A mini review:application of graphene paper in thermal interface materials

LU Le,DAI Wen,*,YU Jin-hong,JIANG Nan,*,LIN Cheng-te,*

(1.Key Laboratory of Marine Materials and Related Technologies, Zhejiang Key Laboratory of Marine Materials and Protective Technologies,Ningbo Institute of Materials Technology and Engineering, Chinese Academy of Sciences, Ningbo 315201, China;2.Center of Materials Science and Optoelectronics Engineering, University of Chinese Academy of Sciences, Beijing 100049, China)

Abstract:Accumulated heat is the primary problem that needs to be solved in current electronic products.There is an urgent need for designing innovative high-performance thermal interface materials (TIMs) with excellent heat dissipation performance.Based on the development status of TIMs,graphene paper-based TIMs that are ultrathin thickness and have high through-plane thermal conductivity show great potential.From this perspective,we introduce four types of graphene paper (including graphene/polymer composite papers,graphene/metal composite papers,graphene/ceramic composite paper,and graphene/carbon composite paper) and vertically aligned graphene paper as TIMs.Based on the applications of these TIMs,their advantages and limitations are discussed.Finally further research prospects are proposed to promote the practical applications of graphene paper-based TIMs.

Key words:Thermal interface materials;Graphene paper;Thermal conductive interlayers

1 Introduction

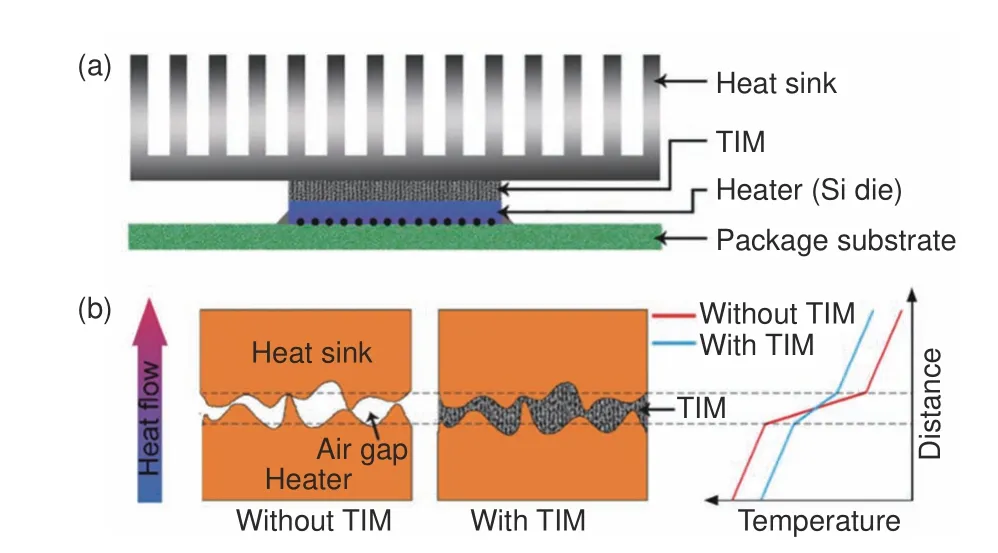

Currently,solving the problem of heat accumulation is the primary task for achieving electronic products with good performance and long lifetimes,because electronics have become more intelligent,miniaturized and integrated[1,2].In an actual thermal management system (Fig.1(a)),there are micro gaps between the heater and heat sink due to mechanical processing and other reasons,which seriously affects heat conduction[3,4].Using flexible TIMs with high through-plane thermal conductivity to fill these micro gaps can effectively remove the heat generated by the heating element (Fig.1(b))[5–7].Compared with other TIMs,the thermal pads have the advantages of no pump-out effect and convenient replacement.Commercial thermal pads with a thermal conductivity of 1–5 W m−1K−1are made of thermally conductive filler in a polymer matrix,but the high degree of cross-linking of the polymer results in thick bond line thickness[8,9].However,with the upgrading of electronic equipment,the accompanying ultrahigh power density has exceeded the processing capacity of traditional commercial TIMs[6].

Fig.1 (a) Schematic diagram of a typical ball grid array electronic package (b) Schematic diagram of a TIM filling the air gap between the heater and mating interface of the heat sink.Reprinted with permission from:(a,b)Reference[3],Copyright 2018,MDPI.

