Experimental Study of the Main Influencing Factors in Mechanical Properties of Conglomerate1

ZHOU Bo ,GE Hongkui ,ZHOU Wei ,WANG Jianbo ,HAO Hongyong ,WANG Xiaoqiong and LIU Pengyu

1) Research Institute of Experiment and Detection of Xinjiang Oilfield Company,Karamay 834000,China

2) Xinjiang Laboratory of Petroleum Reserve in Conglomerate,Karamay 834000,China

3) Unconventional Oil and Gas Technology Research Institute,China University of Petroleum,Beijing 102249,China

4) China University of Petroleum-Beijing At Karamay,Karamay 834000,China

In recent years,with the success of exploration and development of conglomerate reservoirs in Mahu Depression,Junggar Basin,China,it is urgent to study the mechanical properties and its influencing factors of conglomerate which is considered as a new oil and gas reservoir.Based on the investigations of petrologic characteristics,heterogeneity and mechanical properties of conglomerate in Baikouquan formation,the content and geometric characteristics of gravel in conglomerate,the main factors in heterogeneity and the mechanical behavior in the triaxial compression experiment of conglomerate are analyzed in this paper.The results show that the size and content of gravel in conglomerate varies greatly,and conglomerate has strong heterogeneity under the influence of gravel content and size.An analysis of mechanical properties of conglomerate shows that conglomerate is characterized by plasticity.Besides,the sphericity is negatively correlated to the gravel content,while the heterogeneity increases with the increase of conglomerate plasticity.Due to the existence of heterogeneous gravel,local stress may concentrate in conglomerate when the stress is loaded.Consequently,a large number of micro-cracks appear at the edge of gravel,demonstrating the strong plasticity of conglomerate.This paper is of referential significance to the study of rock mechanical properties and the evaluation of engineering properties in conglomerate development.

Key words:Conglomerate;Petrological characteristics;Heterogeneity;Mechanical properties;Plasticity

INTRODUCTION

In the last five years,continuous breakthroughs have been achieved in the exploration of hydrocarbon-rich Mahu Depression in Junggar Basin.Specifically,China's first efficient reservoir group has discovered a quasi-continuous reservoir with 100 million ton reserves in lower Triassic Baikouquan formation (Gao Gang et al.,2017).Mahu Depression has been proved to contain abundant reserves;however,Baikouquan formation,which is a conglomerate reservoir with extremely low porosity and permeability in the depression,is thought difficult to provide satisfied economic production without fracturing treatment.(Jia Haibo et al.,2017).Since the first geological exploration in the Mahu Reservoir,numerous studies have been conducted regarding sedimentary and reservoir development characteristics(Kang Xun et al.,2018;Zhou You et al.,2018).The results show that the formation mainly consists of sand and conglomerate and has complex lithofacies.Existing investigations are conducted based on the aspects of particle size,tectonic type and diagenesis,etc.Besides,the classification of conglomerate has also been investigated (Jia Haibo,et al.,2017).

Up to now,only limited studies on mechanical properties of conglomerate reservoirs have been conducted.Mngadi et al.investigate the mechanical behavior of conglomerate through tensile strength tests,uniaxial and triaxial compression tests.The results indicate that conglomerate has strong heterogeneity and poor regularity in mechanical properties(Mngadi S.B.et al.,2019;Walton G.et al.,2015).Liu Gang et al.(2018) propose a method to characterize rock heterogeneity and establish a discrete element model with PFC,which suggests that the uniaxial compressive strength and tensile strength decrease linearly with the increase of heterogeneity and stress concentration (Lan Hengxing et al.,2010;Liu Gang et al.,2018).Khanlari G.R.analyzes the relationship among gravel content,contact mode and mechanical properties of conglomerate,and the results show that mechanical properties of conglomerate are highly correlated with the petrological characteristics.Particularly,gravel content is closely related to mechanical parameters (Khanlari G.R.et al.,2016).So far,no research has been made regarding the correlation between mechanical properties of conglomerate and petrological characteristics,contact relationship and the cementation of gravel.

Studies on the materials akin to conglomerate mainly focus on mechanics of concrete.Sih G.C.and Ditommaso A.propose that the presence of aggregate in concrete may result in multiple tortuous micro-cracks at crack tips in the plastic zone (Sih G.C.et al.,1985).Yu Xiaozhong's research on concrete show that stress-strain curves of aggregate in concrete and hardened cement slurry both have long linear elastic stages and rapidly attenuated post-peak stages,indicating typical brittle behavior.However,concretes containing aggregate and cement slurry show plastic characteristics.When the stress is 0.30-0.50 times of the strength value,the stress-strain curve deviates from the straight line and the sample begins to dilate.Furthermore,the post-peak curve has a long straight section (da Fonseca A.V.et al.,2014).However,the influencing factors of concrete plasticity have not been further studied.

Mechanical properties of conglomerate have not been studied in detail,especially the correlation between mechanical properties and petrological characteristics.In this paper,petrological characteristics,structural characteristics,rock heterogeneity and mechanical properties of conglomerate are studied by experiments.Relationship between mechanical properties of conglomerate and petrology is established to analyze the micro-mechanism and clarify main influencing factors in conglomerate mechanical properties.This study provides a reference for drilling engineering and hydraulic fracturing in conglomerate reservoirs.

1 EXPERIMENTAL SAMPLES AND PROCEDURES

1.1 Samples and Equipment

Samples in this study are collected from conglomerate reservoirs of the lower Triassic Baikouquan formation in Mahu-1(MH-1) well block.Mahu Depression is located in the northwest margin of Junggar Basin and is the secondary structural unit in the basin.Several fan delta sedimentary systems develop in the depression,providing favorable conditions for the formation of an excellent large-scale fan delta accumulation system.The Triassic Baikouquan formation in this block has developed into an important exploration horizon.Main rocks in this block are sandstone,conglomerate and glutenite.The reservoir of Baikouquan formation in the study area is widely developed,forming a multilayer structure.It is a typical reservoir with low porosity and low permeability.Conglomerate mainly consists of volcanic rock debris such as tuff,andesite and granite,as well as the fine terrigenous clastic particles such as quartz,feldspar,mica and interstitial materials such as argillaceous complex.

