Direct Ink Writing of Gypsum:Developing a Printable Gypsum Paste

ZHOU Hongli, CAI Zhiyong, WANG Xiaofeng, ZENG Jin, FENG Yan, PENG Chaoqun, WANG Richu

Direct Ink Writing of Gypsum:Developing a Printable Gypsum Paste

ZHOU Hongli1, CAI Zhiyong1, WANG Xiaofeng1, ZENG Jin2, FENG Yan1, PENG Chaoqun1, WANG Richu1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China; 2. School of Metallurgy and Environment, Central South University, Changsha 410083, China)

Gypsum is a common material for statues, building, and casting molds (alloys and ceramics). Due to the incomplete hydration reaction between water and gypsum, it is difficult to print high-strength gypsum products using 3D printing techniques such as Binder Jetting. To enhance its strength, the hydration reaction should be completely performed, which could be fulfilled by direct ink writing (DIW). However, the reaction in the gypsum paste for DIW is so fast that less time is left for operating a 3D printer. In this work, a printable gypsum paste with a reasonable setting time was developed to print 3D gypsum structuresdirect ink writing. A retarder and a thickener were introduced into the paste to prolong its setting time for operating and tailor its rheological property for printing, respectively. The setting time, expansion and rheological propertiesof the pastes were tested by the Vicat apparatus, consistometer and rheometer, respectively. The results show that citric acid (CA) is a suitable retarder, although decreases its compressive strength due to the directional grown gypsum crystals resulting from the selective adsorption of CA on gypsum powder, while hydroxypropyl methylcellulose(HPMC) is an acceptable thickener, which affects forming flocculation structure in the paste, resulting in higher viscosity and shear modulus. Optimal amounts of CA and HPMC for the printable gypsum paste are 0.6% and 0.3% (in mass), respectively. Three-dimensional gypsum structures such as spider web and scaffold are successfully printeddirect ink writing, which compressive strength is around 20 MPa, much higher than that printedBinder Jetting.

direct ink writing; gypsum; retarder; thickener; rheological property; casting

Gypsum is a common gel material, because of its green environmental protection, low production cost, and has become one of the most competitive building materials such as a building interior decoration[1], and an advanced industrial material[2],. Especially, gypsum is used as a mold material for metal casting due to its good surface quality, low cost, and less energy consumption[3]. The most widely utilized traditional gypsum casting process is Investment Casting, also named Lost Wax Casting. Firstly, a designed and fabricated wax mold is covered by a gypsum paste which is hardenedhydration reaction; then the max mold is removed by heating. Molten metal is cast into the gypsum mold to form parts[4]. Obviously, this manufacturing process is so complex, waste-time, high-cost and even unacceptable for parts with complex-shape[5-7].

The upcoming 3D printing technology, which is a landmark technology of major changes in the modern manufacturing industry, has provided a powerful route to improve this method. 3D printing technology is prone to realize complex samples with special external and internal forms[8], possessing the characteristics of controllable accuracy, time-saving, and cost-saving[9-11]. Thus, to print three-dimensional gypsum mold, the Massachusetts Institute of Technology (MIT) developed a 3D printing technology named Powder Bed Binder Jet (PBBJ, also named as 3D printing, 3DP) in 1992[12]. This method is based on binding powder particles or pellets, either by injecting a reaction solution or by a polymeric binder in a route of layer-by-layer until the structure is completed[13-15]. Three-dimensional gypsum partsPBBJ/ 3DP have been widely applied in areas such as Civil Engineering, Rock Mechanics, Medicine and Casting,[16-20]. However, the compressive strength and Young᾽s modulus of these parts are not high, only 8.63 MPa and 1.74 GPa, respectively[21]. The reason is that gypsum hydration happened in the mixture of particles/ pellets and the solution/binder is not complete. It is attributed to less water and the short reaction time during the printing, which is an intrinsic drawback of PBBJ/3DP. Although some treatment processing such as dipping process[21], heat-treatment[22]and pre-moisturize[23]have been developed to improve its mechanic properties, it doesn’t work effectively, only make compressive strength reach 11 MPa. Thus, more wide application of 3D gypsum parts is blocked by their mechanical properties.