In recent years,graphene paper prepared by stacking graphene nanosheets (3 500–5 300 W m−1K−1)with ultrahigh intrinsic thermal conductivity has been widely used as an efficient heat sink for portable devices[10–12].Many researchers have turned their attention to the development of graphene paper.Meanwhile,the thermal resistance of the corresponding graphene/metal interface is determined by the electron-phonon coupling effect,which is one of the main problems in the study of thermal boundary conductance[11–14].Graphene papers as TIMs can be used to connect to a metal heat sink to achieve direct contact between the horizontal graphene and metal.Based on the ultra-high in-plane thermal conductivity of graphene paper,the ease of large-scale preparation and low production costs,the possibility for the practical application TIMs in academic circles and industry is rising[15–18].From this perspective,we focus on 4 graphene papers (including graphene/polymer,graphene/metal,graphene/ceramic,and graphene/carbon composite paper) and vertically aligned graphene paper as TIMs,then review their development.Additionally,we discuss their advantages and limitations.We hope to provide some assistance for the further development of graphene paper-based TIMs.

2 Hybrid graphene paper

The graphene/graphene oxide (GO) nanosheets exfoliated by chemical or thermal treatment receive different interactions (such as van der Waals (vdW)forces and hydrogen bonds)[19],and can be spontaneously or passively arranged to form a well-oriented layer structure.Based on this,many different assembly processes have been developed to produce graphene paper,such as electrospinning[20],vacuum filtration[21–23],wet spinning[24],inkjet printing[25],dip coating[26]and spin coating[27].After the graphene papers were annealed by high temperature,the defects of graphene are healed and their crystallinity were improved[28].The graphene papers have the high heat transfer at the in-plane direction.However,the phonon transport barrier across the vdW interface between the graphene layers leads to the extremely low through-plane thermal conductivity of the graphene paper (0.1–3.4 W m−1K−1)[18,28,29].Moreover,during the compression process,due to the rearrangement of the graphene orientation,the vertical thermal conductivity of the graphene paper is further reduced[13].To date,various thermally conductive interlayers materials,such as carbon materials (CNTs,carbon fibres,graphene,etc.),ceramic particles,metals and polymer chains,have emerged to make graphene-based paper with improved through-plane thermal conductivity and using vertically aligned graphene paper as TIMs is the research focus.

2.1 Graphene/polymer composite paper

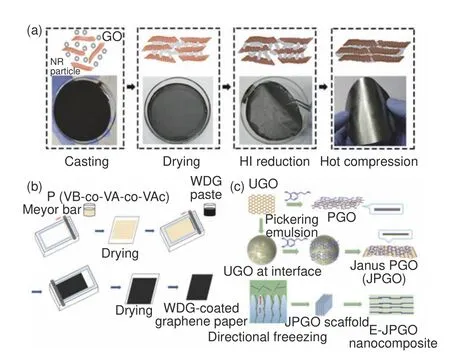

In many studies,graphene/GO and polymers were mixed to prepare graphene/polymer composite papers to enhance their mechanical properties.Inspired by the layered structure of natural nacre,natural rubber as a flexible matrix is compounded with graphene nanosheets (Fig.2(a)),and this paper exhibits excellent flexibility[30].In another study,a graphene-based TIM hybrid paper was fabricated by a coating or slot die-coating method (Fig.2(b))[31].A poly (vinyl butyral-co-vinyl alcohol-co-vinyl acetate)(P(VBcoVA-co-VAc)) copolymer was used as an adhesion layer to attach to the surface of graphene nanosheets.However,the two methods did not show any appreciable increase in the through-plane conductivity.This unsatisfactory progress is mainly attributed to the strong interfacial phonon scattering of the polymer and graphene leading.Polydopamine and graphene oxide have good interfacial interactions.As shown in Fig.2(c),Wang et al.[32]fabricated graphene composite paper based on asymmetrically polydopamine-functionalized Janus graphene oxide scaffolds via the bidirectional freeze-casting method,improving the high through-plane thermal conductivity of the paper from 0.20 to 0.78 W m−1K−1.Surprisingly,the paper exhibits electrical insulation properties (>1014Ω cm).In addition,some studies have confirmed that modification of cellulose nanofibers can enhance the through-plane thermal conductivity by forming a"bridge" between graphene nanosheets.Chen et al.[33]produced a flexible graphene/cellulose nanofiber (CNFG) composite paper by simple vacuum-assisted filtration.The through-plane thermal conductivity of the CNFG composite paper loaded with 50 wt% graphene reached 5 W m−1K−1and slightly changed after thousands of bending cycles.Due to the difficulty of graphene dispersion in a polymer matrix and the low thermal conductivity of the polymer,the throughplane thermal conductivity of the graphene/polymer composite paper is lower than that of commercial TIMs (~5–10 W m−1K−1),leading to insufficient heat transfer requirements in practical applications.As the poor conductors of heat,polymers are not suitable thermal conductive interlayers,but a small amount can be added to enhance the strength of graphene papers.

