适用于黄河水滴灌的灌水器筛选研究

刘 露,侯 鹏,刘泽元,吴乃阳,李玮珊,邬若男,王海军,马永久,李云开

适用于黄河水滴灌的灌水器筛选研究

刘 露1,侯 鹏1,刘泽元1,吴乃阳1,李玮珊1,邬若男1,王海军2,马永久3,李云开1※

(1. 中国农业大学水利与土木工程学院,北京 100083;2. 唐山致富塑料机械有限公司,唐山 064100;3. 甘肃亚盛亚美特节水有限公司,兰州 730000)

传统的黄河水滴灌系统灌水器选择方法常以抗堵塞能力高低为标准,极易产生成本过高、资源浪费等问题。该研究提出了综合考虑使用年限需求、系统成本投入及碳足迹的滴灌带产品选择方法,并开展了黄河水原位加速测试试验。结果表明:黄河水滴灌条件下不同类型灌水器产品的生命周期、投入成本和碳足迹差异较大,以1 a使用期的毛管不冲洗处理组为例,内镶贴片式生命周期均值最高,内镶圆柱式、贴条式次之,单翼迷宫式最低,分别为309.8、170.3、158.1、135.9 h;成本与碳足迹为圆柱式最高,内镶贴片式、贴条式次之,单翼迷宫式最低,较前3者成本分别低52.7%~67.5%、17.1%~63.5%、28.7%~54.7%,产生的碳足迹分别低0~15.5%、10.6%~17.1%、8.9%~12.6%。并在此基础上建议河套灌区黄河水滴灌条件下1 a使用期的向日葵、3 a使用期的枸杞及5 a使用期的苜蓿分别选择流量为2.7 L/h的单翼迷宫式、1.4和2.8 L/h(配合毛管冲洗)的内镶贴片式灌水器。研究可为沿黄流域滴灌技术高质量发展和快速推广提供支撑。

生命周期;灌溉;泥沙;灌水器;堵塞;毛管冲洗

0 引 言

滴灌因其精量、可控等优点已成为高质量开发利用黄河水的方式之一[1]。但黄河水泥沙浓度高达3.7~26.5 kg/m3[2],极易引起灌水器堵塞问题,制约了黄河水滴灌技术的推广[3]。目前主要通过修建大型沉沙池和配备过滤器等关键设备来缓解泥沙带来的灌水器堵塞问题,但这无疑会导致系统成本大幅度增加[4-5]。事实上,不同类型灌水器的抗堵塞能力明显不同,根据其特性选择适宜的灌水器产品可降低对系统沉淀、过滤的要求。因此,合理的灌水器选择方法尤为重要。

国内外学者针对高含沙水滴灌系统灌水器产品的选择展开了大量的工作。牛文全等[6]建议含沙水条件下选择抗堵塞性能较好的大流量灌水器;Zhou等[7]提出了面向多水源、多种运行条件下的灌水器抗堵塞性能综合相对指数(Anti-Clogging Relative Index,CRI)来选择灌水器的方法,建议在满足使用要求的前提下选用CRI较高的灌水器;Wang等[8]通过准确评价灌水器压头分布的水力模型来预报灌水器的抗堵塞性能,并结合灌溉模式及灌溉土壤水力特性等来对进行灌水器选择;王新端等[9]研究表明流道形式和结构参数是抗堵塞性能的重要影响因素,建议选择双向流道灌水器,其水力性能及抗堵性能均优于迷宫式流道灌水器;Liu等[10]建议选择抗堵塞性能好的压力补偿式灌水器进行滴灌,但同时指出其价格昂贵且受温度影响大;Brown等[11]研究认为滴灌系统中灌水器用量较大,成本是灌水器选择的重要因素;马宁等[12]研究表明迷宫式灌水器具有节本、增效的特点,短期内出流稳定,使用期限短时建议选用薄壁迷宫式滴灌带。总体而言,目前以抗堵塞性能为主、价格为辅的灌水器选择依据,并未研究考虑产品使用年限及环境负效益,还存在一定的局限性,因此急需建立综合考虑不同使用年限需求、成本和环境影响(以滴灌系统投入的碳足迹(Carbon Footprint,CF)为例)等多因素影响下的灌水器选择方法。

基于此,本文选取16种灌水器产品,在内蒙古河套灌区开展了黄河水滴灌系统原位加速测试试验,并以河套灌区使用年限需求为1 a(以向日葵为例)、3 a(以枸杞为例)、5 a(以苜蓿为例)的灌溉作物为应用对象,综合考虑灌水器的使用年限、成本以及碳足迹,建立了面向不同灌溉作物的滴灌带产品选择方法,研究可为高含沙水滴灌系统的灌水器选择提供全新思路,并为黄河水滴灌技术的规模化应用提供理论支撑。

