冷冻面团品质劣变及改良研究进展

袁婷婷,张 栩,向小青,常译丹,牛 猛,张宾佳,贾才华,许 燕,赵思明

冷冻面团品质劣变及改良研究进展

袁婷婷,张 栩,向小青,常译丹,牛 猛※,张宾佳,贾才华,许 燕,赵思明

(华中农业大学食品科学技术学院,武汉 430070)

冷冻面团技术实现了面团制作与烘焙的分离,具有标准化、方便化等优势,因此在世界范围得到快速发展。然而,受冰晶形成和冻藏作用的影响,冷冻面团仍然存在品质容易劣变和缺乏高效改良方法等问题。该研究主要从冷冻面团的发酵特性、面团主要组分如面筋蛋白和淀粉的特性、面团结构、冷冻面团的流变学特性等方面对冷冻面团的劣变现象与机理进行综述,以及改进冷冻工艺,筛选抗冻酵母,添加酶制剂、抗冻剂、乳化剂等改良方法进行总结。通过对冷冻面团发酵特性、面筋蛋白结构、面团水合状态等劣变关键因素的分析,为冷冻面团的抗冻研究提供参考,该研究旨在为冷冻面团品质劣变的抑制与高效改良技术的开发提供理论基础与实践参考。

冷冻;质量控制;冷冻面团;面筋蛋白;水分分布;蛋白质结构;酵母活性

0 引 言

随着人们对高品质食物的不断追求,以及各类连锁经营模式的广泛发展,冷冻面团技术应运而生。但是,冷冻面团技术也存在着一些问题,如冷冻面团所生产的面包或者馒头会出现体积变小,硬度增加,货架期变短等品质劣变问题[1-5]。其中,引起劣变的原因主要是:酵母细胞由于冰晶的破坏导致酵母活性及产气性降低,面筋蛋白的网络结构由于冰晶的重结晶作用遭到破坏,破损淀粉含量增加会与面筋蛋白竞争水分导致面筋蛋白失水[6-10]。目前国内外学者已经对冷冻面团品质劣变问题做了大量的研究,针对品质劣变问题的研究主要聚焦在面团结构特征、流变特性、加工性能[11-12],以及对冷冻面团中面筋蛋白、麦谷蛋白、麦醇溶蛋白的聚集行为和理化特性等方面[13-14]。而针对品质改良方面的研究多数停留在改进冷冻工艺,筛选抗冻酵母,以及乳化剂、亲水胶体、酶制剂、变性淀粉等添加剂的使用。而单一食品添加剂的使用具有一定的局限性,抗冻蛋白类生产成本高,限制其广泛应用,乳化剂的过量摄入会引起自身免疫疾病[15]。本文主要对引起冷冻面团劣变的因素进行综合分析,以期从提高酵母活性、稳定面筋蛋白结构、降低水分的流动性、稳定淀粉结构这些方面,为解决冷冻面团劣变提供全面的理论指导,解决冷冻面团所面临的困境,同时为高效健康改良剂的开发提供思路。

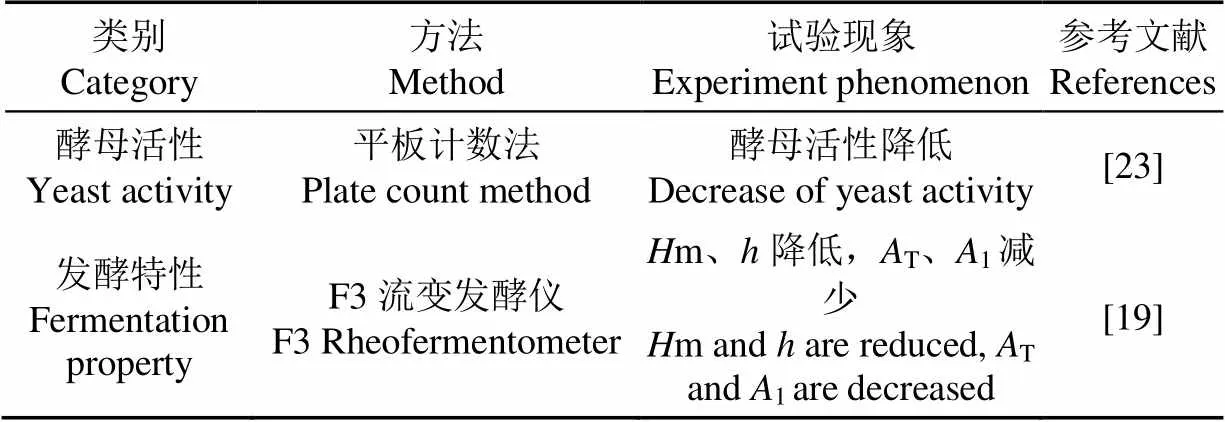

1 冷冻面团的发酵特性

在面团的制作过程中,相比化学膨松剂,酵母更具优势[16],且酵母活性与面团的醒发时间、体积、硬度和孔隙率存在密切关系[17]。冷冻面团中酵母细胞的生存能力取决于细胞膜的组成和完整性[18],而冰晶的形成会对酵母细胞膜造成机械损伤,导致酵母细胞损伤或死亡[19],还会导致还原剂如谷胱甘肽的释放,最后通过破坏面筋蛋白的二硫键来削弱面团的结构[20]。面团在冻藏过程中酵母活性降低,发酵特性减弱,具体表现为最大发酵高度和最终发酵高度降低。生产上使用的酵母在28 ℃左右快速生长,并进行有氧和无氧呼吸[21],孟露等[22]对面包酵母在-20 ℃无糖环境下模拟面团发酵7 d,发现酵母的存活率为43%,发酵力下降42%,也有研究发现同样温度冻藏28 d的时候,面团中酵母存活率为48.5%[23],主要原因是后者的酵母存活率是在添加10%蔗糖的条件下测定的。刘玫[19]研究发现冻结后和冻藏28d后的酵母存活率分别为87.53%和25.02%。温度的波动也会破坏酵母细胞[24],Jia等[25]研究表明,面团的最大发酵高度和最终发酵高度可反映面团在发酵过程中的产气能力和持气能力。酵母细胞在-18 ℃下冻藏28 d后死亡率为47.4%,继续冻藏6周后,面团发酵阶段的m从28.7 mm降低至24.3 mm,在气体释放阶段,气体保留率从90.4%降低至85.3%[26]。面团在经历6次冻融循环之后,生产的面包比容显著降低(<0.05),可能是由于冰晶刺穿了酵母细胞,降低了冷冻保存过程中酵母存活率,减少了面筋网络在发酵过程中保留CO2的能力[27]。汤晓娟[28]研究也得到相同的结论,冻藏使酵母存活率呈显著下降的趋势(<0.05),且面团的产气和持气能力显著降低(<0.05)。表1是酵母在冻藏期间的变化情况,即冻藏过程中,酵母活性降低,面团最大发酵高度m和最终发酵高度降低,总产气量T和持气量1减少。

表1 酵母在冻藏期间变化情况表征

注:m:面团最大发酵高度,m;:面团最终发酵高度,m;T:总产气量,mL;1:持气量,mL。

Note:m: maximum dough fermentation height, m;:the final dough fermentation height, m;T: total gas volume, mL;1: gas retention volume, mL.

冻藏对酵母活性的影响主要是因为冰晶引起的[29],冰晶对冷冻面团的影响可以概括为以下两个方面:1)冻结过程中酵母细胞内冰晶的形成会对细胞膜造成破坏,降低酵母活性[30];2)细胞外的面团基质中会形成冰晶,则盐、糖、其他分子的浓度会增加,导致细胞内渗透压增加,使酵母细胞失水死亡[31]。冻藏过程中冰晶的形成和重结晶作用会破坏酵母细胞壁,造成酵母活性降低,进而影响面团的产气能力与持气量,发酵性能降低,因此冷冻面团生产的产品质构特性下降,体积减小,孔隙率减小,硬度增加。

针对冷冻面团中酵母活性和产气性能低的问题,目前国内的研究大多集中在筛选抗冻酵母:1)筛选天然抗冻酵母:汪正强等[32]从土壤、谷物、果蔬、空气等不同来源筛选分离得到60多株酵母菌,得到三株耐冻酵母菌;2)特定的培养条件选育抗冻酵母:艾羽函[33]发现用20%质量分数的葡萄糖培养酵母时,酵母的抗冻能力和面团的产气能力最佳,这是由于高渗环境有利于酵母合成海藻糖、甘油和乙醇,而海藻糖和甘油能够增强酵母的抗冻性[34],因此可以通过高渗培养酵母提高酵母的抗冻能力;3)生物技术培养抗冻酵母:谭海刚等[35]研究发现,敲除NTH1基因后能明显改善酵母菌株的耐冻特性。其他方法:李娜等[36]的研究表明,通过酵母与碳酸氢钠混配,也可以解决冷冻面团酵母细胞活性和持气力,当碳酸氢钠用量为0.2%~0.4%时,冷冻面团馒头表现出较好的表面色泽、外观形状、内部气孔分布、气味、口味以及口感,且能促进面筋蛋白二硫键的形成。

