鸡粪高固体浓度进料厌氧消化连续运行性能

宋亚朋,乔 玮,胡婉蓉,董仁杰

鸡粪高固体浓度进料厌氧消化连续运行性能

宋亚朋1,2,乔 玮1,2※,胡婉蓉3,董仁杰1,2

(1. 中国农业大学工学院,北京 100083; 2. 中国农业大学国家能源生物燃气高效制备及综合利用技术研发试验中心,北京 100083; 3. 中国地质大学(北京)水资源与环境学院,北京 100083)

以鸡粪为处理对象,进料总固体(Total Solids, TS)浓度控制在15%,进行鸡粪高固体浓度进料厌氧消化试验,在水力停留时间(Hydraulic Retention Time, HRT)为 60 d的条件下,连续运行155 d考察发酵性能。试验结果表明,在有机负荷(Organic Load Rate, OLR)为1.5 g/(L·d)(以Volatile Solids, VS计算)和总氨氮(Total Ammonia Nitrogen, TAN)浓度7.5 g/L的条件下,甲烷产率达到326 mL/g,总挥发性脂肪酸(Total Volatile Fatty Acids, TVFA)浓度在0.5 g/L左右,pH值在8.3以上,实现了低有机酸残留的鸡粪高固体浓度进料厌氧消化的稳定运行。鸡粪的水解率、酸化率以及产甲烷率分别为61%、47%和47%。厌氧污泥的比产甲烷活性(Specific Methanogenic Activity, SMA)为0.042 g/(g·d),显示有较好的代谢活性,利用一级动力学模型进行模拟,动力学常数为0.202 d-1,相关性系数为0.982。该研究验证了通过延长HRT适当降低OLR的方式,鸡粪高固体浓度进料厌氧消化可以耐受极高的氨氮浓度,为工程应用提供了可能性。

粪;厌氧消化;高固体;SMA;物料平衡

0 引 言

鸡粪中含有大量易降解有机物,适合用厌氧消化的方式处理,产甲烷潜能达到300~370 mL/g[1-2]。但是,鸡粪总氮含量占干质量的 3.2%~4.9%[1, 3-4],直接进行厌氧消化易受高浓度氨氮的抑制[2, 5-6],通常需要在厌氧处理前加水稀释至总固体浓度低于10%。但是,加水稀释增加了进料体积及后续沼液产量,加剧了沼气工程“沼液出路难”的压力。另一方面,加水稀释也减少了沼液中的氮含量,降低了沼肥营养价值。高固体浓度进料厌氧消化具有减少反应器体积,提高体积产气量,降低加热能耗,减少沼液产量,降低原料运输成本等优势[7-8]。如何减少稀释用水,提高进料物质浓度,缓解氨抑制,实现高固体浓度进料厌氧消化是鸡粪处理的一个瓶颈问题。研究发现在高固体浓度进料厌氧条件下,鸡粪发酵很难成功。当鸡粪进料总固体浓度为15%~20%,HRT (Hydraulic Retention Time)为20 d条件下,总挥发性有机酸最高达到25.0 g/L,甲烷产率最低下降至20 mL/g,厌氧消化过程处于崩溃状态[9-10]。目前,高浓度鸡粪进料厌氧消化研究较少,进料固体浓度、有机负荷、氨氮浓度以及它们的协同作用对厌氧消化性能的影响尚不明确,是否能建立稳定运行的鸡粪高固体浓度进料厌氧消化工艺还有待长期试验的证明。

本研究考察了进料TS(Total Solid)浓度为15%、HRT 60 d条件下的高固体浓度鸡粪进料厌氧消化性能,通过反应器长期运行的试验为基础,分析了物料平衡、污泥乙酸产甲烷活性等,以期为鸡粪高固体浓度进料厌氧消化的应用提供试验支撑。