1 材料与方法

1.1 滴灌系统灌水器抗堵塞性能测试原位加速试验

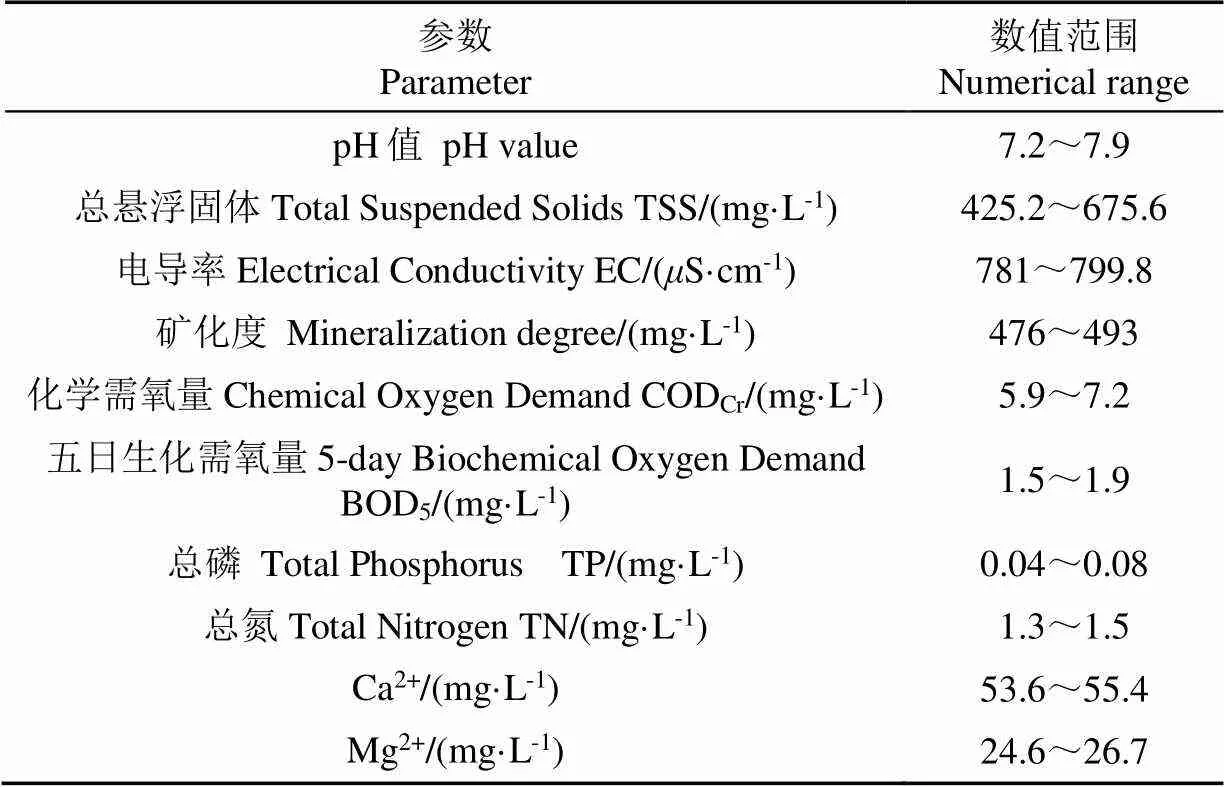

本试验在内蒙古河套灌区磴口县乌兰布和沙漠边缘的中国农业大学引黄滴灌试验基地(40°24′32′′N,107°02′19′′E)进行。试验用水为黄河高含沙水,取自河套灌区乌沈干渠,经沉沙池过滤后进入滴灌系统,试验期间水质特征如表1所示。

表1 高含沙水水质参数

试验通过原位加速测试平台来进行[13],测试平台设置为4层,通过分流调压的方式实现每层工作压力恒定为0.1 MPa,每天运行前进行压力校准。系统首部过滤采用两级过滤模式,一级过滤采用滤料粒径为1~2 mm的砂石过滤器,二级过滤采用120目叠片过滤器(过滤精度0.125 mm)。系统每运行60 h,对砂石过滤器进行反冲洗,并对叠片过滤器进行手动清洗。当相对平均流量小于50%时停止试验。试验自2017年7月1日起运行,不冲洗处理组至2017年9月1日结束,冲洗处理组至9月21日结束。黄河水毛管冲洗和不冲洗处理组每日累计运行9 h,分别累积运行720和600 h。毛管冲洗处理组的冲洗频率采用60小时1次,流速采用0.45 m/s,冲洗时间为6 min。试验装置测试平台如图1所示。

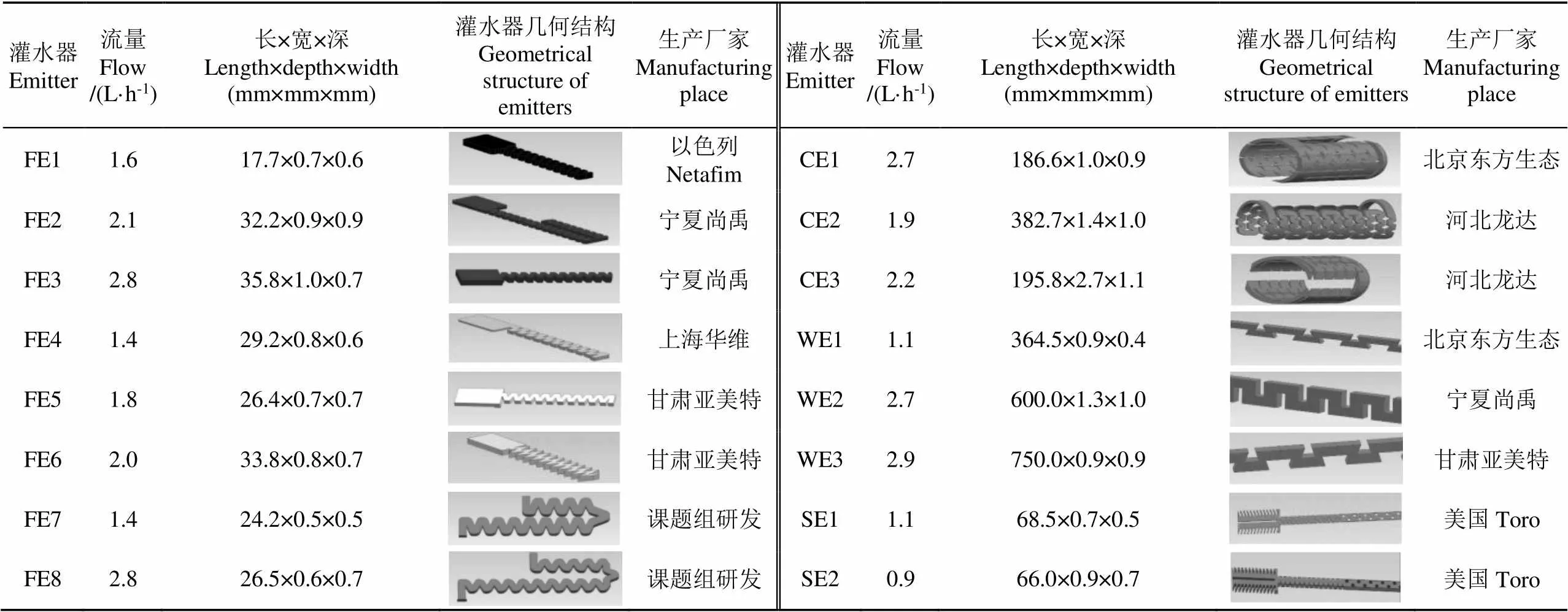

试验共选用16种灌水器,包括8种内镶贴片式灌水器(Flat Emitter,FE)、3种内镶圆柱式灌水器(Cylindrical Emitter,CE)、3种单翼迷宫式灌水器(Single Wing Labyrinth Emitter,WE)和2种内镶贴条式灌水器(Strip Emitter,SE)。每种灌水器设置8个重复,每条滴灌带布设15 m,灌水器间距为0.3 m,共计45个灌水器。运行期间定期进行流量测试,测试频率为每60小时1次,测流小车为4层结构,每层凹槽内隔0.3 m放一个直径为20 cm的小桶进行流量采集。开始测流时,将小车迅速推至待测滴灌带下方,并同时按下秒表(精度0.01 s),当流量采集3 min后,迅速将小车撤离。采用高精度电子天平(精度0.001 g)分别对空桶和测流小桶质量进行称量,并记录数据。灌水器及其特征参数见表2。