Direct ink writing (DIW) is one of the most promising and inexpensive 3D printing techniques[24]. It depends on continuous ink/paste to assemble a three-dimensional structure in a layer-by-layer build sequence[25]. The paste with special rheological property is pressed out from a nozzle smoothly, and the printed figures maintain their shape upon being released without pressure. Because of its material flexibility and low cost, DIW is used extensively in many fields, such as ceramics, metals and polymers. For printing gypsum, DIW provides adequate hydration, which is a promise to high strength mold, similar to the traditional molding process[26]. Comparedwithprinting gypsum Binder Jetting[16-20], it avoids the generation of pores andguarantees to obtaining parts with higher mechanical strength. However, the reaction of gypsum hydration is so fast that less time for operating DIW, that is, the transition time from flow- to solid-status is too short. Besides, low shear elastic modulus and high flowabilityof gypsum paste, which are resulted from bleeding of gypsum, are unfriendly to DIW.

In this work, in order to prolong hydration for operating and tailor the rheological property of gypsum for printing, retarders and thickeners were introduced into its paste. The optimal retarder and thickener were selected, according to the setting time, expansion degree, rheological property of gypsum paste. Moreover, hydration of the gypsum paste with a retarder and a thickener was analyzed. A printable gypsum paste for DIW has been developed and printed into three-dimensional parts such as spider webs and scaffolds.

1 Experimental

1.1 Raw materials

The gypsum powders are commercial-hemihydrate gypsum (Zaozhuang Jinzheng Gypsum Co., Ltd). The-calcium sulfate hemihydrate content is about 98% (in mass). The water consumption for standard consistency is 0.41, and the specific surface area of gypsum is 4122 cm2/g, the average particle size of gypsum powder is 75 μm.

Three retarders were used: Tartaric acid (TA, Xilong Scientific Co., Ltd), sodium tripolyphosphate (STPP, Xilong Scientific Co., Ltd), citric acid (CA, Xilong Scientific Co., Ltd). Two thickeners were used: Hydroxypropyl methylcellulose (HPMC, Shanghai Aladdin Biochemical Technology Co., Ltd, viscosity (2.0% (in mass), 10000 mPa·s), methylcellulose (MC, Shanghai Aladdin Biochemical Technology Co., Ltd). All additives were AR grade.

1.2 Setting time and fluidity test

Firstly, a retarder (tartaric acid, sodium triphosphate or citric acid dosage set at 0.2%, 0.4%, 0.6%, 0.8% and 1.0% (in mass) of gypsum powder) and a thickener (HPMC or MC dosage set at 0.1%, 0.2%, 0.3%, 0.4%, 0.5% (in mass) of gypsum powder) were mixed with water and dissolved respectively. And then gypsum powders were added to the solution to form pastes. The pastes were manually stirred for about 120 s, and then the planetary agitator was used to mix each of them clockwise and counterclockwise for 15 s. The setting time of gypsum paste was determined according to GB/T9776-2008 (China National Standard for Building Gypsum). Setting time measured by a Vicat apparatus. The initial setting time is the time when the needle cannot reach the bottom of the steel ring at a height of 40 mm, and the final setting time is the time when the needle cannot penetratethe paste. The expansion degree of gypsum paste was determined according to GB9776- 88 (China National Standard for Building Gypsum), the gypsum paste was pulled out from the pipe with an inner diameter of 50 mm and height of 100 mm to evaluate the expansion degree of gypsum paste (fluidity). The expansion degree is the average of the two vertical cross diameters. Each data was averaged over three experimental values.

1.3 Paste preparation and rheology measurements

Firstly, different amounts of retarders and thickeners were evenly mixed in some water to form a solution, and then the weighed gypsum powder was poured into the solution and stirred manually for 2 min. Then, it was put into a planetary agitator and mixed for 15 s clockwise and counterclockwise, respectively. The rheological behavior of the plaster was studied by using a rheometer (AR2000EX, TA) with a parallel plate (40 mm). Measurements using the shear stress scanning mode oscillation technique showed a steady increase in shear stress from 1 Pa to 1000 Pa at a fixed frequency of 1 Hz. All rheological measurements were performed at 25 ℃.

1.4 Direct ink writing

The 3D structures were printed by a pressure- controlled 3D printer (System 30M, Hyrel International, Norcross, GA, USA). The paste was poured into a 10 mL syringe which was put into a planetary agitator to deform bubbles. The printer position adjustment system is mounted on a moving--class controlled by a computer regulator to ensure that the paste is accurately deposited on a glass plate. The 3D design is carried out by Auto CAD, and slice setting is provided by Prusa Slicer software to determine the layer height, printing speed, and extrusion width,. The extrusion speed multiplier of the printer is set as 1.5 and the nozzle diameter is 0.84 mm. The printed gypsum sample is placed at room temperature (25 ℃) for 4–6 h for hardening and then placed in a 60 ℃-thermostat drying oven for strength curing.