1 材料与方法

1.1 接种及物料

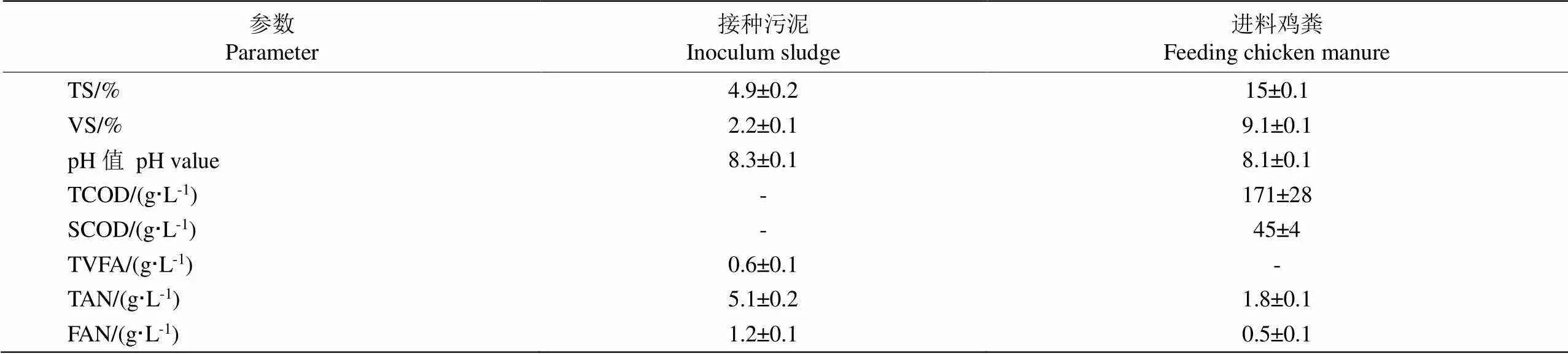

接种污泥取自试验室连续稳定运行100 d以上的中温鸡粪厌氧消化反应器,该反应器的进料总固体浓度为10%,水力停留时间为20 d,搅拌均匀后接种到反应器中。鸡粪原料取自北京某养鸡农场,使用搅拌机(JYLC012,中国九阳)将鸡粪进行破碎、匀浆并于4℃环境下冷藏,使用时用去离子水将其TS稀释至15%,接种污泥和进料鸡粪的理化性质如表1所示。

1.2 试验设计

1.2.1 连续试验装置

试验采用全混式连续搅拌反应器,总体积6 L,有效容积4 L,放置在水浴槽中,水浴槽使用加热器(AS ONE亚速旺,TMK-2K)控制温度在(37±1)℃。每天手动进料一次,采用蠕动泵(BT100N,保定申辰)出料保持反应器相同液位高度,反应器及其试验装置流程如图1所示。

表1 接种污泥和鸡粪性质

注:TS:总固体;VS:挥发性固体;TCOD:总化学需氧量;SCOD:溶解性化学需氧量;TVFA:总挥发性脂肪酸;TAN:总氨氮;FAN: 游离氨。

Note: TS: Total Solid; VS: Volatile Solid; TCOD: Total Chemical Oxygen Demand; SCOD: Soluble COD;TVFA: Total Volatile Fatty Acids; TAN: Total Ammonia Nitrogen; FAN: Free Ammonia Nitrogen.

1. 厌氧消化反应器 2. 搅拌器 3. 进料口 4. 出料泵 5. 沼液储存罐 6. 取样针 7. 沼气取样口 8. 水封瓶 9. H2S吸收瓶 10. 湿式气体流量计 11. 水浴加热器 12. 水浴槽 13. 温度控制器 14. 平衡气袋

1.2.2 比产甲烷活性测试

比产甲烷活性试验中,首先取发酵罐新鲜出料,在 8 000 r/min下离心20 min后去除上清液,然后加入营养液后混合均匀重复上述离心步骤,制备接种污泥,营养液成分见预试验[1]。将上述制备的接种污泥20 mL置于发酵瓶(120 mL)中,再次加入80 mL营养液,乙酸添加浓度设置为2 000 mg/L(试验组),未添加乙酸的发酵瓶为对照组,每组设置2个平行。使用氮气吹扫发酵瓶中空气营造厌氧环境,并使用橡胶塞密封,置于恒温 (37±1)℃ 振荡水槽(一恒科技,DKZ-3B)中,每2~4 d用玻璃注射器测定产气量。

1.3 分析方法

TS、挥发性固体(Volatile Solids, VS)和挥发性悬浮固体(Volatile Suspended Solids, VSS)采用重量法、氨氮利用纳什分光光度法、化学需氧量(Chemical Oxygen Demand, COD)采用重铬酸钾法、连续长期发酵实验沼气产量采用湿式流量计(LML-1,北京金志业)、挥发性脂肪酸采用日本岛津气相色谱仪(GC-2010Plus),色谱柱为RTX-WAX毛细色谱柱,氮气分压为0.4 MPa,流速为40 mL/min,分流比30,进样口温度设为230℃,FID检测器温度250℃,进样体积10L、沼气成分采用日本岛津气相色谱(GC-8A),色谱柱为10 m×2 mm不锈钢色谱柱,氢气分压为0.6 MPa,载气流速为20 mL/min,进样口温度120℃、柱温50℃,检测器温度120℃,进样体积为0.5 mL、pH值采用pH计(梅特勒-托利多,FE28)。