1、3、5 a使用期灌水器对应作物的灌水频率参考张丽霞等[14-16]的研究,选用每7天1次,根据Han等[13]的研究,该频率下,可通过式(1)将原位加速测试的流量均匀度转化为实际大田间歇运行结果。

式中为原位加速测试中流量均匀度,为大田歇运行测试流量均匀度。

1.2 滴灌系统流量均匀度测试与评估方法

采用称重法[17]对滴灌系统灌水器进行流量测试,采用Pei等[18]的校正方式对实测流量进行校正,消除温度及压力对流量测试的影响。灌水器堵塞评价指标流量均匀度(Cristiansen of Uniformity,CU)的计算方法参考Li等[19]的研究。参照《微灌工程技术规范》(GB/T 50485-2009),流量均匀度CU不应低于80%。将CU等于80%时对应的滴灌时间定义为灌水器的生命周期(Life Cycle,LC),年累积滴灌时间小于灌水器生命周期时的最大年限值定义为灌水器的使用年限。

1.3 灌水器产品选择方法

1.3.1 模型假设

在对不同使用年限的作物计算过程中,为实现滴灌带铺设产生的成本及碳足迹的计算目标,做出以下假设:

1)选择1 a生向日葵、3 a生枸杞和5 a生苜蓿作为河套灌区灌水器产品使用年限为1、3、5 a的大田灌溉作物,经调研,1 a使用期采用壁厚为0.2 mm的4大类滴灌带,3、5 a使用期分别采用壁厚为0.4、0.6 mm的内镶贴片式和内镶圆柱式滴灌带进行分析。

2)向日葵、枸杞和苜蓿的滴灌系统控制面积均为80 hm2,灌水定额分别为2 745、6 675、3 750 m³/hm2[14-16],毛管间距分别为80、150、50 cm,枸杞的毛管布设采用一带灌一行,向日葵、苜蓿的毛管布设采用一带灌两行。单位面积滴灌带铺设参照《微灌工程技术规范》(GB/T 50485-2009)。

3)本文中滴灌带的碳足迹,其生命周期的研究边界划定为从产品生产到报废,即考虑灌溉设备和相关材料的生产、运行和使用过程,不包括生命周期边界上游生产设备制造与耗材、运输和下游的农产品销售、运输与消费者使用等[20]。

4)滴灌带铺设成本为灌水器在使用年限内单位面积的总投入,不考虑滴灌带的折旧。其他设备的折旧年限为10 a,主要设备及材料的估算参考Chen等[20]的研究。

表2 试验用灌水器几何参数

注:灌水器间距均为0.3 m,管径均为16 mm;FE为内镶贴片式灌水器,记作FE1~FE8,统称FEs;CE为内镶圆柱式灌水器,记作CE1~CE3,统称CEs;WE为单翼迷宫式灌水器,记作WE1~WE3,统称WEs;SE为内镶贴条式灌水器,记作SE1~SE2,统称SEs。下同。

Note: The distance between emitters are 0.3 m, and the pipe diameters are 16 mm; FE is flat emitters, written as FE1-FE8, collectively referred to as FEs; CE is cylindrical emitters, written as CE1-CE3, collectively referred to as CEs; WE is single wing labyrinth emitters, written as WE1-WE3, collectively referred to as WEs; SE is strip emitters, written as SE1-SE2, collectively referred to as SEs. Same as below.

1.3.2 灌水器选择模型

为建立综合考虑使用年限、成本和碳足迹(CF)多因素影响下的灌水器选择方法,该研究提出灌水器评价指标a,来表征总体的变异程度,a值最小的产品即选取的目标灌水器产品。计算过程如下:

利用相关系数法将3个影响因子原始值(流量均匀度CU、成本(元)、总碳足迹CFt(kg))标准化,得到影响因子下各灌水器的隶属度值(x);运用SPSS统计软件中主成分分析法得到各公因子方差e,将其折算为权重系数K。

式中x为影响因子下第个灌水器的原始值;xmax为第种灌水器的最大值;xmin为第种灌水器的最小值。

影响因子流量均匀度CU、成本和总碳足迹CFt的原始值x的计算公式[19-20]如下:

2 结果与分析

2.1 不同类型灌水器CU变化及生命周期

黄河水滴灌系统16种灌水器CU变化如图2所示。从图2可知,CU随系统运行时间的增长呈现出先缓慢后快速的下降趋势。每种灌水器各取平均值进行比较,相同运行时间下,FEs的CU最高,其余从大到小依次为CEs、SEs、WEs。不进行毛管冲洗条件下,CU降至80%(对应滴灌时间为生命周期)时,4种类型灌水器(FEs、CEs、SEs、WEs)累积滴灌时间的平均值分别为309.8、170.3、158.1、135.9 h,冲洗后滴灌时间平均值增加至372.3、260.7、164.7、172.2 h,分别增加了20.2%、53.1%、26.7%、4.2%。

不同使用期灌水器代表作物对应的灌水时间、灌水器生命周期如表3所示,当作物滴灌时间小于灌水器生命周期时,即认为该灌水器满足灌水要求。对于1 a使用期(以向日葵为例)灌水器而言,即使不进行毛管冲洗,各灌水器的滴灌时间仍在其生命周期范围内,满足灌水要求;对于3 a使用期(以枸杞为例)而言,不进行毛管冲洗条件下,SEs的累积灌水时间超出灌水器生命周期,尽管毛管冲洗处理虽使其生命周期延长了2.6%~5.6%,但依然不满足灌水要求;而对于5 a使用期(以苜蓿为例)而言,若不进行毛管冲洗,仅有FE2、FE8、CE1这3种灌水器累积灌水时间在其生命周期内,毛管冲洗处理分别将FE5、FE7、CE3的生命周期提升了82.9%、12.5%、63.2%,可以满足生命周期灌水要求,FE2设置毛管冲洗后反而无法满足生命周期灌水要求,其余灌水器毛管冲洗处理前后均无法满足灌水要求。

注:CU为克里斯琴森均匀系数,即流量均匀度。

Note: CU is Cristiansen coefficient of uniformity, namely the flow uniformity.

