Microstructure of high thermal conductivity mesophase pitch-based carbon fibers

YE Chong ,WU Huang ,ZHU Shi-peng ,FAN Zhen ,HUANG Dong, ,HAN Fei ,LIU Jin-shui,,YANG Jian-xiao,LIU Hong-bo

(1.College of Materials Science and Engineering, Hunan University, Changsha 410082, China;2.Hunan Province Engineering Research Center for High Performance Pitch Based Carbon Materials,Hunan Toyi Carbon Material Technology Co., Ltd., Changsha 410000, China;3.Hunan Province Key Laboratory for Advanced Carbon Materials and Applied Technology, Hunan University, Changsha 410082, China;4.Key Laboratory of Advanced Functional Composite Materials, Aerospace Research Institute of Materials and Processing Technology, Beijing 100076, China)

Abstract:The microstructural characteristics of high thermal conductivity mesophase pitch-based carbon fibers were investigated by XRD,Raman spectroscopy,SEM and TEM.The relationship between microstructural characteristics and thermal conductivity is discussed.Results show that the radial structure is always accompanied by a splitting stucture.La has more significant impact on the thermal conductivity than Lc.The Raman spectroscopy ID/IG value of the cross section was used as an essential index to evaluate the thermal conductivity of the carbon fibers.The microstructural characteristics including large graphite crystallite size,high preferred orientation along the fiber axis,and few defects contribute to the high thermal conductivity of the carbon fibers.

Key words:Microstructure;Mesophase pitch;Carbon fiber;High thermal conductivity

1 Introduction

Mesophase pitch-based carbon fibers have higher Young’s modulus and thermal conductivity compared with polyacrylonitrile-based carbon fibers,owing to their well-developed graphite crystallites and highly oriented crystalline along the fiber axis.These superior properties allow mesophase pitch-based carbon fibers to be widely used in the fields of aerospace vehicles,electronic devices,and so on[1–3].The high performance mesophase pitch-based carbon fibers are usually fabricated by a series of processes including pitch-synthesis,melt-spinning,pre-oxidation,carbonization,graphitization,surface treatment,and so on.Among them,melt-spinning plays a crucially important role in controlling the microstructures and physical property of mesophase pitch-based carbon fibers.Until now,several various microstructural characteristics have been widely reported,such as the random structure,radial structure,onion-skin structure,flatlayer structure and folded-radial structure,and these microstructural characteristics are highly dependent on the melt-spinning conditions[4,5].

Many studies have focused on the effects of melt-spinning technological parameters,spinneret design and chemical composition of pitch on the microstructures and properties of the mesophase pitchbased carbon fibers[6–10].Compared with chemical composition of mesophase pitch,melt-spinning is a direct and effective approach to control the microstructure and properties of carbon fibers.Many researchers investigated the relationship between the typical microstructures of the mesophase pitch-based carbon fibers and the corresponding properties.The microstructure of mesophase pitch-based carbon fibers with ultra-high modulus was studied by Morinobu Endo[11].The relationship between the microstructure and the mechanical property of different carbon fibers (P25,P55,P75,P100 and P120,Cytec),with thermal conductivities in the range of 97−640 W·m−1·K−1,was investigated by Yanling Huang[12].The microstructural difference of the mesophase pitch-based fibers (E01,E35,E55,E75,E105,E120,E130,DU PONT) was also examined by G.M.Pennock[13].Although much data have been reported in the literature on the microstructures of mesophase pitch-based carbon fibers,there are few reports on the microstructural features of the high thermal conductive mesophase pitch-based carbon fibers,especially for ultra-high thermal conductive (≥600 W·m−1·K−1)carbon fibers.To obtain a high thermal conductivity,it is necessary to systematically explore the microstructures of mesophase pitch-based carbon fibers in terms of the degree of graphitization,crystalline size,and preferred orientation.

In the present work,the relationship between microstructural characteristics and thermal conductivity of mesophase pitch-based carbon fibers was investigated.The morphology,crystalline size,preferred orientation,and other microstructural characteristics of the carbon fibers were systematically analyzed by XRD,Raman spectroscopy,SEM and TEM.This work will provide meaningful guidance for the fabrication of the high thermal conductive mesophase pitchbased carbon fibers.