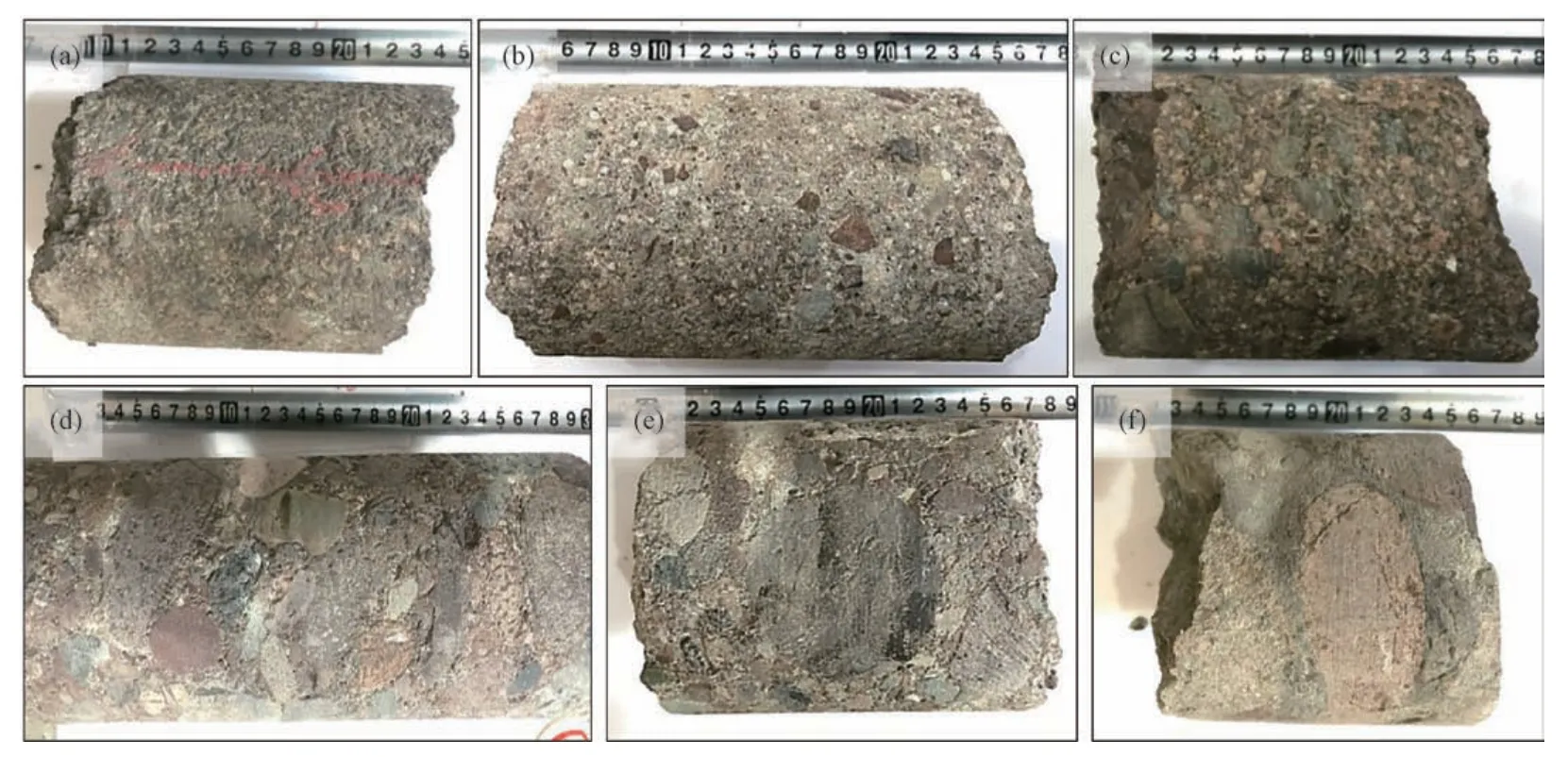

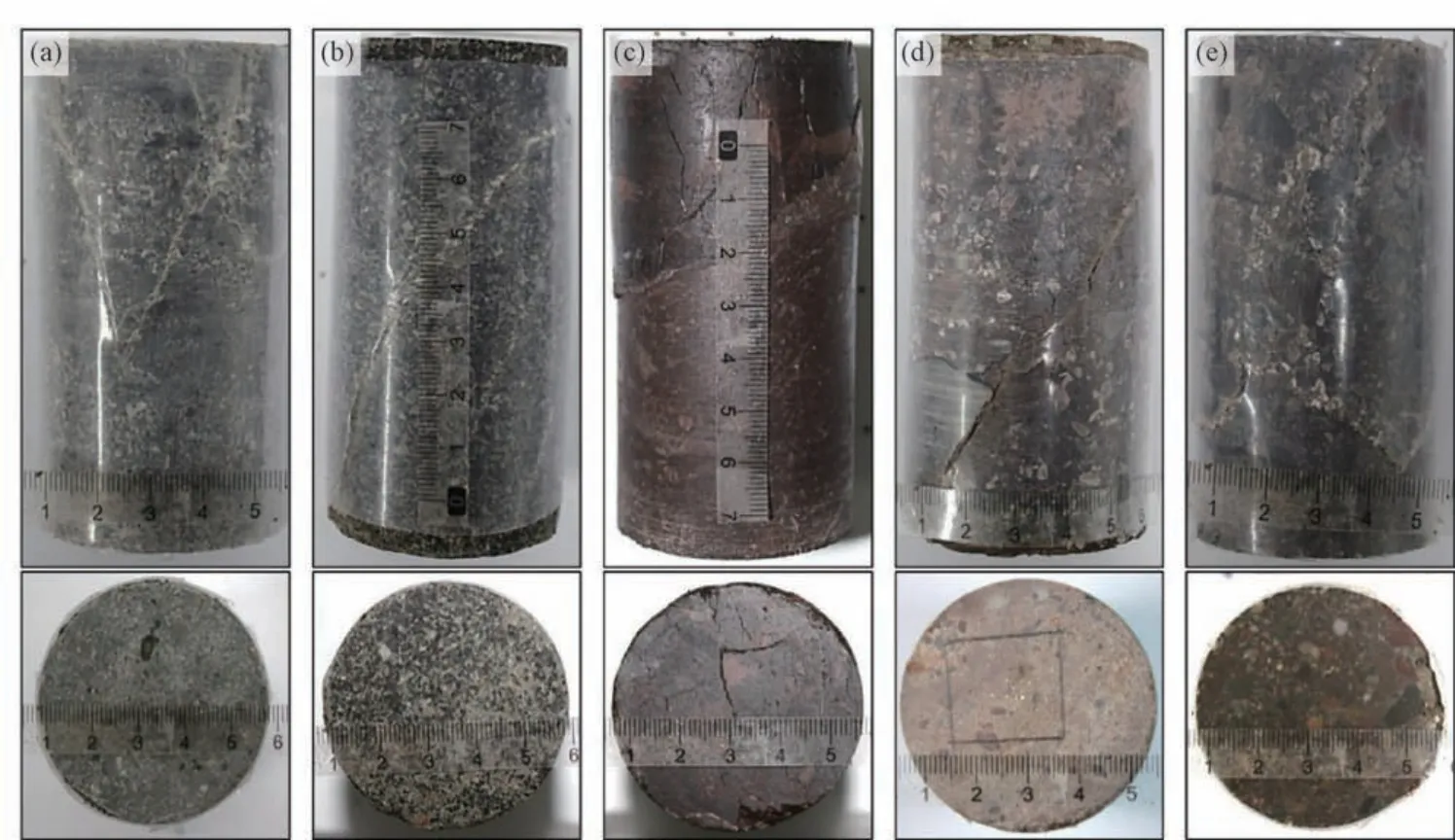

The Lithology of the reservoirs is relatively complex,which includes gray conglomerate as shown in Fig.1 (a) and (b),brown conglomerate as shown in Fig.1(c),(d),(e) and(f),and interbedded development of sandstone and mudstone.The gravel in the reservoir is poorly sorted and its size ranges from 2 mm to 10 cm.Due to the long-distance transportation of debris,the gravel has good roundness.Support modes of gravel include matrix support(Fig.1 (a),(b)),grain support (Fig.1 (c),(d)),and mixed support (Fig.1 (c),(d)).