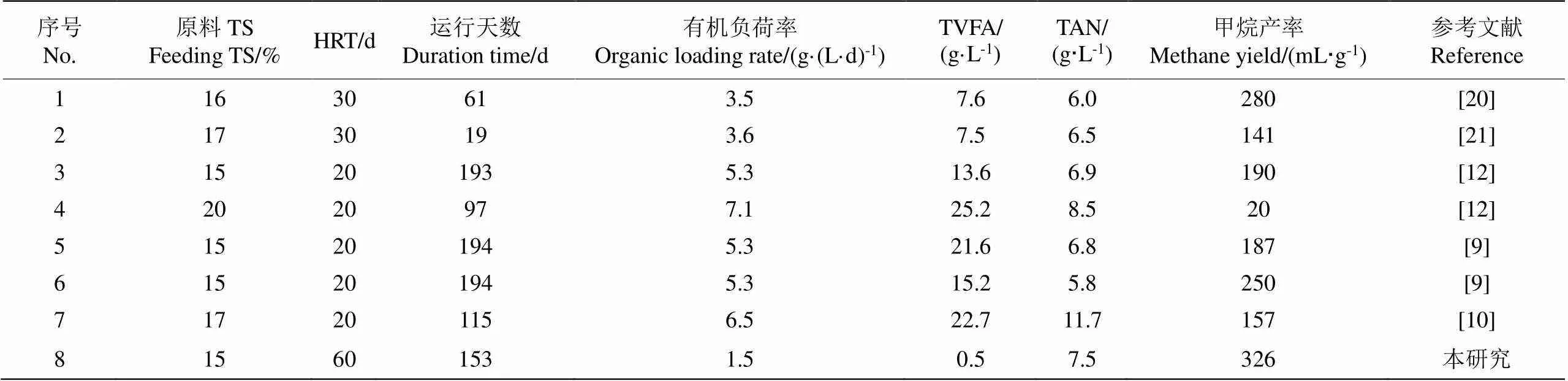

1.4 计算方法

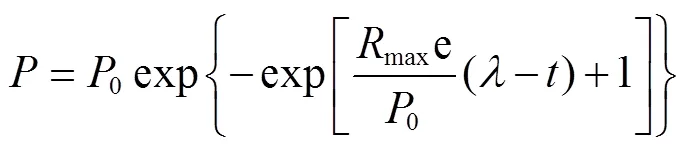

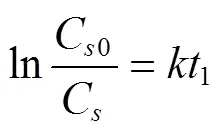

污泥产甲烷活性测定中,产气量以及产气速率使用修正的Gompertz模型以及一级动力学模型进行拟合,分别如式(1)~(2)所示。比产甲烷活性值(Specific Methanogenic Activity, SMA)参照文献[11-12]计算,如式(3)所示。

式中为时刻的累积产甲烷量,mL;0为最大产甲烷潜能,mL;max为最大产甲烷速率,mL/d;为迟滞期,d;为试验时间,d;e为自然常数,e≈2.7183。

式中C0最大产甲烷量,mL;C为最大产甲烷量减去时刻的产甲烷量,mL;为速率常数,d-1;1为消化时间,d。

公式(3)中CH4是累积产甲烷量,mL;V是接种污泥添加量,L;是与COD转化系数(350 mL/g),每g COD产甲烷350 mL;VSS 是接种污泥生物量,g/L;2是具有最大产甲烷速率消化时间,d。

厌氧消化过程中的物质转化性能通过测定原料、沼液以及沼气中的COD值,然后根据原料水解率、酸化率以及产甲烷率公式进行计算,计算公式见文献[13]。

2 结果与讨论

2.1 长期厌氧消化性能

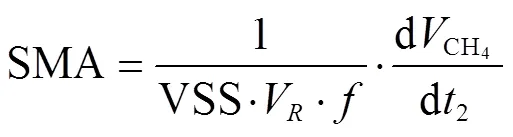

高固体浓度鸡粪进料厌氧消化反应器运行155 d,反应器发酵性能见图2及表2序号8。运行初期0~40 d,容积产气量由0.27 L/(L·d)逐渐上升至0.65 L/(L·d)(图2a),甲烷产率也由150 mL/g上升至405 mL/g,随后开始下降,60 d后甲烷产率稳定维持在315~330 mL/g左右(图2b)。整个运行周期的甲烷含量均在70% 以上,运行前40 d的甲烷含量达到81%,随后甲烷含量降至76%(图2c)。

另外,本文中采用长期运行的鸡粪发酵罐的沼液进行接种,该发酵罐的鸡粪进料TS浓度 10%, HRT 20 d,OLR 3 g/(L·d)。本试验中进料TS浓度升高至15%,OLR降低至1.5 g/(L·d),运行负荷比接种污泥之前所在的环境要低一些,这导致在进料运行初期,氨氮浓度还没有明显上升的情况下,有机物降解更加充分,有机酸浓度出现降低的趋势。随着发酵时间的延长,微生物系统进入持续稳定的发酵状态,有机酸浓度略有升高,并维持了稳定。在前40 d,TVFA平均浓度为420 mg/L,其中乙酸浓度为360 mg/L,占85%(图2d)。运行稳定期(40~150 d),TVFA浓度稳定在470 mg/L左右,仍以乙酸为主(85%),还有少量的丙酸(48 mg/L,10%),整个发酵过程的TVFA浓度均在较低水平。采用TS浓度低于10% 的鸡粪原料作为发酵基质,HRT设置为20~40 d,有机负荷为2.5~4 g/(L·d),TAN 为2.5~6.5 g/L,消化系统TVFA达到0.65~6.7 g/L之间[9-10, 14-19],可以看出,本试验设置进料TS为15%、HRT 60 d达到了与进料TS小于10%的鸡粪湿式厌氧消化系统接近的发酵性能。对于高固体浓度鸡粪进料厌氧消化,采取延长HRT 适当降低OLR的方式,能够实现发酵系统长期稳定运行。