2 面团各组分的变化

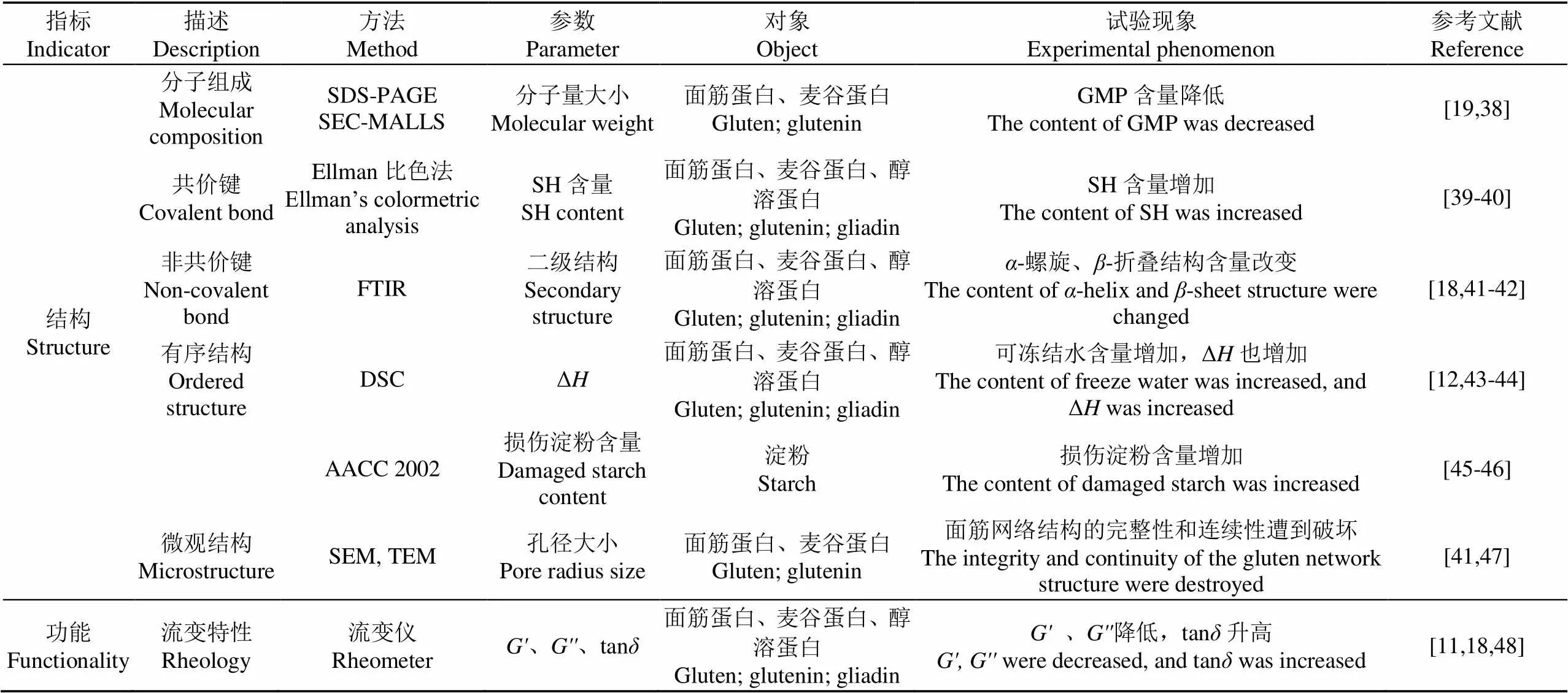

面团作为一个复杂的体系,主要包括面筋蛋白、淀粉、水分等成分,在一定含水率的情况下,小麦蛋白质与淀粉相互作用,促进了面筋网络结构的形成。其中面筋蛋白作为面团的骨架结构,淀粉颗粒通过吸水膨胀支撑和强化面团结构。面团在冻藏过程中,由于冰晶的生长和重结晶作用,面筋蛋白网络结构遭到破坏,损伤淀粉含量也会增加,面筋蛋白中的水分发生转移,造成水分重新分布[37],同时冷冻面团中的可冻结水含量增加。因此,冷冻面团的劣变主要可概括为以下3个方面:1)面筋蛋白网络结构的破坏;2)水分重新分布;3)损伤淀粉的影响。表2是面团在冻藏期间结构和品质劣变的表征,冷冻面团的结构和功能特性都发生改变,主要表现为麦谷蛋白和醇溶蛋白的共价键发生断裂,非共价键发生改变,麦谷蛋白大分子聚合体(Glutenin Macropolymer,GMP)含量降低,可冻结水含量增加,损伤淀粉含量增加,面筋蛋白微观结构遭到破坏,最后导致面团的黏弹性降低,品质劣变。

表2 面团冻藏期间结构和品质劣变的表征

注:SDS-PAGE:十二烷基硫酸钠-聚丙烯酰胺凝胶电泳;SEC-MALLS:尺寸排阻色谱-多角度激光光散射;FTIR:傅里叶转换红外光谱;DSC:差示扫描量热;Δ:焓;SEM, TEM:扫描电子显微镜,透射电子显微镜;、、tan:弹性模量,黏性模量,损耗角正切。

Note: SDS-PAGE: Sodium Dodecyl Sulphate Polyacrylamide Gel Electrophoresis; SEC-MALLS: Size Exclusion Chromatography Multi-Angle Laser Light Scattering; FTIR: Fourier Transform Infrared Spectroscopy; DSC: Differential Scanning Calorimetry; Δ: Enthalpy; SEM, TEM: Scanning Electron Microscopy, Transmission Electron Microscopy;、、tan: Elastic Modulus, Viscous Modulus, Loss Tangent.

2.1 面筋蛋白结构

面筋蛋白的构架蛋白麦谷蛋白和醇溶蛋白在面团的形成过程中产生了连续的黏弹性网络结构,面筋网络在面团发酵和蒸煮过程中对面团的延展性、产品尺寸和质量方面起着决定性的作用[49]。面筋网络可以保持酵母发酵过程中产生的CO2气体[50],现代聚合物理论认为面筋蛋白分子量大小和结构与其功能特性紧密相关,而GMP的数量、面团结构特性与冷冻面团制作的产品质量之间存在相关性[51]。面团在冻藏过程中由于冰晶的作用使水分发生重新分布,面筋蛋白作为面团的主要功能性成分,冻藏过程中高分子量的面筋蛋白发生解聚,导致面筋网络退化。对面筋蛋白结构的具体研究包括分子量大小、二硫键的变化、表面疏水性及二级结构的变化。

2.1.1 蛋白质分子量

面筋蛋白在十二烷基硫酸钠(Sodium Dodecyl Sulfate,SDS)溶液中的溶解度可以反映面筋蛋白的聚合程度,GMP解聚被认为是表征面筋蛋白品质劣变的主要指标之一[52],因此研究冻藏过程中面筋蛋白和麦谷蛋白SDS溶解度和GMP含量可以解释面筋蛋白的劣变机制。刘玫[19]研究发现经历冻结和冻藏处理的面筋蛋白和麦谷蛋白的SDS溶解度增加,GMP含量降低,且SDS-LMW(Low Molecular Weight)(<91 000 Da)部分含量增加程度高于SDS-HMW(High Molecular Weight)(91 000~688 000 Da)部分。经历60 d冷冻储藏导致GMP含量显著降低(<0.05),而SDS可溶性单体组分增加[38],推测冻结和冻藏阶段由于冰晶的形成和重结晶导致GMP发生解聚,生成了SDS可溶性蛋白。Zhao等[53]研究发现,经历冻融循环后的面筋蛋白分子量显著降低(<0.05)。高分子量麦谷蛋白(High Molecular Weight Glutenin Subunits,HMW-GS)和低分子量麦谷蛋白(Low Molecular Weight Glutenin Subunits,LMW-GS)亚基比例也是分子量分布的决定因素之一,Jia等[54]研究表明,冻藏5周之后,HMW/LMW的比率降低为新鲜面团的31.3%,由于谷蛋白的解聚导致高分子量麦谷蛋白亚基数量减少,而低分子量亚基数量增加。此外,王沛[39]的研究也得到相同的结论,可溶性蛋白的分子量分布范围不随冷冻时间的延长而变化,但可溶性蛋白的含量随冷冻时间的延长而增加,并研究了麦醇溶蛋白对面筋蛋白结构形成的阻碍作用,建立了GMP的解聚度和冻藏时间及醇溶蛋白含量呈线性正相关的关系,证实了面筋蛋白和谷蛋白中GMP的解聚过程主要通过链外二硫键的断裂作用进行。因此,冻藏过程中由于冰晶的作用导致面筋蛋白的关键组分GMP发生了解聚作用,使其骨架结构遭到破坏,进而弱化了面团的网络结构。