2 Experimental

2.1 Materials

Five kinds of high thermal conductive mesophase pitch-based carbon fibers were employed in this work.The fibers were XN-90 (Nippon Graphite Fiber Corp),K13C2U (Mitsubishi Chemical Functional Products Inc.),K13D2U (Mitsubishi Chemical Functional Products Inc.),K1100 (Cytec) and HNU-3000(homemade) respectively.

2.2 Microstructural characterization

Crystallite structural parameters were tested by X-ray diffraction (XRD) on a D/Max-2550 PC diffractometer apparatus with CuKα radiation (λ=0.154 184 nm) with Si as an internal standard.Interlayer spacingd002,crystalline sizes (La,Lc) and degree of graphitization (g) were calculated based on the XRD data[14].Misorientation angles (Z) of graphene sheets with reference to the fiber axis were measured by full width at half maxima (FWHM) of the diffraction profile from the azimuthal scan.

Morphology and microstructures of the fibers were examined by scanning electron microscopy(SEM,NOVA 400 NANO),transmission electron microscopy (TEM,Titan G260-300) and Raman spectroscopy (Horiba JY,XploRA,λ=633 nm),respectively.

2.3 Thermal conductivity test

Thermal conductivity of the carbon fibers was obtained by an indirect method.The axial electrical resistivity of carbon fibers was measured with a fourprobe method,and the thermal conductivity values were calculated by different empirical formulas.The calculated values were compared with the manufacturers’ data[15–17].

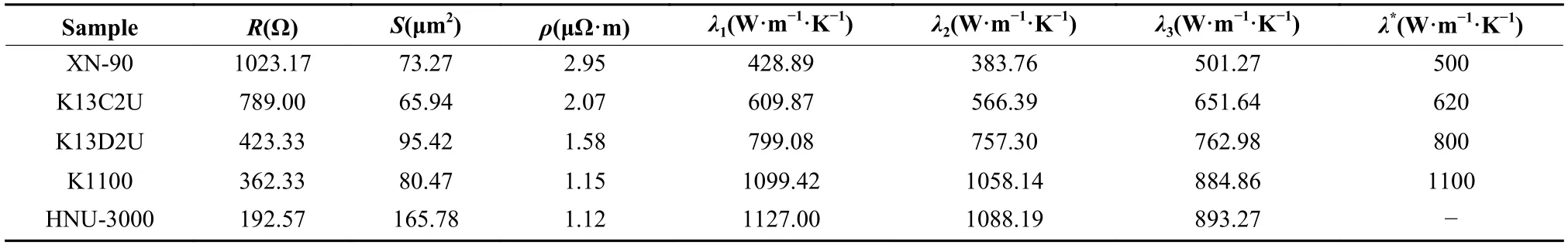

The empirical formulaλ1=1261/ρwas established by Zhang X[18].λ2=1272.4/ρ−49.4 was established by Yamamoto[19],andλ3=440000/(100ρ+258)−295 was created by Lavin[20].The results show that the thermal conductivity values calculated from the formulaλ1=1261/ρare consistent with the reported values when the thermal conductivity exceeds 600 W·m−1·K−1.When the thermal conductivity is less than 600 W·m−1·K−1,the formulaλ=440000/(100ρ+258)−295 is more accurate.The properties of the 5 mesophase pitch-based carbon fibers are listed in Table 1.

Table 1 Properties of the five types of mesophase pitch-based carbon fibers.

3 Results and discussion

3.1 SEM

SEM micrographs and schematic diagrams of these carbon fibers are shown in Fig.1.It can be seen that all the fibers present obvious graphite layer-structure.XN-90,K13C2U,and K13D2U are all roundshape,while K1100 and homemade HNU-3000 exhibit a round-split structure.Some irregular hole-defects are observed on the cross section of XN-90 .The outer region of XN-90 exhibits a folded-radial structure,while the central region shows onion-skin structure(Fig.1(a)).Both K13C2U and K13D2U present visible folded-like structure.It should be noted that the graphite layers in the outer region of K13D2U are larger in size and more ordered along the axial direction in comparison with K13C2U (Fig.1(b) and Fig.1(c)).As a result,K13D2U possess higher thermal conductivity than K13C2U.Both K1100 and HNU-3000 present well-developed graphite layers,as shown in Fig.1(d) and Fig.1(e).Notably,K1100 show a perfect radial-split structure.However,HNU-3000 seems to be folded-radial structure with the thicker graphite layers.Among these 5 types of fibers,K1100 and HNU-3000 have the largest graphite layer,the highest orientation and the highest thermal conductivity.Based on the above results,it can be found that the orientation and size of the graphite layers are highly correlated with the thermal conductivity of the carbon fibers,and the carbon fibers with a radial structure unavoidably exhibit wedge-splitting features.