1.5 X-ray analysis

The early hydration products of gypsum paste were studied usingX-ray powder diffraction (XRD, D/max- 2500, Japan). At each specified hydration time, the hydration reaction was immediately terminated by immersinginto an ethanol solution. The immature gypsum was ground into a powder, then separated by vacuum filtration and dried in a vacuum oven at 40 ℃. These tests were carried out at 40 kV, 30 mA, 4 (°)/min, 5° to 80° with a step size of 0.02°.

1.6 SEM test

Scanning electron microscope (SEM, Quanta, USA) was used to analyze the microstructure of gypsum samples. At each specified hydration time, the gypsum paste was immediately terminated in an excess ethanol solution and the gypsum was ground into a powder, adhered to a sample holder with a conductive adhesive, and then the sample holder was placed on an ion sputtering apparatus covered with conductive film (Au). After the vacuum is less than 5×10–5Pa, set the electron gun acceleration voltage at 15 kV, probe current at 50 μA, working distance at 8–10 mm, and then open the beam to observe the image.

1.7 Mechanical properties

The compressive strength of the samples was tested using a universal testing machine (MTS) with a loading speed of 0.3 kN/s and a measurement range of 3 d cured samples. The compressive strength was tested following the national standard GB/T 9776-2008 (China National Standard for Building Gypsum). The samples were grouted and printed gypsum parts. The grouted samples include one sample without additives, one sample with 0.6% (in mass)CA, one sample with 0.6% CA and 0.3% HPMC (in mass).Thesamples’ shape was a cylinder with a diameter of 50 mm and a height of 100 mm.The cubic gypsum samples were printed with dimensions of 40 mm×40 mm×10 mm and the cylindrical gypsum samples were printed with dimensions of 30 mm in diameter and 10 mm in height. Each data was averaged over three experimental values.

2 Results

2.1 Effect of retarder on gypsum paste

To prolong the setting time of gypsum for printing, a retarder should be added to the paste to retard its hydration. Three retarders, tartaric acid, sodium tripolyphosphate, and citric acid, were selected as candidates. The effect of retarder on setting time is shown in Fig. 1(a). It can be seen that the setting time of the paste increases with increasing admixture and the effect of CA is the most significant. As the content of CA is 0.4% (in mass), the initial setting time of gypsum paste is 199min, which is suitable to direct ink writing. However, the content of sodium tripolyphosphate and tartaric acid is 0.6% (in mass), the time is only ~ 50 min. It is much shorter than that time of CA, which is consistent with others’ work[27]. The setting time restricts the printing operation. The longer the setting time is, the more the operation time for printing is. Based on this rule, CA is chosen as the suitable one.

Fig. 1(b) shows that fluidity varies with CA at different hydration time. The degree of expansion is an evaluation of loss fluidity. The addition of CA plays a role on the degree of expansion[28], which is not affected by the amount of CA. Besides, the fluidity of paste with CA could be maintained and even is notsignificantly changed with time. For example, the initial fluidity of paste with 0.1% (in mass)CA is ~200 mm and reduced to ~150 mmafter 60 min. However, the fluidity of paste without CA is changed from 180mm to 0 mm in 20 min. This confirms that CA is an effective retarder to prolong the time for operatingdirect ink writing.

A rheology test was performed on the gypsum paste to further study its viscoelastic behavior, as shown in Fig. 1(c). The pastes exhibit typical shear-thinning behavior. There is obviously yield stress as illustrated in each curve, which is the point at which the paste transitions from elastic reversible deformation to irreversible flow[29]. That is, below the value of yield stress, the paste is purely elastic rheology[30]. Moreover, Fig. 1(c) also indicates that the amount of citric acid plays an important role in this value. According to the data in Fig. 1(c), the yield stresses of pastes with different amounts of critic acid are shown in Fig. 1(d). The yield stress of paste increases with CA content, reaches the maximum as the content is 0.6% (in mass), and then decreases with increasing CA content. The maximum value of yield stress is around 25 Pa, which nears the gravity per unit volume, 27 Pa (calculated from the density of gypsum paste, 2.7 g/cm3). This shows that the paste could support itself gravity. Last but not least, the shear elastic modulus of paste with 0.6% (in mass) CA is relatively high (Fig. 1(c)), ~27 kPa, which indicates that the paste has high rigidity to keep its shape. Therefore, the optimal amount of CA in the gypsum paste is 0.6% (in mass).