2.1.2 二硫键

麦谷蛋白和醇溶蛋白主要通过共价键来进行分子内/分子间的相互作用并形成面筋蛋白网络结构。作为面筋蛋白的功能基团,游离巯基(Free Thiol,S-H)通常可通过形成二硫键(Disulfide Bond,S-S)来参与到蛋白聚集行为中,同时S-S键也是维持面筋蛋白三维网络结构的主要作用力,通过链内和链间的共价S-S键决定面筋蛋白的功能特性,从而决定面团的最终使用质量[55]。刘玫[19]对面筋蛋白的S-S键含量进行了测定,发现S-S键含量在冻藏28 d后显著降低(<0.05),说明二硫键在冻藏过程中发生了断裂。王沛[39]研究发现在冻藏60 d后,冷冻面团中面筋蛋白的S-H 含量由 6.89mol/g 升至11.03mol/g,推测S-S键的断裂形成游离S-H,进而导致面筋蛋白网络弱化。Xuan等[56]的研究发现,冻藏60 d后面筋蛋白的游离S-H含量增加了82.93%,但面筋蛋白中游离S-H含量在冻藏15 d时出现了下降的趋势,推测冷冻收缩现象导致面筋蛋白内部形成了更多的链内/链间S-S键[57]。朱建[58]发现面筋蛋白经历冻融循环后的S-S键含量显著降低(<0.05),S-H含量显著升高(<0.05),证实了冻融循环对面筋蛋白的结构造成破坏。赵雷[40]发现,与恒温冻藏相比,冻融对S-S键的破坏比较大,由于面筋蛋白的自由氨基含量没有变化,面筋蛋白的亚基也没有发生变化,游离S-H含量随着冻藏时间的增加而增加,这就表明,由于二硫键断裂使得面筋蛋白的大聚合体发生了解聚现象导致了面筋蛋白分子量的下降,这与上述蛋白质分子量的研究结果一致。冻藏期间蛋白质空间构象的重排是由S-S键和疏水相互作用共同作用的[59],温度波动引起的水分迁移和冰晶的重结晶对面筋蛋白和谷蛋白的网络结构造成挤压和破坏,造成二硫键密度分布不均匀从而使键合作用变弱,氧气将这部分键合作用较弱的二硫键氧化,从而使部分二硫键断裂[40]。

2.1.3 表面疏水性

疏水相互作用是维持蛋白质结构的作用力,它对蛋白质的功能特性和稳定性具有重要作用,相比蛋白质的整体疏水性,表面疏水性更能揭示蛋白质结构的变化[60],8-苯胺-1-萘磺酸荧光探针法是一种常用的测定蛋白质表面疏水性的方法。面筋蛋白中的疏水氨基酸主要包括亮氨酸、脯氨酸等,这些氨基酸之间一般以疏水相互作用存在,朱建[58]研究发现经冻融循环处理的面筋蛋白的表面疏水性增加。柳小军[61]研究表明,随冻藏时间和冻融循环次数的增多,面筋蛋白表面疏水性显著增加(<0.05)。因此,冻藏过程中冰晶破环了面筋蛋白结构,导致结构弱化,面筋蛋白构象发生改变,使疏水基团暴露,因此表面疏水性增加。

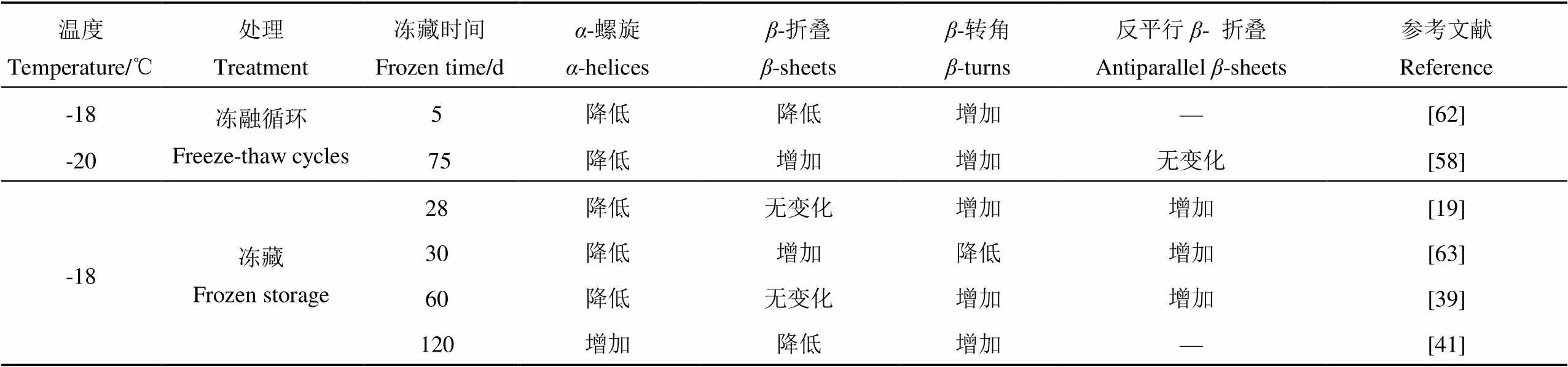

2.1.4 二级结构

蛋白质的二级结构与面筋蛋白网络结构特征密切相关。二级结构的分析可以用傅里叶转换红外光谱(Fourier Transform Infrared Spectroscope,FTIR)进行分析,主要有-螺旋,-折叠,-转角和-反平行4种结构,其中-螺旋、-折叠是有序结构,-螺旋一般为支撑多肽的主要骨架结构,-折叠含量一般在各二级结构中占主要地位,而-转角和-反平行是无序结构。表3为冷冻面团二级结构的变化的表征,主要表现为-螺旋结构的降低,不同的研究显示的二级结构变化存在差异,可能与冷冻面团的配方有关。-折叠主要依赖于麦谷蛋白的水合作用,-螺旋是醇溶蛋白的特征结构,维持-螺旋结构的主要作用力为氢键,冷冻破坏了-螺旋结构中的氢键等非共价键,蛋白质的亲水和疏水残基暴露在外界环境中,导致蛋白分子间、分子内出现新的交联现象,从而改变了蛋白质的二级结构[14]。

表3 冷冻面团二级结构变化的表征

注:“—”未显示反平行-折叠结构含量。

Note: “—” The content of antiparallel-sheets structure is not showed.

由上可见,面筋蛋白在冻藏过程结构的破坏主要概括为以下过程:冻藏过程中冰晶的形成和重结晶导致面筋蛋白GMP发生解聚,这种解聚主要是二硫键的断裂引起的,通过对面筋蛋白的表面疏水性进行分析发现,表面疏水性增加,进而引起面筋蛋白二级结构发生变化,主要表现为-螺旋和-折叠结构弱化,最终导致面筋蛋白结构破坏。

酶制剂类食品添加剂能够增强面筋蛋白结构,因具有高效、天然、安全的特性被广泛应用于冷冻面团的加工中[15],常用的酶制剂有:葡萄糖氧化酶,转谷氨酰胺酶,纤维素酶等。袁永利[64]研究发现,添加葡萄糖氧化酶之后的面团冻藏35 d仍然有大量的连续的面筋网络存在。葡萄糖氧化酶在有氧条件下发生氧化反应生成葡萄糖酸内酯,释放的过氧化氢可以将面筋蛋白中的游离S-H氧化成S-S,进而增强面筋网络的结构[65]。Tang等[66]研究表明,转谷氨酰胺酶可以降低高分子量谷蛋白亚基与低分子量谷蛋白亚基的比例,并增加GMP的粒径。转谷氨酰胺酶可用于蛋白质的交联,可以减少冷冻面团中由于冰晶导致的面筋强度降低。谷氨酰胺转氨酶存在的情况下,赖氨酸残基上的-氨基酸和谷氨酰胺残基上的-羟酰胺基反应生成-赖氨酸异肽键,-赖氨酸异肽键作用力比氢键和其他非共价键强,从而起到增强筋力的作用[65]。

2.2 水分分布

持水性是蛋白质的重要功能性质,柳小军[61]研究了冻藏对小麦面筋蛋白持水性的影响,结果显示冻藏会使面筋蛋白的持水性显著性下降(<0.05),且经历冻融循环后,面筋蛋白的持水性进一步降低。汤晓娟[28]研究发现,湿面筋的含水率随冻融循环次数的增多而减少,这主要是由于冰晶的生长和重结晶作用,小麦面筋蛋白低温变性导致隐藏在其内部的部分疏水基团暴露,使得小麦面筋蛋白网络对水分子的束缚力减弱[59]。具体来说,面筋蛋白在冻藏过程中的吸水能力下降是由S-S共价键及非共价键变化共同作用引起的蛋白空间构象重排所致,最终导致小麦面筋蛋白持水性的下降。

2.2.1 水分的迁移与重新分布

冷冻面团中水分的分布情况直接影响着面团的发酵活力和面筋的网络结构,最终影响冷冻面团产品的质量[67]。面团中的水分分布一般用时域核磁共振(Time-Domain Nuclear Magnetic Resonance,TD-NMR)测定横向弛豫时间来表示,面团中的水一般可以分成3部分,分别对应冷冻面团在弛豫时间内的3个峰21、22、23。21表示与淀粉或蛋白质氨基酸残基结合最为紧密的深层结合水,22表示介于深层结合水和自由水之间的弱结合水,23表示可冻结的自由水,而自由水是面团在冻藏过程中极易失去的一部分水。随着冻藏时间的延长,深层结合水比例从17.40%下降至14.40%,而自由水占比上升了3.40%[68],Jiang等[41]研究发现冻藏120 d后,冷冻面团中的深层结合水含量显著降低(<0.05),自由水含量显著增加(<0.05),弱结合水含量无显著改变(>0.05)。面筋蛋白中的深层结合水和弱结合水对冻藏敏感,它们的2弛豫时间峰值的宽度和幅度的变化受冻藏时间的增加而变化[13]。随着冻融循环次数的增多,自由水含量显著增加(<0.05),深层结合水含量显著降低(<0.05),表明面筋网络在经历冻融循环之后脱水[69]。Zhang等[70]研究发现经历冻融循环处理后,冷冻面团中的深层结合水显著降低(<0.05),而自由水显著增加(<0.05),表明冻融处理后冷冻面团中的水分流动性进一步增加。Ding等[43]用低场核磁共振(Low Field-Nuclear Magnetic Resonance,LF-NMR)在高空间分辨率下无损实时显示水分分布,发现新鲜面团的彩色图像均匀且边缘清晰,表明水分均匀的分布在新鲜面团的内部和表面,冻融循环后,这种均匀状态被破坏,水分主要集中在面团的中心,边缘分布较少,这是由于冻融处理后面团中的水分含量降低,导致质子密度的信号强度降低[27]。冷冻面团中的水分由于重结晶作用会发生重新分布,经过冻藏和冻融处理后,面筋蛋白的疏水相互作用增强,导致面筋蛋白与深层结合水和弱结合水的作用力减弱,导致面团中水分流动性增加,进一步导致面团失水。图1[39]是冷冻面团中水分在宏观、微观及分子水平的分布情况。

