Effect of Grain Particle Size on Quality of Multi-grain Chips Under Screw Extrusion Processing

Yan Zi-hao , Zheng Xian-zhe, Wang Li-ping, Tan Bin, Liu Yan-xiang, Qiao Cong-cong, and Tian Xiao-hong

1 College of Engineering, Northeast Agricultural University, Harbin 150030, China

2 Academy of National Food and Strategic Reserves Administration, Beijing 100037, China

Abstract: Multi-grain chips processed by screw extrusion processing have high nutrition and production value with a low glycemic index. To analyze the effects of particle sizes on the qualities of multi-grain chips extrusion processing by using a single screw extruder, mesh numbers were selected as 80, 100 and 120 to describe different grain particle sizes. It was found that the particle sizes of the raw materials had effects on the basic components, sensory properties, texture properties, antioxidant activities and in vitro digestibilities of extruded chips. The results showed that with the decrease of particle sizes, the moisture contents, starch contents of the chips decreased, and fat contents, dietary fiber contents increased. The edible qualities of the chips increased with the decrease of the grain sizes of raw materials. The antioxidant capacities and estimated glycemic indexes of the three kinds of chips showed a trend of decreasing first, and then increasing with the decrease of particle sizes. Correlation analysis showed that the total antioxidant capacities of chips were negatively correlated with the estimated glycemic indexes. The research results provided valuable guidance for the quality processing of multi-grain chips under extrusion processing.

Key words: multi-grain, chip, particle size, extrusion processing, antioxidant, in vitro digestion

Introduction

The grain chips are a favored food product due to their crispness and refreshing taste. As a common processing product, fried chips have plentiful advantages, including aroma, attractive appearance and high energy. However, fried chips can cause obesity, produce carcinogens and destroy nutrients of raw materials. Extrusion processing technology has high feasibility and efficiency for the chips processing which consists of technology steps in crushing, kneading, mixing, ripening, sterilization, pre-drying and molding (Liuet al., 2008). In extrusion processing, high pressure in chamber of extruder expanses the materials processed to form the crispy puffed products in a short time with high nutrient composition retained. Therefore, extrusion technology has been widely used in the food industry. Multigrain extrusion processing may produce novel and enforced nutrition food products such as semen coicis, quinoa and Tartary buckwheat. At present, the research topics of extruded chips focus on the selection of raw materials (Han, 2019), edible qualities (Laurentet al., 2005) and processing technologies (Fu, 2012). However, the particle size of raw grain, as an ignorance factor, directly influences the physical and chemical properties, volume expansions, edible qualities and nutrition digestion of multi-grain chips processed by extrusion. Therefore, the effects of grain particle sizes on the edible qualities, antioxidant activities andin vitrodigestibilities of extruded cereal chips were investigated in this study, which was expected to provide technical supports for the production of cereal chips.

Materials and Methods

Experimental materials and instruments

The grain raw materials used in the experiment (Tartary buckwheat, millet, highland barley, quinoa, mung bean and oat) were all purchased from local supermarkets (Beijing, China).

The total dietary fiber kit and the total starch kit were purchased from Megazyme, Ireland; the total antioxidant capacity kit was purchased from Nanjing Jiancheng Institute of Biological Engineering (Nanjing, China);α-amylase and pepsin were purchased from Sigma Company, USA; all other reagents used in the experiment were analytical pure.

Pulverizer (WF-400), single screw extruder (FMDJ-90), tablet press (FMFK300) and oven (FMRD-200) were all purchased from Hunan Fumake Food Engineering Technology Co., Ltd. (Hunan, China); dietary fiber analyzer (Fiber E) was purchased from FOSS (Sweden); texture analyzer (TA-XT Plus) was purchased from Stable Micro Systems (UK); T6 UV-Vis spectrophotometer was purchased from Beijing Pullout General Instrument Co., Ltd (Beijing, China).