The samples are collected at a depth of 3 404.38-3 417.50 m.In the process of core drilling,the gravel with weak cementation is easy to be broken into pieces,thus it is difficult to obtain small rock samples,which are also unrepresentative.Therefore,samples in the experiment are chosen with a size of Φ 50×100 mm.Besides,they are wrapped with heat shrinkable tube and the end faces are polished with machine tool,ensuring the parallelism is less than 0.05 mm and according with the requirement of rock mechanics test standard.Five representative samples are selected,as shown in Fig.11 below.

The mechanical testing equipment is a triaxial compression testing machine named TAW-2000 produced by Chaoyang testing machine factory,Changchun.Its confining pressure can reach 100 MPa with flexible loading of hydraulic oil;the stress control precision can reach 0.1 MPa.Test accuracy of the axial strain gauge is 0.05 mm,and that of the radial strain gauge is 0.03 mm.

Tektronix-TBS1102B oscilloscope is used to test the ultrasonic wave velocity in rocks.The acoustic generator is Olympus-5077PR.In the experiment,the frequency is set as 0.25 MH-z.The acoustic sensor is Nano30 produced by PAC (Physical Acoustics Corporation).Besides,the response bandwidth is 0-400 kHz and the main frequency is 0.25 MHz.

Figure 1 Samples of Baikouquan formation in Mahu-1 well block,with full diameter of 96 mm.The scale number unit in the plots is centimeter

1.2 Experiment Procedure

The strong heterogeneity of conglomerate is mainly influenced by gravel size,content and cementing strength between gravels and matrixes.Therefore,a large number of auxiliary analyses are necessary to explain the mechanical behavior of conglomerate.In this experiment,five analytical tests are conducted:

(1) Heterogeneity tests are conducted mainly by testing the ultrasonic wave velocity in samples.Longitudinal wave velocities are tested in the nondestructive experiment.

(2) The confining pressure is set as 10 MPa and applied to samples.Meanwhile,the axial force is applied by displacement-control method and the triaxial compression tests are conducted to obtain stress-strain curves.

(3) Samples are cut into thin slices,polished and then analyzed with scanning electron microscope.

(4) Gravels are separated from matrixes in the process of grinding,and then each gravel size is analyzed by screening.

(5) A mineral composition analysis of powders smaller than 180 μm obtained in previous steps is conducted to collect the cement composition information.The above steps can ensure that the same sample is used for analyses and tests.The following steps,the principle of the first non-destruction and destruction,are used to ensure the accuracy of analyses and tests.For the fluency of the article,experimental results are not presented in the above order.

2 RESULTS

2.1 Petrological Characteristics of Conglomerate

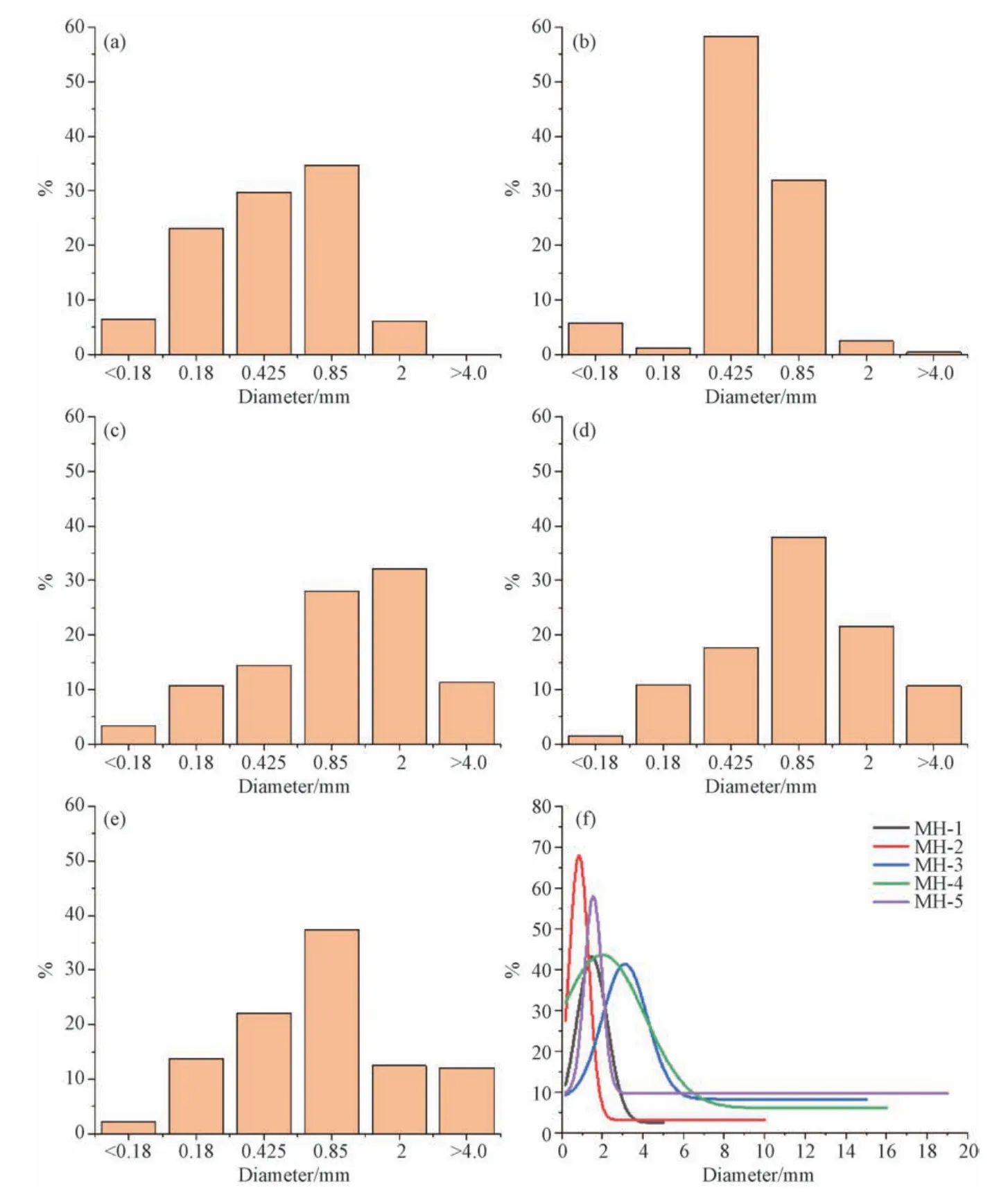

Petrological characteristics of conglomerate include gravel size,content,shape,sorting and sphericity.In order to analyze the petrological characteristics of conglomerate,half of the samples with the size of Ф 50×100 mm are cut and then ground manually.The grinding step stops when the rock with the largest particle size in the mortar is gravel,and rocks are screened by sieve analyses.Gravels greater than 5 mesh are measured by vernier caliper and then weighed.Samples with particle sizes less than 5,10 mesh,20 mesh,40 mesh and 80 mesh are used for sieving.After that,each mass is weighed respectively,and the mass percentage content of the gravel with different particle size is calculated.After screening,further grind and screening are processed until no impurities are attached to the surface of gravels larger than 10 mesh (the diameter of the sieve mesh is 2 mm,and a rock with a diameter more than 2 mm is gravel based on geological definition) for the purpose of ensuring the accuracy of particle size statistics.Gravels or powders corresponding to different mesh numbers are then weighed,providing content information of gravel in each particle size,as shown in Fig.2.Manual measurements are conducted on gravels with larger particle size,which can also facilitate the observation of gravel morphology.The results are shown in Fig.3.