Fig 1 Water distribution in frozen dough at the macroscopic, microscopic and molecular levels

2.2.2 可冻结水含量

冰晶是破坏冷冻面团面筋蛋白网络结构的主要因素之一,而可冻结水的含量决定了在冻藏过程中冰晶的生成量,可冻结水含量的测定通过差示扫描量热(Differential Scanning Calorimetry,DSC)仪。冷冻面团中可冻结水比例随冻藏时间的延长而增加[41],冷冻面团经历了30 d冻藏处理后可冻结水比例从31.7%增加到47.5%[44]。经历5次冻融循环之后,面团中可冻结水比例从38.70%增加到44.34%[72],由于在冻结过程中,只有可冻结水转化为冰晶,因此冰晶的熔融焓值(Δ)可以反映样品中的可冻结水比例[43]。经历12周冻藏处理的面团的焓值从76 J/g增长到86 J/g,而同时经历冻融循环面团的焓值从76 J/g增长到89 J/g,且焓值在前四周会增加明显,水分迁移和冷冻后可冻结水立即增加,主要归因于面团初次暴露在这样的低温环境中引起的面筋网络结构的劣变[12]。Xuan等[56]研究发现,经历60 d的冻藏之后,焓值Δ从134.20 J/g增加至166.27 J/g。可冻结水含量和焓值Δ的升高可能是因为冻藏过程中冰晶的生长和重结晶作用,减弱了面筋蛋白中非极性、极性氨基酸之间的相互作用,使面团中不能冻结的松散的结合水与小麦面筋蛋白的相互作用减弱,这部分结合水从面筋网络中释放出来,进而转变成了自由水,导致冷冻面团中的可冻结水含量增加[57,61],这也与上述自由水含量增加的结果一致。

目前食品胶体和抗冻剂类食品添加剂主要用于控制冷冻面团中水分子的迁移,进而阻止大冰晶的形成。常用的食品胶有黄原胶、海藻酸钠、卡拉胶等。其中黄原胶有很强的吸水性,能够使水分均匀分散在面筋网络结构中,减缓因冰晶的迁移与生长带来的面筋蛋白结构破坏,汪星星[72]的研究表明,添加黄原胶、卡拉胶能够有效抑制二硫键的断裂,抑制冷冻面团黏弹性模量的降低,保护面筋蛋白网络结构。常用的抗冻剂有抗冻蛋白,海藻糖,抗冻肽类。其中抗冻蛋白主要有3种作用:1)热滞活性;2)重结晶抑制活性;3)细胞膜保护作用,因此抗冻蛋白通过抑制冰晶的作用保护面筋蛋白结构[73],目前抗冻肽已经成功应用于冷冻面团。Chen等[74]的研究表明,添加抗冻肽减弱了在冻融处理过程中水分的流动性,并改善了冷冻面团中的水分分布。海藻糖具有很强的抗脱水作用,可以有效防止面筋蛋白在寒冷环境下遭受损伤,周一鸣等[75]的研究表明,通过复配海藻糖、食品胶、乳化剂、酶制剂能够使冷冻面团面筋蛋白网络结构清晰完整,使冷冻面团馒头比容极显著提高(<0.01),增强面团的抗冻性。

2.3 损伤淀粉

淀粉作为面团中占比最大的物质,在冷冻面团的劣变过程中也发挥着重要作用。面团在经历冻藏/冻融循环之后,损伤淀粉(Damaged Starch,DS)含量会增加,导致吸水率增加,使水分从面筋基质中流出[8],损伤淀粉的含量高也会使面团发黏且不易成型,弹性和可伸展性的下降,与此同时,由于面筋与损伤淀粉之间竞争水分,也会导致面团的结构较弱[76]。图2[45]为天然淀粉和损伤淀粉的SEM图,观察到天然淀粉的表面光滑平坦,损伤淀粉表面粗糙。DS的含量会影响面团对水的吸收和面粉的混合特性,但是适量的DS(12.2%~21.9%)可以改善粉质特性,将水分保留在面团中,对冷冻面团更有利[77]。冻藏过程中DS含量显著增加(<0.05)[78],DS含量增加会降低双螺旋结构,导致面团的稳定性受到影响。且DS增加1%可使面团吸水能力提高约4倍,慢速(-0.14 ℃/min)冷冻面团的DS在冻藏期间含量高于快速(-1.75 ℃/min)冷冻面团的DS。Tao等[79]研究发现,经历10次冻融循环处理的淀粉使面团的弹性模量(Elastic Modulus,), 黏性模量(Viscous Modulus,)增加,且损耗角正切(Loss Tangenttan)值没有显著变化(>0.05),主要原因是损伤淀粉含量增加导致更少的水分来形成面团[80]。经历冻藏后的淀粉使面筋蛋白的-螺旋、-折叠转换成无序的-转角和无规则卷曲,使面团形成时间增加,tan值降低,面包芯的硬度显著增加(<0.05),最终导致面包的品质下降,因此,损伤淀粉的增加将导致面团品质的下降[46]。冻藏处理改变了小麦淀粉结构性质,弱化了淀粉颗粒与蛋白质分子之间的相互作用,导致面筋蛋白的二级结构变得无序化,面筋网络结构疏松,面团的黏弹特性发生改变,最后降低冷冻面团品质。

Fig 2 Scanning electron micrographs of native and damaged starch granules

3 冷冻面团微观结构和流变特性

3.1 面团的微观结构

面筋蛋白在冻藏过程中结构的变化可以通过SEM观察,也可以通过激光共聚焦电子显微镜观察。在冻藏初期,冷冻面团面筋蛋白维持着高度的三维网状结构,孔洞致密且均匀,尺寸范围从8~20m[41]。冻藏之后面筋网络发生断裂,面筋结构变得非常粗糙,更多的淀粉颗粒被暴露出来[28]。冻藏60 d的面筋蛋白由于相邻孔洞之间的网络破坏导致孔径变大,且分布不规则,这是由于冰晶的形成和生长,导致S-H增加,S-S键断裂[56]。Wang等[13]研究发现,经历60 d的冻藏之后,连续的面筋网络结构遭到破坏,可以观察到在面筋蛋白和冰晶之间发生相分离,面筋网络的冷冻收缩过程减少了分离相邻冰晶的蛋白质的间隙区域,从而对微观结构造成机械损伤[39]。忻晨[81]发现面筋蛋白的网络结构在经历冻藏之后,由平滑完整的结构变得孔径变大,导致网络结构的完整性和连续性遭到破坏,这是由于面筋蛋白在冻藏过程脱水,使得冰晶含量增多导致的。水的相变会引起冰晶的体积增大,面筋蛋白的间隙区域由于冷冻收缩过程受到挤压,导致面筋蛋白的微观结构受到机械损伤[82]。随着冻藏时间的延长,面筋网络出现了不同程度的破损,面筋膜变得稀薄,并且出现了较多不同形状的孔洞,冻融处理会导致更为严重的网络结构的破坏,面筋网络断裂,连续性变差,可能导致最终产品的持气性降低,产品品质不佳[83]。

3.2 流变学特性

面团是一种具有黏弹性的物料,它的黏弹性主要来源于具有弹性的麦谷蛋白和黏性的醇溶蛋白,面团的流变性能在一定程度上决定其最终产品品质。面筋蛋白和麦谷蛋白的弹性模量(Elastic Modulus,)都大于黏性模量(Viscous Mudulus,),说明其主要体现固体性质。冻藏过程中,损耗角正切(Loss Tangent,tan)是衡量蛋白质品质的重要指标之一,其值越大说明蛋白劣变程度越高[84]。研究表明面筋蛋白的弹性模量随着冻藏时间的延长而降低,醇溶蛋白的黏弹特性在冻藏过程中没有显著差异(>0.05)[85-86],因此推测面筋蛋白的黏弹特性在冻藏期间的变化主要由麦谷蛋白导致的。Ribotta等[11]研究发现冷冻和冻藏导致面团和显著降低(<0.05),证明冷冻和冻藏会使面团弹性和黏性降低。冻藏过程中,面团的弹性模量和黏性模量都逐渐降低,可能是面筋蛋白和淀粉颗粒之间的结构被破坏。经历5次冻融循环处理后,面团的和降低,且tan值随冻融循环次数的增加而增加,表明面团的黏弹性都下降了[70]。Tang等[69]发现经历冻融循环处理后,和显著降低(<0.05),tan值显著增加(<0.05),随着冻融循环次数的增多,这是由于冰的重结晶等因素对面筋蛋白的破坏较为严重,导致流变学性能下降[83]。冻藏过程中,面筋蛋白和谷蛋白的与GMP含量存在显著正相关关系(gluten=0.964,glutenin=0.985),表明二者弹性的降低与其中的GMP解聚直接相关[39]。Li等[87]研究分析冰晶可以使面筋网络变得无序,导致面团质构特性改变。冷冻面团流变学特性的改变也可以用冷冻过程中冰晶的形成来解释,冰晶的重结晶破坏了面筋蛋白的网络结构[7,11,88-89],导致其黏弹性降低,且黏弹性损失与GMP解聚也存在显著正相关。因此,GMP解聚也是引起面筋蛋白黏弹性下降的主要原因之一。面筋蛋白流变学特性在冻藏过程中的劣变主要概括为以下3个方面:1)相对分子量,一般分子量越大,面筋蛋白的黏弹性越好[90];2)面筋蛋白结构,冻藏由于冰晶作用对面筋蛋白的结构造成破坏,因此导致其黏弹性下降[54];3)面团中的水分分布及水分状态也会影响其黏弹特性[91]。面团在冻藏过程中,水分重新分布及重结晶作用导致面筋蛋白GMP解聚,共价及非共价键变化,因此面筋蛋白结构遭到破坏,流变学特性发生变化,和减小,tan值增加,对面团的加工特性产生不利影响并在一定程度上决定产品品质。