图2 黄河水滴灌条件下不同类型灌水器CU变化

Fig.2 Variation of CU in different types of drip irrigation emitters using Yellow River water

表3 不同作物滴灌时间及灌水器生命周期

注:LC为生命周期;向日葵、枸杞、苜蓿分别代表1 a生向日葵、3 a生枸杞和5 a生苜蓿。下同。

Note: LC is life cycle; Sunflower, Chinese wolfberry and alfalfa represent 1-year-old sunflower, 3-year-old Chinese wolfberry and 5-year-old alfalfa, respectively. Same as below.

2.2 不同类型灌水器滴灌带成本核算

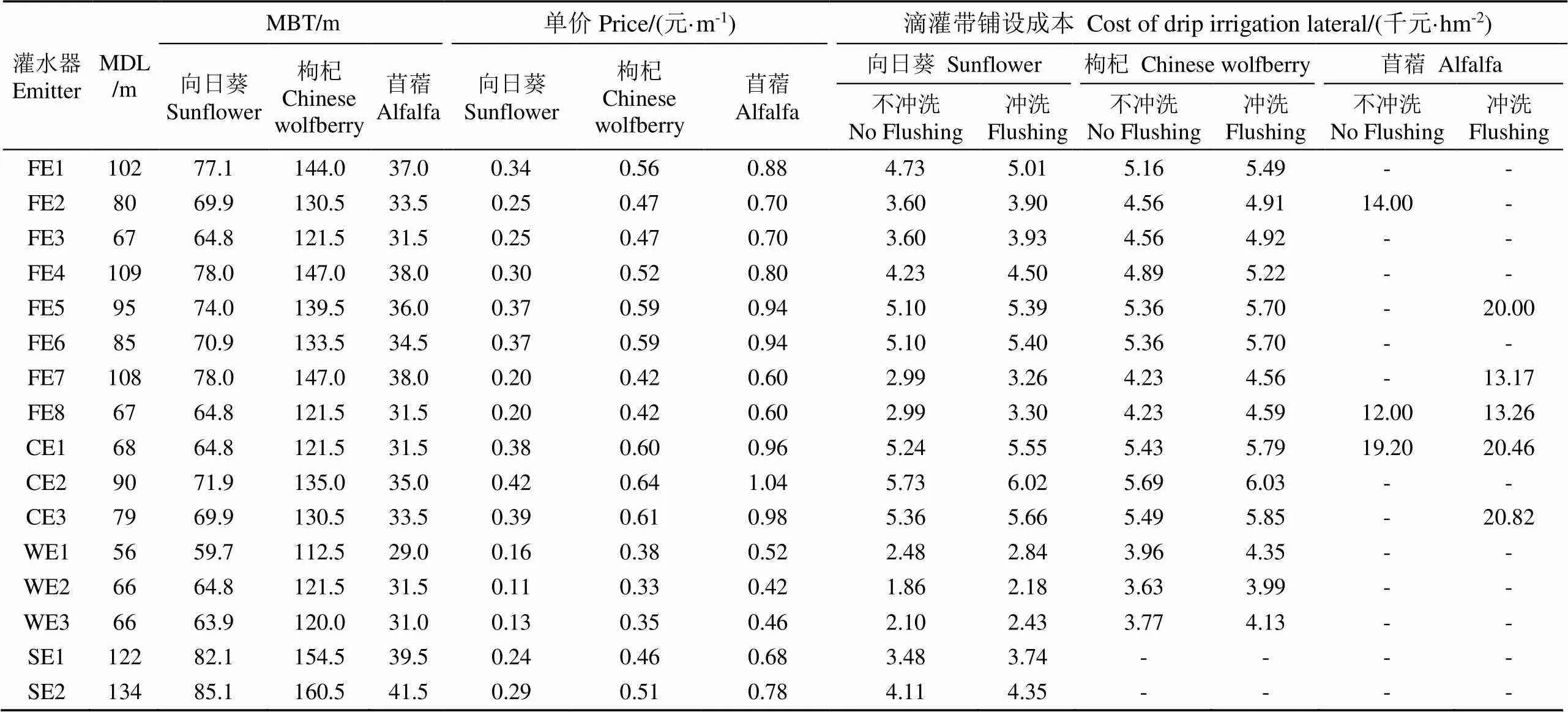

不同类型滴灌带毛管、支管极限铺设长度及其消耗成本见表4,其中,单价为不同类型灌水器对应每米滴灌带的价格(1、3、5 a使用期的滴灌带壁厚分别为0.2、0.4、0.6 mm,故价格不同)。由表4可知,虽然所有灌水器均满足1 a使用期(以向日葵为例)的灌水要求,但不同类型灌水器的成本明显不同,毛管冲洗前,CEs成本最高,FEs、SEs次之,WEs分别比前面三者低52.7%~67.5%、17.1%~63.5%、28.7%~54.7%;毛管冲洗后,成本投入均有所增加,增加幅度最高的是WEs(14.5%~17.2%),其次是FEs(5.7%~10.4%)、SEs(5.8%~7.5%)、CEs(5.1%~5.9%)。对于3 a使用期(以枸杞为例)而言,毛管冲洗前后,整体变化规律与向日葵较一致,WEs、FEs、CEs成本分别增加了9.5%~9.9%、6.3%~8.5%、6.0%~6.6%。对于5 a使用期(以苜蓿为例)而言,毛管不冲洗条件下FE2、FE8、CE1三者的成本分别为14.00、12.00、19.20千元/hm2,毛管冲洗处理后FE5、FE7、CE3满足了灌水要求,但成本分别增加了6.4%、9.8%、6.2%。