(a) Setting timecontent of retarder; (b) Fluiditycontent of citric acid (CA) in the gypsum paste; (c) Shear elastic modulusshear stress; (d) Yield stresscontent of CA

2.2 Effect of thickener on gypsum paste

To further improve the rheological property for DIW, HPMC and MC are introduced into gypsum paste as thickeners. Their influence on the initial setting time of gypsum paste is shown in Fig. 2(a). The initial setting time of gypsum paste containing HPMC or MC is prolonged. Especially, as the HPMC content reaches 0.4% (in mass), the initial setting time is the longest, ~14 min. As a result, the addition of HPMC or MC in the paste is helpful to prolong the setting time.

The effect of thickeners on paste fluidity is shown in Fig. 2(b). The fluidity of gypsum pastes decreases with the content of HPMC or MC increasing, and the effect of HPMC is better. The expansion degree of paste without thickener is 180 mm, and that with 0.3% (in mass) HPMC reduces to 80 mm. However, the expansion degree of paste with 0.3% (in mass) MC is still 175 mm.And thus, to improve the fluidity of paste, HPMC prefers to MC.

To set the content of HPMC, a rheology test was also performed on the gypsum paste with 0.6wt% (in mass) CA and different amounts of HPMC, as shown in Fig. 2(c). All of the pastes exhibit shear-thinning behavior. The shear elastic modulus and yield stress increase with HPMC content. It is attributed to HPMC wraps water molecules easily and quickly, accelerating the formation of the gypsum flocculation structure[31].For a printable paste, high shear elastic modulus and suitable yield stress are required. The yield stress should be the minimum value but above the gravity.The yield stress and elastic shear modulus of the pastewith 0.6% (in mass) CA and 0.3% (in mass) HPMC are ~50 Pa and ~0.9 MPa, respectively,which are large enough to keep the paste from collapsing.

2.3 Structure and mechanical properties of three-dimensional gypsum

The printable gypsum paste with CA and HPMC was printed into 3D structures of scaffold and spider by DIW, as shown in Fig. 3(a–f). It is clear that the 3D complex structures retained their integrity after printing and drying, and the surfaces are flat. Note that the shape of the printed line and opening holes in the-axis was slightly changed. The reason is that the deposited filaments have to through a bridge path that requires high elastic modulus and yield stress to avoid collapse and maintain their print shape. Figs. 3(g–i) demonstrate the microstructure of printed gypsum parts. The layers feature is obvious, which is compact due to the complete hydration undergoing DIW. The surface is relatively flat. The dihydrate crystals resulting from hydration are densely connected to each other, although few micro- sized holes are kept.

Fig. 2 Effect of thickener on gypsum paste

(a) Setting timecontent of thickeners; (b) Fluiditycontent of thickener; (c) Shear modulus of elasticity of HPMC with different dosage; (d) Yield stresscontent of HPMC

Fig. 3 Structures and microstructures of printed 3D gypsum

(a, d) Scaffold structure with three horizontal lines and three vertical lines appearing alternately and periodically in the-axis, the cross angle is 60°;(b, e) Spider structure consisting of alternate layers of radial and circular rods;(c, f) Scaffold structure with three horizontal lines and three vertical lines appearing alternately and periodically in the-axis, the cross angle is45°; (g–i) Microstructure of printed gypsum parts

The compressive strength of gypsum samples fabricated by molds and DIW is shown in Fig. 4. The compressive strength of the gypsum samples by molds without and with CA (0.6%) (in mass), are ~44 and ~20 MPa, respectively. In general, the compressive strength of gypsum should be declined by adding CA, and the better the effect of a retarder is, the lower the mechanical properties of hydrated gypsum are[32]. So, CA isn’t a suitable additive when the gypsum needs high strength. The compressive strength of the gypsum with HPMC and CA is ~22 MPa, which is lower than that without additives.It is attributed to the addition of CAwhich affects the crystal growth (More explanation see Section 3). Compared to the compressive strength of gypsum containing CA with/without HPMC, it is interesting that HPMC plays a positive role in the enhancement of compressive strength. Moreover, the compressive strength of printed cube and cylinder is ~16 and ~23 MPa, which is higher than that of the printed gypsum parts by Binder Jetting, around 10–13 MPa[21].