Fig.1 SEM micrographs and sketches of mesophase pitch-based carbon fibers:(a) XN-90,(b) K13C2U,(c) K13D2U,(d) K1100 and (e) HNU-3000.

3.2 XRD

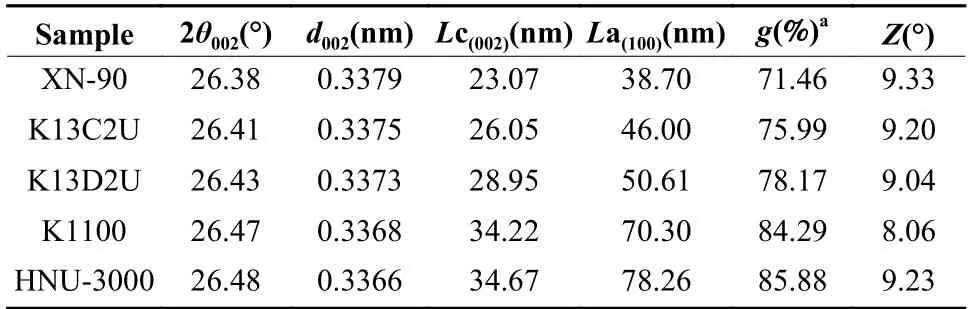

The XRD patterns of the carbon fibers are shown in Fig.2.As seen,all of the 5 types of carbon fibers exhibit narrow and sharp peak of (002) and distinct peak of (004) in the equatorial scan patterns (Fig.2(a)),indicating the large crystallite size and small interlayer spacing.The results demonstrate that the graphite layers are compactly stacked and orderly aligned along the fiber axis direction.

Fig.2(b) displays the meridional scan patterns of the 5 kinds of carbon fiber.The diffraction peaks of(100) and (101) planes are clearly displayed in these patterns,indicating the three-dimensional ordered structure of the graphite crystallites in all the 5 kinds of carbon fiber.

The misorientation angle Z is determined by FWHM of the diffraction profile from the azimuthal scan (Fig.2(c)),as listed in Table 2.Among them,the Z value of K1100 carbon fiber is the smallest,indicating the highest orientation degree of the graphite layers in K1100.In XN-90,K13C2U,K13D2U and K1100,the Z value gradually decreases and the thermal conductivity increases in turn.However,it is interesting to find that HNU-3000 have a larger Z value than K13C2U,K13D2U and K1100,which does not agree with the above mentioned results.This result is attributed to the larger graphite layers in HNU-3000,which inhibits the regular arrangement of graphite crystallites along the fiber axis direction during graphitization.

Fig.2 XRD patterns of the five kinds of carbon fiber with high thermal conductivities:(a) Equatorial scan,(b) Meridional scan,(c) Azimuthal scan on (002) crystal face and (d) powder diffraction.

Table 2 Crystalline parameters and degree of graphitization of carbon fibers.

As shown in Fig.2(d),the (002) peak is narrow and sharp,and the (004) peak can also be clearly seen in all the fibers.The interlayer spacing ofd002,graphene-layer stacking height ofLc,graphite crystallite width ofLa and graphitization degree ofgare calculated according to the XRD powder diffraction patterns,as listed in Table 2.From Table 1 and 2,it can be found that theLa,Lc andgvalues all have positive correlations with thermal conductivity of the fibers,while thed002value has a negative correlation with it.Considering the largerLa,smallerLc and higher thermal conductivity in HNU-3000 than K1100,it can be concluded that theLa has more significant impact on the thermal conductivity than theLc.Smallerd002,largerLa,Lc andgmean more perfect crystal with fewer defects,contributing to the increase of the mean free path and the decrease of the scattering of phonons,further leading to higher thermal conductivity[21,22].