MH-1 and MH-2 have a small gravel content and a small particle size of 6.14 mm.Only one type of gravel grain in MH-1 has a particle size of 6 mm,while others are less than 4 mm.The gravel is gray silica.MH-2 has a maximum particle size of 9.8 mm.The content of gravel with a particle size greater than 4 mm is 0.41%,and that with a particle size greater than 2 mm is 2.83%.The gravel surface color is grey-celadon,and the particle size of the peak content is 0.425 mm.MH-3,MH-4 and MH-5 all have a high gravel content and a large particle size.In detail,the gravel content is 43.45%,32.09% and 24.50%,respectively.The maximum particle size is 15 mm,24.8 mm (the maximum gravel is shown in Fig.7 (c) but not shown in Fig.3 (d)),and 23.6 mm,respectively.The maximum particle size of MH-3 is 2 mm,and that of MH-4 and MH-5 is 0.85 mm.In conclusion,the maximum particle size of the gravel in the order from small to large is MH-1,MH-2,MH-3,MH-5 and MH-4.

The Gaussian curve shown in Fig.2(f) is obtained by fitting statistical results of particle size and mass content percentage.According to the statistical results,the particle size corresponding to the peak content in the order from small to large is MH-2,MH-1,MH-5,MH-4 and MH-3,and the corresponding particle size is 0.85 mm,1.46 mm,1.55 mm,2.00 mm and 3.11 mm.

The standard deviation of the Gaussian fitting curve of particle size represents the distribution of gravel particle size,2σcan be used to characterize the sorting of gravels,which in the order from high to low is MH-5,MH-2,MH-1,MH-3 and MH-4.Obviously,particle size distribution of MH-5 is more concentrated,indicating the best sorting.On the contrary,MH-4 has the worst sorting.

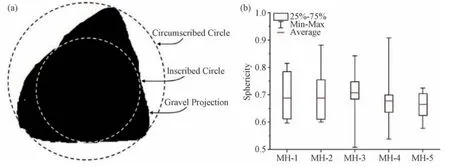

Railey sphericity calculation is used in gravel sphericity statistics,and gravel pictures are projected,as shown in Fig.4 (a).A circumscribed circle and an inscribed circle of the gravel are made for diameter calculation.Then,the ratio of two measured diameters is calculated to obtain the sphericityφ.

Diis the diameter of the inscribed circle,andDcis the diameter of the circumscribed circle.The closer the sphericity value is to one,the better it is,the closer it is to zero,the worse it is.

Figure 2 Distribution diagram of gravel content and particle size of samples:(a),(b),(c),(d) and (e) are the histograms of gravel content of MH-1,MH-2,MH-3,MH-4 and MH-5,respectively;(f) is the curve of particle size distribution of five samples

Statistical results of gravel sphericity are shown in a boxplot in Fig.4 (b).The average sphericity is between 0.66 and 0.71,which is a relatively narrow range,indicating good sphericity.However,the distribution of the sphericity of samples is largely different from each other.MH-3 and MH-4 have a large span of sphericity distribution,which is 0.51-0.84 and 0.54 -0.91,respectively,indicating a discrete distribution.The degree of sphericity dispersion in the order from large to small is MH-4,MH-3,MH-2,MH-1,MH-5 (the difference of sphericity is 0.37,0.33,0.28,0.21,0.15).The lower limits of the sphericity of MH-1-MH-5 are similar to each other,which are 0.60,0.60,0.51,0.54,and 0.58,respectively.

Figure 3 Gravel with a large size:(a),(b),(c),(d),and (e) are gravel from MH-1,MH-2,MH-3,MH-4,and MH-5,respectively.The minimum scale unit is mm.

