Linear Shaped Charge Cutting Property and Charge Cutting Mechanism of Mg-Gd-Y-Zn Alloy

WANG Yanbo,ZHOU Haitao,XIAO Lü,HOU Xiangwu,SUN Xin,CHEN Ge,DONG Xiwang

(Shanghai Aerospace Precision Machinery Research Institute,Shanghai 201600,China)

Abstract:The linear shaped charge cutting technology is an effective technology for aircraft separation.It can separate invalid components from aircrafts timely to achieve light-weight.Magnesium alloy is the lightest metal material,and can be used to cast effective light-weight components of an aircraft construction.However,the application study of the linear shaped charge cutting technology on magnesium alloy components is basically blank.In response to the demand for the linear separation of magnesium alloys,the Mg-12Gd-0.5Y-0.4Zn alloy is selected to carry out the target shaped charge cutting test.The effects of the shaped charge line density,cutting thickness,and mechanical properties on the cutting performance of the alloy are studied.The shaped charge cutting mechanism is analyzed through the notch structure.The results show that the linear shaped charge cutting performance is significantly affected by the penetration and the collapse.The higher the linear density is,the stronger the ability of the linear shaped charge cutter is,and the greater the penetration depth is,which is advantageous.However,the target structure will be damaged when it is too large(e.g.,4.5 g·m-1).Within 12 mm,when the cutting thickness of the target increases,the penetration depth increases.The lower the tensile strength is,the greater the penetration depth is,and the more conducive the penetration depth to the shaped charge cutting is.When the elongation(EL)increases to 12%,the collapse of the target is incomplete and the target cannot be separated.When the tensile strength of the Mg-Gd-Y-Zn alloy is less than 350 MPa,the EL is less than 6.5%,the cutting thickness is less than 12 mm,and the linear shaped charge cutting of the magnesium alloy can be achieved stably.

Key words:shaped charge cutting;linear shaped charge cutting mechanism;magnesium alloy;mechanical properties;penetration

0 Introduction

During the flight of aircrafts,especially rockets and missiles,some components need to be separated timely after they have performed functions,so that the weight of the aircraft can be reduced and the per‑formance can be improved.The linear shaped charge cutting technology is the main technology to realize the separation of aircrafts.It has a wide range of ap‑plications on missiles.The technology forms a shaped jet through explosive,which has the characteristics of high energy density and strong directionality,and can cut all kinds of metal and nonmetallic materials in a very short time.The tech‑nology has the advantages of high speed,high effi‑ciency,safety,and reliability,and is not restricted by the environment.

Magnesium alloy is the lightest metal structure material in practical application at present.If a large amount of magnesium alloy is used in casting compo‑nents of aircrafts for aerospace and military to replace aluminum alloy and steel,the weight of the aircrafts will be effectively reduced,and the performance of the aircrafts will be much improved.Heat-resis‑tant magnesium alloy can be formed by adding rare earth elements to magnesium alloy.Compared with pure magnesium alloy,heat-resistant magnesium al‑loy has better high temperature strength,creep resis‑tance,and heat resistance.In foreign countries,heatresistant magnesium alloy has been widely used in structural parts such as aircraft skin,satellite space structure,spacecraft frame,engine hood,engine cyl‑inder block,and gearbox shell.Mg-Gd-Y heat-re‑sistant magnesium alloys have great application potential in the aerospace field because of their good mechanical properties at room temperature and high temperature.

At present,the linear shaped charge cutting technology is widely used on aluminum alloy compo‑nents,but the application study on magnesium alloy components is basically blank.The effects of the pa‑rameters of the shaped charge cutter on the cutting performance have been reported by many studies,but the reports on the properties of magnesium alloy components are seldom.In many applications of the shaped charge cutting technology,the integrity of the structure after shaped charge cutting is required.However,the differences in the properties and struc‑ture of a target often lead to the failure of the target.

At present,there are no clear criteria to ensure the stability of shaped charge cutting,which limits the application of magnesium alloy in the field of shaped charge cutting

1 Experiment

The test material in this paper is Mg-12Gd-0.5Y-0.4Zn magnesium alloy,and the experiment is de‑signed by adjusting the three parameters,i.e.,the shaped charge line density,the cutting thickness,and the mechanical properties,as shown in Tab.1.The effects of various parameters on the shaped charge cutting performance and penetration process of highperformance magnesium alloy targets are studied.