3.3 Raman spectra

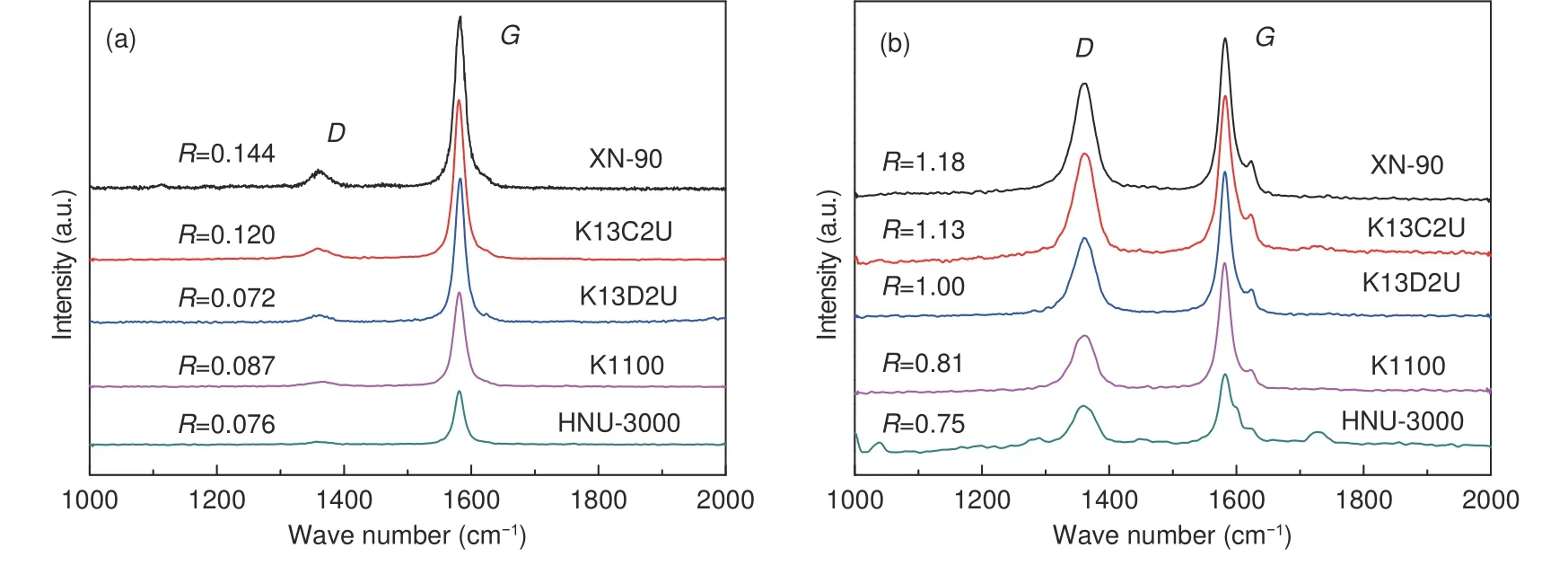

Fig.3 shows Raman spectra of the 5 kinds of carbon fibers on their surface (Fig.3(a)) and cross section (Fig.3(b)).Dpeak at 1 360 cm−1represents the number of the disordered layer structures,which is caused by lattice defects,small sizes of crystallites and low degrees of orientation.TheGpeak at 1 580 cm−1is attributed to the in-plane bond-stretching vibration of sp2-hybridized C atoms.The intensity ratio ofDpeak toGpeak,denoted asID/IG,is defined as the degree of disorderR[23].There is a negative correlation between the thermal conductivity andRon the cross section of the 5 kinds of fiber.A smallerRvalue in carbon fiber represents a higher thermal conductivity.The difference ofRvalues on the surface and cross section is mainly ascribed to the skin-core structure in the carbon fibers.It is worth noting that K1100 and HNU-3000 have largerRvalues on the surface but smallerRvalues on the cross section compared with K13D2U.It is believed thatRvalue on the cross section can be used as an important index to evaluate the thermal conductivity of carbon fibers.

Fig.3 Raman spectra of the 5 kinds of carbon fiber:(a) surface and (b) cross section.