Fig.2 Manufacturing method and corresponding structure of the polymer to improve the through-plane thermal conductivity of graphene paper:(a)natural rubber,(b) P(VBcoVA-co-VAc),and (c) polydopamine.Reprinted with permission from:(a) Reference[30],Copyright 2019,American Chemical Society;(b) Reference[31],Copyright 2019,Elsevier;and (c) Reference[33],Copyright 2018,Royal Society of Chemistry.

2.2 Graphene/metal composite paper

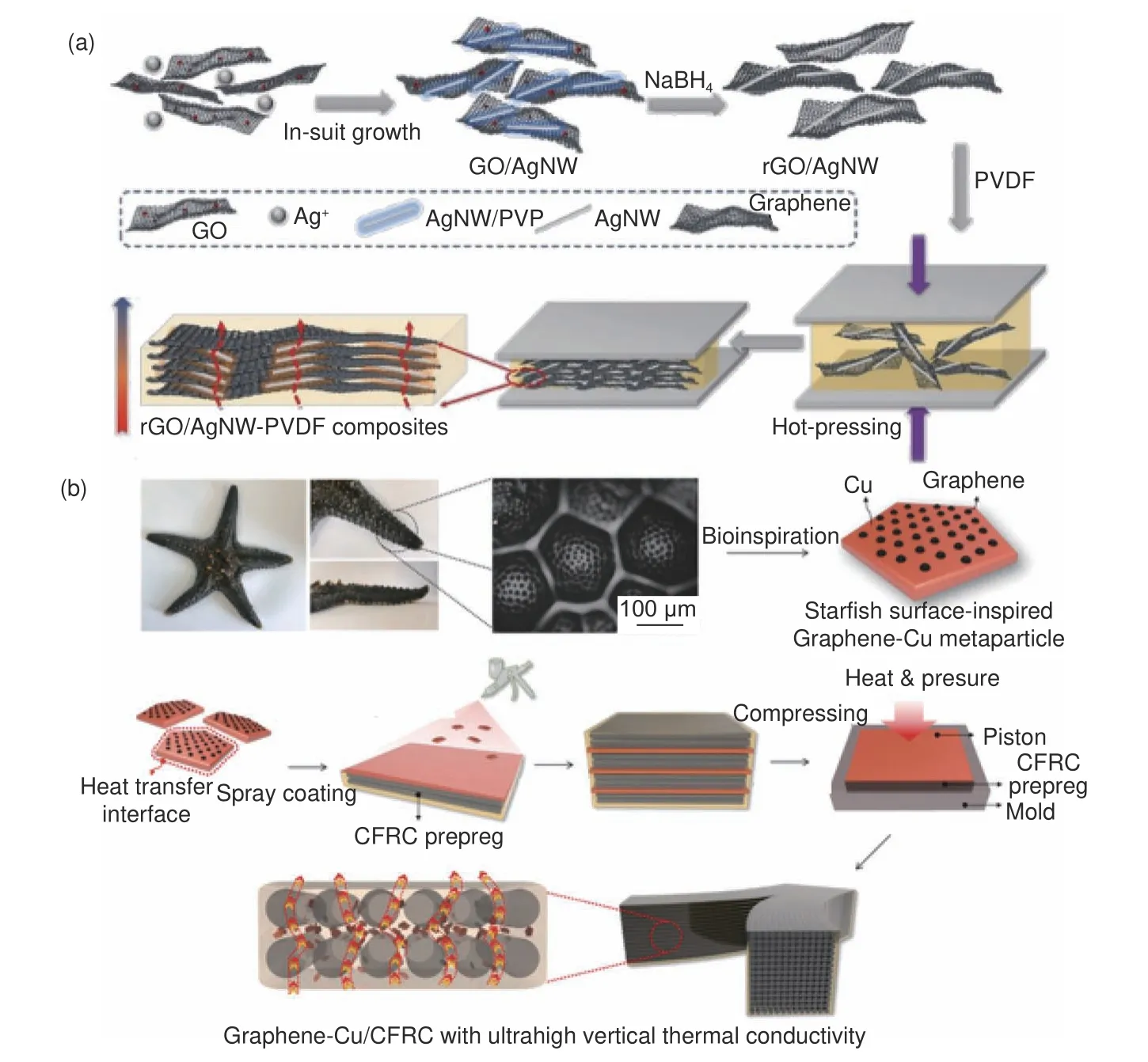

In recent years,using metal particles with high thermal conductivity as a thermally conductive interlayer has been considered a promising solution to solve the low through-plane thermal conductivity of graphene paper.Xiang et al.[33]first synthesized monodisperse Au nanoparticles on the surface of exfoliated graphene nanosheets.The authors found that adjacent the graphene nanosheets were electrically connected but thermally disconnected by the Au nanoparticles.They believed that electrons could tunnel at the Au/graphene nanosheets interfaces,whereas phonons were scattered across this interface.Huang et al.[34]achieved Ag+ion-intercalated GO paper by evaporating GO/AgNO3aqueous aerosols.Then the paper was reduced by sodium borohydride ethanol solution.The composite paper afforded a throughplane thermal conductivity of 3.3 W m−1K−1(25 μm)which was higher than that of graphene paper(2.4 W m−1K−1(25 μm)).Although Au/Ag nanoparticles can bridge the gap between graphene layers,the heat cannot transfer efficiently.As shown in Fig.3(a),Li et al.[35]prepared Ag nanowires (AgNWs)-decorated reduced graphene oxide (rGO/AgNWs)fillers by growing AgNWs in the space between graphene nanosheets.The through-plane thermal conductivity of the paper (2.6 W m−1K−1) was 260%more than pure graphene.Lee et al.[36]obtained the starfish surface-like graphene-Cu particles via spray coating (Fig.3(b)).The copper particles between the layers are in contact with each other to form an effective heat conduction network,which increases the through-plane thermal conductivity of the composite material by 520%.Although metal materials have ultrahigh thermal conductivity,the interaction between metal and graphene is relatively weak,and the Kapitza impedance is relatively large,resulting in composite papers with a limited through-plane thermal conductivity.Metals that have good interaction with carbon materials and high thermal conductivity are the focus of the next research,such as Ni.

Fig.3 (a) Schematic of the fabrication procedure of rGO/AgNWs-PVDF nanocomposites,(b) Schematic of the manufacturing process of graphene-Cu/CFRC.Reprinted with permission from:(a) Reference[35],Copyright 2020,American Chemical Society and (b) Reference[36],Copyright 2019,Elsevier.