2.2 Structural Features

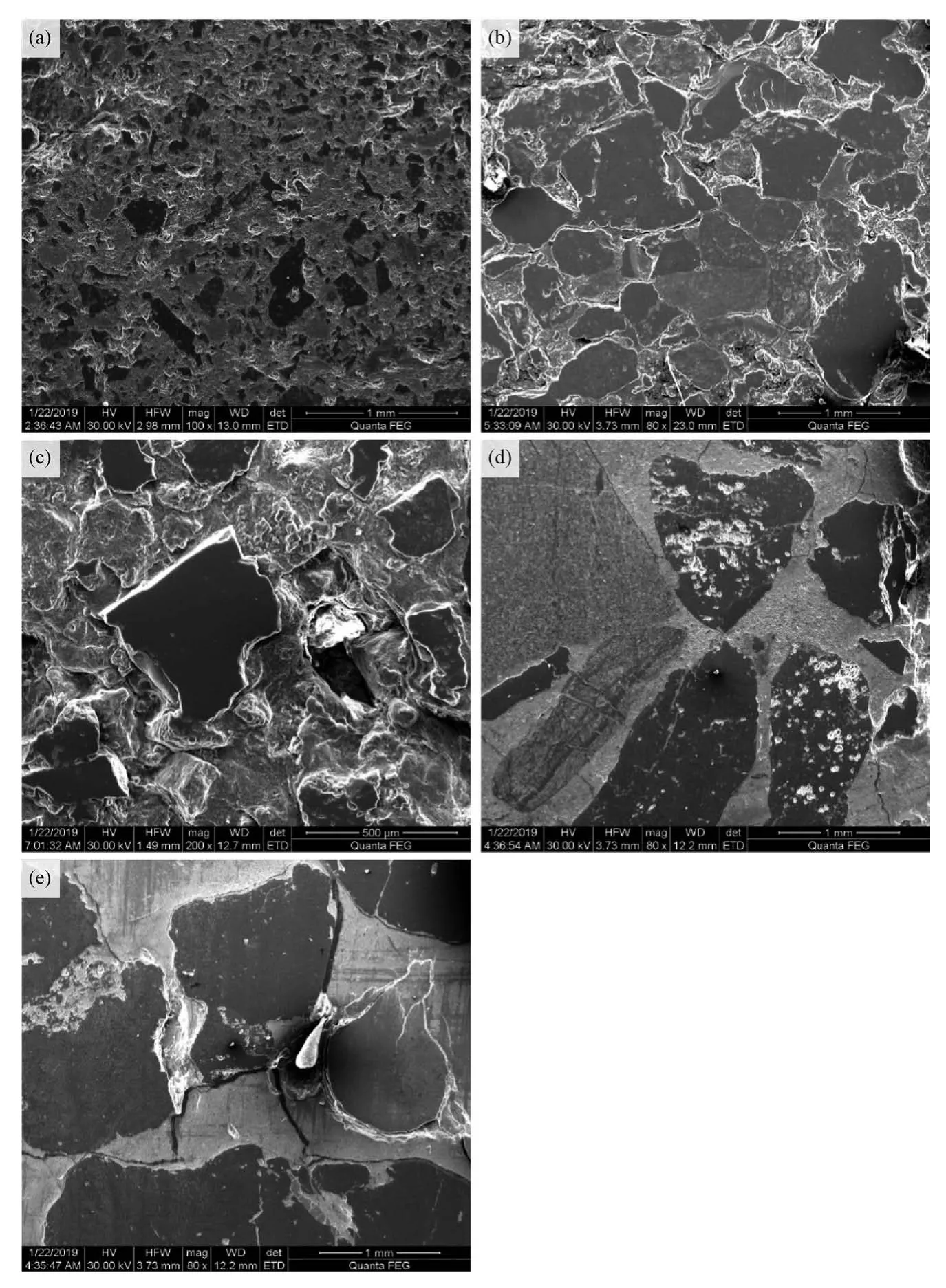

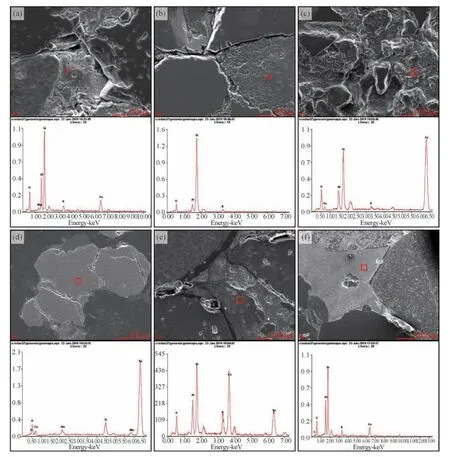

Particle size,content,shape,sorting and sphericity of the gravels are analyzed above,but structural characteristics generated by interaction between gravels and matrixes have not yet been described.For a better characterization,one section of each sample is ground,polished,and observed with an electron microscope,as shown in Fig.5.Due to the loose consolidation of conglomerate,it is difficult to prepare samples for electron microscope sections,especially for parts with large gravels.Therefore,red gravels in the SEM photograph shown in Fig.5 cannot fully represent the size shown in Fig.3.However,SEM images are more accurate for analyses of conglomerate support mode,and electron microscope images are still used for analyses in this study.According to the analysis of Fig.5,MH-1 and MH-3 are supported by matrixes,and the gravels are embedded into matrixes and then cemented.MH-2,MH-4 and MH-5 are in gravel support mode.The gravels are contact with each other,similar to a ball-and-stick model.Gaps between gravels are filled with cement.The main components of gravel are quartz,feldspar and calcite.The composition of the cement will be discussed in the next section.

Figure 4 Gravel sphericity statistics

The type of cementation is an important factor that influences the mechanical properties of conglomerate.According to previous geological exploration data,the types of reservoir cementation are mainly argillaceous cementation,calcareous cementation and siliceous cementation.In this analysis,two works are conducted to support the conclusion of cementation type.Firstly,powders with particle size lower than 180 um in section 3.1 are analyzed by XRD,and their components are mainly from cementitious substances.Through the analysis,mineral composition and content of cementitious substances can be obtained quantitatively.This method has high sampling rate and comprehensive results.However,due to the inevitable addition of gravel debris during the grind process,some errors may occur.Further EDS analyses of sample flakes are required to search direct cement and obtain element distribution,so as to determine the composition of cement.Another method is sampling,which is more intuitive but less comprehensive.In this study,the two methods are combined to obtain a more accurate type of cementation.