由于接种污泥的TAN浓度较低(5.1 g/L),运行初期反应器中的TAN浓度也较低,0~40 d,反应器TAN浓度为5.8 g/L,随着反应器周期性进料,TAN浓度升高至7.5 g/L(图2e)。厌氧消化中,TAN主要以铵离子(NH4+)和游离氨(NH3, Free Ammonia Nitrogen, FAN)两种形式存在,发酵系统的TAN、pH值以及温度等影响着FAN的浓度,FAN被认为是对厌氧消化产生氨抑制的主要因 素[14-16],其浓度超过0.6 g/L就会对厌氧消化产生抑制作用[17]。本试验中,发酵液的FAN浓度由运行初期的1.5 g/L逐渐升高至2.6 g/L,pH值维持在8.3以上(图2f),消化系统有充足的碱度保障,发酵系统未出现氨抑制。表2比较了高固体浓度鸡粪进料中温(37℃)厌氧消化在不同TAN、FAN、OLR以及HRT条件下的发酵性能,HRT为20~30 d、有机负荷3.5~7.5 g/(L·d)、TAN 在6.0~ 12 g/L,甲烷产率普遍低于250 mL/g,VFA浓度积累超过25 g/L,发酵过程产生严重的氨抑制[9-10]。高固体浓度进料鸡粪厌氧消化,较短的HRT易造成氨抑制,发酵过程不易正常进行。