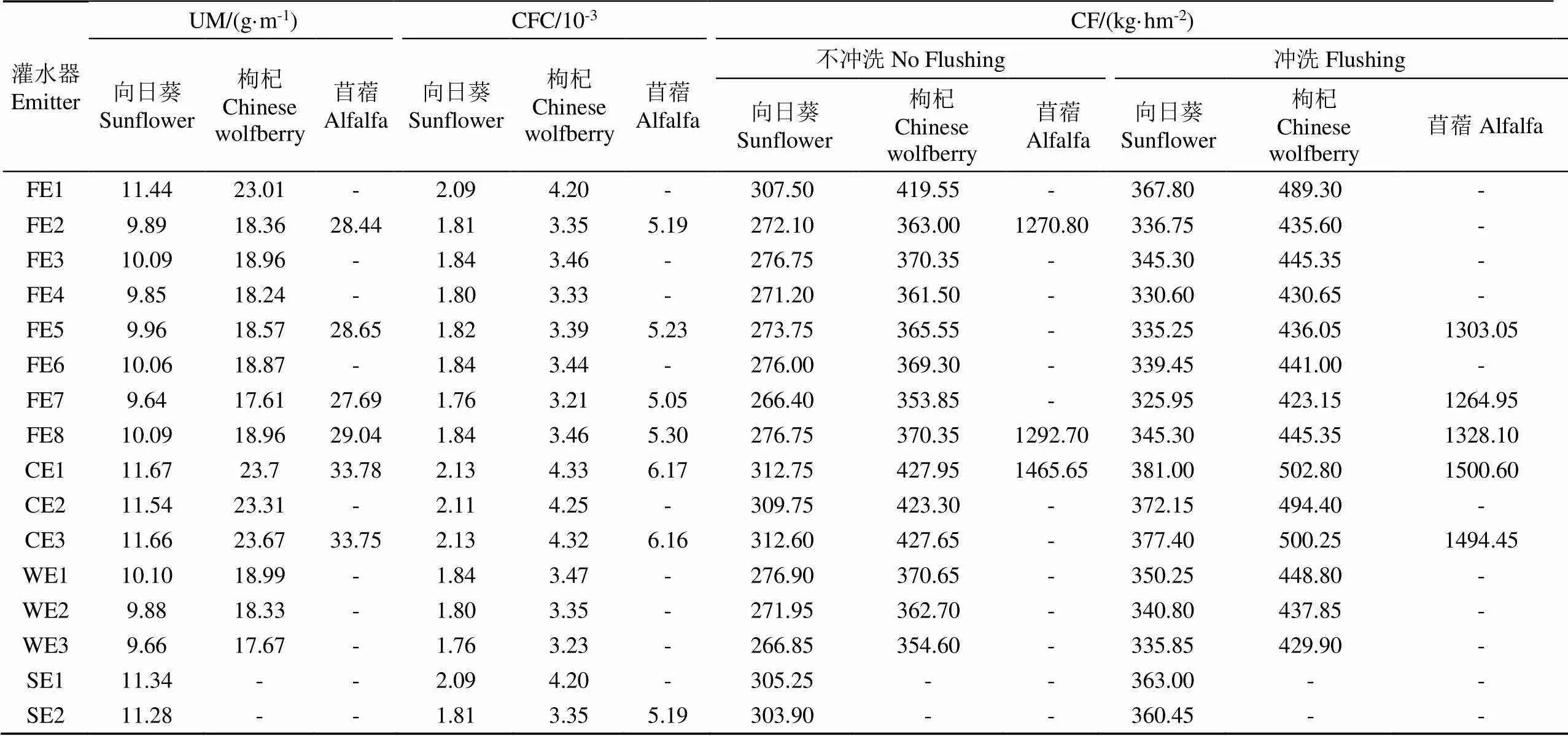

2.3 不同类型灌水器产品碳足迹

依据毛管、支管的极限铺设长度核算每公顷地块使用不同灌水器产品所产生的碳足迹,见表5。对于1 a使用期而言,不进行毛管冲洗时,CEs产生的碳足迹最高,其次是SEs、FEs,WEs最低,比前面三者分别低10.6%~14.7%、8.9%~12.6%、0~13.2%,毛管冲洗后,碳足迹均有所增加,增加幅度最大的是WEs(25.3%~26.5%),其余依次为FEs(19.6%~24.8%)、CEs(20.1%~21.8%)、SEs(18.6%~18.9%)。3 a使用期(以枸杞为例)的碳足迹总体变化规律与1 a使用期(以向日葵为例)一致,WEs的碳足迹分别比CEs、FEs低12.4%~17.1%、0~15.5%;毛管冲洗后,三者的碳足迹分别增加了20.7%~21.2%、16.8%~17.5%、16.6%~20.3%。对于5 a使用期(以苜蓿为例)而言,FE2、FE8、CE1三者产生的碳足迹分别为1.27×103、1.29×103、1.47×103kg/hm2,毛管冲洗后FE5、FE7、CE3满足了灌水要求,但碳足迹分别增加了19.3%、19.6%、17.0%。

表4 毛管、支管极限铺设长度及成本

注:“-”为不满足灌水生命周期要求的灌水器,对其不进行分析;毛管报价来源于生产厂家;内镶贴条式和单翼迷宫式滴灌带使用周期为1 a,表中价格未考虑更换问题;3种作物铺设的滴灌带壁厚分别为0.2、0.4、0.6 mm;成本为该作物种植年限内的总投入;MDL代表毛管极限铺设长度,MBT代表支管极限铺设长度。

Note: “-”is emitters that do not meet the requirements of the life cycle, and they are not analyzed; The price of drip irrigation lateral were from manufacturers; The drip irrigation lateral with inlaid strip and single-wing labyrinth have one year service life. Therefore, the price mentioned in the table did not considered the replacement issue; The wall thickness of drip irrigation lateral for the three crops are 0.2, 0.4 and 0.6 mm respectively; The cost includes the total investment within the crops planting life; MDL means the maximum laying length of drip irrigation laterals, MBT means the maximum laying length of branch tubes.

表5 不同滴灌带的碳足迹

注:UM代表单位质量,数据来源于生产厂家;CFC代表碳足迹系数,为能源及材料系数的总和;CF代表碳足迹。下同。

Note: UM means the unit mass, and the data comes from manufacturers; CFC means the carbon footprint coefficient, which is the sum of energy and material factors; CF means the carbon footprint. Same as below.