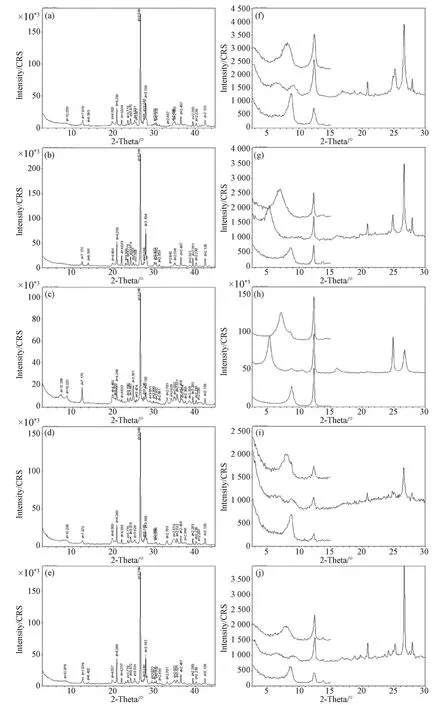

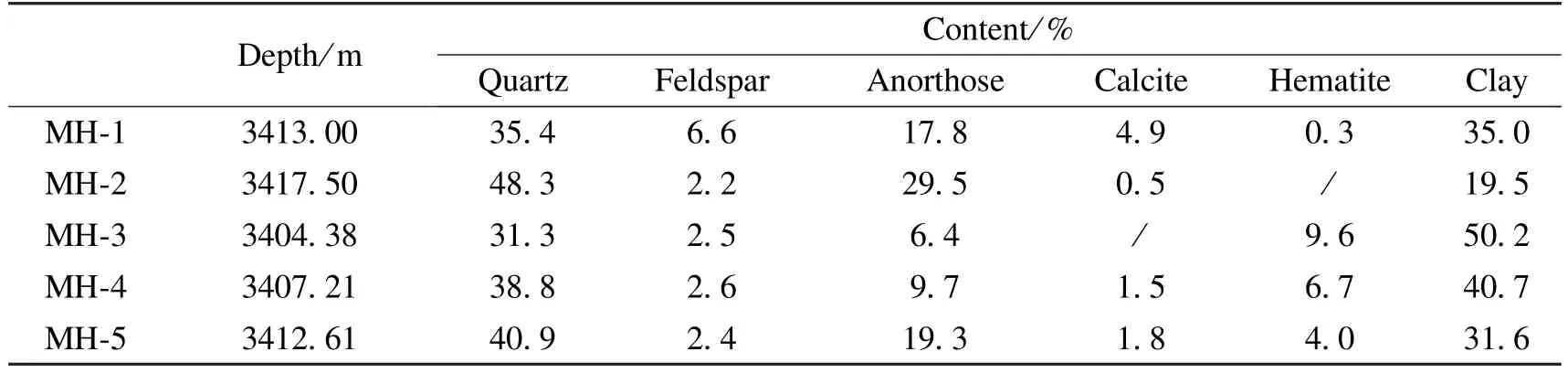

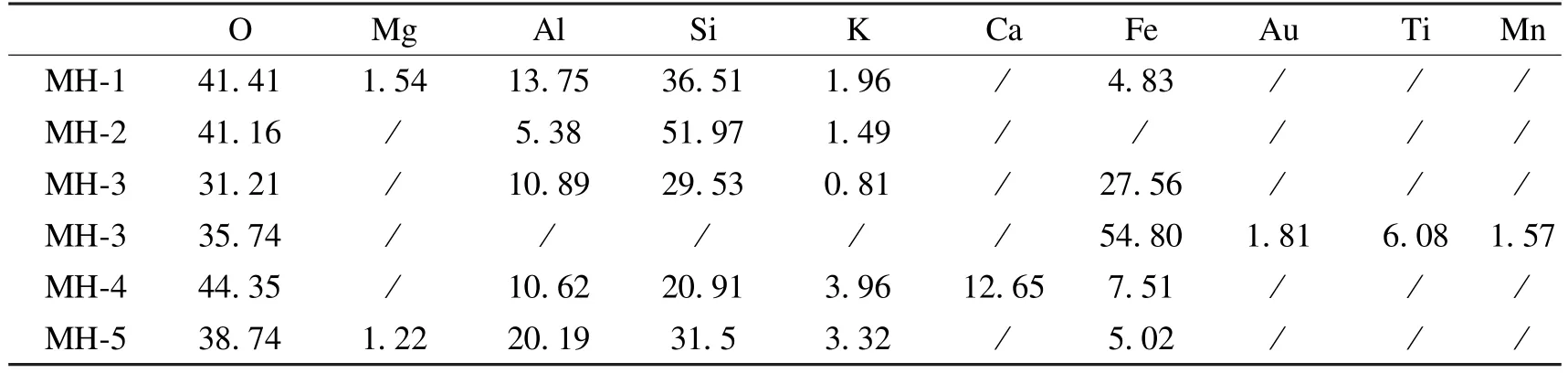

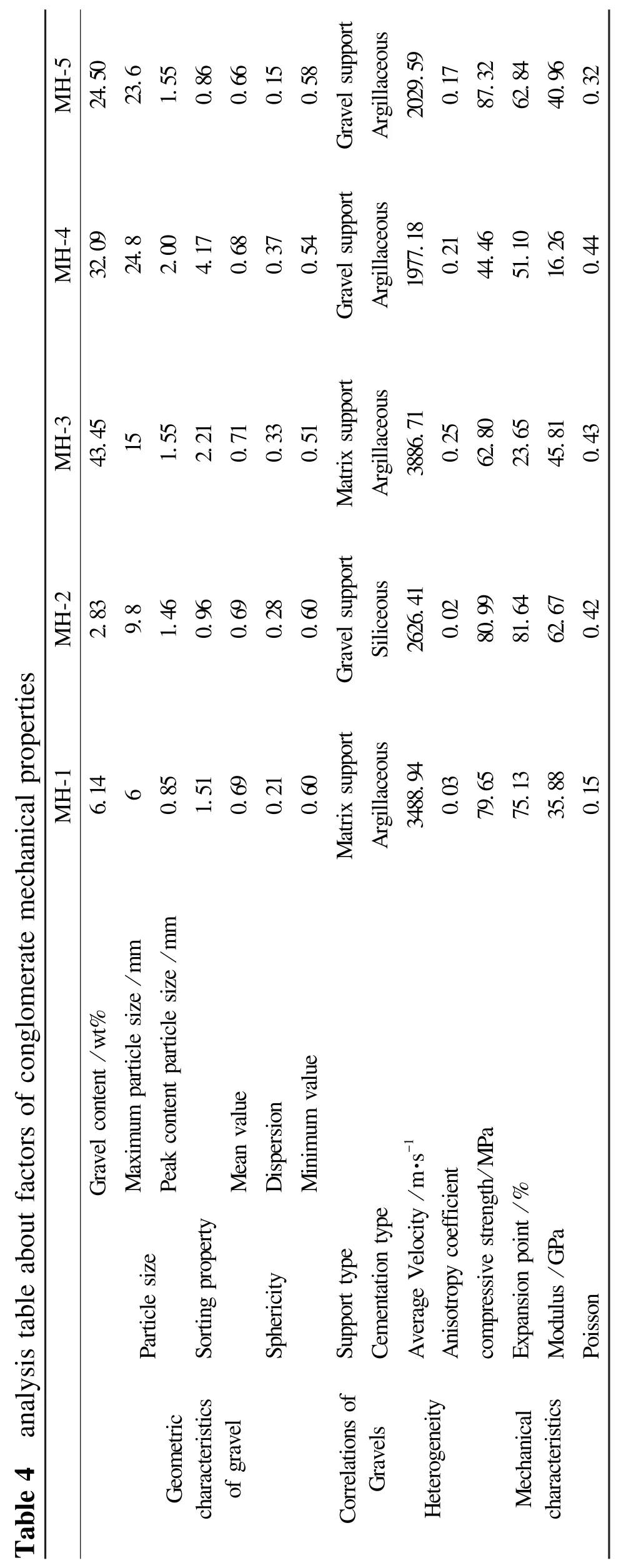

Table 1 and Table 2 show the test results of mineral composition and clay composition of cement.In detail,contents of quartz and potassium feldspar in the five samples are similar.Quartz and plagioclase contents of MH-2 are the highest while the content of clay is the lowest;the feldspar content of MH-3 is the lowest while the content of clay is the highest with a value of 50.2wt%,representing clay cementation.In addition,only MH-1 and MH-2 do not contain hematite,as reflected in Fig.3.The gravel surface color of MH-3,MH-4 and MH-5 is dark red due to the oxidized diagenetic environment,which is related to hematite content.MH-3 contains a large quantity of montmorillonites,and the other four samples mainly consist of illite-smectite mixed layers,the content of which is more than 63wt%,indicating large water sensitivity.

Figure 5 SEM images of conglomerate

EDS results show that the cement of MH-1,MH-3,MH-4 and MH-5 are silicaaluminates containing Mg,K and Fe,and its main composition is clay.MH-3 contains welldeveloped ferruginous concretions,as shown in Fig.6(d).Combined with the results in Table 1 and Table 3,MH-1,MH-3,MH-4 and MH-5 are characterized by argillaceous cementation,while the main chemical elements of MH-2 are O and Si and the main composition is quartz.Combined with the test results in Table 1,2 and 3,it can be concluded that MH-1,MH-3,MH-4 and MH-5 are characterized by muddy cementation,and the cementation strength is relatively weak in general.MH-2 is featured by siliceous cementation with good cementation strength.