Fig. 4 Compressive strength of different gypsum samples

3 Discussion

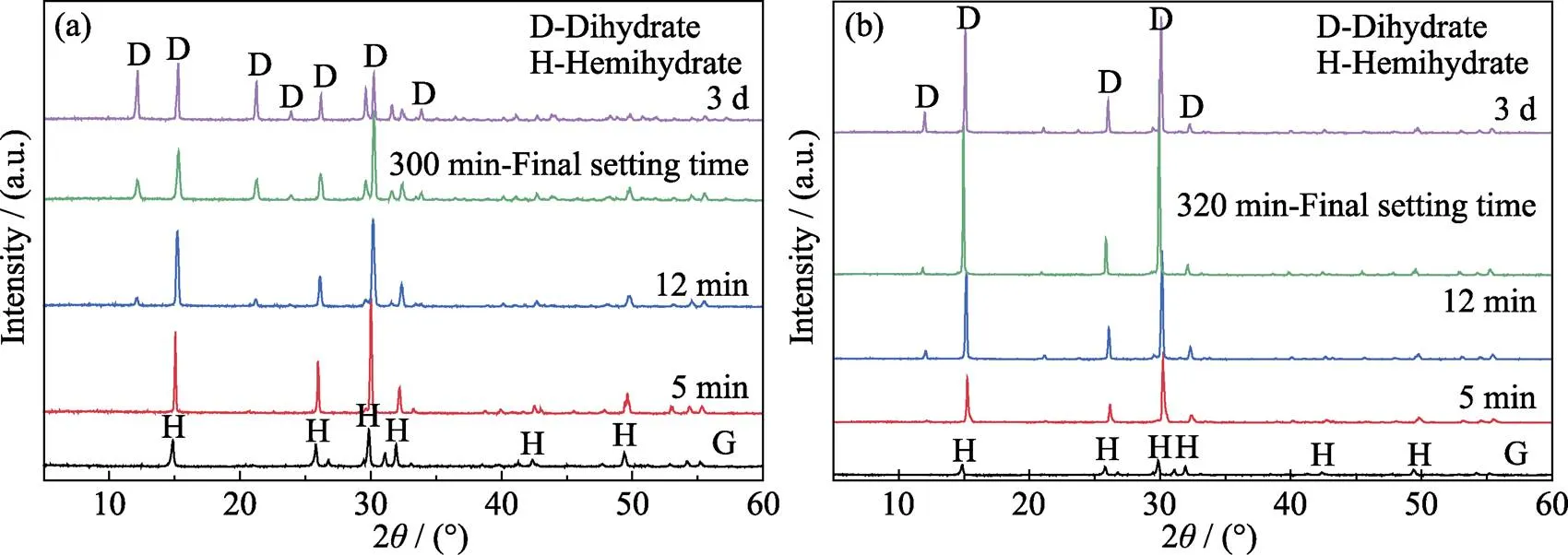

The hydration reaction happens upon gypsum contact with water. Hemihydrate gypsum (H) is dissolved into waterand graduallyprecipitated out in the form of dihydrate gypsum (D)[33]. The transition of gypsum during hydration from H to D was monitored by XRD, as shown in Fig. 5. In the gypsum paste with CA, D is detected after a reaction about of 12 min. The initial setting time, however, is 199 min (Fig. 1(a)). It implies that the dissolution of H and the formation of D regenerated gypsum crystal network happen simultaneously. With a precipitation of D, the amount of free water is reduced, resulting in a decrease in fluidity. The initial setting time is set as the paste losesits fluidity completely. When all H has been dissolved and a crystalnetwork of D has been formed preliminarily, the interlocked dihydrate crystal with a certain structural strength is formed. And thus, the paste has an initial strength at this time, called final setting time[34-35]. CA selectively absorbed on H or hinders precipitating D from water. Thus, the initial time of paste is prolonged by adding CA.Besides, the D crystal growth is inhibited by the selective absorption of CA, which affects forming D crystal network[34-35].

The microstructure transition of gypsum with CA/HPMC during hydration is shown in Fig. 6. In the gypsum paste with CA, the prismatic gypsum crystals become shorter, smaller and more plate-like. Regarding HPMC, hydrogen bonds are formed between its functional group and water molecules, causing water molecules to be fixed or warped, forming more and more small groups of water and HPMC. These groups increase contact points between the precipitated D and fill crystal network gaps. The result is that the flocculation of D in the paste is accelerated, which is beneficial to obtaining a more compact crystal network[36].As shown in Fig. 5, the XRD peaks of the pastes with HPMC and CA are sharper than that with only CA, indicating that the crystal degree of D is high in the former. That is, HPMC plays a positive role in the precipitation of D[36-37]. As illustrated in Fig.6(e–h), accompanied by hydration reaction, the interconnected contact sites of D increase and the small H and D are embedded, which encourages the flocculation structure of D.