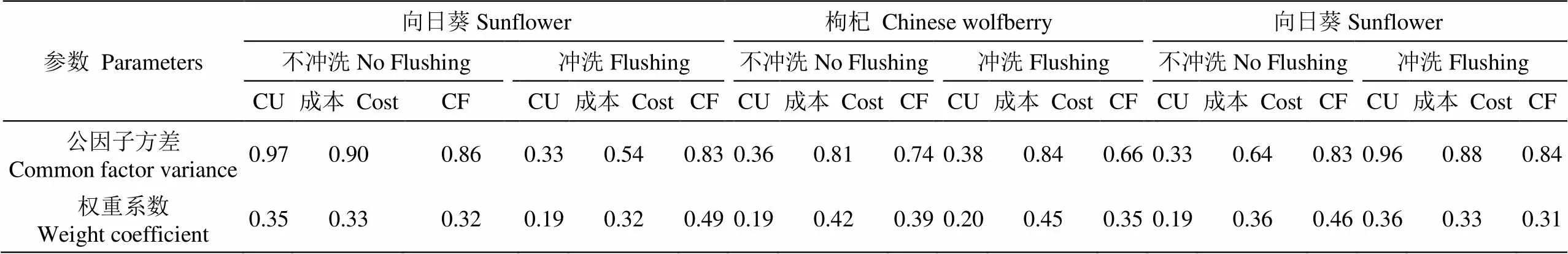

2.4 黄河水滴灌系统灌水器产品选择

基于本文建立的灌水器产品选择模型,指标影响因子权重和选择结果分别见表 6和表7。整体来看,不同类型灌水器产品评价指标a值差异比较明显。对于1 a使用期(以向日葵为例)而言,各处理组均满足生命周期内灌水要求,建议选择a值最低的灌水器产品,即毛管不冲洗处理组的WE2产品(a=0.33)。对于3 a使用期(以枸杞为例)而言,在不进行毛管冲洗时,WEs和FEs的a值较低,毛管冲洗后a值的变化无明显规律。整体来看,建议选择a值最低的灌水器产品,即毛管不冲洗处理组的FE7产品(a=0.30)。而对于5 a使用期(以苜蓿为例)而言,不冲洗处理组满足灌水要求的产品为FE2、FE8、CE1,三者a值分别是0.47、0.45、0.92,经过毛管冲洗后FE5、FE7、CE3达到灌水要求(三者a值分别为0.63、0.45、0.90),且FE8(a=0.44)、CE1(a=0.89)依然满足灌水要求,因此从中选取a值最低的灌水器产品,即毛管冲洗处理组的FE8产品。

表6 灌水器评价指标的公因子方差和权重系数

表7 不同作物灌水器产品选择

注:a为灌水器评价指标。

Note:ais evaluation index of emitter.

3 讨 论

滴灌灌水器流道尺寸微小,黄河水高泥沙浓度等特征加剧了灌水器堵塞的风险[21]。准确、合理地选择适宜的灌水器产品,有利于延长滴灌系统的使用寿命,避免频繁更换滴灌带[7]。试验选用4大类共16种灌水器产品,发现不同类型灌水器之间生命周期存在差异,主要原因是自身结构特征及材质不同[22-24]。总体来看,灌水器生命周期最长的是FEs,其次为CEs、SEs、WEs。SEs和WEs系列产品,整体生产基于吸附成型工艺,流道往往难以形成尖角且伴随老化形变等问题[12],同时灌水器内部水流紊乱程度不高、泥沙随水的跟随性偏低[25],易堵塞灌水器,从而导致生命周期变短,因此普遍用作一次性滴灌带。FEs与CEs的流道结构等参数基本一致,湍流强度以及泥沙随水跟随性高且堵塞物质容易脱落[26-28],故其抗堵塞能力较强,生命周期较长。但CEs的流道长度远远大于FEs,使得堵塞物质容易在流道内沉积[29],导致其生命周期低于FEs。

本文研究发现是否设置毛管冲洗与灌水器的使用年限有关:对于1、3 a使用期(分别以向日葵和枸杞为例)而言,毛管冲洗并未改变其灌水要求,且会增加系统成本;仅5 a使用期(以苜蓿为例)需设置毛管冲洗,在该使用期内,由于试验误差,FE2毛管冲洗处理组生命周期略低于不冲洗处理组,但整体来看毛管冲洗处理对5 a使用期灌水器生命周期提升的效果明显。根据本文建立的在黄河水滴灌条件下针对不同使用年限需求的灌溉作物,综合考虑灌水器生命周期、成本和碳足迹的滴灌带选择方法模型,使用期为1、3、5 a时(分别以向日葵、枸杞和苜蓿为例)应分别选择WE2、FE7、FE8灌水器产品,这与以往的选择方法明显不同(表8)。比较而言,流量法[6]和CRI法[7]对滴灌带的使用年限考虑较少,所有使用年限作物均选择毛管冲洗条件下具有高抗堵塞性能的WE3、FE8产品,这将使得1 a使用期灌水器的成本将分别增加30.6%、77.4%,碳足迹分别增加23.5%、27.0%;对于3 a使用期灌水器,碳足迹将分别增加21.5%、4.7%;对于5 a使用期而言,第1种方法的选择结果不满足灌水要求,这是由于灌水器的抗堵塞性能评价需要考虑多方面的因素,单一考虑额定流量存在局限性[30]。

本文仅初步建立了黄河水滴灌灌水器适用性产品的选择方法,由于试验条件有限,仅分析了4种类型共16种灌水器,适用于不同水源、多种作物以及全部灌水器选择体系的建立有待进一步研究。

表8 不同灌水器选择方法比较

注:“-”为不进行毛管冲洗,“+”为进行毛管冲洗;CRI为抗堵塞性能综合相对指数。

Note: “-” is no flushing, “+” is flushing; CRI is anti-clogging relative index.

4 结 论

1)黄河水滴灌系统在不进行毛管冲洗条件下,不同灌水器之间生命周期、成本和碳足迹均存在较为明显的差异。对于生命周期而言,内镶贴片式均值最高,单翼迷宫式最低;以1 a使用期的毛管不冲洗处理组为例,单翼迷宫式灌水器产品的成本较内镶圆柱式、内镶贴片式和内镶贴条式灌水器产品成本分别低52.7%~67.5%、17.1%~63.5%、28.7%~54.7%,且产生的碳足迹低10.6%~14.7%、0~13.2%、8.9%~12.6%。

2)黄河水滴灌系统设置毛管冲洗后,灌水器生命周期延长了2.6%~82.9%,但毛管冲洗的同时会使得滴灌带的铺设成本和碳足迹分别增加5.1%~17.2%、16.6%~26.5%。整体来看,毛管冲洗对1、3 a使用期(分别以向1 a生向日葵和3 a生枸杞为例)灌水器的整体效果较差,对5 a使用期(以5 a生苜蓿为例)灌水器的效果较明显。

3)在本文过滤模式下,综合考虑滴灌带产品的生命周期、生产成本和碳足迹等因素,目前黄河水滴灌条件下1、3 a使用期(分别以1 a生向日葵和3 a生枸杞为例)建议分别选择在毛管不冲洗条件下流量为2.7 L/h的单翼迷宫式和1.4 L/h的内镶贴片式灌水器,而对于5 a使用期(以5 a生苜蓿为例)宜选用带有毛管冲洗流量为2.8 L/h的内镶贴片式灌水器。

[1]孙景生,康绍忠. 我国水资源利用现状与节水灌溉发展对策[J]. 农业工程学报,2000,16(2):1-5. Sun Jingsheng, Kang Shaozhong. Present situation of water resources usage and developing countermeasures of water-saving irrigation in China[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2000, 16(2): 1-5. (in Chinese with English abstract)