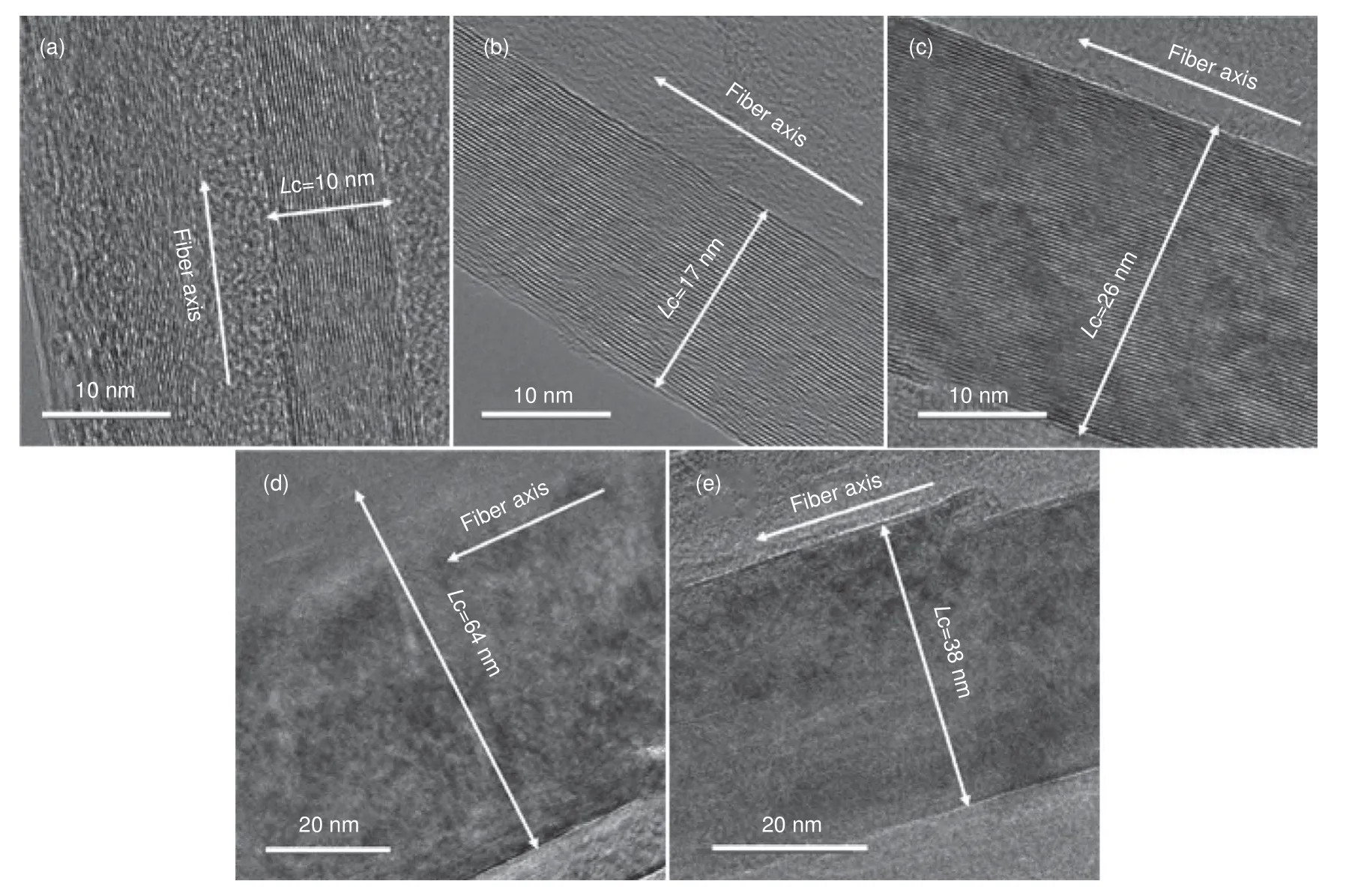

3.4 HRTEM

The HRTEM micrographs of the 5 kinds of carbon fibers are shown in Fig.4.As seen,all the carbon fibers present an ordered lattice structure along the fiber axis direction.There is a positive correlation between the thermal conductivity and crystal size.The result well agrees with theLc values from XRD analysis in Table 2.In addition,many crystalline defects such as distortion,disorientation,dislocation and discontinuity of crystallites can also be found in HRTEM images.In particular,the crystalline defects in K1100 and HNU-3000 are rarely found.Considering the thermal conductivity,it is evident that fewer crystalline defects will bring higher thermal conductivity.