Fig. 5 XRD patterns at different hydration time for gypsum pastes with different agents

(a) 0.6% (in mass) citric acid gypsum at different hydration time; (b) 0.6% (in mass) citric acid and 0.3% (in mass) HPMC at different hydration time

Selective absorption of CA on gypsum crystal affects the rheological property of gypsum paste. With the progress of hydration reaction, gypsum paste gradually transforms from flow to solid. The directional crystal growth caused by CA leads to smaller crystal size and slower hydration reaction, resulting in almost no change in the fluidity of the paste with time (Fig. 1(b)). On the other side, the intrinsic acidity of CA also has an influence on the pH of the gypsum paste. With the addition of CA, the gypsum pastes experience a process from alkaline to acidic. When the content of CA is 0.6% (in mass), the pH of paste is 7–9, the complex formed by acid ions and Ca2+has the highest stability[38]. Thus, the yield stress of paste is the highest as the content of CA is 0.6%(in mass) (Fig. 1(c,d)). After adding 0.6% (in mass) HPMC into the paste CA, more water is captured by this polymer, which accelerates the flocculation of D and enhances the viscosity of gypsum. Therefore, there is a decrease of fluidity, an increment of shear elastic modulusand yield stress, with the content of HPMC increasing (Fig. 2).

Fig. 6 SEM images of gypsum at different hydration time

(a-d) Gypsum with 0.6% (in mass) CA at different hydration time ((a) 5 min, (b) 12 min, (c) 20 min, (d) 300 min (final setting time)); (e-f) Gypsum with 0.6% (in mass) CA and 0.3% (in mass) HPMC at different hydration time ((e) 5 min, (f) 12 min, (g) 20 min, (h) 320 min (final setting time))

Moreover, the mechanical properties of gypsum are also affected by CA and HPMC. During the hydration of a gypsum paste without additives, dihydrate crystals hide at the grain boundaries and trigger off growing along with the grain boundary space, forming thin flakes or fine needles of dihydrate gypsum dispersions at the crossed and connected place, resulting in a porous mesh structure. After the formation of this crystalline structure network, new hydration products continuously fill the gaps of this network. The crystal contact points keep increasing, and the Van der Waals force and chemical bonding forces are generated at the contact points of crystal intersection, which is sum up to the strength of gypsum[33]. The selective adsorption of CA on dihydrate gypsum leads to directional crystal growth[39-40], which decreases the contact point (Fig. 6(a–d)). Thus, the presence of CA hinders the hydration, prolonging the induction period of reaction and slowing down the hydration rate.Meanwhile, the nucleation rate of dehydrated is also reduced by CA. So, the compressive strength of the solidified paste is declined (Fig. 4). From this perspective, CA is not a good retarder for strength which is detrimental to mechanical strength.

4 Conclusions

To print three-dimensional gypsum structures by Direct Ink Writing, a printable gypsum paste is developed in this work. A retarder is introduced into the paste to retard the hydration reaction, and citric acid is chosen as a suitable one. In the hydration, CA selectively adsorbed on gypsum crystal affects its crystal growth resulting in a directional growth. Hydroxypropyl methylcellulose is used as a thickener to improve the shear elastic modulus of the paste. The optimal formula of the printable gypsum paste is 56% (in mass) of gypsum powder, 35% (in mass) of water, 0.6% (in mass) of CA, and 0.3% (in mass) of HPMC. Three-dimensional gypsum structures such as spider web and scaffolds were successfully printeddirect ink writing. The compressive strength of the printed gypsum parts is around 20 MPa. Although it is lower than that of a gypsum paste without a retarder and a thickener because of the directional crystal growth, it is much higher than that printedBinder Jetting.

[1] ZHANG J X, ZHANG Y, LIU J K,Research on the properties of high-strength gypsum based tile adhesive in interior decoration., 2020, 165(5): 05015.

[2] PHONGTHORN J, PANUWAT J. Utilization of several industrial wastes as raw material for calcium sulfoaluminate cement., 2019, 12(20): 3319–3331.