2.3 Graphene/ceramic composite paper

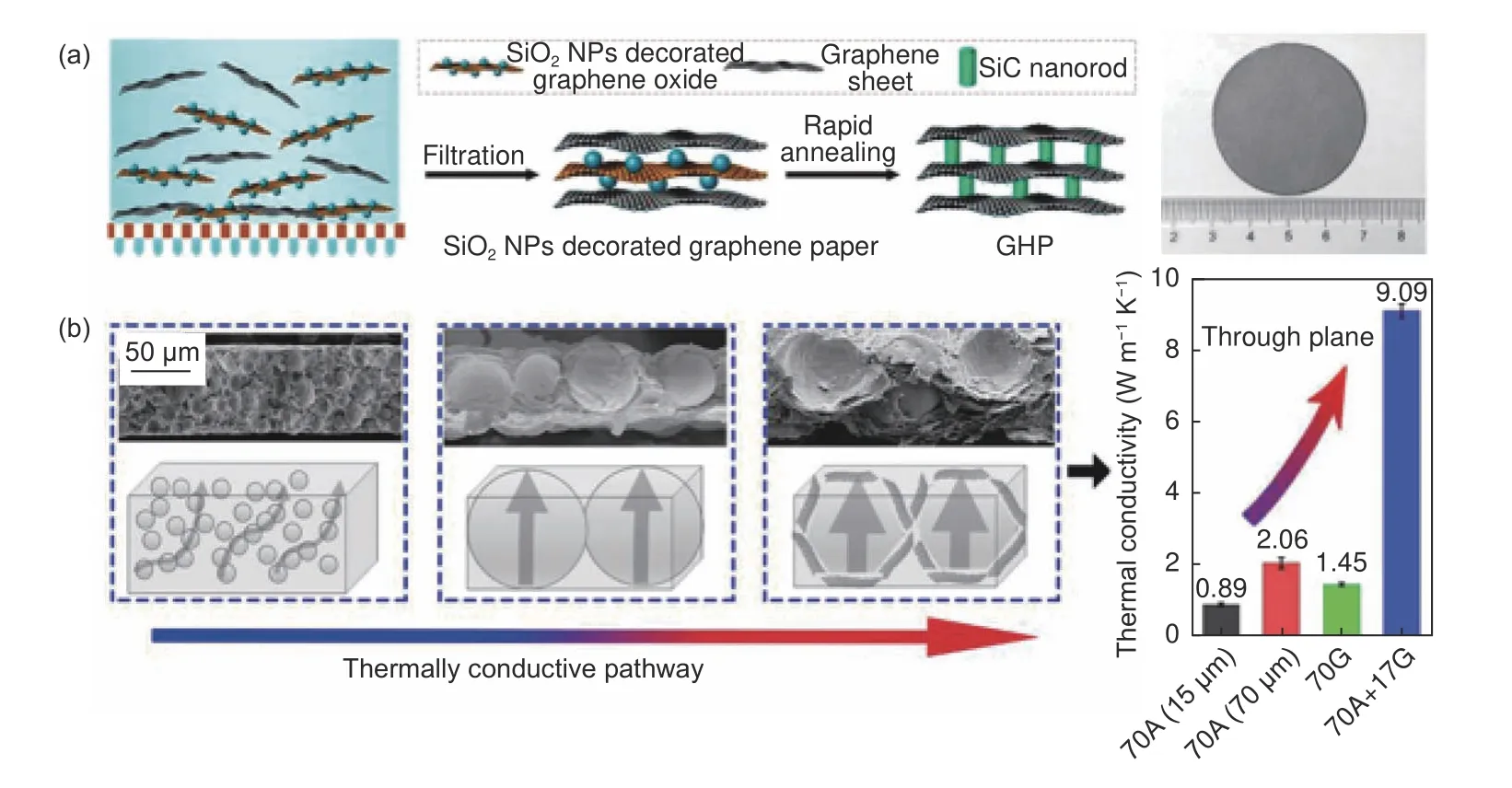

Compared with expensive gold and silver,many ceramic materials also have good thermal conductivity,such as BN (300–600 W m−1K−1)[37,38],SiC (80–300 W m−1K−1)[39],and Al2O3(30 W m−1K−1)[40,41].Wang et al.[42]used polydopamine to modify SiC nanowires to enhance the dispersibility of SiC nanowires and improve the interface interaction with graphene oxide.However,the resultant composite paper presented through-plane thermal conductivity of 0.3 W m−1K−1by introducing 80 wt% SiC nanowires and polydopamine.Dai et al.[13]pointed out that the weak interfacial heat conduction between them was based on weak vdW interactions.As shown in Fig.4(a),they used silicon oxide nanoparticles to modify graphene,and then grew silicon carbide nanowires by high-frequency heat treatment at 1 400 °C to prepare silicon carbide/graphene hybrid paper.The graphene/SiC interface was linked by covalent C-Si bonds.Based on the results of nonequilibrium molecular dynamics simulation,the thermal conductivity of the interface between the graphene/SiC nanowires connected by covalent C-Si bonds was higher than that of the vdW interaction by 1 order of magnitude.Compared to pristine paper,the through-plane thermal conductivity of the hybrid graphene paper increased by 2.2 times.Under 75 psi compression,the through-plane thermal conductivity of the hybrid graphene could be further increased to 17.6 W m−1K−1.Improvement in the efficiency of heat transfer can be achieved not only by enhancing interfacial interactions,but also by reducing the filler/filler interface.The single-layer particle structure can make full use of the intrinsic thermal conductivity of the filler and minimize the filler/filler interface.Graphene nanosheets are not simply arranged horizontally,but are partially arranged in a vertical direction.The flexible paper exhibits a high through-plane thermal conductivity(9.09 W m−1K−1) (Fig.4(b))[43].However,high through-plane thermal conductivity is only one of the necessary factors as an excellent TIMs and deformability is also a basic feature.Thus,this single-layer particle structure inherently limits its application as a TIM.In general,covalent bonding of ceramics and graphene can greatly reduce the thermal interface resistance and increase the through-plane thermal conductivity.It has become a potential method for the application of paper-like thermal interface materials.