Preparation process and technological parameters

The preparation process was as the followings. Raw materials crushing → sieving → mixing evenly, according to the proportion (Tartary buckwheat 30%, millet 28%, highland barley 21%, quinoa 10.5%, mung bean 7% and oat 3.5%) → determination of moisture content → humidity control (21%) → extrusion → molding → baking → finished products. The 80 M, 100 M and 120 M respectively represented the chips made by squeezing through 80-mesh, 100-mesh and 120-mesh screens after raw materials were crushed.

According to the preliminary experiment, extrusion parameters for multi-grain chip were selected as single screw extruder main screw speed of 400 r · min-1,feeding speed of 25 kg · h-1; baking machine temperature 200℃ and conveyor belt speed 60%.

Methods for determination of basic components

Moisture determination was based on GB/Z 21922-2008; protein determination was based on GB/T 24318-2009, and Dumas combustion method was for determination; fat determination was based on GB/T 5009.6-2016; dietary fiber determination was based on the methods of AOAC 985.29 and AACC 32-05, the total dietary fiber (TDF) content in food and food products was determined by the phosphate buffer method; the total starch content determination was based on Megazyme total starch (TS) assay kit.

Sensory evaluation

The sensory evaluation system (Zhang, 2017) and evaluation criteria are shown in Table 1. Sensory of chips was evaluated in taste, shape and smell. Sensory evaluation was performed by eight researchers with professional backgrounds. The comprehensive score was the sum of the product of each score and its weight.

Table 1 Criteria and weight of score

Texture determination

TA-XT Plus texture analyzer was used to measure the hardness and brittleness of the chips. Hardness represented the ability of the chips to resist external pressure on its surface. The brittleness was characterized by the peak number generated when the triangle was broken. The more peaks, the more crisper the chips were. The compression mode was selected for the experiment as the compression distance of 5 mm, the velocity of probe movement of 1 mm · s-1, and the returning velocity of probe of 10 mm · s-1. Thirty samples were randomly selected and the average data was taken.

Polyphenols extraction

Polyphenols were extracted with anhydrous methanol and ethyl acetate (Caiet al., 2015). Free polyphenols extraction: 2.00 g sample was accurately weighed and placed in a 50 mL centrifuge tube, and 40 mL anhydrous methanol was added. The solution was ultrasonized for 30 min, centrifuged for 10 min, and the supernatant was collected. Repeated the above operation three times, and the supernatant was rotatingly steamed and dried, then the volume was constant with methanol to 2 mL. Combined polyphenols extraction: added 15 mL 2 mol · L-1NaOH to the precipitate after free polyphenols extraction, and reacted for 1 h at room temperature without light. Adjusted pH to neutral, added 20 mL ethyl acetate, centrifuged for 10 min, collected the supernatant, repeated the operation three times, the supernatant rotatingly evaporated with methanol volume to 2 mL.

Determination of phenolics content

Folin-Ciocalteu method (Caiet al., 2004) was used to determine the phenolics content of the samples, and the standard curve was established with gallic acid as the standard sample. The phenolics content of the sample was expressed as the milligram of gallic acid contained in 100 g dry base (mg · 100 g-1).

Determination of flavonoids content

Flavonoids content of the sample was determined by NaNO2-Al(NO3)3method (Baoet al., 2005). Rutin was used as the standard sample to develop a standard curve. Flavonoids content of the sample was expressed by the number of mg Rutin contained in 100 g dry base (mg · 100 g-1).

Determination of antioxidant activity

The determination of DPPH · free radical scavenging ability was based on the method with reference to Kauret al(2006).

ABTS+· free radical scavenging ability was determined according to method of Shenet al(2009).

The total antioxidant capacity was determined according to the requirements of the total antioxidant capacity test kit (T-AOC) of Nanjing Jiancheng Biological Engineering Institute.

