Design and Implementation of Drying Device in Macadamia Nut Digital Management

Bo YANG Wei HUANG Liming TANG Zheng FU Zhongwen LIANG

Abstract Macadamia, as the main industry of rural revitalization in Guangxi, has high economic value and good ecological benefits. However, the traditional way of drying macadamia nuts after harvest is very extensive. It cannot guarantee the quality and can cause mildew easily, thereby seriously restricting the industrial development. This paper introduced a device with a weighing device, which allows operators to understand the drying effect in time and thus reduces the loss of nutrition. The device solves the problem of relying on the weather to harvest, and ensures the drying effect of macadamia nuts.

Key words Macadamia nut; Digital agriculture; Drying device; Sustainable development

Received: October 21, 2021 Accepted: December 28, 2021

Supported by Guangxi Science and Technology ProgramProject of China (Guike AD19245169); Yulin City Scientific Research and Technology Development Plan Project (YuShiKe 20202001, 2019Cxpt00A4, YuShiKe 20204038).

Bo YANG (1979-), male, P. R. China, senior agronomist, devoted to research about functional agriculture.

Macadamia (Macadamia integrifolia Maiden & Betche) has high economic value and good ecological benefits. Macadamia nuts are the "king of dried fruits", and macadamia is known as the main variety of rural revitalization in Guangxi. However, the traditional way of drying macadamia nuts after harvest is very extensive[1]. It cannot guarantee the quality and can cause mildew easily, thereby seriously restricting the industrial development. In the prior art, there are also some drying boxes for macadamia nuts, but during the drying operation, there will be the problem of excessive drying, resulting in the loss of nutrients of macadamia nuts, so the quality cannot be guaranteed, and certain economic losses are caused[2-3]. It is mainly specific that the drying time of different quantities of macadamia nuts is different, and taking a unified drying time as the standard will inevitably lead to different drying results, unless macadamia nuts are weighed in advance, and then the specified weight is loaded into the tray for drying operation[4-5]. However, an additional process is added accordingly, which is very uneconomical. Based on this problem, in this study, we designed a drying oven with the function of automatic weighing, so as to solve this problem.