3.3 产品品质改良

乳化剂可以与冷冻面团中的蛋白质、淀粉相结合,防止淀粉老化,降低面筋蛋白和淀粉之间的水分迁移,增强面团的冻融稳定性,进而改善冷冻面团的品质。其中蔗糖酯和聚山梨醇酯可以与麦谷蛋白形成复合物,强化面团结构;单甘酯则与淀粉相互作用形成复合物,延缓冷冻面团产品硬化[92];双乙酰酒石酸单(双)甘油酯(Diacetyl Tartaric acid Ester of Monoglycerides, DATEM)能够强化面筋网络机构,增强面包的持气能力[11]。周锦枫等[93]的研究表明,DATEM可以降低冷冻面团中水分迁移速度,并提高其所生产面包的比容。-淀粉酶通过分解损伤淀粉为糊精、麦芽糖或葡萄糖等的简单化合物,为酵母提供营养物质,促进酵母的生长和繁殖,极大的提高冷冻面团的发酵特性[94],Thuy等[95]的研究表明,添加0.01%的-淀粉酶可以显著增强冷冻面团的筋力。而变性淀粉有良好的持水性及抗冻融效果,应用于冷冻面团中可以提高其质量。王亚楠等[96-97]的研究表明醋酸酯马铃薯淀粉显著增加冷冻面团的持水力,减弱水分子的流动性,且增大了面包的比容,改善面包的品质。目前也有研究发现一些兼具抗冻和营养特性的原料,Wang等[98]的研究表明加入2%的黑麦麸皮阿拉伯木聚糖能够改善冷冻面团的品质;Bea等[99]的研究发现添加50%全麦面粉的冷冻面团有很好的冻融稳定性,这些新型冷冻面团改良剂还具有一定的生理功能。

除了外源添加改良剂,冷冻面团的加工工艺也会影响面团的品质,采用速冻的方式进行冻结会使形成的冰晶细小且均匀,对面团的影响较小;冻藏条件也会影响冰晶的生长和水分重结晶。Kenny等[100]的研究表明,冷冻面团的适宜冻藏温度为-18~-22 ℃,Du等[101]的研究发现,在-35℃速冻温度下,能减缓冷冻面团的品质劣变,采用冷冻前不发酵和快速发酵的方式能够降低酵母的敏感性,增强面团的抗冻效果[102-103]。

4 结论与展望

本文从面团在冻藏过程中酵母活性和产气性能、面团主要组分特性、面团结构和流变学特性4个方面对冷冻面团的劣变规律进行了综述,针对冷冻工艺方面,采用先进的冷冻设备,减少温度波动来降低冷冻面团的裂变;针对酵母活性降低,一般通过筛选抗冻酵母提升冷冻面团产气性低的问题;针对面筋蛋白结构弱化,酶制剂类食品添加剂被用来增强面筋蛋白结构;针对水分迁移的问题,添加食品胶和抗冻剂类来阻止水分迁移引起的大冰晶的形成;针对淀粉结构的破坏,变性淀粉的添加可以通过增强面团的持水力来改善冷冻面团品质。乳化剂可以降低水分迁移,防止淀粉老化,但是过量摄入会诱发自身免疫疾病。酶制剂具有天然、安全、高效的优点。抗冻蛋白虽然可以修复细胞超微结构,但是成本高。变性淀粉原料来源广、方便、经济。单一的食品添加剂有一定的局限性,通过复配使用添加剂已经成为一种趋势。综上可见,随着人们对营养、健康的追求越来越高,开发天然、绿色、健康、营养型抗冻剂具有广阔的应用前景。

[1] 周舟,杜险峰. 冻藏过程中面团组分的变化及改良剂的研究进展[J]. 食品科技,2020,45(12):144-149.

Zhou Zhou, Du Xianfeng. Research progress of changes in dough components and improvers during frozen storage[J]. Food Science and Technology, 2020, 45(12): 144-149. (in Chinese with English abstract)

[2] Dalvi-Isfahan M, Jha P K, Tavakoli J, et al. Review on identification, underlying mechanisms and evaluation of freezing damage[J]. Journal of Food Engineering, 2019, 255: 50-60.

[3] Maity T, Saxena A, Raju P S. Use of hydrocolloids as cryoprotectant for frozen foods[J]. Critical Reviews in Food Science & Nutrition, 2018, 58(3): 420-435.

[4] Yang S, Jeong S, Lee S. Elucidation of rheological properties and baking performance of frozen doughs under different thawing conditions[J]. Journal of Food Engineering, 2020, 284: 110084.

[5] 范会平,李瑞,郑学玲,等. 酵母对冷冻面团发酵特性及馒头品质的影响[J]. 农业工程学报,2016,32(20):298-305.

Fan Huiping, Li Rui, Zheng Xueling, et al. Effect of yeast products on fermentation characteristics of frozen dough and quality of steamed bread[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(20): 298-305. (in Chinese with English abstract)

[6] Feng W J, Ma S, Wang X X. Quality deterioration and improvement of wheat gluten protein in frozen dough[J]. Grain & Oil Science and Technology, 2020, 3(1): 29-37.

[7] Baier-schenk A, Handschin S, Vonschönau M, et al. In situ observation of the freezing process in wheat dough by confocal laser scanning microscopy (CLSM): Formation of ice and changes in the gluten network[J]. Journal of Cereal Science, 2005, 42(2): 255-260.

[8] Yang Y, Zheng S S, Li Z, et al. Influence of three types of freezing methods on physicochemical properties and digestibility of starch in frozen unfermented dough[J]. Food Hydrocolloids,2021, 115: 106619-106626.

[9] Omedi J O, Huang W N. Advances in present-day frozen dough technology and its improver and novel biotech ingredients development trends: A review[J]. Cereal Chemistry, 2019, 96(1): 34-56.

[10] Kim H J, Yoo S H. Effects of combined-amylase and endo-xylanase treatments on the properties of fresh and frozen doughs and final breads[J]. Polymers, 2020, 12(6): 1349-1358.

[11] Ribotta P D, Perez G T, Len A E, et al. Effect of emulsifier and guar gum on micro structural, rheological and baking performance of frozen bread dough[J]. Food Hydrocolloids, 2004, 18(2): 305-313.

[12] Lu L, Yang Z, Guo X N, et al. Effect of NaHCO3and freeze–thaw cycles on frozen dough: From water state, gluten polymerization and microstructure[J]. Food Chemistry, 2021, 358:129869-129879.

[13] Wang P, Xu L, Nikoo M, et al. Effect of frozen storage on the conformational, thermal and microscopic properties of gluten: Comparative studies on gluten-, glutenin- and gliadin-rich fractions[J]. Food Hydrocolloids, 2014, 35: 238-246.

[14] Wang P, Chen H Y, Mohanad B, et al. Effect of frozen storage on physico-chemistry of wheat gluten proteins: Studies on gluten-, glutenin- and gliadin-rich fractions[J]. Food Hydrocolloids, 2014, 39: 187-194.

[15] 王岸娜,施桂林,吴立根,等. 食品添加剂对冷冻面团品质影响的研究综述[J]. 河南工业大学学报:自然科学版,2018,39(5):127-132.

Wang Anna, Shi Guilin, Wu Ligen, et al. Review on effects of food additives on frozen dough[J]. Journal of Henan University of Technology: Natural Science Edition, 2018, 39(5): 127-132. (in Chinese with English abstract)

[16] Wang P, Yang R Q, Gu Z X, et al. Comparative study of deterioration procedure in chemical-leavened steamed bread dough under frozen storage and freeze/thaw condition[J]. Food Chemistry, 2017, 229: 464-471.

[17] Akbarian M, Dehkordi M S M, Ghasemkhani N, et al. Hydrocolloids and cryoprotectant used in frozen dough and effect of freezing on yeast survival and dough structure: A review[J]. Research Laboratory for Agricultural Biotechnology & Biochemistry, 2015, 9(3): 1-9.

[18] Meziani S, Jasniewski J, Ribotta P, et al. Influence of yeast and frozen storage on rheological, structural and microbial quality of frozen sweet dough[J]. Journal of Food Engineering, 2012, 109(3): 538-544.

[19] 刘玫. 重组抗冻蛋白对冷冻面团品质劣变的干预及其机制研究[D]. 无锡:江南大学,2018.