Tab.1 Shaped charge cutting experiment on the Mg-Gd-Y-Zn magnesium alloy

1.1 Shaped charge line density

The U-shaped charge cutter is used,and the shaped charge line density is set to be 2.7 g·m,3.6 g·m,and 4.5 g·m,respectively.

1.2 Cutting thickness

The structure of the target is shown in Fig.1,where“1”is a stiffener,“2”is a stepped weakening groove,“3”is a transition arc,“4”is a fixed nut,and“”is the cutting thickness.During the test,the linear shaped charge cutter is aligned with the weakened groove,fixed with a fixing nut and a sheath,and then detonated from one end.

Fig.1 Schematic diagram of the target

The cutting thickness of each step of the thinner is set to be 4.8 mm,6.0 mm,6.8 mm,7.2 mm,7.6 mm,and 8.0 mm,respectively,and the cutting thickness of each step of the thicker is set to be 8.0 mm,8.8 mm,9.6 mm,10.4 mm,11.2 mm,and 12.0 mm,respectively.

1.3 Mechanical properties

The mechanical properties of the Mg-Gd-Y-Zn magnesium alloy at room temperature are adjusted through solid solution and aging heat treatment pro‑cesses,and the targets with different ultimate tensile strength(UTS)and elongation(EL)are prepared,as shown in Tab.1.

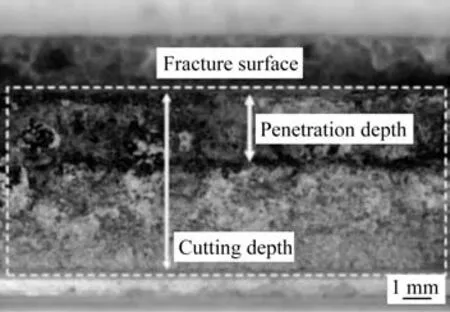

The fracture morphology of the linear shaped charge cutting test is shown in Fig.2,and the lowmagnification is shown in Fig.3.It is found that there are obvious differences between the upper and lower sections.The upper part is a clear and orderly striped ripple,while the lower part is disorderly and irregu‑lar.It can be concluded that the separation of the Mg-Gd-Y-Zn magnesium alloy specimen includes prepenetration and late collapse.

Fig.2 Fracture morphology of the target fracture

Fig.3 Low-magnification photo of the target fracture

The penetration depth of the cutting thickness section is measured and analyzed by observing the low-magnification structure of the target.At the same time,the macrostructure and microstructure of the target after the test are analyzed,the microstructure morphology of the longitudinal section of the target fracture is observed,the energy spectrum is tested,and the cutting performance of the target is analyzed.

2 Results and discussion

2.1 Effects of the shaped charge line density on the cutting performance of magnesium alloys

The results of the tests for Targets No.1,No.2,No.3,and No.7 are shown in Fig.4.It can be seen that the targets are all completely separated.The shaped charge line densities of Targets No.1 and No.2 are 2.7 g·mand 3.6 g·m,respectively.The surfaces of Targets No.1 and No.2 are intact,the slit quality is good,and there is no cracking or deformation.

Fig.4 Test results for Targets No.1,No.2,No.3,and No.7

The shaped charge line densities of Targets No.3 and No.7 are 4.5 g·m,resulting in deforma‑tion,bending,and failure of the structure.This indi‑cates that the higher the linear density is,the stronger the ability of the cutter is.Therefore,for the Mg-Gd-Y target with the tensile strength less than 349 MPa and the EL less than 6.4%,the shaped charge line density should be less than 4.5 g·m,which can meet the needs of the linear shaped charge cutting and ensure the structural integrity after cutting.

Continue Fig.4 Test results for Targets No.1,No.2,No.3,and No.7

The calculated penetration depths of Targets No.1,No.2,and No.3 are shown in Fig.5.The da‑ta show that the penetration depth increases with the increase in the shaped charge line density.The maxi‑mum penetration depth of Target No.1 is 2.74 mm,and the minimum penetration depth of Target No.1 is 2.38 mm.The penetration depths of Targets No.2 and No.3 are basically larger than 3 mm.The maxi‑mum penetration depth of Target No.3 is 4.04 mm.The difference between the penetration depths of Targets No.2 and No.1 is larger than that between Targets No.3 and No.2.For the Mg-Gd-Y alloy,the cutting ability increases greatly when the shaped charge line density increases from 2.7 g · mto 3.6 g·mand then gradually when the shaped charge line density continuously increases to 4.5 g·m.In addition,when the cutting thickness increases from 4.8 mm to 8.0 mm,the penetration depth of the tar‑get increases gradually.