Design of the Drying Device for Macadamia Digital Management

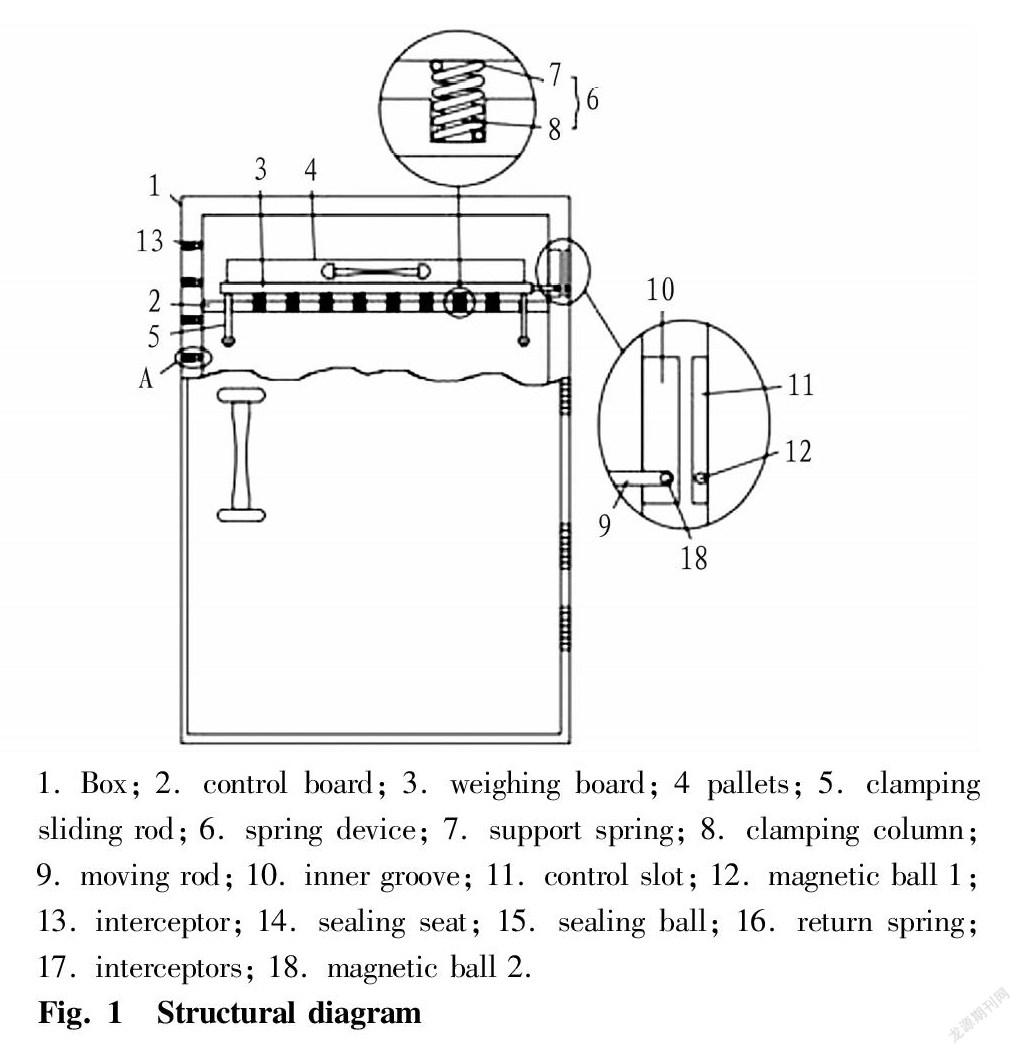

The utility model relates to a drying box with a weighing device ensuring the quality of macadamia nuts. It comprises the following key points: a box door is hinged on one side of the box, and a drying mechanism is arranged at the bottom of the groove of the box; a plurality of cuboid-shaped control boards are fixedly connected in the inner cavity of the box body, the upper end of the control boards is provided with a cuboid-shaped weighing board, and the upper end of the weighing board is provided with a tray; the four corner positions of the weighing board are fixedly connected with a clamping sliding rod, the upper end of which is fixedly connected with the tray, and the lower end of each clamping sliding rod passes through a through hole opened on the control board; several evenly distributed spring devices are arranged between the control boards and the weighing board, one side wall of the weighing board is fixedly connected with a moving rod, the side wall of the inner cavity of the box is provided with an inner groove, one end of the moving rod extends into the inner groove, and the end of the moving rod is embedded with a magnetic ball; a control groove is arranged on the outer wall of the box on one side of the inner groove, and a magnetic ball is arranged in the control groove; and a plurality of intercepting devices are arranged on the side wall of the box away from the magnetic ball 1.

Each spring device comprises a support spring and a clamping column. The upper bottom surface of corresponding control board is provided with a cylindrical groove. The support spring is located in the groove, and the middle of the support spring is movably sleeved with the clamping column, the lower bottom surface of which is fixedly connected with the bottom surface of the cylindrical groove.

Each intercepting device is installed in a through hole opened on the side wall of the box. The intercepting device comprises a sealing seat, a sealing ball, a return spring and an intercepting seat. The shape of the sealing seat is a cylinder, and the bottom surface of one end of the cylinder is provided with an arc surface groove, which is engaged and connected with the sealing ball. The shape of the intercepting seat is a circular plate, and a plurality of evenly distributed through holes are arranged on the circular plate. The outer walls of the intercepting seat and the sealing seat are fixedly connected with the inner wall of the through holes on the side wall of the box. The sealing seat is located at the end near the inner cavity of the box in the through hole of the side wall of the box. One end of the sealing seat back to the inner cavity of the box is contacted with a sealing ball, one end of the sealing ball back to the sealing seat is contacted with a return spring, and one end of the return spring away from the sealing ball is contacted with the interception seat.