Figure 6 The XRD spectrum corresponding to Table 1 and Table 2

Figure 7 SEM and EDS images of conglomerate

2.3 Heterogeneity

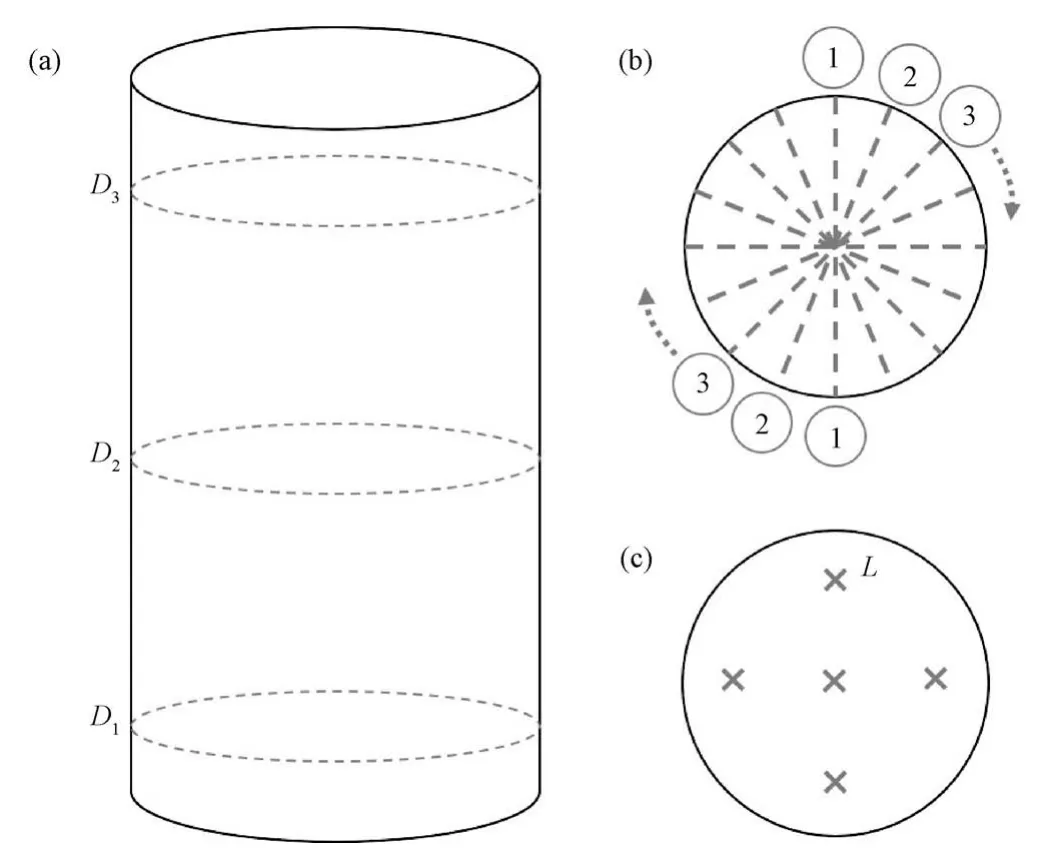

The presence of gravel in conglomerate and the cementation between gravel-gravel and gravel-matrix leads to different attenuation degrees of wave velocity,providing a measure to evaluate the heterogeneity of conglomerate.The schematic diagram of the testing process is shown in Fig.4.The sample size is Φ 50×100 mm,as shown in Fig.7(a).In detail,three layers are tested,D1andD2are 20 mm away from top and bottom surfaces respectively,withD3in the middle.As shown in Fig.7(b),eight groups of wave velocity are tested at an interval of 22.5° on each layer.Fig.7(c) shows five groups of axial wave velocityL.One group is in the center,and another four groups are 10 mm away from the edge.

Table 1 Results of mineral composition analysis of cement

Table 2 Results of clay type analysis of cement.

Table 3 EDS results of cement.The results in the table are the content percentages of atomicity.

Figure 8 Schematic diagram of sound wave test

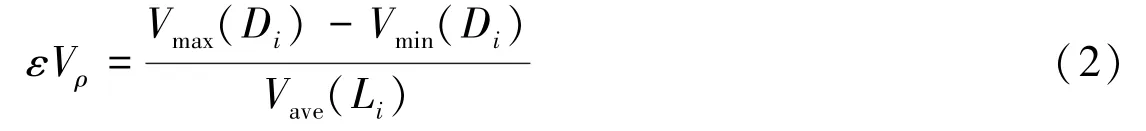

Test results of wave velocity are shown in the radar diagram in Fig.8,in which the four colors representD1,D2andD3radial wave velocities andL-axial wave velocity,respectively.The test length in axial direction is 100 mm,a large size which may result in a small change in axial wave velocity (VL).Therefore,the average value of the five axial wave velocities is calculated to represent the degree of rock compactness and cementation.The radial wave velocity has great variation and is more sensitive to the conglomerate distribution,thus is suitable to characterize the anisotropy coefficient of the whole rock.

whereVmax(D1,D2,D3) represents the maximum value of the average radial wave velocity inD1,D2andD3,Vmin(D1,D2,D3) represents the minimum value of the average radial wave velocity inD1、D2andD3,Vave(L1,L2,L3,L4,L5) is the average value of the axial wave velocity.

Anisotropy coefficient in the plane is important for understanding the influence of composition on heterogeneity.Therefore,the anisotropy coefficient in the planeεSis calculated by Equa.(2),(3):

WhereεSis the anisotropy coefficient in the plane,Max(VDi),Min(VDi) represent the maximum and minimum value of radial wave velocity.

As shown in Fig.9,average values of axial wave velocities of MH-1 and MH-3 are larger,and their values are 3 488.94 m/s,3 886.71 m/s.That of MH-2,MH-4 and MH-5 are smaller,which are 2 626.41 m/s,1 977.18 m/s and 2 029.59 m/s respectively.MH-1 and MH-3 are supported by homogeneous matrixes,resulting in larger wave velocities.MH-2,MH-4 and MH-5 are gravel-or mixed-supported.Sound waves scattered or attenuated at the gravel boundaries for many times may cause a smaller wave velocity.Due to the weak consolidation of local gravels,the velocity cannot be measured in some radial wave tests.Therefore,theD1wave velocity line in Fig.9(a),theD2wave velocity line in Fig.9(b),D2andD3wave velocity lines in Fig.9(d),D1andD2wave velocity lines in Fig.9(e) are partially discontinuous.

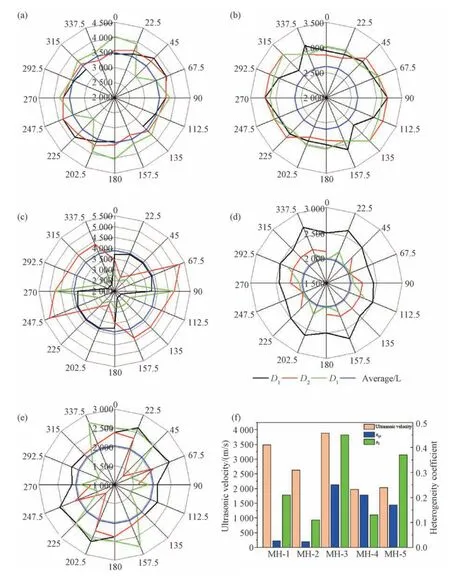

MH-3 and MH-5 radar diagrams show that the maximum and minimum wave velocity values vary widely,possibly resulted from the anisotropic distribution of gravel.This anisotropic distribution leads to a high anisotropy coefficient up to 0.25.The biggest difference of wave velocity is more than one time.MH-1,MH-2 and MH-4 radar diagrams are nearly circular,indicating a more homogeneous distribution with a minimum anisotropy coefficient of 0.02.As shown in Fig.9,there is a good correlation between the anisotropy coefficient and the gravel content in Section 3.1.The heterogeneity increases with the increase of the gravel content.The main reason is that the multiple scattering at gravel edges leads to the attenuation of sound wave and the decrease of the wave velocity.

2.4 Triaxial Compression Test Results

Stress-strain test results under 10 MPa confining pressure are shown in Fig.10.The compressive strength of MH-1,MH-2,MH-3,MH-4 and MH-5 is 79.65MPa,80.99 MPa,62.80 MPa,44.46 MPa and 87.32 MPa,respectively.At the same time,it can be obtained that the elastic modulus is 35.88 GPa,62.67 GPa,45.81 GPa,16.26 GPa,40.96 GPa,and the Poisson's ratio is 0.15,0.42,0.43,0.44 and 0.32,respectively.

Samples after triaxial compression tests are shown in Fig.11.Main fracture surfaces of MH-1,MH-2 and MH-4 are relatively clear.In particular,the main fracture surfaces of MH-4 bifurcate around the gravel edge.However,no main fracture plane is generated in MH-3 and MH-5.