图2 容积产气量、甲烷产率、沼气成分、TVFA浓度、氨浓度以及pH值变化

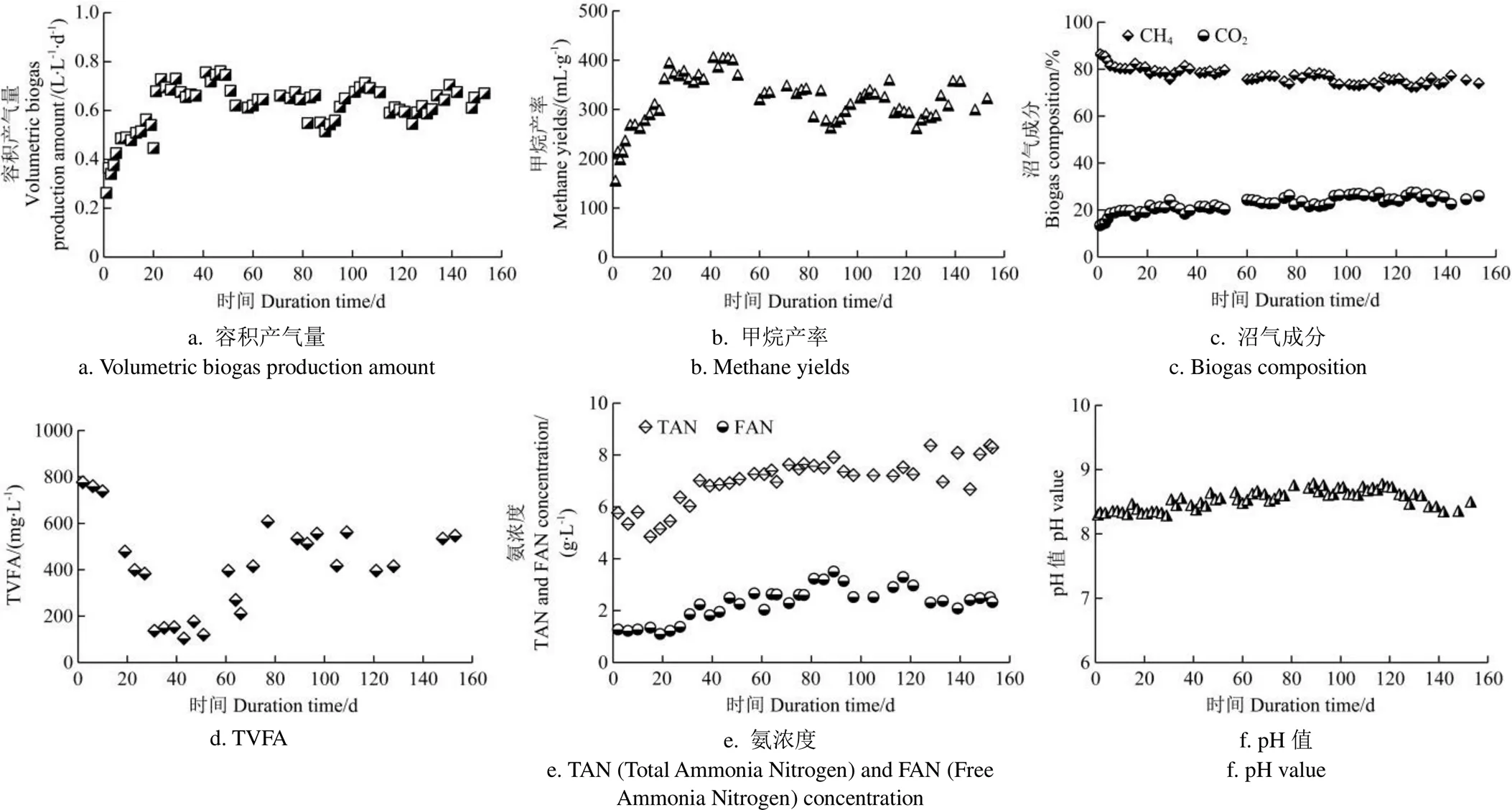

表2 鸡粪中温厌氧消化性能对比

2.2 长期运行的物质转化及物料平衡

通过高固体浓度鸡粪进料长期连续厌氧消化试验,基于物料平衡分析鸡粪原料的物质转化及利用情况,如图3所示。鸡粪原料水解率、酸化率以及产甲烷率分别为61%、47%和47%(图3a),原料酸化率和产甲烷率基本一致,证明TVFA保持较低的浓度,经过酸化阶段产生的挥发性脂肪酸基本都被转化为了甲烷。而当酸化率大于产甲烷率时,有机酸会大量积累,进一步抑制产甲烷菌活性,导致恶性循环[20-22]。鸡粪原料经过水解,酸化,乙酸化过程形成供产甲烷菌利用的代谢基质乙酸和氢气,而VFAs是厌氧消化过程物质转化重要的中间产 物[23-24],它是衡量水解、酸化过程的重要指标。有研究表明,当乙酸浓度高于2.3 g/L,丙酸浓度高于0.3 g/L或者丁酸浓度高于2.0 g/L时,产甲烷菌的活性就会受到抑制[25]。本试验中,TVFA的浓度为470 mg/L左右,残余TVFA占进料有机物总量0.5%以下,乙酸、丙酸是最主要的TVFA的组分,分别占85%和10%,其余组分仅占5% 左右(图3b)。另外,原料水解率较酸化率高14% 左右,证明部分鸡粪原料经过水解后没有被有效转化为有机酸,这部分未被酸化的有机物增加了出料的有机物浓度。高固体浓度鸡粪进料厌氧消化中,氨抑制影响着鸡粪原料的水解转化效率[26],有研究表明通过原位氨吹脱的处理方式降低鸡粪原料氨氮浓度,水解转化率能够达到70%以上[27]。进料TS含量也是影响鸡粪原料水解、酸化转化率的因素,在TS 5%和7.5%的进料条件下,鸡粪原料中超过60%的有机物能够被转化为CH4,水解转化率能够达到70%以上,酸化转化率和产甲烷率均可达到60%以上[28]。而对于高固体浓度鸡粪厌氧消化过程有机物质的转化情况,需要进一步考察鸡粪原料TS,TAN浓度与厌氧消化水解、酸化、产甲烷转化率的关系。

注:PCOD为固体中的化学需氧量 (chemical oxygen demand, COD);VFAs-COD是出料中VFAs对应的COD;CODCH4是根据标准条件下COD与产甲烷转化率系数计算得出的COD (350 mL/g);SCOD* = SCOD - VFAs-COD;PCOD = TCOD - SCOD。

根据对进出物料TS、VS以及COD的测定,计算发酵罐性能稳定时期(41~153 d)的物料平衡。进料中TCOD浓度为171 g/L,其中SCOD和PCOD的占比分别为26.5% 和73.5%。每日进料鸡粪TS和VS量分别为 10 g、6.1 g(VS/TS = 0.61),出料TS、VS量分别为3.8 g、2.3 g,TS和VS的去除率分别为62% 和66%(图3c),处理效果高于其他畜禽粪污(猪粪、牛粪等)厌氧消化VS的去除率[29]。连续发酵过程,PCOD、VFAs-COD、CODCH4分别占38.9%、0.3% 和47.4%(图3d)。在较短HRT条件下的鸡粪厌氧消化工艺中,鸡粪进料TS 为15%、HRT 20 d,PCOD、VFAs-COD、CODCH4分别占35%,8%和44%,VFAs-COD占比相比于本实验结果显著提 高[30]。每日沼气产量为2.5 L,其中CH4和CO2的含量分别为76.3%和23.7%(图4a)。所以,采用适当延长HRT适当降低发酵体系OLR的方式能够提高鸡粪物料的利用效率,缓解氨抑制程度,实现高固体浓度鸡粪进料发酵体系的稳定运行。