Fig.4 (a) Schematic of the fabrication process and photograph of silicon carbide/graphene hybrid paper,(b) Morphology and through-plane thermal conductivity of graphene hybrid paper with different thermally conductive structures.Reprinted with permission from:(a) Reference[13],Copyright 2019,American Chemical Society and (b) Reference[43],Copyright 2020,Elsevier.

2.4 Graphene/carbon composite paper

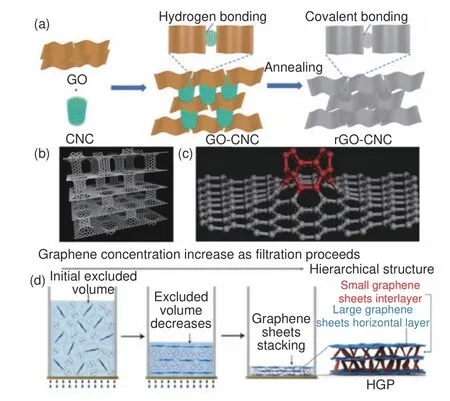

Enhancing the interaction between graphene nanosheets has become a key issue for breaking through the through-plane thermal conductivity of graphene paper.Compared with other materials,carbon materials have a better interaction with graphene.Nan et al.[44]fabricated hybrid graphene paper by embedding nanodiamond particles into graphene oxide functionalized by cationic poly(diallyldimethylammonium chloride),improving the through-plane thermal conductivity of the paper from 0.36 to 0.48 W m−1K−1.Some studies fabricated reduced graphene oxide/multiwalled carbon nanotubes (CNTs)hybrid paper via vacuum filtration,but the methods did not show any appreciable increase in the throughplane thermal conductivity.Kong et al.[45]deposited GO into the precursor followed by carbonization,but the through-plane thermal conductivity was only 0.4 W m−1K−1.Zou et al.[46]used small organic molecules with benzene rings (such as 1-pyrenemethanol) to modify graphene nanosheets followed by carbonization with improved through-plane thermal conductivity.As shown in Fig.5(a),Meng et al.[47]reported a hybrid graphene paper with added cellulose nanocrystals.After high-temperature annealing,the cellulose nanocrystal phase was carbonized into nanorods.The through-plane thermal conductivity of paper was improved from 3.9 to 4.6 W m−1K−1.Carbon nanorods effectively connected the boundaries and gaps between graphene sheets.Georgios et al.[48]designed a pillared-graphene network structure model(Fig.5(b)) that used CNTs to connect the graphene sheets.The high axial thermal conductivity of this unique graphene–CNT structure resulted from the replacement of noncovalent interactions with covalent bonding.Jiang et al.[49]inserted metal catalyst particles between graphene nanosheets and annealed them toin-situgrow carbon nanorings (Fig.5(c)).The through-plane thermal conductivity of the hybrid paper was increased by 3 times,reaching 5.8 W m−1K−1.Optimizing the structure and arrangement between graphene sheets to make proper use of their anisotropy can significantly enhance the through-plane thermal conductivity of graphene paper.Gao et al.[50]reported the assembly behavior of graphene with different sizes based on rapid suction filtration.Graphene sheets with large lateral dimensions tend to stack horizontally,and graphene sheets with small dimensions are more random.As shown in Fig.5(d),Gao et al.prepared graphene paper by quickly filtering a mixed solution of large and small graphene nanosheets.After graphitization,the thermal conductivity of the graphene paper improved from 6.3 W m−1K−1to 12.6 W m−1K−1.Compared with polymers,metals and ceramics,carbon materials (especially graphene) have more advantages as thermally conductive interlayers.However,due to the limitation of the existing technology,there is less heat transfer medium in the vertical direction,and there is still a lot of room for the through-plane thermal conductivity.