Fig.5 Penetration depths of Targets No.1,No.2,and No.3 with different cutting thicknesses

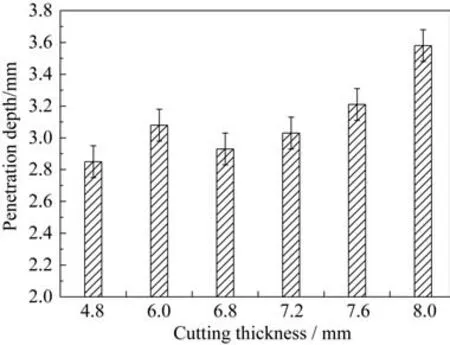

2.2 Effects of the cutting thickness on the cutting performance of magnesium alloys

The separation and calculated penetration depth results of Target No.6 are shown in Fig.6.It can be seen that the penetration depth increases with the in‑crease in the target cutting thickness within 12 mm.When the cutting thickness increases from 8 mm to 12 mm,the penetration depth of the target increases gradually,which is consistent with the conclusion in Subsection 2.1.Moreover,the penetration depth at the cutting thickness of 8 mm is 2.65 mm,which is similar to that of Target No.1(see Fig.7).

Fig.6 Separation picture and calculated penetration depth of Target No.6

From the experimental results of Targets No.1,No.2,and No.3 in Subsection 2.1,it can be seen that when the tensile strength of the target ranges from 344 MPa to 349 MPa,the EL ranges from 6.15% to 6.5%,the cutting thickness is less than 12 mm,and the target can be completely sepa‑rated by adjusting the shaped charge line density.The Mg-Gd-Y alloy is also selected in the test.The results show that its linear shaped charge cutting per‑formance is good.

2.3 Effects of the mechanical properties on the cutting performance of magnesium alloys

The separation and calculated penetration depth results of Target No.4 are shown in Fig.7.Combined with the experimental results in Subsection 2.1,it can be seen that when the shaped charge line density is 2.7 g·m,the cutting tensile strength ranges from 323 MPa to 349 MPa,and the EL ranges from 5.5%to 6.5%.After cutting,the fracture surface of the tar‑get is flat,the slit quality is good,the structure is complete,and there is basically no deformation.

Fig.7 Separation picture and calculated penetration depth of Target No.4

Compared with the properties of Target No.1 shown in Fig.5,the EL of Target No.4 is basically the same,the tensile strength is lower,but the pene‑tration depth is slightly larger.It can be inferred that the tensile strength affects the penetration depth of the target.The lower the tensile strength is,the greater the penetration depth is,and the more favor‑able the linear shaped charge cutting is.

The longitudinal macroscopic fracture of Target No.5 is shown in Fig.8(a),and the low power struc‑ture of the fracture surface is shown in Fig.8(b).It can be seen that the target is not completely separat‑ed.There are obvious penetration holes and small cracks,but there is incomplete collapse along the penetration hole.When the strength of the target is low and the EL is high,the target cannot be separat‑ed by the shaped charge line density 2.7 g·m.This may be owing to the high EL of the material.

Fig.8 Separation results of Target No.5

The calculated penetration depth results of Tar‑get NO.5 are shown in Fig.9.It can be seen that the target tensile strength is 241 MPa,the EL is 12%,and the maximum and minimum penetration depths are 3.58 mm and 285 mm,respectively,which are much larger than those of Target No.1(see Fig.5).Moreover,the lower the tensile strength is,the high‑er the EL of the material is,and the larger the pene‑tration depth is,which is beneficial to the shaped charge cutting of the target.