Determination of in vitro characteristics

In vitrodigestion characteristics were determined as the followings (Maet al., 2013). The 5 g sample was immersed in 50 mL distilled water. The 0.5 mL sample solution was placed in a 50 mL centrifuge tube. Added 10 mL of HCl-KCl buffer with pH 1.5 and 0.2 mL of pepsin solution (0.1 g · mL-1), and placed in a 40℃ water bath to oscillate for 1 h. Added 0.5 mol · L-1sodium acetate buffer with pH 6.9 to replenish the volume to 25 mL. The 5 mLα-amylase (2.6 IU) was added and oscillated in a water bath at 37℃. At 0, 20, 30, 60, 90, 120 and 180 min of enzymatic hydrolysis, 1 mL of the solution was removed and placed in boiling water bath to kill the enzyme. Glucose as the standard, 3, 5-dinitrosalicylic acid method was used to determine the content of reducing sugar at different enzymatic hydrolysis times.

The rapidly digestible starch (RDS), slowly digestible starch (SDS) and resistant starch (RS) were calculated by referring to Liet al. (2017), and the formula was as the followings:

FGwas free glucose content (mg);G20andG120respectively denoted the glucose content in the digestive juice at the corresponding time of enzymatic hydrolysis (mg);TGwas the total glucose (mg);TSwas the total starch content (mg); 0.9 was the conversion coefficient.

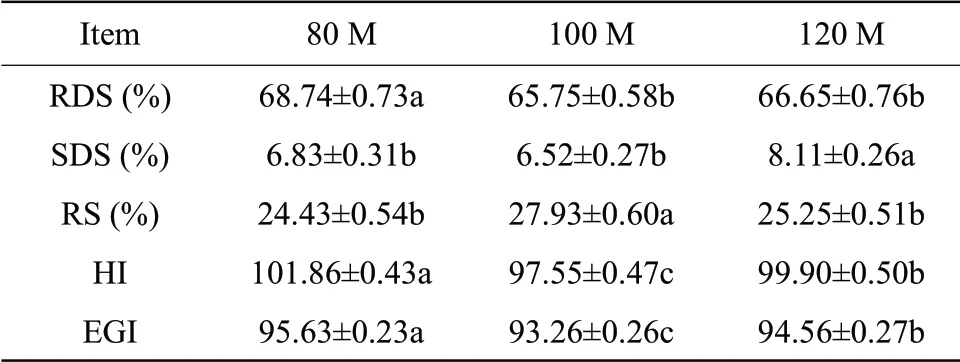

Starch hydrolysis curve was plotted with starch hydrolysis rate as ordinate and time as abscess coordinate. The area under the curve (AUC) was calculated, and then the starch hydrolysis index (HI) and the estimated glycemic index (EGI) of the sample were obtained.

Data processing

All the experimental data were expressed as mean ± standard deviation. SPSS 19.1 software was used to analyze the data. Ducan's multiple test was used for significance analysis,P<0.05 was considered significant, and Pearson was used for correlation coefficient. Qrigin 9.1 software was used for drawing.

Results

Basic components

The basic composition of food was of great significance to the quality of food, which not only affected the sensory qualities of food, but also affected the functional characteristics of food. The basic components of different multi-grain chips were shown in Table 2. The moisture, fat, starch and dietary fiber in the basic components of the chips are significantly affected by the particle sizes of different raw materials (P<0.05). There were significant differences in the moisture contents among the chips (P<0.05). The smaller powder particle sizes resulted in the lower moisture contents of the chips. The protein contents showed a gradually increasing trend, but there was no significant difference among different chips (P>0.05). The smaller particle sizes of the raw materials caused the lower water-holding capacities of the materials and the more water lost in the processing process. With the decrease of the particle sizes of raw material powder, the contents of fat and dietary fiber increased gradually, while the contents of starch decreased.