[3] PHETRATTANARANGSI T, PUNCREOBUTR C, KHAMKONGKAEO A,The behavior of gypsum-bonded investment in the gold jewelry casting process., 2017, 657: 144–150.

[4] WEISE J, HILBERS J, HANDELS F,New core technology for light metal casting., 2019, 21(4): 1800608.

[5] MA CHANGLIANG, ZHANG YUE, ZHANG HUANYUE,Manufacturing of herringbone gear model by 3D printing assisted investment casting., 2019, 332(4): 042045.

[6] MA Y, TANG B, YAO Q M,Common defects and their solutions in plaster investment precision casting., 2020, 41(7): 664–666.

[7] SHEN Y, ZHENG G, FENG C M. Research progress in investment casting precision casting technology., 2019(01): 54–62.

[8] HEAD D, VANORIO T. Effects of changes in rock microstructures on permeability: 3-D printing investigation., 2016, 43(14): 7494–7502.

[9] LIGON S C, LISKA R, STAMPFL J,Polymers for 3D printing and customized additive manufacturing., 2017, 117(15): 10212–10290.

[10] AMBROSI A, PUMERA M. 3D-printing technologies for electrochemical applications., 2016, 45(10): 2740–2755.

[11] HISHAM H H, ARIFIN S S, AYA A,3D printable conductive materials for the fabrication of electrochemical sensors: a mini review., 2018, 96: 27–31.

[12] CIMA M, LEXINGTON, SACHS E M,Three-dimensional Printing Techniques. U.S., Patent, 5387380, 1995.2.7.

[13] CASTILHO M, RODRIGUES J, PIRES I,. Fabrication of individual alginate-TCP scaffolds for bone tissue engineering by means of powder printing., 2015, 7(1): 15004–15023.

[14] JARIWALA S H, LEWIS G S, BUSHMAN Z J,. 3D printing of personalized artificial bone scaffolds., 2015, 2(2): 56–64.

[15] SNYDER T J, ANDREWS M, WEISLOGEL M,3D systems' technology overview and new applications in manufacturing, engineering, science, and education., 2014, 1(3): 169–176.

[16] LIU H B, MENG F J, HUA S Z. 4D mapping of the fracture evolution in a printed gypsum-like core by using X-ray CT scanning., 2021, 2021: 1–12.

[17] SONG R, WANG Y, ISHUTOV S,A comprehensive experimental study on mechanical behavior, microstructure and transport properties of 3D-printed rock analogs., 2020, 53(12): 5745–5765.

[18] JAVAN R, ELLENBOGEN A L, GREEK N,A prototype assembled 3D-printed phantom of the glenohumeral joint for fluoroscopic-guided shoulder arthrography., 2019, 48(5): 791–802.

[19] BUDA M, BRATOS M, SORENSEN J A. Accuracy of 3-dimensional computer-aided manufactured single-tooth implant definitive casts., 2018, 120(6): 913–918.

[20] RODRÍGUEZ-GONZÁLEZ P, FERNÁNDEZ-ABIA A I, CASTRO- SASTRE M A,Heat treatments for improved quality binder jetted molds for casting aluminum alloys., 2020, 36: 101524.

[21] WU Z J, ZHANG B, WENG L,. A new way to replicate the highly stressed soft rock: 3D printing exploration., 2020, 53(1): 467–476.

[22] ASADI-EYDIVAND M, SOLATI-HASHJIN M, SHAFIEI S S,. Structure, properties, andbehavior of heat-treated calcium sulfate scaffolds fabricated by 3D printing., 2016, 11(3): e151216.

[23] SELVARAJ S B, SINGAMNENI S. Pre-moisturized-hemihydrate for 3d printed molds., 2015, 31(8): 1102–1112.

[24] SHAHARIAR H, KIM I, BHAKTA R,. Direct-write printing process of conductive paste on fiber bulks for wearable textile heaters., 2020, 29(8): 085018.

[25] FIOCCO L, ELSAYED H, BADOCCO D,. Direct ink writing of silica-bonded calcite scaffolds from preceramic polymers and fillers., 2017, 9(2): 025012.

[26] LIU C B, GAO J M, TANG Y B,. Preparation and characterization of gypsum-based materials used for 3D robocasting., 2018, 53(24): 16415–16422.

[27] ZHANG Y Y, YANG J S, CAO X Y. Effects of several retarders on setting time and strength of building gypsum., 2020, 240: 117927.

[28] HILL J, PLANK J. Retardation of setting of plaster of paris by organic acids: understanding the mechanism through molecular modeling., 2004, 25(12): 1438–1448.