Realization of the Drying Device in Macadamia Digital Management

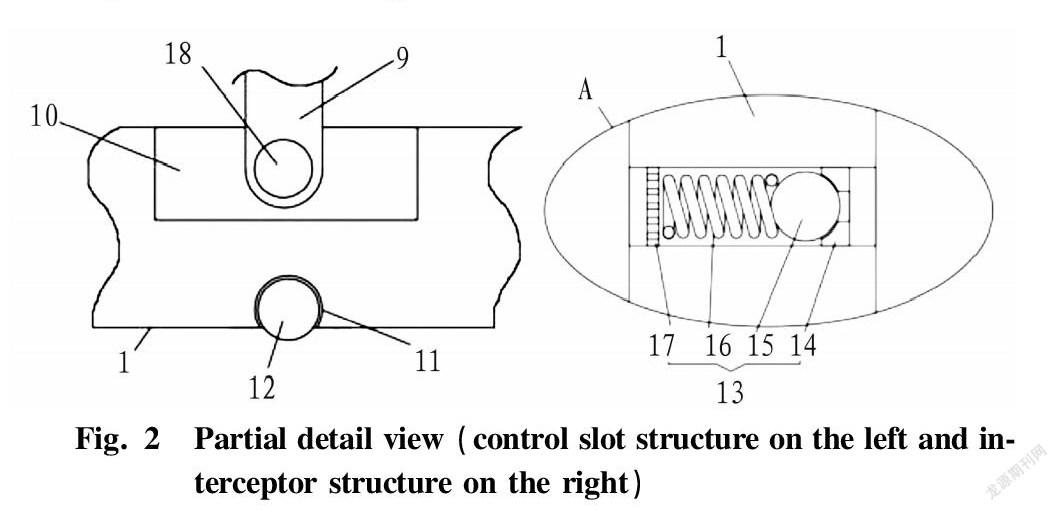

The specific implementation scheme is as follows: as shown in Fig. 1-Fig. 2, a drying box with a weighing device ensuring the quality of macadamia nuts includes box 1. One side of box 1 is hinged with box door, the bottom of groove of box 1 is provided with drying mechanism, the inner cavity of box 1 is fixedly connected with several rectangular control boards 2, and several control boards 2 are vertically arranged in the inner cavity of box 1. The two opposite edges of the control board 2 are fixedly connected with the inner wall of the box 1. One of the other two opposite edges is not in contact with the box door, and the other is at a certain distance from the drying mechanism. The drying mechanism is the drying heat source in the prior art. The upper end of the control board 2 is provided with a rectangular weighing board 3, and the upper end of the weighing board 3 is provided with a tray 4. The four corner positions of the weighing board 3 are fixedly connected with the clamping sliding rod 5, the upper end of the clamping sliding rod 5 is fixedly connected with the tray 4, the lower end of the clamping sliding rod 5 passes through the through hole opened on the control board 2, several evenly distributed spring devices 6 are arranged between the control board 2 and the weighing board 3, one side wall of the weighing board 3 is fixedly connected with the moving rod 9, and the inner cavity side wall of the box 1 is provided with an inner groove 10. One end of the moving rod 9 extends into the inner groove 10, and the end of the moving rod 9 is embedded with the magnetic ball 18. The outer wall of the box 1 on one side of the inner groove 10 is provided with a control groove 11, the control groove 11 is provided with magnetic ball 12, and a number of interception devices 13 are arranged on the side wall of the box 1 away from the magnetic ball 12. The cross section of the control groove 11 is circular as shown in Fig. 2, and a part of the circular is cut off. In this way, the spatial position of the magnetic ball 12 can be limited without affecting the rolling of the magnetic ball 12, and part of the magnetic ball 12 can be displayed outside. It is necessary to set a scale mark on the outer wall of the box 1 on the side of the position of the control slot 11, so that people can observe the moving direction of the magnetic ball 12, and then determine the evaporation in the inner cavity of the box 1. The magnetic ball 18 is opposite to the magnetic ball 12, and they attract each other.

The spring device 6 includes a support spring 7 and a clamping column 8. The upper and bottom surfaces of the control board 2 are provided with cylindrical grooves. The support spring 7 is located in the grooves. The middle of the support spring 7 is movably sleeved with a clamping column 8. The lower bottom surface of the clamping column 8 is fixedly connected with the bottom surface of the cylindrical groove. The clamping column 8 plays a certain clamping role to limit the support spring 7 and ensure the stable deformation of the support spring 7. The lower end of the support spring 7 is welded and fixed with the bottom surface of the groove.