从进料物质平衡的角度来看,高固体浓度鸡粪进料厌氧消化过程与传统湿法厌氧消化相比,显著降低了原料的稀释用水和沼液产量,为工程应用提供了可能性[12,31],如图4b所示。鸡粪常被稀释到较低的TS(<10%)以避免氨抑制。将鸡粪从25% 稀释至8%(常规湿式厌氧消化),所需稀释水量约为2.13 m3/t,这在以前的文献中也有类似描述[31]。相比之下,在本研究中,TS稀释为15% 时,稀释用水量为0.67 m3/t,相应减少了69%的稀释水量和47%的沼液排放量,经济与环境效益显著。

a. 鸡粪代谢平衡图a. Chicken manure metabolism balance diagramb. 不同固体含量鸡粪厌氧消化物料平衡图b. Material balance diagram with different solid contents

2.3 乙酸产甲烷活性

乙酸是产甲烷菌可以直接利用的前体物质,污泥的乙酸产甲烷能力是反应污泥活性的重要参数。本试验采用乙酸钠为发酵基质,进行污泥产甲烷活性测试,并利用Gompertz模型拟合累积沼气产量、甲烷产量和产甲烷速率,同时利用一级动力学方程进行污泥活性的表征,如图5所示。乙酸浓度设置为2 000 mg/L,SMA值为0.042 g/(g·d),高于其他高固体浓度鸡粪进料厌氧消化的SMA值[11,30](0.032~0.042 g/(g·d))。用Gompertz模型计算(图5a),测得的累积沼气产量和累积甲烷产量分别为412、286 mL/g,模型决定系数2为0.998,拟合结果与实际值相吻合。另外,Gompertz模型显示产甲烷速率在5.1 d时达到最大35 mL/(g·d),发酵迟滞期为1.34 d,主要因为反应器长期运行时乙酸浓度较低(500 mg/L以下),污泥活性测试中乙酸浓度设置为2 000 mg/L,微生物需要适应一段时间才能够发挥较好的乙酸代谢作用。图5b 为乙酸产甲烷活性的一级动力学模拟结果,动力学常数为0.202 d-1,决定系数为0.982,拟合度也较高,说明乙酸降解过程符合一级动力学特征,产甲烷速率与乙酸浓度呈正相关。

图5 累积沼气产量和沼气产率以及一级动力学模型

3 结 论

1)通过采取延长水力停留时间(60 d)适当降低有机负荷的方式,在总氨氮为7.5 g/L的条件下实现了高固体浓度进料(TS 15%)鸡粪厌氧消化的长期稳定运行,甲烷产率达到326 mL/g。

2)鸡粪原料水解率、酸化率以及产甲烷率分别为61%、47% 和47%,TVFA低于500 mg/L,系统未出现氨抑制和有机酸积累。污泥SMA值为0.042 g/(g·d),具有良好的乙酸代谢活性。

3)高固体浓度鸡粪进料厌氧消化与常规湿式厌氧消化相比具有稀释水量少、沼液产量小等优点,具备经济效益和环境效益的双重优势。

[1] 乔玮,毕少杰,尹冬敏,等. 鸡粪中高温厌氧甲烷发酵产气潜能与动力学特性[J]. 中国环境科学,2018,28(1):234-243.

Qiao Wei, Bi Shaojie, Yin Dongmin, et al.Biogas production potential and kinetics of chicken manure methane fermentation under mesophilic and thermophilic conditions[J].China Environmental Science, 2018, 28(1): 234-243.

[2] Fuchs W, Wang X, Gabauer W, et al. Tackling ammonia inhibition for efficient biogas production from chicken manure: Status and technical trends in Europe and China[J]. Renewable and Sustainable Energy Reviews, 2018, 97: 186-199.

[3] Shen X, Huang G, Yang Z, et al. Compositional characteristics and energy potential of Chinese animal manure by type and as a whole[J]. Applied Energy, 2015, 160: 108-119.

[4] Choi H, Sudiarto S, Renggaman A, Prediction of livestock manure and mixture higher heating value based on fundamental analysis[J]. Fuel, 2014, 116: 772-780.

[5] Calli B, Mertoglu B, Inanc B, et al. Effects of high free ammonia concentrations on the performances of anaerobic bioreactors[J]. Process Biochemistry, 2005, 40(3/4): 1285-1292.

[6] Yu Q, Sun C, Liu R, et al. Anaerobic co-digestion of corn stover and chicken manure using continuous stirred tank reactor: The effect of biochar addition and urea pretreatment - ScienceDirect[J]. Bioresource Technology, 2020, 319: 124197.

[7] Duan N, Dong B, Wu B, et al. High-solid anaerobic digestion of sewage sludge under mesophilic conditions: Feasibility study[J]. Bioresource Technology, 2012, 104: 150-156.

[8] Bujoczek G, Oleszkiewicz J, Sparling R, et al. High Solid Anaerobic Digestion of Chicken Manure[J]. Journal of Agricultural Engineering Research, 2000, 76(1): 51-60.