Fig.5 (a) Schematic assembly of the hierarchical chiral architecture of the graphene-based composite film,(b) Pillared-graphene-CNTs network structure model,(c) Molecular structure of the optimized junction of carbon nanorings and graphene sheets,(d) Schematic illustrating the fabrication process of hierarchically structured graphene paper.Reprinted with permission from:(a) Reference[47],Copyright 2018,American Chemical Society;(b) Reference[48],Copyright 2008,American Chemical Society;(c) Reference[49],Copyright 2018,American Chemical Society and(d) Reference[50],Copyright 2021,Elsevier.

2.5 Vertically aligned graphene paper as TIMs

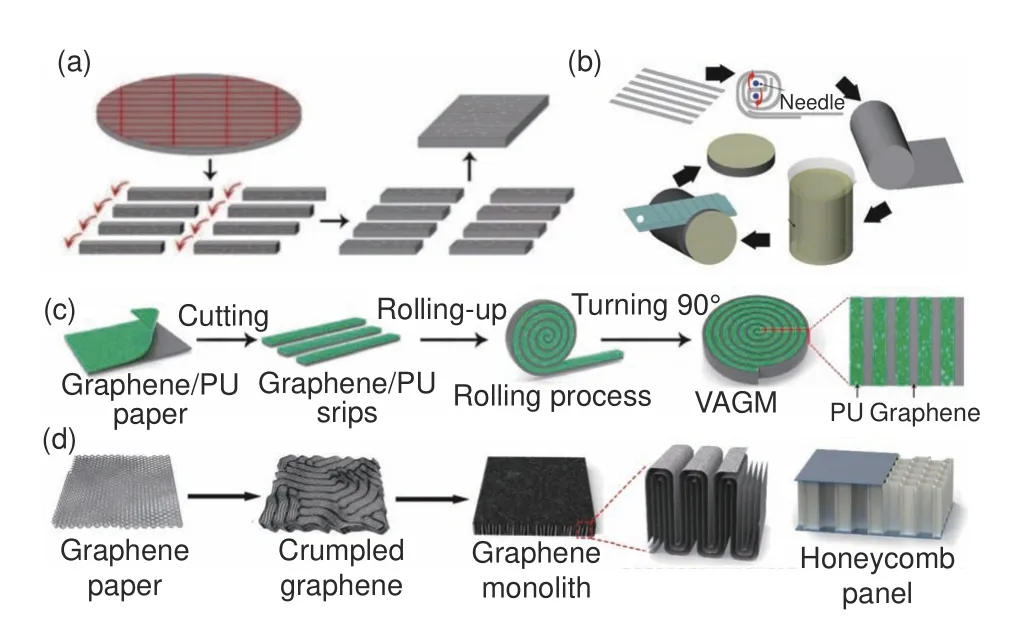

Apart from the incorporation with thermal conductive interlayers,the graphene papers can also be used as TIMs by“rotating-reassembling”.In 2011,Wong et al.[51]reported a TIM via stacking graphene papers (Fig.6(a)).There was an indium coating on the surface,the through-plane thermal conductivity of the obtained sample was 75.5 W m−1K−1and the contact thermal resistance (Rcontact) is 5.1 K mm2W−1.As shown in Fig.6(b),Zhang et al.[52]reported a composite material was made by rolling graphene papers into vertically arranged graphene sheets,and then infiltrating PDMS into them.The through-plane thermal conductivity of the composite reached 614.85 W m−1K−1.However,the high density leads to its inferior deformability and high compression strength (6.506 MPa),constraining its application as a TIM.Tan et al.[7]constructed a loosely packed and vertically aligned graphene framework to solve the problem in Fig.6(c).The sample was prepared by rolling up graphene papers with porous polymer foam attached and attaching nano-gold foil on both sides of the sample.Exhibiting a through-plane thermal conductivity of 276 W m−1K−1,theRcontactis 41 K mm2W−1.Dai et al.[4]proposed a method for manipulating the stack structure of traditional graphene paper through a machining process (Fig.6(d)).The graphene monolith with vertically aligned graphene sheets and horizontal graphene layers has a through-plane thermal conductivity of 143 W m−1K−1,theRcontactof 5.8 K mm2W−1and a low compressive modulus of 0.87 MPa.Due to most of vertically aligned graphene sheets,these samples have good through-plane thermal conductivities,and the soft indium,gold foils and horizontal graphene layers coating on the sides can reduce theRcontact.However,limited by the existing processing technology,the thickness of the vertically aligned graphene paper is~0.2–3 mm which would increase the total thermal resistance.The optimization of high through-plane thermal conductivity and low total thermal resistance is still a huge challenge.

