental group with Cotton-CAA-PHMB exhibited better wound healing performance than the control group during the whole process,and the reasons should be the inactivation of bacteria and bacterial adhesion (including the debris) by cotton-CAA-PHMB.Therefore,the wound inflammation was reduced,and concurrently wound coagulation was promoted,which were beneficial to the wound healing.

Usually,wound healing includes three processes: inflammation period,repair period and mature period.Among them,the repair period includes epithelial regeneration and granulation formation.H&E staining method was employed to evaluate the wound regeneration in different phases.The inflammatory phase includes the establishment of haemostasis and the influx of inflammatory cells into the injured tissue.Regarding the developed dressing,Cotton-CAA-PHMB,exhibited the accelerated haemostatic effect which could activate the inflammatory phase in advance.As shown in Fig.7C,on the 3rdand 7thday,less inflammatory cells and scattered blood presented,meanwhile,the blood in the tissues was gradually collected and decreased,implying that granulocytes and macrophages had phagocytized necrotic cells and bacteria.The results indicated that the inflammatory stage of the experimental group was earlier than that of the control group.At the 14thday,both the wounds of the experimental group and the control group basically healed completely.However,from the 14-day tissue staining (Fig.7C),compared with the control group,the skin appendages of the experimental group were almost intact,while the skin of the control group still exhibited slight inflammation and bleeding,which meant that the wound in the experimental group entered the mature stage earlier than that in control group [34–37].These facts provided strong evidence that Cotton-CAA-PHMB could promote the healing of infected wounds and reconstruct its structure more regular and form more hair follicles.

In conclusion,according to the requirements and tough issues of desirable wound healing,a fresh type of antibacterial cotton dressing,Cotton-CAA-PHMB,with the prominent features of safe and potent antibacterial property,bacteria adsorption and their bacterial debris removal,larger fluids absorption capacity,and blood coagulation has been fabricated.Such dressing was facilely prepared through chemically anchoring PHMB on cotton dressing,and the yielded rough and hydrophobic surface benefited the dressing with better bacteria adsorption and water retention capacity,thus Cotton-CAA-PHMB could effectively remove the bacterial debris,promote blood coagulation,and avoid the accumulation of exudate around the wound.In addition,Cotton-CAA-PHMB exhibited durable antibacterial activity (>99.99%) even after tens of washing,repeated use,UV irradiation,dying and conditioned under high temperature.In vitrostudies proved that the antibacterial cotton dressing had good cytocompatibility and could promote platelet expression.Finally,based on the infection intervened skin wound model,Cotton-CAA-PHMB could positively inhibit the inflammation level and accelerate the wound healing,and the healing rate was higher than that of the control group during the whole process.Therefore,the multifunctional antibacterial cotton dressing developed in this study is highly expected to be used for infected wound healing and as other medical covers.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work was financially sponsored by the National Natural Science Foundation of China (Nos.51803128,52073186,21802097),Fundamental Research Funds for the Central Universities (No.20826041D4160),Sichuan Science and Technology Programs (Nos.2020KJT0031-2020ZHCG0051,2020KJT0061-2020ZHFP0148),State Key Laboratory of Polymer Materials Engineering (No.sklpme2021-3–01),and Funding of Engineering Characteristic Team,Sichuan University (No.2020SCUNG122).

Supplementary materials

Supplementary material associated with this article can be found,in the online version,at doi:10.1016/j.cclet.2021.12.086.

Chinese Chemical Letters2022年6期

Chinese Chemical Letters2022年6期

- Chinese Chemical Letters的其它文章

- Photochemical defluorinative functionalization of α-polyfluorinated carbonyls via spin-center shift

- Methods of screening,monitoring and management of cardiac toxicity induced by chemotherapeutics

- Light-guided tumor diagnosis and therapeutics: From nanoclusters to polyoxometalates

- Nanofluidics for sub-single cellular studies:Nascent progress,critical technologies,and future perspectives

- Effective purification of oily wastewater using lignocellulosic biomass:A review

- Recent advances in microchip-based methods for the detection of pathogenic bacteria