[2]安催花,鲁俊,吴默溪,等. 黄河下游河道平衡输沙的沙量阈值研究[J]. 水利学报,2020,51(4):402-409. An Cuihua, Lu Jun, Wu Moxi, et al. The threshold value of equilibrium sediment transport in the Lower Yellow River[J]. Journal of Hydraulic Engineering, 2020, 51(4): 402-409. (in Chinese with English abstract)

[3]胡春宏,张晓明. 论黄河水沙变化趋势预测研究的若干问题[J]. 水利学报,2018,49(9):1028-1039. Hu Chunhong, Zhang Xiaoming. Several key questions in the researches of runoff and sediment changes and trend predictions in the Yellow River[J]. Journal of Hydraulic Engineering, 2018, 49(9): 1028-1039. (in Chinese with English abstract)

[4]孙贯芳,于健,杜斌,等. 过滤后黄河水对滴灌系统的影响[J]. 排灌机械工程学报,2015,33(10):901-907. Sun Guanfang, Yu Jian, Du Bin, et al. Influence of the Yellow River water filtered on drip irrigation system[J]. Journal of Drainage and Irrigation Machinery Engineering, 2015, 33(10): 901-907. (in Chinese with English abstract)

[5]张杰武. 高含沙水泥沙分离系统设计与分析[J]. 节水灌溉,2015(5):88-91. Zhang Jiewu. Design and Analysis of high sediment bearing water and sediment separation system[J]. Water Saving Irrigation, 2015(5): 88-91. (in Chinese with English abstract)

[6]牛文全,刘璐. 浑水泥沙粒径与含沙量对迷宫流道堵塞的影响[J]. 排灌机械工程学报,2011,29(6):547-552. Niu Wenquan, Liu Lu. Influence of muddy water concentration and particle diameter on clogging of labyrinth channels[J]. Journal of Drainage and Iirrigation Mmachinery Eengineering, 2011, 29(6): 547-552. (in Chinese with English abstract)

[7]Zhou B, Zhou H X, Li Y K, et al. Using an anti-clogging relative index (CRI) to assess emitters rapidly for drip irrigation systems with multiple low-quality water sources[J]. Agricultural Water Management, 2019, 221: 270-278.

[8]Wang J, Chen R, Yang T, et al. A computationally-efficient finite element method for the hydraulic analysis and design of subsurface drip irrigation subunits[J]. Journal of Hydrology, 2021, 595(1): 125990.

[9]王新端,白丹,宋立勋,等. 不同结构滴灌双向流道灌水器抗堵性能对比试验[J]. 农业工程学报,2018, 34(14): 78-85. Wang Xinduan, Bai Dan, Song Lixun, et al. Contrast experiment on anti-clogging performance of bidirectional flow channel emitters with different structures in drip irrigation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(14): 78-85. (in Chinese with English abstract)

[10]Liu H J, Huang G H. Laboratory experiment on drip emitter clogging with fresh water and treated sewage effluent[J]. Agricultural Water Management, 2009, 96(5): 745-756.

[11]Brown M J, Bondurant J A, Brockway C E. Subsurface trickle irrigation management with multiple cropping[J]. Transactions of the ASAE, 1981. 24(6): 34478.

[12]马宁,祁新萍. 新疆地区单翼迷宫式滴灌带产品质量状况浅析[J]. 广州化工,2015,43(13):52-54. Ma Ning, Qi Xinping. Analysis of single wing labyrinth drip irrigation belt product quality in Xinjiang Region[J]. Guangzhou Chemical Industry, 2015, 43(13): 52-54. (in Chinese with English abstract)

[13]Han S Q, Li Y K, Zhou B, et al. An in-situ accelerated experimental testing method for drip irrigation emitter clogging with inferior water[J]. Agricultural Water Management, 2019, 212(1): 136-154.

[14]张丽霞,王瑞萍,刘宏云,等. 向日葵膜下滴灌灌溉试验研究[J]. 内蒙古水利,2020(10):10-11. Zhang Lixia, Wang Ruiping, Liu Hongyun, et al. Experimental Study on drip irrigation under film for sunflower[J]. Inner Mongolia Water Resources, 2020(10): 10-11. (in Chinese with English abstract)

[15]侯建安,南雄雄,康超,等. 滴灌频率和定额对枸杞园土壤水热分布及产量的影响[J]. 经济林研究,2019,37(2):58-66. Hou Jian’an, Nan Xiongxiong, Kang Chao, et al. Effects of drip irrigation frequency and quota on soil water and heat distribution and fruit yield in Lycium barbarum garden[J]. Nonwood Forest Research, 2019, 37(2): 58-66. (in Chinese with English abstract)

[16]何子建,史文娟,杨军强. 膜下滴灌间作盐生植物棉田水盐运移特征及脱盐效果[J]. 农业工程学报,2017,33(23):129-138. He Zijian, Shi Wenjuan, Yang Junqiang. Water and salt transport and desalination effect of halophytes intercropped cotton field with drip irrigation under film[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(23): 129-138. (in Chinese with English abstract)

[17]Muhammad T, Zhou B, Li Y K, et al. Effects of phosphorus-fertigation on emitter clogging in drip irrigation system with saline water[J]. Agricultural Water Management, 2021, 243(1): 106392.

[18]Pei Y T, Li Y K, Liu Y Z, et al. Eight emitters clogging characteristics and its suitability under on-site reclaimed water drip irrigation[J]. Irrigation Science, 2014, 32(2): 141-157.

[19]Li Y K, Song P, Pei Y T, et al. Effects of lateral flushing on emitter clogging and biofilm components in drip irrigation systems with reclaimed water[J]. Irrigation Science, 2015, 33(3): 235-245.

[20]Chen X Z, Kelly R T, Pieter R O, et al. Environmental impact assessment of water-saving irrigation systems across 60 irrigation construction projects in northern China[J]. Journal of Cleaner Production, 2020, 245(11): 83-88.

[21]张杰武,冯吉,徐飞鹏,等. 引黄滴灌砂石过滤器滤料过滤性能[J]. 排灌机械工程学报,2016,34(4):357-361. Zhang Jiewu, Feng Ji, Xu Feipeng, et al. Sand filter performance on drip irrigation with the Yellow River[J]. Journal of Drainage and Irrigation Mechanical Engineering, 2016, 34(4): 357-361. (in Chinese with English abstract)

[22]Zhou B, Li Y K, Liu Y Z, et al. Effect of drip irrigation frequency on emitter clogging using reclaimed water[J]. Irrigation Science, 2015, 33(3): 221-234.