Table 2 Contents of basic components in 100 g chips

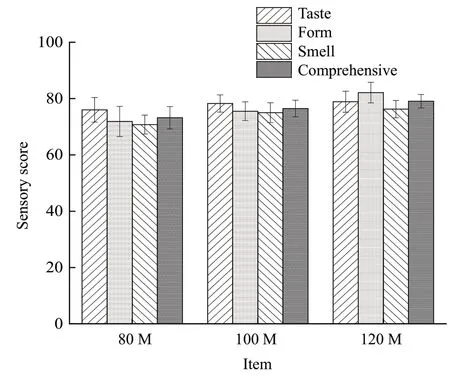

Sensory quality

Fig. 1 showed the sensory score of chips, in which the comprehensive score was the sum of the product of each index score and the weight of each index. As could be seen from Fig. 1, with the decrease of the particle sizes of raw powder, the chips' taste, form and smell score all showed a trend of gradual increase. The comprehensive score of 80 M was 73.19, the comprehensive score of 100 M was 4.45% higher than that of 80 M, and the comprehensive score of 120 M was 3.30% higher than that of 100 M.

Fig. 1 Sensory evaluation score

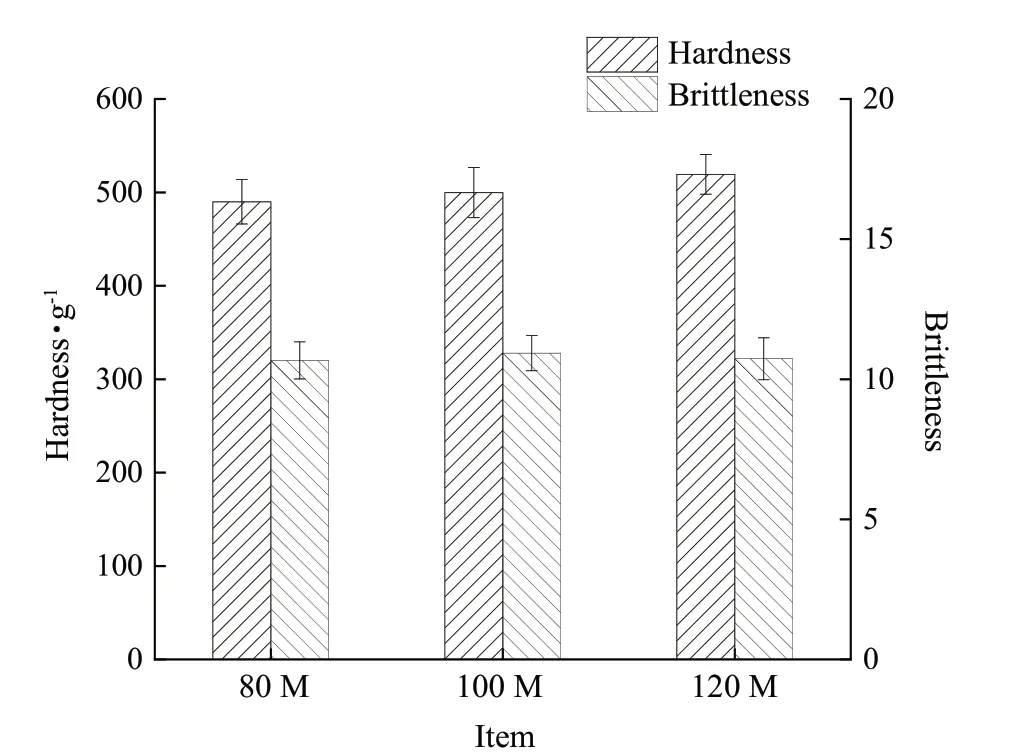

Texture characteristics

Fig. 2 showed the texture characteristics of chips. There were significant differences among 80 M, 100 M and 120 M (P<0.05), and the smaller the particle sizes of raw material powder, the greater the hardness of chips. Wang(2018) studied the texture characteristics of black rice and black bean noodles with different particle sizes, and found that the hardness of noodles increased with the decrease of raw material particles. Similarly, in study of different grinding methods on pea flour quality, it was found that the particle fineness of raw material powder prepared by roller milling was the smallest while the hardness of pea flour was the highest (Tianet al., 2016). In addition, a similar phenomenon was observed in noodles (Chenet al., 2011; Menget al., 2014). The chips made of small particle materials had a tighter surface than those of large particle materials.