Liu Mei. Intervention and Mechanism Study of Recombinant Antifreeze Proteins on Quality Deterioration of Frozen Dough[D]. Wuxi: Jiangnan University, 2018. (in Chinese with English abstract)

[20] Öztürk S, Cerit İ, Mutlu S, et al. Enrichment of cookies with glutathione by inactive yeast cells (): Physicochemical and functional properties[J]. Journal of Cereal Science, 2017, 78: 19-24.

[21] Yi J, Kerr W L. Combined effects of freezing rate, storage temperature and time on bread dough and baking properties[J]. LWT - Food Science and Technology, 2009, 42(9): 1474-1483.

[22] 孟露,刘晗诚,刘雅涵,等. 代谢组和转录组学分析工业面包酵母 () ABY3冷冻胁迫应答机制[J/OL]. 食品科学,[2020-01-14]2020:1-14. https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=CAPJ&dbname=CAPJLAST&filename=SPKX2020041600R&v=17WwU59A5kCjiDB%25mmd2B68XkFFc9FiSdlydmZtnyvXegsX6M0rH%25mmd2Bp1sNMuOLO6xGEMPi.

Meng Lu, Liu Hancheng, Liu Yahan, et al. Metabolome and transcriptome analysis of response mechanism of baker's yeast under freeze stress[J]. Food Science, [2020-01-14]2020:1-14. https://kns.cnki.net/kcms/detail/ detail.aspx?dbcode=CAPJ&dbname=CAPJLAST&filename=SPKX2020041600R&v=17WwU59A5kCjiDB%25mmd2B68XkFFc9FiSdlydmZtnyvXegsX6M0rH%25mmd2Bp1sNMuOLO6xGEMPi. (in Chinese with English abstract)

[23] Nguyen C T, Yuan M, Yu J S, et al. Isolation of ice structuring collagen peptide by ice affinity adsorption, its ice-binding mechanism and breadmaking performance in frozen dough[J]. Journal of Food Biochemistry, 2018, 42(3): e12506.

[24] Berglund P T, Shelton D R, Freeman T P. Frozen bread dough ultrastructure as affected by duration of frozen storage and freeze-thaw cycles[J]. Cereal Chemistry, 1991, 68(1): 105-107.

[25] Jia C L, Huang W N, Wu C, et al. Frozen bread dough properties modified by thermostable ice structuring proteins extract from Chinese privet () leaves[J]. Cereal Chemistry, 2012, 89(3): 162-167.

[26] Zhang C, Zhang H, Wang L. Effect of carrot () antifreeze proteins on the fermentation capacity of frozen dough[J]. Food Research International, 2007, 40(6): 763-769.

[27] Chen X, Wu J H, Li L, et al. The cryoprotective effects of antifreeze peptides from pigskin collagen on texture properties and water mobility of frozen dough subjected to freeze–thaw cycles[J]. European Food Research & Technology, 2017, 243(7): 1149-1156.

[28] 汤晓娟. 产胞外多糖酸面团发酵及其冷冻面团抗冻机理研究[D]. 无锡:江南大学,2019.

Tang Xiaojuan. Sourdough Fermented by Exopolysaccharide Forming Strain: Application and Mechanism Studies in Frozen Dough[D]. Wuxi: Jiangnan University, 2019. (in Chinese with English abstract)

[29] Luo W H, Sun D W, Zhu Z W. Improving freeze tolerance of yeast and dough properties for enhancing frozen dough quality: A review of effective methods[J]. Trends in Food Science & Technology, 2018, 72: 25-33.

[30] Muldrew K, Mcgann L E. Mechanisms of intracellular ice formation[J]. Biophysical Journal, 1990, 57(3): 525-532.

[31] Randez-gil F, Sanz P, Prieto J A. Engineering baker's yeast: Room for improvement[J]. Trends in Biotechnology, 1999, 17(6): 237-244.

[32] 江正强,王怡斯,李里特. 低糖面团用耐冷冻酵母的筛选及其性质[J]. 中国粮油学报,2009,24(6):15-19.

Jang Zhengqiang, Wang Yisi, Li Lite. Screening and characterization of freeze-tolerant yeast[J]. Journal of the Chinese Cereals and Oils Association, 2009, 24(6): 15-19. (in Chinese with English abstract)

[33] 艾羽函. 不同酵母对发酵速冻面团品质影响及冻藏过程中蛋白质变化的研究[D]. 郑州:河南农业大学,2019.

Ai Yuhan. Effects of Different Yeasts on the Quality of Frozen Dough and Protein Changes During Freezing and Storage[D]. Zhengzhou: Henan Agricultural University, 2019. (in Chinese with English abstract)

[34] 李晓军,徐鹏,栾静,等. 耐高渗酿酒酵母的代谢流分析[J]. 食品与生物技术学报,2009,28(3):356-360.

Li Xiaojun, Xu Peng, Luan Jing, et al. The metabolic flux analysis of the osmotolerant[J]. Journal of Food Science and Biotechnology, 2009, 28(3): 356-360. (in Chinese with English abstract)

[35] 谭海刚,董健,王光路,等. 中性海藻糖酶基因缺失对面包酵母耐冷冻性的影响[J]. 现代食品科技,2014,30(2):66-71, 16.

Tan Haigang, Dong Jian, Wang Guanglu, et al. Effect of neutral trehalase genes deletion on the freeze-tolerant characteristics of bread yeast[J]. Modern Food Science and Technology, 2014, 30(2): 66-71, 16. (in Chinese with English abstract)

[36] 李娜,缪治炼,邢丽,等. 碳酸氢钠对酵母细胞活性及冷冻面团品质的影响[J]. 生物加工过程,2020,18(5):642-649.

Li Na, Miu Zhilian, Xing Li, et al. Effects of sodium bicarbonate on yeast cell activity and frozen dough quality[J]. Chinese Journal of Bioprocess Engineering, 2020, 18(5): 642-649. (in Chinese with English abstract)

[37] Li J, Kang J, Wang L, et al. Effect of water migration between arabinoxylans and gluten on baking quality of whole wheat bread detected by magnetic resonance imaging (MRI)[J]. Journal of Agricultural & Food Chemistry, 2012, 60(26): 6507-6514.

[38] Yu W J, Xu D, Zhang H, et al. Effect of pigskin gelatin on baking, structural and thermal properties of frozen dough: Comprehensive studies on alteration of gluten network[J]. Food Hydrocolloids, 2020, 102: 105591-105601.

[39] 王沛. 冷冻面团中小麦面筋蛋白品质劣变机理及改良研究[D]. 无锡:江南大学,2016.

Wang Pei. Gluten Deterioration in Frozen Dough: Mechanism and Improvement Study[D]. Wuxi: Jiangnan University, 2016. (in Chinese with English abstract)

[40] 赵雷. 冻藏对面筋蛋白分子量、链结构及聚集态影响的研究[D]. 广州:华南理工大学,2012.

Zhao Lei. Study on Effect Frozen Storage on Molecular Weight and Distribution, Chain Conformation and Aggregated State Structure of Gluten[D]. Guangzhou: South China University of Technology, 2012. (in Chinese with English abstract)

[41] Jiang Y L, Zhao Y M, Zhu Y F, et al. Effect of dietary fiber-rich fractions on texture, thermal, water distribution, and gluten properties of frozen dough during storage[J]. Food Chemistry, 2019, 297: 124902-124911.

[42] 王世新,杨强,李新华.水分对冷冻小麦面团质构及面筋蛋白二级结构的影响[J].食品科学,2017,38(09):149-155.

Wang Shixin, Yang Qiang, Li Xinhua. Effect of moisture on texture and gluten protein secondary structure in frozen wheat dough[J]. Food Science, 2017,38(09):149-155. (in Chinese with English abstract)

[43] Ding X L, Zhang H, Wang L, et al. Effect of barley antifreeze protein on thermal properties and water state of dough during freezing and freeze-thaw cycles[J]. Food Hydrocolloids, 2015, 47: 32-40.

[44] Huang L Q, Wan J J, Huang W N, et al. Effects of glycerol on water properties and steaming performance of prefermented frozen dough[J]. Journal of Cereal Science, 2011, 53(1): 19-24.

[45] Barrera G N, Georgina C D, Jorge C P, et al. Evaluation of the mechanical damage on wheat starch granules by SEM, ESEM, AFM and texture image analysis[J]. Carbohydrate Polymers, 2013, 98(2): 1449-1457.

[46] 陶晗. 小麦淀粉在冻藏过程中品质劣变机理及其对面团品质影响的研究[D]. 无锡:江南大学,2017.

Tao Han. Wheat Starch Deterioration during Frozen Storage: Mechanism and Effect on the Quality of Dough[D]. Wuxi: Jiangnan University, 2017. (in Chinese with English abstract)

[47] Kieffer R, Schurer F, Köhler P, et al. Effect of hydrostatic pressure and temperature on the chemical and functional properties of wheat gluten: Studies on gluten, gliadin and glutenin[J]. Journal of Cereal Science, 2006, 45(3): 285-292.

[48] Leray G, Oliete B, Mezaize S, et al. Effects of freezing and frozen storage conditions on the rheological properties of different formulations of non-yeasted wheat and gluten-free bread dough[J]. Journal of Food Engineering, 2010, 100(1): 70-76.