[23]李云开,周博,杨培岭. 滴灌系统灌水器堵塞机理与控制方法研究进展[J]. 水利学报,2018,49(1):103-114. Li Yunkai, Zhou Bo, Yang Peiling. Research advances in drip irrigation emitter clogging mechanism and controlling methods[J]. Journal of Hydraulic Engineering, 2015, 49(1): 103-114. (in Chinese with English abstract)

[24]Yang B, Wang J D, Zhang Y Q, et al. Anti-clogging performance optimization for dentiform labyrinth emitters[J]. Irrigation science, 2020, 38(1): 1-11.

[25]杨晓池. 迷宫式灌水器流道内水沙两相流研究[D]. 西安:西安理工大学,2006. Yang Xiaochi. Study on Water-sediment Two Phase Flow in Labyrinth Emitter Channel[D]. Xi'an: Xi'an University of Technology, 2006. (in Chinese with English abstract)

[26]Li Y K, Pan J C, Chen X Z, et al. Dynamic effects of chemical precipitates on drip irrigation system clogging using water with high sediment and salt loads[J]. Agricultural Water Management, 2019, 213: 833-842.

[27]Li Y K, Feng J, Xue S, et al. Formation mechanism for emitter composite-clogging in drip irrigation system[J]. Irrigation Science, 2019, 37(2): 169-181.

[28]Sun H S, Li Y K, Feng J, et al. Effects of flow path boundary optimizations on particle transport in drip irrigation emitters[J]. Irrigation and Drainage, 2016, 65(4): 417-425.

[29]李建梅. 单翼迷宫式滴灌带外观质量异常的产生及其处理措施[J]. 现代农业,2008(10):60-61. Li Jianmei. Appearance quality abnormality of single-wing Labyrinth drip irrigation belt and its treatment measures[J]. Modern Agriculture, 2008(10): 60-61. (in Chinese with English abstract)

[30]刘燕芳,李丹,吴普特,等. 不同类型灌水器在硬水滴灌条件下的堵塞特征[J]. 农业工程学报,2018,34(3):96-102. Liu Yanfang, Li Dan, Wu Pute, et al. Clogging characteristic of different emitters in drip irrigation with hard water[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(3): 96-102. (in Chinese with English abstract)

Selection of suitable drip-emitters for Yellow River water drip irrigation

Liu Lu1, Hou Peng1, Liu Zeyuan1, Wu Naiyang1, Li Weishan1, Wu Ruonan1, Wang Haijun2, Ma Yongjiu3, Li Yunkai1※

(1.,,,100083,;2..,.,,064100,;3.-.,.,730000,)

Diversified irrigation water has become an increasingly urgent need, due mainly to the limited fresh water resources and water pollution in China. Consequently, Yellow-river water irrigation has attracted more attention in recent decades. Since the Yellow River is the most sediment-filled river on earth, emitter clogging by a high concentration of sand has confined to the application of drip irrigation. Naturally, anti-clogging performance has been a commonly-used indicator to select the appropriate emitters. However, resource waste, high costs, and carbon footprint have posed a great challenge on both the anti-clogging performance and service life, when selecting the emitter products. In this study, an experimental field test was conducted to select emitter and lateral products suitable for drip irrigation with Yellow-River water, concurrently considering the anti-clogging performance, service life, system cost, and carbon footprint. SPSS Principal Component Analysis (PCA) was used to establish selection indexes, and then to screen the suitable emitter products for various crops in different years. 16 kinds of emitters were also analyzed using Cristiansen Uniformity (CU) coefficient, including inlaid plain channel emitters, inlaid cylindrical emitters, single-wing labyrinth, and inlaid strip emitters. 3 crops were selected to evaluate the drip irrigation laterals. The experimental water was taken from the Wushen Canal in Hetao Irrigation District, and then filtered with sedimentation basin before entering into the drip irrigation system. Irrigation water was treated through the homogeneous filtration of a sand filter and a laminated filter. The work pressure was maintained at 0.1 MPa in operation. The Yellow-River water was operated for 9 h/d with a flushing frequency of once every 60 h at a flow rate of 0.45 m/s and a flushing time of 6 min, a total of 600 h (flushing water) and 720 h (non-flushing water). The results showed that there were significant differences in life cycle, cost and carbon footprint in different types of drip-emitters. The longest life cycle was found in flat emitters, followed by cylindrical emitters, strip emitters, and single wing labyrinth emitters. The highest cost was found in cylindrical emitters, followed by flat emitters, strip emitters, and single wing labyrinth emitters. CU of all emitters showed a slow and then rapid downward trend. The highest carbon footprint was cylindrical emitters, followed by flat emitters, strip emitters, and single wing labyrinth emitters. Taking the no-flushing capillary for one-year life cycle as an example, the costs of single wing labyrinth emitters are 52.7%-67.5%, 17.1%-63.5% and 28.7%-54.7% lower than that of cylinder emitters, flat emitters and strip emitters, respectively, and the carbon footprint is 10.6%-14.7%, 0-13.2% and 8.9%-12.6% lower. Consequently, it was recommended to use the single wing labyrinth drip emitter with 2.7 L/h for a 1-year usage period (sunflower), the flat emitter with 1.4 L/h for a 3-year usage period (Chinese wolfberry), and the flat emitter with 2.8 L/h (with capillary flushing) for a 5-year usage period (alfalfa) in the crop irrigation in Inner Mongolia Hetao Irrigation Area. Capillary flushing demonstrated relatively low effects on the 1 and 3-year period (sunflower and Chinese wolfberry), however, the effects were more obvious on the 5-year use period (alfalfa). This finding can provide a new perspective for the selection of drip-emitter products in large-scale drip irrigation with the high-sand Yellow-River water.

life cycle; irrigation; silt; emitter; clogging; lateral flushing

10.11975/j.issn.1002-6819.2021.06.013

S275.6

A

1002-6819(2021)-06-0099-09

刘露,侯鹏,刘泽元,等. 适用于黄河水滴灌的灌水器筛选研究[J]. 农业工程学报,2021,37(6):99-107.doi:10.11975/j.issn.1002-6819.2021.06.013 http://www.tcsae.org

Liu Lu, Hou Peng, Liu Zeyuan, et al. Selection of suitable drip-emitters for Yellow River water drip irrigation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(6): 99-107. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2021.06.013 http://www.tcsae.org

2021-01-06

2021-03-05

国家重点研发计划(2017YFD0201504);国家自然科学基金重大项目(51790531)

刘露,研究方向为引黄滴灌灌水器堵塞。Email:1418685169@qq.com

李云开,教授,博士生导师,研究方向为精量高效滴灌装备原理、设计及应用。Email:yunkai@cau.edu.c