Phenolics and flavonoids contents

Phenolics and flavonoids were important antioxidant active ingredients in cereal food, which could delay or inhibit the oxidation process of lipids and other biofilms by blocking the chain reaction caused by free radicals (Liet al., 2009), which played a health care role in preventing aging and assisting in the treatment of chronic diseases (Yaoet al., 2015). Fig. 3A showed phenolics contents of different chips. It could be seen that phenolics substances mainly existed in free form in the chips prepared in the experiment. The total phenolics contents ranged from 66.13 to 73.11 mg · 100 g-1, which was lower than raw phenolics contents (Hanet al., 2019). Extrusion process had a certain degree of destruction of phenolics substances. The contents of free phenolics and the total phenolics in 80 M were significantly higher than those in 100 M and 120 M (P<0.05), but there was no significant difference in the contents of combined phenolics among different chips. Therefore, in the extrusion process, the large particle feedstock could better protect the structure of free phenolics than the small particle feedstock. The flavonoids contents of different chips are shown in Fig. 3B. The total flavonoids contents ranged from 407.21 to 475.16 mg · 100 g-1. The effects of grain particle sizes on the contents of flavonoids were different from those of phenolics. The contents of free flavonoids and the total flavonoids in 120 M were significantly higher than those in 80 M and 100 M, while the contents of combined flavonoids were significantly lower than those in 80 M and 100 M. Therefore, the particle sizes affected the conversion of combined flavonoids to free flavonoids.

Fig. 2 Effects of particle sizes on texture characteristics

Fig. 3 Contents of free phenolics, combined phenolics, the total phenolics (A), free flavonoids, combined flavonoids and the total flavonoids (B)

Antioxidant activity

Free radicals were active substances produced during normal metabolic processes in the body. Studies on free radical biology had shown that a variety of human diseases, such as cardiovascular diseases, cancer and aging, was related to excessive free radicals produced in the body (Kaliora and Dedoussis, 2007). The free radical scavenging ability of different chips is shown in Table 3. Among them, ABTS+· scavenging ability of free extracts at 100 M and 120 M was significantly higher than that at 80 M (P<0.05), and the particle sizes of raw materials had no significant effects on ABTS+· free radical scavenging ability of combined phenolics. DPPH· free radical scavenging activity of the free extract from 80 M was 42.34, which was significantly higher than that from 100 M and 120 M. The free radical scavenging ability of ABTS+ · and DPPH· was different in different chips. Phenolics and flavonoids had a targeted scavenging effect on free radicals, and phenolics mainly acted on DPPH· free radicals, while flavonoids had a closer scavenging ability with ABTS+· free radicals (Caiet al, 2015). With the decrease of particle sizes, the total antioxidant capacity of the three kinds of chips firstly decreased, and then increased.

Table 3 Free radical scavenging and the total antioxidant abilities of chips

Characteristics of in vitro digestion of multigrain chips

The hydrolysis rates of the total starch in different particle size chips are shown in Fig. 4. It could be seen that the extrusion greatly improved the digestibilities of grain chips. At the initial stage of enzymolysis, the total starch of the tested samples was rapidly decomposed into reducing sugar byα-amylase, and the enzymolysis of the starch was basically completed from beginning in 30 min. After 30 min, the digestibilities of the total starch were different, which indicated thatin vitrodigestion of extruded chips was mainly affected by slow digestion starch. In the whole simulated digestion experimentin vitro, the hydrolysis rate of the total starch at 80 M was the highest, followed by 120 M and the lowest was 100 M.

Fig. 4 The total starch hydrolysis rate of white bread and chips

RDS, SDS, RS, HI and EGI of chips

Englystet al. (1992) classified starch into RDS, SDS and RS from the perspective of digestive characteristics, and the contents of the three kinds of starch were closely related to food digestive characteristics and human health (Yu and Lian, 2011). The contents of RDS, SDS and RS in different chips are shown in Table 4. RDS contents of all the three starches were above 65%, indicating that the extruded chips were extremely digestible and absorbed by the body. The content of RDS in 80 M was the highest, the content of SDS in 120 M was the highest, and the content of RS in 100 M was the highest. Interestingly, there was no linear relationship between the changes of EGI and the changes of particle sizes due to digestive properties of food depending on many factors.