Fig.9 Penetration depth of Target No.5

2.4 Analysis on the cutting mechanism of the Mg-Gd-Y-Zn magnesium alloy

The SEM and EDS results on the fracture sur‑face side of Target No.1 are shown in Fig.10,where the gray area is magnesium alloy,and the black area is the mosaic resin of the gold phase.It can be seen that the cracks in the target are glued with a lot of white matter from top to bottom,and the energy spectrum analysis shows that the Pb content of the white matter is close to 80%,indicating that it is the residue of the cutting jet.For the target,the jet produced by the shaped charge cutter can continuous‑ly penetrate the target and cause the target collapse until the target is completely separated.Therefore,the residue of the jet will be distributed in each area of the fracture surface.

Fig.10 SEM and EDS results of the cutting fracture side of Target No.1

Continue Fig.10 SEM and EDS results of the cutting fracture side of Target No.1

The microstructure of the fracture side of Target No.1 is shown in Fig.11.It can be seen that the cross section is relatively flat,there are basically no longitu‑dinal cracks,and the fracture is basically transgranular.

Fig.11 Microstructure of the cutting fracture side of Target No.1

The SEM images of the fracture surface side of Target No.5 are shown in Fig.12.It can be seen that there is an oval penetration hole above the fracture sur‑face and a macroscopic crack extension area below.The surface of the penetration hole is completely cov‑ered by a continuous jet.The jet residue on the crack surface exists only near the penetration hole,and there is no jet residue at the front end of the crack.

Fig.12 SEM images of the cutting fracture side of Target No.5

From Fig.12,it can be seen that the jet knife formed by the cutter strikes Target No.5.The pene‑tration hole forms from the collision point and be‑comes larger with the continuous penetration.In this process,with the expansion of the penetration aper‑ture,the jet adheres to the sidewall of the hole,then a crack appears at the front end of the penetration hole,and finally the crack absorbs the energy from the jet knife for expansion continuously.Until the jet penetrates a certain position,the penetration velocity decreases to its critical value.Since the mechanical energy transferred by the jet to the front magnesium alloy structure is not enough to support the crack to continually expand,when the penetration resistance becomes larger,the penetration terminates,and the target does not collapse completely.Moreover,when the shaped charge line density is 2.7 g·m,the EL of Target No.5 is large,the strength is low,the ability to resist the jet impact and crack expansion is strong,and the crack growth at the front end of the penetra‑tion hole is greatly resisted.This makes the late col‑lapse section of Target No.5 incomplete after prepenetration,and thus Target No.5 cannot be separat‑ed smoothly.The microstructure of the fracture side of Target No.5 is shown in Fig.13.It can be seen from Fig.13(a)that the grains at the edge of the penetration hole are elongated along the penetration direction.When the jet penetrates and enlarges the hole,the structure of the hole wall is arranged to both sides,the grains are subjected to the compres‑sive stress perpendicular to the jet,and the size in this direction is shortened and becomes oblate.From Fig.13(b),it can be seen that the crack also grows in the way of transgranular fracture.

Fig.13 Microstructure of the cutting fracture side of Target No.5

3 Conclusions

1)The greater the shaped charge line density is,the stronger the ability of the cutter is,and the greater the penetration depth of the target is.Howev‑er,if the shaped charge line density is too high,the integrity of the structure of the target will be de‑stroyed,and the shaped charge line density of the Mg-Gd-Y target should not be greater than 3.6 g·m.

2)The greater the cutting thickness is,the greater the penetration depth of the target is.The lower the strength of the target is,the higher the EL is,the greater the penetration depth is,and the more favorable the linear shaped charge cutting is.

3)The large EL of the target will affect the lat‑er collapse section,and the target cannot be separat‑ed.When the tensile strength of Mg-Gd-Y alloy is less than 350 MPa,the EL is less than 6.5%,the cutting thickness is less than 12 mm,and the linear shaped charge cutting of Mg-Gd-Y-Zn alloy can be realized stably.

- 上海航天的其它文章

- 序言

- 企业简介

- Microstructure and Property Analysis of AerMet100 Steel Manufactured by In-situ Rolling Mixed Wire Arc Additive Manufacturing

- Effect of Isothermal Forging on the Microstructure and Mechanical Properties of Mg-8Gd-3Y-0.5Zr Alloy

- Fabrication and Investigation on Double-Hollow Shell CoFe Oxide@TiO2 Nanocube with Superior Electromagnetic Properties

- Investigation on Thermal and Dimensional Stability of Epoxy Resin In-Situ Modified by Cyanate Ester Resin and Polydimethylsiloxane