Fig.4 HRTEM images of the five kinds of carbon fiber:(a) XN-90,(b) K13C2U,(c) K13D2U,(d) K1100 and (e) HNU-3000.

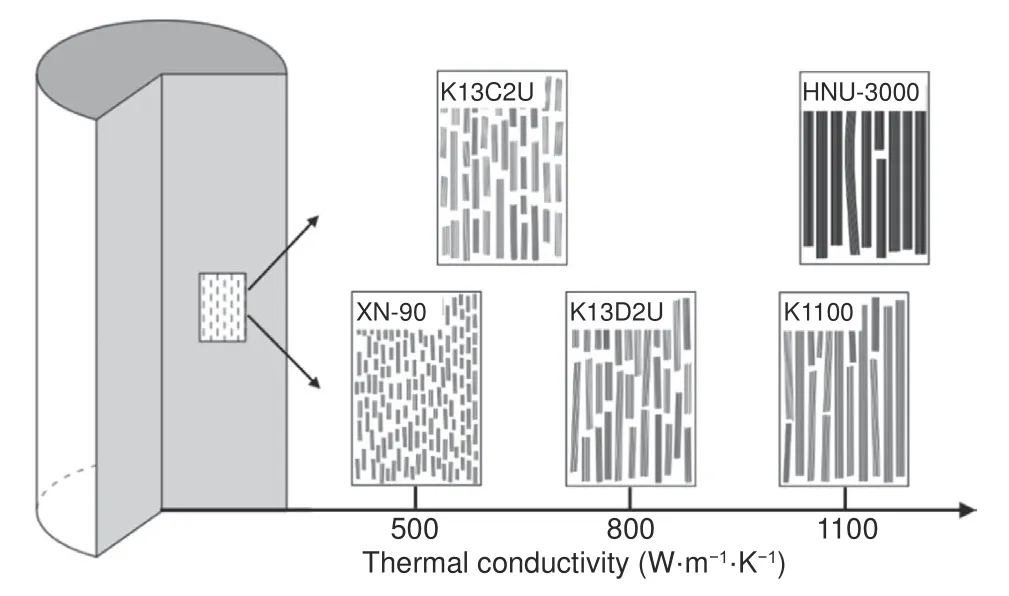

Based on the above analysis,the axial structural characteristics of the 5 high thermal conductive carbon fibers are depicted in Fig.5.For the 5 kinds of mesophase pitch-based carbon fiber,the large graphite crystalline size,high preferred orientation degree along the axis direction,and few crystalline defects in carbon fibers lead to the high thermal conductivity.

Fig.5 Sketches of the crystallite structure in the longitudinal section for the high thermal conductive carbon fibers.

4 Conclusion

Based on the comparison of the five kinds of different high thermal conductive mesophase pitch-based carbon fiber in this work,it is found that the homemade HUN-3000 carbon fiber possesses the highest thermal conductivity of 1 127 W·m−1·K−1.The result shows that the radial structure is always accompanied by a split structure and high thermal conductivity.La has more significant impact on the thermal conductivity than theLc.Smallerd002,largerLa,Lc andgmean more perfect crystal structures with fewer defects,thus contributing to the increase of mean free path and the decrease of the scattering of phonons,leading to higher thermal conductivity.Rvalue on the cross section can be used as the important index to evaluate the thermal conductivity of carbon fibers.The microstructure of the carbon fibers with a large graphite crystallite size,high preferred orientation degree along the axis direction,and few crystalline defects is conductive to the high thermal conductivity.

Acknowledgements

The Innovation and Entrepreneurship Investment Project of Hunan Provincial Science and Technology Department (2018GK5065);Special Fund for Innovative Construction Province of Hunan(2019GK2021,2019RS2058).

- 新型炭材料的其它文章

- Properties and microstructures of a matrix graphite for fuel elements of pebble-bed reactors after high temperature purification at different temperatures

- 高导热聚酰亚胺石墨膜/环氧树脂复合材料的制备与性能表征

- TiC-modified CNTs as reinforcing fillers for isotropic graphite produced from mesocarbon microbeads

- One-pot modified“grafting-welding”preparation of graphene/polyimide carbon films for superior thermal management

- Thermal conductivity of graphite nanofibers electrospun from graphene oxide-doped polyimide

- A mini review:application of graphene paper in thermal interface materials