The intercepting device 13 is installed in the through hole opened on the side wall of the box 1. The intercepting device 13 includes a sealing seat 14, a sealing ball 15, a return spring 16 and an intercepting seat 17. The shape of the sealing seat 14 is a cylinder, and the bottom surface of one end of the cylinder is provided with an arc groove. The groove is engaged with the sealing ball 15. The intercepting seat 17 is a circular board, and a number of evenly distributed through holes are arranged on the circular board, The outer walls of the interception seat 17 and the sealing seat 14 are fixedly connected with the inner wall of the through hole on the side wall of the box 1.

The sealing seat 14 is located at the end near the inner cavity of the box 1 in the through hole of the side wall of the box 1. The end of the sealing seat 14 away from the inner cavity of the box 1 is in contact with the sealing ball 15, the end of the sealing ball 15 away from the sealing seat 14 is in contact with the return spring 16, and the end of the return spring 16 away from the sealing ball 15 is in contact with the blocking seat 17.

Working Principle of the Drying Device in Macadamia Digital Management

In the drying operation of the dryer, the macadamia drying box installed in the tray 4 evaporates water, and the evaporated gas is discharged to the outside through the intercepting device 13. Specifically, the air pressure pushes up the sealing ball 15 to make a gap between the sealing ball 15 and the sealing seat 14. In this way, the gas is discharged to the outside through the intercepting device 13, and the pressure in the inner cavity of the box 1 is reduced after the gas is discharged, The return spring 16 will push the sealing ball 15 to form a sealing effect between the sealing ball 15 and the sealing seat 14, so as to prevent the external gas from entering the inner cavity of the box 1 through the intercepting device 13 in reverse. The moisture in the Macadamia drying box evaporates and the weight is reduced. In this way, several support springs 7 push the weighing board 3 to rise a certain distance, the weighing board 3 drives the moving rod 9, and the moving rod 9 rises and moves, The magnetic ball 18 and the magnetic ball 12 attract each other to make the magnetic ball 12 rise by a certain distance. The worker can understand the drying of macadamia nuts in the inner cavity of the box 1 by watching the rising distance of the magnetic ball 12.

Conclusion

Compared with the prior art, The advantages of the drying device in the macadamia digital management realized in this paper are as follows: (1) the macadamia drying operation is realized through a simple structural design, and the macadamia drying progress in the inner cavity of the box is known for the first time by observing the movement of the magnetic ball 1, which is very practical; and (2) through the design of the interception device, the device realizes the single process of gas emission, ensures that the environment in the inner cavity of the box is not affected by the outside, and makes the drying operation stable. Therefore, the device can timely show the drying effect, and reduce nutrient loss.

References

[1] HUANG W, SHEN MY, LIU ZL, et al. Effects of different application methods and application rates of biological nano-selenium on the quality of passion fruit[J]. Medicinal Plant, 2020, 11(3): 68-69, 92.

[2] HUANG W, WANG WL, CHEN HS, et al. Effect of the concentration and spraying position of organic nano Se on the yield and quality of macadamia[J]. Basic & Clinical Pharmacology & Toxicology, 2020, 126(S2): 21.

[3] CHEN Z, WANG D, MA L, et al. Internet of Things technology in monitoring system of sustainable use of soil and land resources[J]. IEEE Access, 2020(8): 152932-152940.

[4] HUANG W, LU ML, LIANG X, et al. Design and application of water, fertilizer and pesticide integrated automatic control device[J]. Plant Diseases and Pests, 2020, 11(1): 30-32.

[5] LI X, WANG D, LI M. Convenience analysis of sustainable e-agriculture based on blockchain technology[J]. Journal of Cleaner Production, 2020(271): 122503.

[6] LIU Z, HUANG W, WANG D. Functional agricultural monitoring data storage based on sustainable block chain technology-Science Direct[J]. Journal of Cleaner Production, 2020, 281(7-8): 124078.

- 农业生物技术(英文版)的其它文章

- Expression Analysis of Heat Shock Protein 70 Gene in Rice (Oryza sativa L.)

- Changes in Physiological and Biochemical Characteristics of Floral Organ

- Research Progress on Lonicera japonica Thunb. Affected by Environmental Stress

- Research Progress on Genetic Diversity of Snap Bean

- Allelopathic Effects of Cedrus deodara Needle Extracts on Seed

- Development Status and Countermeasures of Passiflora spp. Seedling Industry in Qinzhou, Guangxi