Fig.6 (a) Schematic illustrating the assembly of vertically aligned graphene monolith via“rotating-reassembling”as-prepared graphene paper,(b) Schematic of the fabrication procedure of the vertically aligned graphene paper/PDMS composite,(c) Schematic illustrating the fabrication process of vertically aligned graphene framework,(d) Schematic illustrating the structural change of the graphene based on the proposed method.Reprinted with permission from:(a) Reference[51],Copyright 2011,American Chemical Society;(b) Reference[52],Copyright 2016,Elsevier;(c) Reference[7],Copyright 2021,Elsevier and (d) Reference[4],Copyright 2019,American Chemical Society.

3 Conclusion and perspectives

This review mainly covers the latest developments in the graphene-based papers and discusses the feasibility from the perspective of TIMs applications.The interfacial thermal conductance by covalent bonding is higher than vdW interactions,so ceramics and carbon materials show greater potential as thermal conductive interlayers.In addition,compared with other thermal conductive interlayers,carbon materials have higher high temperature resistance and higher thermal conductivity,showing greater potential to improve the through-plane thermal conductivity of graphene paper.Optimizing the structure and arrangement of low-dimensional carbon materials and hightemperature thermal reduction are the key to breaking the through-plane thermal conductivity of graphene paper-based TIMs.By constructing an ideal heat transfer structure,the through-plane thermal conductivity of the graphene-based papers can reach a satisfactory value.The through-plane thermal conductivities of recently reported graphene papers is summarized in Table 1.However,there are still some issues to consider when developing the most advanced TIM.More attention should be paid to its thermal interface resistance instead of just increasing the through-plane thermal conductivities.Surface functionalization or surface treatment of micro/nano structures can be used to adjust the interface to reduce theRcontact.Explore the influence of the compression deformation ability of the graphene paper-based TIMs on its actual use.Due to the poor binding force of the crystalline sp2bond,the sample is easy to break and fall off after compression.The fallen toner may cause a short circuit and affect the use of precision equipment The electrical insulation,long-term stability,flame retardancy and long-term stability of TIMs are worth considering in practical applications.

Table 1 The summary of through-plane thermal conductivity with reported graphene-based papers prepared using various methods.

Acknowledgements

The authors are grateful for the financial support by the National Key R&D Program of China(2017YFB0406000),the Project of the Chinese Academy of Sciences (XDC07030100,XDA220 20602,KFZD-SW-409,ZDKYYQ20200001,and ZDRW-CN-2019-3),CAS Youth Innovation Promotion Association (2020301),Science and Technology Major Project of Ningbo (2018B10046 and 2016S1002),the Natural Science Foundation of Ningbo (2017A610010),Foundation of State Key Laboratory of Solid lubrication (LSL-1912),National Key Laboratory of Science and Technology on Advanced Composites in Special Environments(6142905192806),KC Wong Education Foundation(GJTD-2019-13),China Postdoctoral Science Foundation (2020M681965),and the 3315 Program of Ningbo.

- 新型炭材料的其它文章

- Properties and microstructures of a matrix graphite for fuel elements of pebble-bed reactors after high temperature purification at different temperatures

- Microstructure of high thermal conductivity mesophase pitch-based carbon fibers

- 高导热聚酰亚胺石墨膜/环氧树脂复合材料的制备与性能表征

- TiC-modified CNTs as reinforcing fillers for isotropic graphite produced from mesocarbon microbeads

- One-pot modified“grafting-welding”preparation of graphene/polyimide carbon films for superior thermal management

- Thermal conductivity of graphite nanofibers electrospun from graphene oxide-doped polyimide