[9] Bi S, Qiao W, Xiong L, et al. Improved high solid anaerobic digestion of chicken manure by moderate in situ ammonia stripping and its relation to metabolic pathway[J]. Renewable energy, 2020, 146(2): 2380-2389.

[10] Pan J, Ma J, Zhai L, et al. Enhanced methane production and syntrophic connection between microorganisms during semi-continuous anaerobic digestion of chicken manure by adding biochar[J]. Journal of Cleaner Production, 2019, 240: 118178.

[11] Wandera S M, Qiao W, Algapani D E, et al. Searching for possibilities to improve the performance of full scale agricultural biogas plants[J]. Renewable energy, 2018, 116: 720-727.

[12] Bi S, Westerholm M, Qiao W, et al. Metabolic performance of anaerobic digestion of chicken manure under wet, high solid, and dry conditions[J]. Bioresource Technology, 2020, 296: 122342.

[13] Xiao B, Qin Y, Wu J, et al. Comparison of single-stage and two-stage thermophilic anaerobic digestion of food waste: Performance, energy balance and reaction process[J]. Energy Conversion and Management, 2017, 156: 215-223.

[14] Kadam P C, Boone D R, Influence of pH on Ammonia Accumulation and Toxicity in Halophilic, Methylotrophic Methanogens[J]. Applied & Environmental Microbiology, 1996, 62(12): 4486-4492.

[15] Wiegant W M, Zeeman G, The mechanism of ammonia inhibition in the thermophilic digestion of livestock wastes[J]. Agricultural Wastes, 1986, 16(4): 243-253.

[16] Sun C, Cao W, Banks C J, et al. Biogas production from undiluted chicken manure and maize silage: A study of ammonia inhibition in high solids anaerobic digestion[J]. Bioresour Technol, 2016, 218: 1215-1223.

[17] Angelidaki I, Ahring B K, Anaerobic Thermophilic Digestion of Manure at Different Ammonia Loads: Effect of Temperature[J]. Water Research, 1994, 28(3): 727-731.

[18] Ama B, Sba C, Ysa C, et al. Overcome inhibition of anaerobic digestion of chicken manure under ammonia-stressed condition by lowering the organic loading rate - ScienceDirect[J]. Bioresource Technology Reports, 2020, 9: 1-8.

[19] Recep Nder S, Bayrakdar A, Molaey R, et al. Synergistic Effect of Sulfide and Ammonia on Anaerobic Digestion of Chicken Manure[J]. Waste and Biomass Valorization, 2019, 10(1): 1-7.

[20] Bayrakdar A, Molaey R, Sürmeli R Ö, et al. Biogas production from chicken manure: Co-digestion with spent poppy straw[J]. International Biodeterioration & Biodegradation, 2016, 119: 205-210.

[21] Bayrakdar A, Molaey R, Öndersürmeli R, et al. Biogas production from chicken manure: Co-digestion with spent poppy straw[J]. International Biodeterioration & Biodegradation, 2017, 119: 205-210.

[22] Mahdy A, Bi S, Song Y, et al. Overcome inhibition of anaerobic digestion of chicken manure under ammonia-stressed condition by lowering the organic loading rate - ScienceDirect[J]. Bioresource Technology Reports, 2020, 9: 100359.

[23] Ye C, Cheng J J, Creamer K S, Inhibition of anaerobic digestion process: A review[J]. Bioresour Technol, 2008, 99(10): 4044-4064.

[24] Azbar N, Ursillo P, Speece R E, Effect of process configuration and substrate complexity on the performance of anaerobic processes[J]. Water Research, 2001, 35(3): 817-829.

[25] 任南琪,王爱杰. 厌氧生物技术原理与应用[M]. 北京:化学工业出版社,2004.

[26] Wei Y, Yuan A C W H, Li X, Enhanced hydrolysis and acidification strategy for efficient co-digestion of pretreated corn stover with chicken manure: Digestion performance and microbial community structure[J]. Science of the Total Environment, 2020, 720: 137401.

[27] Yin D, Qiao W, Negri C, et al. Enhancing hyper-thermophilic hydrolysis pre-treatment of chicken manure for biogas production by in-situ gas phase ammonia stripping[J]. Bioresource technology, 2019, 287: 121470.

[28] Bi S J, Qiao W, Xiong L P, et al. Effects of organic loading rate on anaerobic digestion of chicken manure under mesophilic and thermophilic conditions[J]. Renewable Energy, 2019, 139: 242-250.

[29] 野池达野. 甲烷发酵[M]. 北京:化学工业出版社,2014.

[30] 乔玮,熊林鹏,毕少杰,等. 梯度提高进料浓度对鸡粪连续中温发酵产甲烷的影响[J]. 农业工程学报,2018,34(9):233-239.

Qiao Wei, Xiong Linpeng, Bi Shaojie, et al.Effect of gradually raising feeding total solid on methane production during continuous mesophilic fermentation of chicken manures[J].Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(9): 233-239.