Correlation analysis

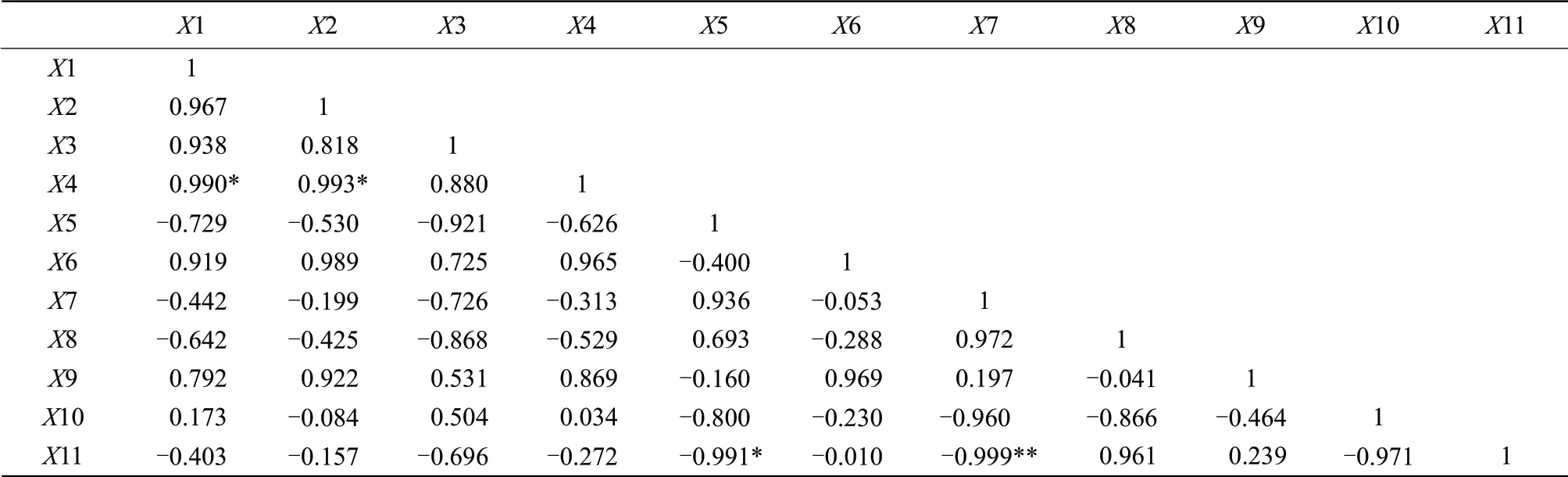

The correlation between basic components, texture properties, antioxidant activities andin vitrodigestibilities was analyzed in order to obtain the connection between each other. Protein, fat, dietary fiber, hardness, the total phenolics, the total flavonoidss, the total antioxidant capacity, RDS, SDS, RS and EGI were expressed byX1,X2,X3,X4,X5,X6,X7,X8,X9,X10 andX11, respectively. It could be seen from Table 5 that protein and fat had significant influence on the hardness of the chips (P<0.05). The higher contents of protein and fat resulted in the higher hardness of the chips. In addition, there was a significant negative correlation between EGI value and the total phenolics and the total antioxidant capacity, indicating that the stronger the total phenolics and the total antioxidant capacity, the lower EGI value of the chip.