[29] GENSOWSKI K, TEPNER S, SCHWEIGERT S,Conductive highly filled suspensions for an electrochemical dispensing approach to pattern full-area thin metal layers by physical vapour deposition., 2020, 10(1): 27–31.

[30] HOWARD A BARNES. The yield stress—a review or ‘παντα ρει’—everything flows?, 1999, 81(1): 133–178.

[31] LIU C B, GAO J M, CHEN X M,. Effect of polysaccharides on setting and rheological behavior of gypsum-based materials., 2021, 267: 120922.

[32] CAMARINI G, PINTO M C C, MOURA A G D,Effect of citric acid on properties of recycled gypsum plaster to building components., 2016, 124: 383–390.

[33] LIU C B, GAO J M, TANG Y B,. Early hydration and microstructure of gypsum plaster revealed by environment scanning electron microscope., 2019, 234: 49–52.

[34] SINGH M, GARG M. Retarding action of various chemicals on setting and hardening characteristics of gypsum plaster at different pH., 1997, 27(6): 947–950.

[35] QU J D, LI B Z, PENG J H. Influence of retarders on the microstructure of hardened building gypsum paste and the mechanism of its strength loss., 2011, 250(253): 313–320.

[36] BÜLICHEN D, PLANK J. Water retention capacity and working mechanism of methyl hydroxypropyl cellulose (MHPC) in gypsum plaster-which impacthas sulfate?, 2013, 46: 66–72.

[37] THOMPSON B R, HOROZOV T S, STOYANOV S D,. Hierarchically porous composites fabricated by hydrogel templating and viscous trapping techniques., 2018, 137: 384–393.

[38] MENG X L, WANG Q Q, WANG Y L. Effect of retarder on properties of FGD gypsum., 2019, 49(4): 17–18.

[39] MAGALLANES-RIVERA R X, ESCALANTE-GARCÍA J I, GOROKHOVSKY A. Hydration reactions and microstructural characteristics of hemihydrate with citric and malic acid., 2009, 23(3): 1298–1305.

[40] LANZÓN M, GARCÍA-RUIZ P A. Effect of citric acid on setting inhibition and mechanical properties of gypsum building plasters., 2012, 28(1): 506–511.

石膏的直写成型:可打印石膏浆料的研制

周红莉1, 蔡志勇1, 王小锋1, 曾婧2, 冯艳1, 彭超群1, 王日初1

(中南大学 1. 材料科学与工程学院, 长沙 410083; 2. 冶金与环境学院, 长沙 410083)

石膏是雕像、建筑和铸造模具(合金和陶瓷)的常用材料。采用直写成型(Direct Ink Writing, DIW)打印石膏可避免其他3D打印技术(如Binder Jetting, PBBJ等)中存在水化反应不充分等问题, 获得高强度3D打印石膏。为了延缓水化反应获得充足的打印操作时间, 本研究通过添加缓凝剂和增稠剂, 研制了一种适用于直写成型的石膏浆料, 并打印了多种石膏三维结构(如蜘蛛网和木材堆积结构等)。结果表明, 质量分数为0.6%柠檬酸(Citric Acid, CA)的缓凝效果最好, 极大地减少了石膏流动性的经时损失。质量分数为0.3%羟丙基甲基纤维素(Hydroxypropyl Methylcellulose, HPMC)的增稠效果最好, 使石膏浆料具有良好的打印性能。CA的选择性吸附使得石膏晶体定向生长, 延长水化反应时间, 但一定程度降低石膏强度。HPMC加速石膏浆料中絮凝结构形成, 导致其粘度和剪切弹性模量升高。直写成型3D石膏件的抗压强度约为20 MPa, 远高于PBBJ等方法制备的石膏件的抗压强度。

直写成型; 石膏; 缓凝剂; 增稠剂; 流变性能; 铸造

TQ174

A

2021-10-02;

2021-12-02;

2021-12-24

Natural Science Foundation of Hunan Province (2020JJ4729)

ZHOU Hongli (1996–), female, Master candidate. E-mail: summertimezhl@163.com

周红莉(1996–), 女, 硕士研究生. E-mail: summertimezhl@163.com

WANG Xiaofeng, associate professor. E-mail: wangxiaofeng@csu.edu.cn

王小锋, 副教授. E-mail: wangxiaofeng@csu.edu.cn

1000-324X(2022)03-0338-09

10.15541/jim20210606