[49] Wang X Y, Guo X N, Zhu K X. Polymerization of wheat gluten and the changes of glutenin macropolymer (GMP) during the production of Chinese steamed bread[J]. Food Chemistry, 2016, 201: 275-283.

[50] Zhu F. Influence of ingredients and chemical components on the quality of Chinese steamed bread[J]. Food Chemistry, 2014, 163: 154-162.

[51] Sapirstein H D, Suchy J. SDS-protein gel test for prediction of bread loaf volume[J]. Cereal Chemistry, 1999, 76(1): 144-150.

[52] Hayta M, Schofield J D. Heat and additive induced biochemical transitions in gluten from good and poor breadmaking quality wheats[J]. Journal of Cereal Science, 2004, 40(3): 245-256.

[53] Zhao L, Li L, Liu G Q, et al. Effect of freeze–thaw cycles on the molecular weight and size distribution of gluten[J]. Food Research International, 2013, 53(1): 409-416.

[54] Jia C L, Huang W N, Rayas-duarte P, et al. Hydration, polymerization and rheological properties of frozen gluten-water dough as influenced by thermostable ice structuring protein extract from Chinese privet () leaves[J]. Journal of Cereal Science. 2014, 59(2): 132-136.

[55] Herbert W. Chemistry of gluten proteins[J]. Food Microbiology, 2006, 24(2): 115-119.

[56] Xuan Y F, Zhang Y, Zhao Y Y, et al. Effect of hydroxypropylmethylcellulose on transition of water status and physicochemical properties of wheat gluten upon frozen storage[J]. Food Hydrocolloids, 2017, 63: 35-42.

[57] Kontogiorgos V, Goff H D, Kasapis S. Effect of aging and ice-structuring proteins on the physical properties of frozen flour-water mixtures[J]. Food Hydrocolloids, 2008, 22(6): 1135-1147.

[58] 朱建. 冻融循环对小麦HMW-GS近等基因系面筋蛋白的物理性能及结构的影响[D]. 杨凌:西北农林科技大学,2019.

Zhu Jian. Effects of Freeze–thaw Cycles on the Physical and Structural Properties of Wheat Gluten with Variations in the HMW-GS at the Glu-B1 Locus[D]. Yangling: Northwest A&F University, 2019. (in Chinese with English abstract)

[59] Esselink E F J, Vanaalst H, Maliepaard M, et al. Process in dough processing and cereal science from unilever research and development: Long-term storage effect in frozen dough by spectroscopy and microscopy[J]. Cereal Chemistry, 2003, 80(4): 396-403.

[60] Srinivasan D. Refolding of thermally unfolded soy proteins during the cooling regime of the gelation process: Effect on gelation[J]. Journal of Agricultural & Food Chemistry, 1988, 36(2): 262-269.

[61] 柳小军. 冻藏对面筋蛋白性能的影响及脱水机理研究[D]. 郑州:河南工业大学,2011.

Liu Xiaojun. The Studies of Frozen Storage on Gluten Properties and Mechanism of Dehydration[D]. Zhengzhou: Henan University of Technology, 2011. (in Chinese with English abstract)

[62] 孙丽洁. 鱼皮抗冻多肽的制备及其提高冷冻面团抗冻性的研究[D]. 无锡:江南大学,2017.

Sun Lijie. Study on the Preparation of Antifreeze Peptide from Fish Skin and Its Cryoprotective Effects on Frozen Doughs[D]. Wuxi: Jiangnan University, 2017. (in Chinese with English abstract)

[63] Yang J J, Zhang B, Zhang Y Q, et al. Effect of freezing rate and frozen storage on the rheological properties and protein structure of non-fermented doughs[J]. Journal of Food Engineering, 2021, 293: 110377-110384.

[64] 袁永利. GOD和TGase在冷冻面团中的应用研究[D]. 无锡:江南大学,2007.

Yuan Yongli. Studies on the Application of GOD and TGase in Frozen Doughs[D]. Wuxi: Jiangnan University, 2007. (in Chinese with English abstract)

[65] 史爽. Ana-rLOX和rGOx-m对冷冻非发酵面团的品质影响及其对冷冻面条的应用研究[D]. 南京:南京农业大学,2015.

Shi Shuang. Effect of Ana-rLOX and rGOx-m on Frozen Non-fermented Dough Quality and Its Application on Frozen Noodles[D]. Nanjing: Nanjing Agricultural University, 2015. (in Chinese with English abstract)

[66] Tang X, Wang F, Huang W, et al. The combination of rhizopus chinensis lipase and transglutaminase affects the rheology and glutenin macropolymer properties of frozen dough[J]. Cereal Chemistry, 2016, 93: 377-385.

[67] Ban C, Yoon S, Han J, et al. Effects of freezing rate and terminal freezing temperature on frozen croissant dough quality[J]. LWT - Food Science and Technology, 2016, 73: 219-225.

[68] 龚维,吴磊燕,钟雅云,等. 刺槐豆胶对冷冻面团水分分布及面包品质的影响[J]. 现代食品科技,2018,34(12):67-73.

Gong Wei, Wu Leiyan, Zhong Yayun, et al. Effect of locust bean gum on water distribution and bread quality of frozen dough[J]. Modern Food Science and Technology, 2018, 34(12): 67-73. (in Chinese with English abstract)

[69] Tang X J, Zhang B L, Huang W N, et al. Hydration, water distribution and microstructure of gluten during freeze thaw process: Role of a high molecular weight dextran produced by Weissella confusa QS813[J]. Food Hydrocolloids, 2019, 90: 377-384.

[70] Zhang Y Y, Li Y L, Liu Y, et al. Effects of multiple freeze–thaw cycles on the quality of frozen dough[J]. Cereal Chemistry, 2018, 95(4): 499-507.

[71] 贾春利. 热稳定冰结构蛋白提高冷冻面团体系抗冻性的机制研究[D]. 无锡:江南大学,2013.

Jia Chunli. Studies on Cryoprotective Characteristics of Frozen Doughs Using Thermostable Ice Structuring Protein[D]. Wuxi: Jiangnan University, 2013. (in Chinese with English abstract)

[72] 汪星星. 冻融冻藏过程中三种食品胶对面筋蛋白结构影响的研究[D]. 广州:华南农业大学,2016.

Wang Xingxing. Effect of Hydrocolloids on Protein Structure of Gluten during Freeze-thaw Cycles Storage[D]. Guangzhou: South China Agricultural University, 2016. (in Chinese with English abstract)

[73] 丁香丽. 大麦籽粒抗冻蛋白的制备及抗冻基质的研究[D]. 无锡:江南大学,2015.

Ding Xiangli. Study on the Preparation and the Antifreeze Mechanism of Antifreeze Protein from Barley ()[D]. Wuxi: Jiangnan University, 2015. (in Chinese with English abstract)

[74] Chen X, Wu J H, Li L, et al. The cryoprotective effects of antifreeze peptides from pigskin collagen on texture properties and water mobility of frozen dough subjected to freeze–thaw cycles[J]. European Food Research and Technology, 2017, 243: 1149-1156.

[75] 周一鸣,张亚园,吕欣东,等. 复合改良剂对后发酵馒头冷冻面团冻藏品质的影响[J]. 农业工程学报,2020,36(16):274-282.

Zhou Yiming, Zhang Yayuan, Lv Xindong, et al. Effect of compound quality improver on the frozen quality of frozen dough for steamed bread[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(16): 274-282. (in Chinese with English abstract)

[76] Barrera G N, León A E, Ribotta P D. Use of enzymes to minimize the rheological dough problems caused by high levels of damaged starch in starch-gluten systems.[J]. Journal of the Science of Food and Agriculture, 2016, 96(7): 2539-2546.

[77] Ma S, Li L, Wang X X, et al. Effect of mechanically damaged starch from wheat flour on the quality of frozen dough and steamed bread[J]. Food Chemistry, 2016, 202: 120-124.

[78] Irene S-G M, Benjamín R-W, Isabel T-C P, et al. Effect of freezing rate and storage on the rheological, thermal and structural properties of frozen wheat dough starch[J]. Starch - Stärke, 2016, 68(11/12): 1103-1110.

[79] Tao H, Wang P, Ali B, et al. Fractionation and reconstitution experiments provide insight into the role of wheat starch in frozen dough[J]. Food Chemistry, 2016, 190: 588-593.

[80] León A E, Barrera G N, Pérez G T, et al. Effect of damaged starch levels on flour-thermal behaviour and bread staling[J]. European Food Research & Technology, 2006, 224(2): 187-192.

[81] 忻晨. 不同结构羧甲基纤维素钠影响冷冻面团品质及其机制探究[D]. 武汉:华中农业大学,2018.

Xi Chen. Effect on Sodium Carboxymethyl Cellulose with Different Structures on Quality of Frozen Dough and Its Mechanism[D]. Wuhan: Huazhong Agricultural University, 2018. (in Chinese with English abstract)

[82] Nicolas Y, Smit R J M, Aalst H V, et al. Effect of storage time and temperature on rheological and microstructural properties of gluten[J]. Cereal Chemistry, 2003, 80(4): 371-377.

[83] 潘志琴. 漆酶协同阿魏酸对小麦面团微观结构及冻藏稳定性的影响机制[D]. 广州:华南理工大学,2019.

Pan Zhiqin. Effect of Laccase and Ferulic Acid on the Microstructure and Frozen Stability of Wheat Dough[D]. Guangzhou: South China University of Technology, 2019. (in Chinese with English abstract)

[84] Song Y H, Zheng Q. Dynamic rheological properties of wheat flour dough and proteins[J]. Trends in Food Science & Technology, 2007, 18(3): 132-138.