Table 4 Contents of RDS, SDS, RS and HI, EGI of chips

Table 5 Correlation of basic properties of chips

Discussion

The particle sizes of grain powder were closely related to the qualities of extruded multi-grain chips. First of all, the particle sizes of raw material powder could affect the moisture contents of the product. In the crushing process of raw materials, the fiber structure was damaged, and then affected the water-holding capacities of materials (Liuet al., 2016). The finer the particle sizes of raw materials indicated the more serious the fiber damage and the more water would be lost in the processing process. Similarly, with the decrease of particle sizes of raw material powder, dietary fiber contents gradually increased, which was related to the transformation of insoluble dietary fiber into soluble dietary fiber in the extrusion process (Zhang, 2017). Contents of fat increased, the reason was that the materials with small particle sizes were conducive to the hydrolysis of triglyceride to free fatty acid (Cuiet al., 2017). Starch contents gradually decreased. In the extrusion process, starch gelatinized by heat and degraded by shear force. Gelatinization and degradation were carried out at the same time, which was the difference between extrusion processing and other thermal processings. The changes of grain particle sizes of raw powder had a significant effect on the edible qualities of extruded chips. The smaller the grain particle sizes might form the higher the chips' taste, structure, smell and final sensory score. The smaller raw material particles resulted in the more sufficient reactions in the extrusion process which was helpful for the chip expanding evenly to form delicate and fragrant. Grain partical sizes had a significant effect on product hardness, the reason was that small sizes were more conducive to form a pressureresistant surface (Wang, 2018). It was worth noting that the changes of grain particle sizes had different effects on the contents of phenolics and flavonoids. The structures of both phenolics and flavonoids were destroyed during extrusion processing. However, the grains with large particle sizes could alleviate the damage to a certain extent, while the materials with small particle sizes could promote the conversion of combined flavonoids to free flavonoids. The free radical scavenging ability of the free extract was affected by different grain particle sizes, but the free radical scavenging ability of the combined extract was not significantly affected by different grain particle sizes. Interestingly, the total antioxidant capacity of the chips did not change regularly with the decrease of particle sizes, and the total antioxidant capacity of 80 M was the highest. There were differences inin vitrodigestibilities of different chips, and it should be noted that EGI value of the chips did not change linearly. The reason was thatinvitrodigestion characteristics of food were extremely complex, which was affected by starch, protein, fat, dietary fiber and antioxidant active substances. Correlation analysis showed that protein and fat had significant effects on the hardness of the chips, while the total phenolics and the total antioxidant capacity were negatively correlated with EGI. Antioxidant active substances could form hydrogen bonds and van der Waals forces with starch to change the digestive properties of starch (Coeet al., 2013). In addition, active substances such as polyphenols could inhibitα-amylase, which could also reduce the hydrolysis rates of starch (Li, 2018).

Conclusions

The sizes of raw powder had an important effect on the qualities of multi-grain extruded chips. With the changes of the grain powder particle sizes, some qualities (such as edible qualities and composition characteristics) of multi-grain chips showed regular changes and it was of great significance to the production of extruded chips. Interestingly, the antioxidant capacities andin vitrodigestibilities of the chips did not change linearly with the increase or decrease of grain particle sizes. On one hand, these characteristics were complex and influenced by many factors, on the other hand, the extrusion processing was different from other thermal processings. The results of this experiment had guiding significance for the production of extruded chips, but the extruded processing method had its particularity and was different from other thermal processing methods. Therefore, the influence of grain particle sizes on other forms of products still needs to be further explored.

Journal of Northeast Agricultural University(English Edition)2021年4期

Journal of Northeast Agricultural University(English Edition)2021年4期

- Journal of Northeast Agricultural University(English Edition)的其它文章

- Effect of Foliar GA3 and ABA Applications on Reactive Oxygen Metabolism in Black Currants (Ribes nigrum L.) During Bud Paradormancy and Secondary Bud Burst

- Mining Heat Stress Associated Genes in Tomato Fruit (Solanum lycopersicum L.) Through RNA-seq

- Advances on Current Techniques and Methodologies in Milk Lipidomics

- Cloning of MYB2 Gene from Dryopteris fragrans and Its Response to ABA and Drought Stress

- NIRS Prediction of SOM, TN and TP in a Meadow in the Sanjiang Plain, China

- Screening of Feather Degrading Bacteria and Optimization of Fermentation Conditions from Poultry