[31] Nie H, Liebetrau J, Xu C, et al. Mono-fermentation of chicken manure: Ammonia inhibition and recirculation of the digestate[J]. Bioresource Technology, 2015, 178: 238-246.

Continuously operated process performance of anaerobic digestion of chicken manure with feeding high solid concentration

Song Yapeng1,2, Qiao Wei1,2※, Hu Wanrong3, Dong Renjie1,2

(1.College of Engineering, China Agricultural University, Beijing 100083, China;2 .Research & Development Center for Efficient Production and Comprehensive Utilization of Biobased Gaseous Fuels, Energy Authority, National Development and Reform Committee, China Agricultural University, Beijing 100083, China; 3. School of Water Resources and Environment, China University of Geosciences(Beijing), Beijing 100083, China)

Chicken manure contains a lot of easily degradable organic matter suitable for anaerobic digestion (AD). But, a high concentration of ammonia nitrogen has posed a great challenge to the AD process. Diluting with water can be used to increase the influent volume. Correspondingly, the subsequent digestate yield can be reduced with the decrease of the nitrogen content, as well as the nutritional value of organic fertilizer. It is very necessary to balance between the dilution water and the solid concentration of feedstock for a higher solid AD process. However, only a few studies are reported on the high solid chicken manure AD at present. It is still lacking on the performance of AD under the feedstock with solid concentration, organic load, ammonia nitrogen concentration, and their synergistic effects. In this study, a long-term experiment was carried out to establish the stable and operational high solid AD process of chicken manure. The chicken manure with a high total solid (TS 15%) was also disposed of by the AD process under the hydraulic retention time (HRT) of 60 d through 155 days. The experimental results showed that the methane yield was 326 mL/g (Volatile Solids, VS) under the organic load rate (OLR) of 1.5 g/(L·d) and the total ammonia nitrogen (TAN) concentration of 7.5 g/L. The concentration of total volatile fatty acids (TVFA) was about 470 mg/L, and the pH was above 8.3, indicating the stable operation with low TVFA residues. The hydrolysis, acidogenesis, and methanogenesis efficiencies of chicken manure were 61%, 47%, and 47%, respectively. Among them, the same acidogenesis and methanogenesis efficiencies indicated that the TVFA maintained a low concentration because the TVFA production through the acidogenic phase was been mostly converted into methane. The relationship was also determined between the concentration of TS and TAN chicken manure with the conversion efficiencies of the hydrolysis, acidogenesis, and methanogenesis. The AD performance was also evaluated under different chemical oxygen demand (COD) concentrations of the influent and effluent. The total COD (TCOD) concentration of the feedstock was 171 g/L. The proportions of soluble COD (SCOD) and particulate COD (PCOD) were 26.5% and 73.5%, respectively. In the long-term AD process, the PCOD, VFA-COD, and CH4-COD accounted for 38.9%, 0.3%, and 47.4%, respectively. The biogas production was 2.5 L/d, including 76.3% CH4and 23.7% CO2. The specific methanogenic activity (SMA) of the anaerobic sludge was 0.042 g/(g·d), indicating superior metabolic activity. The accumulation biogas yield and accumulation methane yield were 412 mL/g and 286 mL/g, respectively. The model fitting coefficient2was 0.998 by the Gompertz model. The kinetic constant was 0.202 d-1and the correlation coefficient was 0.982 by the first-order model. Consequently, the degradation process of acetate was in line with the first-order kinetic characteristics, where the methane production rate was positively correlated with the concentration of acetate. The high solid AD of chicken manure can be widely expected to tolerate the extremely high concentration of ammonia nitrogen. Therefore, the improved AD can be used to greatly reduce the dilution water of feedstock and the digestate yield, compared with the conventional. This finding can also provide a promising potential for the engineering application of AD chicken manure in biogas plants.

manures; anaerobic digestion; high total soild concentration; SMA; mass balance

10.11975/j.issn.1002-6819.2021.21.027

X712

A

1002-6819(2021)-21-0237-07

宋亚朋,乔玮,胡婉蓉,等. 鸡粪高固体浓度进料厌氧消化连续运行性能[J]. 农业工程学报,2021,37(21):237-243.doi:10.11975/j.issn.1002-6819.2021.21.027 http://www.tcsae.org

Song Yapeng, Qiao Wei, Hu Wanrong, et al.Continuously operated process performance of anaerobic digestion of chicken manure with feeding high solid concentration[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(21): 237-243. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2021.21.027 http://www.tcsae.org

2021-07-19

2021-10-10

北京市自然科学基金(6182017)

宋亚朋,博士生,研究方向为鸡粪厌氧处理。Email:1053097879@qq.com

乔玮,博士,教授,研究方向为废水和废弃物的厌氧生物处理。Email:qiaowei@cau.edu.cn; wayqiao@sina.cn