[85] Adams V, Ragaee S M, Abdel-Aal E-S M. Rheological properties and bread quality of frozen yeast-dough with added wheat fiber[J]. Journal of the Science of Food and Agriculture, 2017, 97(1): 191-198.

[86] Jasim A, Linu T, Al-Hazza A. Effects of frozen storage on texture, microstructure, water mobility and baking quality of brown wheat flour/-glucan concentrate Arabic bread dough[J]. Journal of Food Measurement and Characterization, 2020, 15(4): 1258-1269.

[87] Li M, Sun Q J, Han C W, et al. Comparative study of the quality characteristics of fresh noodles with regular salt and alkali and the underlying mechanisms[J]. Food Chemistry, 2018, 246: 335-342.

[88] Selomulyo V O, Zhou W B. Frozen bread dough: Effects of freezing storage and dough improvers[J]. Journal of Cereal Science, 2007, 45(1): 1-17.

[89] Havet M, Mankai M, Bail A L. Influence of the freezing condition on the baking performances of French frozen dough[J]. Journal of Food Engineering, 2000, 45(3): 139-145.

[90] Lefebvre J, Mahmoudi N. The pattern of the linear viscoelastic behaviour of wheat flour dough as delineated from the effects of water content and high molecular weight glutenin subunits composition[J]. Journal of Cereal Science, 2007, 45(1): 49-58.

[91] Meerts M, Cardinaels R, Oosterlinck F, et al. The impact of water content and mixing time on the linear and non-linear rheology of wheat flour dough[J]. Food Biophysics, 2017, 12(2): 151-163.

[92] Gómez M, Del Real S, Rosell C M, et al. Functionality of different emulsifiers on the performance of breadmaking and wheat bread quality[J]. European Food Research and Technology, 2004, 219(2): 145-150.

[93] 周锦枫,吴磊燕,钟雅云,等. 三种甘油酯对冷冻面团及其面包品质的对比分析[J]. 现代食品科技,2020,36(3):38-47, 112.

Zhou Jinfeng, Wu Leiyan, Zhong Yayun, et al. Comparative analysis of three glycerides on the quality of frozen dough and bread[J]. Modern Food Science and Technology, 2020, 36(3): 38-47, 112. (in Chinese with English abstract)

[94] Michal H. Effects of trehalose and dough additives incorporating enzymes on physical characteristics and sensory properties of frozen savory danish dough[J]. LWT-Food Science and Technology, 2017, 86: 603-610.

[95] Thuy N T T, Phuong N N M. Improving of bread quality from frozen dough using ascorbic acid and α-amylase[J]. Can Tho University Journal of Science, 2017, 6: 121-126.

[96] 王亚楠,侯召华,檀琮萍,等. 变性淀粉对冷冻面团面包焙烤特性的影响[J]. 粮食与油脂,2017,30(8):81-83.

Wang Yanan, Hou Zhaohua, Tan Congping, et al. Effect of modified starch on baking properties of frozen dough bread[J]. Cereals & Oils, 2017, 30(8): 81-83. (in Chinese with English abstract)

[97] 王亚楠,侯召华,檀琮萍,等. 变性淀粉对冷冻面团水分特性的影响[J]. 粮食与油脂,2017,30(6):63-65.

Wang Yanan, Hou Zhaohua, Tan Congping, et al. Effect of modified starch on water characteristics of frozen dough[J]. Cereals & Oils, 2017, 30(6): 63-65. (in Chinese with English abstract)

[98] Wang P, Tao H, Jin Z Y, et al. Impact of water extractable arabinoxylan from rye bran on the frozen steamed bread dough quality[J]. Food Chemistry, 2016, 200: 117-124.

[99] Bea W, Lee B, Hou G G, et al. Physicochemical characterization of whole-grain wheat flour in a frozen dough system for bake off technology[J]. Journal of Cereal Science, 2014, 60(3): 520-525.

[100] Kenny S, Wehrle K, Auty M, et al. Influence of sodium caseinate and whey protein on baking properties and rheology of frozen dough[J]. Cereal Chemistry, 2001, 78(4):458-463.

[101] 杜浩冉,郑学玲,韩小贤,等.冷冻条件和解冻方式对酵子冷冻面团馒头品质的影响[J].粮食与饲料工业,2015 (05):14-18.

Du Haoran, Zheng Xueling, Han Xiaoxian, et al. Effects of freezing conditions and thawing methods on the qualities of emptins frozen dough for steamed bread[J]. Cereal & Feed Industry, 2015(05):14-18. (in Chinese with English abstract)

[102] 潘振兴. 冷冻保护剂影响冷冻面团发酵与烘焙特性的研究[D]. 无锡:江南大学,2008.

Pan Zhenxing. Study on the Effects of Cryoprotectants on the Fermentation and Baking Characteristics of Frozen Dough[D]. Wuxi: Jiangnan University, 2008. (in Chinese with English abstract)

[103] Rasanen J, Harkonen H, Autio K. Freeze-thaw stability of prefermented frozen lean wheat dough: Effect of flour quality and fermentation time[J]. Cereal Chemistry, 1995, 72(6): 637-642.

Research progress in the deterioration and improvement of frozen dough quality

Yuan Tingting, Zhang Xu, Xiang Xiaoqing, Chang Yidan, Niu Meng※, Zhang Binjia, Jia Caihua, Xu Yan, Zhao Siming

(,430070,)

Frozen dough technology has widely been used beyond family bread production at present. The procedures of dough making and baking have therefore been separated to effectively extend the shelf life of bread, while free of starch aging to ensure the freshness for the convenience of transport and consumption of dough products. Therefore, the technology has been rapidly developed to promote the chain operation of the baking industry in the world. Meanwhile, it is necessary to explore the efficient improvement in response to the frozen dough being easy to deteriorate, due to the formation of ice crystals under freezing storage. This study aims to systematically review the degradation mechanism of frozen dough from the following aspects: the yeast activity and gas production, the changes of key components (such as gluten protein, water distribution, and damaged starch), the microstructure of gluten protein, as well as the rheological properties of frozen dough. The improvement of frozen dough was covered ranging from the freezing technology, the screening of antifreeze yeast, together with the addition of enzyme preparation, antifreeze agents, and emulsifiers. In freezing, the yeast activity and gas production decreased, resulting from the changes in the cell membrane of yeast. The screening of antifreeze yeast effectively strengthened the activity of yeast for a higher quality of frozen dough. Nevertheless, the structure of gluten protein was deteriorated, due to the formation of ice crystals. Specifically, the content of glutenin macromolecular polymer was significantly reduced, and the content of soluble protein increased. The elasticity and hardness of dough relied mainly on the depolymerization of glutenin macromolecular polymer, further on the break of the disulfide bond. Non-covalent bond was also involved in the polymerization of gluten protein. The surface hydrophobicity of gluten protein increased during the frozen storage, where the aggregation state of gluten protein molecular was destroyed to rearrange the gluten protein structure with the exposure of hydrophobic sites. In frozen storage, the secondary structure in gluten protein also changed significantly to damage the whole structure, where there were some changes in the content of-helix and-sheet orderly structure, while an increase in the anti-parallel-sheet, and-turns disorderly structure. As such, the enzyme preparations were used to enhance the structure of gluten protein. The water in the frozen dough was redistributed due to the recrystallization of ice crystals, where the spatial conformation rearrangement of gluten protein was caused by the change of disulfide and non-covalent bond. Thus, the interaction between tightly bound water and gluten protein was weakened, and the water holding capacity of gluten protein decreased. Correspondingly, food gums and antifreeze agents were added to prevent the formation of large ice crystals caused by water migration. Damaged starch transferred the water in gluten protein, and further weakened the interaction between starch granules and gluten protein, indicating an adverse influence on the gluten structure and processing characteristics of dough. The modified starch was generally added to enhance the water holding of dough for the better quality of frozen dough. These approaches contributed to preventing the deterioration of gluten structure, while enhancing the viscoelastic properties of frozen dough. The emulsifier was used to reduce water migration resistance to starch aging. The improvement of freezing technology was a benefit to the antifreeze effect of dough and the less sensitivity of yeast. This review can provide a promising theoretical basis and practical reference to inhibit the quality deterioration of frozen dough. The efficient improvement technology was also evaluated from three key factors, including the fermentation characteristics, the structure of gluten, and the state of water.

freezing; quality control; frozen dough; gluten protein; water distribution; protein structure; yeast activity

袁婷婷,张栩,向小青,等. 冷冻面团品质劣变及改良研究进展[J]. 农业工程学报,2021,37(8):296-306.doi:10.11975/j.issn.1002-6819.2021.08.034 http://www.tcsae.org

Yuan Tingting, Zhang Xu, Xiang Xiaoqing, et al. Research progress in the deterioration and improvement of frozen dough quality[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(8): 296-306. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2021.08.034 http://www.tcsae.org

2020-12-16

2021-04-12

国家重点研发计划项目(2018YFC1604001)

袁婷婷,博士生,研究方向:食品大分子结构与功能特性。Email:794845173@qq.com

牛猛,博士,副教授,研究方向:食品大分子结构与功能特性。Email:nmjay@mail.hzau.edu.cn

10.11975/j.issn.1002-6819.2021.08.034

TS213.2

A

1002-6819(2021)-08-0296-11