Figure 9 Ultrasonic wave velocity test results

Figure 10 Correlation between gravel contents and anisotropic coefficients

3 DISCUSSION

3.1 Mechanical Behavior and Factors of Micro-mechanism in Conglomerate

For the convenience of analysis,the five groups of axial stress-strain curves in Fig.10 are separately drawn as shown in Fig.12.It can be seen from the curves that the conglomerate has experienced a long deformation process from yield stress to peak stress,and a long extension after the peak,reflecting strong plastic characteristics.However,the gravel in this experiment is mainly composed of volcanic rocks,which are siliceous and have high mechanical strength and brittleness.The gravel itself does not have obvious deformation and failure,but local stress and strains are induced around the gravel due to strains between gravels and matrixes.Under stress,the deformation and failure of matrixes and gravel edge will occur (this part will be discussed in detail in section 4.2).Therefore,the content and geometry of the gravel,mechanical properties of matrixes,and the consolidation strength of the gravel are the main factors in the plastic mechanical behavior of conglomerate.

Obviously,the degree of the plasticity is influenced by gravels.In order to facilitate quantitative analysis,the positive and negative inflection points of the volumetric strainstress curve are used to determine the dilation points,and the ratio of the stress at the dilation points to the compressive strength is calculated,as shown in Fig.13.The ratios are 75.13%,81.64%,23.65%,51.10% and 62.84%,respectively.Except for MH-3 and MH-4,the value is positively correlated with compressive strength (Griggs D.et al.,1960;Martin C.D.et al.,1994;Wawersik W.E.et al.,1970).

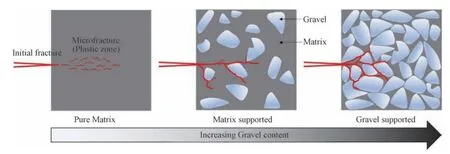

The problem of rock dilatancy is closely associated with the crack propagation in micro scale.Traditional linear elastic fracture mechanics consider that the stress at the crack tip is infinite.However,for any practical engineering materials,the ultimate tensile stress cannot be infinite.Therefore,strictly speaking,under the action of load,a nonlinear micro-fracture zone,namely the plastic zone,is believed to appear at crack tips.For homogeneous rocks,this micro-fracture zone is small and negligible compared to the initial fracture.Nevertheless,for conglomerate with strong heterogeneity,the situation is different.Mechanisms of forming a fracture process zone are complex.In conglomerate with less gravel content,fractures mainly propagate in matrixes,as shown in Fig.14 (b) and (d).

Due to the existence of the fracture process zone,fractures may go through a longstage stable propagation before instability and failure.The stable propagation is mainly influenced by the plastic zone shown in Fig.14.When stress is applied,the gravel deformation is small.The reason is that the stress is concentrated near the gravel,resulting in additional stress and strain.As shown in Fig.14,a large number of fractures develop at the gravel margin.As shown in Fig.16 (c),(d) and (e),the position of the dilation point is influenced by gravel content,sphericity and anisotropy coefficient.The reasons can be ascribed as follows:Gravel sphericity is negatively correlated with gravel content,the stress concentration around a gravel is positively correlated with heterogeneity,and the size of the plastic zone increases with the increase of micro-crack numbers around a gravel.These are also the main reasons why the stronger the plasticity,the earlier the dilation point occurs.For engineering,strong plasticity has a great impact on hydraulic fracture formation,and is an important factor in the evaluation of fracability of conglomerate reservoirs.

Figure 11 Mechanical test results

3.2 Influencing Factors in Mechanical Properties of Conglomerate

Results of experimental analyses are shown in Table 4.The petrological characteristics of conglomerate (particle size,content,sorting and sphericity),structural characteristics(support modes and cementation types),heterogeneity and mechanical parameters are analyzed.In order to determine the main influencing factors on mechanical characteristics,a correlation analysis is conducted,as shown in Fig.16.Rock strength is negatively correlated with gravel sorting and sphericity dispersion.The more unitary the size distribution of gravel,the higher the strength of conglomerate.The more concentrated the gravel sphericity distribution,the higher the strength of conglomerate.Besides,no obvious correlation has been found between gravel size,conglomerate heterogeneity and rock strength.

Figure 12 Images of deformed samples after mechanical loading experiments.

Figure 13 Five groups axial strain -stress curves

Figure 14 Data of dilation points

Figure 15 The schematic diagram of sampling positions in electron microscopy analyses.SEM images of the samples

Figure 16 The fracture at crack tips as the gravel content increases

Figure 17 Correlation analysis of mechanical properties.

The position of dilation point as a plastic characterization has a good linear correlation with gravel content,average sphericity and the anisotropic coefficient of conglomerate.The higher the gravel content,the lower the sphericity and the stronger the heterogeneity.Due to the presence of gravel,the micro-fracture bypasses or bifurcates around the gravel,leading to a stronger plasticity of conglomerate.The larger the particle size of the largest gravel,the greater the Poisson's ratio and the better the correlation.However,there is no obvious correlation between elastic modulus and aforementioned factors.

The above analysis also shows that the heterogeneity of conglomerate is mainly influenced by gravel content.The higher the gravel content,the stronger the conglomerate anisotropy.Furthermore,the mechanical properties of conglomerate are related to the petrological,structural and anisotropic characteristics of conglomerate,and the main influencing factors are gravel content,sphericity,sorting,and anisotropic coefficient.No obvious correlation has been found between the cementation type of conglomerate and the mechanical properties and anisotropy of conglomerate.Therefore,further analyses and discussion are needed in the follow-up investigations.

4 CONCLUSIONS

Petrological and structural characteristics,heterogeneity,and mechanical properties of conglomerate are studied in this paper.the main conclusions are obtained as follows:

(1) Gravels are well-developed in Mahu reservoir.the gravel content is up to 43.45wt% and the diameter is up to 24.8 mm.The gravel sorting varies widely,of which larger particles ranges in 2-24.8 mm,and the smaller ones ranges only in 2-6 mm.Sphericity is generally good,with a mean value of 0.51-0.60.

(2) Different gravel contents lead to different types of support modes.The ones with larger gravel contents are mainly gravel supports,while the ones with smaller gravel contents are mainly matrix supports.The cementing materials are mainly clay and siliceous minerals,which have a great impact on the mechanical characteristics of rocks.

(3) Heterogeneity of conglomerate is characterized by ultrasonic wave velocity,which is closely related to the type of support.Conglomerate with matrix support has a high wave velocity,while conglomerate with gravel support has a low wave velocity.The difference of wave velocity between them is 1909.53 m/s.Heterogeneity is closely associated with gravel content and is a main influencing factor in conglomerate heterogeneity.

The conglomerate tested by mechanical experiments show great difference in rock strength,Young's modulus,Poisson's ratio,as well as strong heterogeneity and plasticity,which are influenced by gravel.In particular,rock strength is negatively correlated with sorting and sphericity dispersion of gravel.The conglomerate strength increases with the increase of the concentration of gravel size distribution as well as the uniformity of gravel sphericity.In addition,higher gravel content will lead to lower sphericity,stronger heterogeneity,and stronger plasticity.

Conglomerate presents strong plasticity,which is a key mechanical characteristic and is of great significance for hydraulic fracturing in the reservoir.The main influencing factors are gravel content,mean sphericity and anisotropic coefficient of conglomerate.Microscopic studies show that micro-cracks in the gravel boundary under stress may form a plastic zone at fracture tips,making the entire rock behave plastically in the process of fracture propagation.

Earthquake Research Advances2020年3期

Earthquake Research Advances2020年3期

- Earthquake Research Advances的其它文章

- Research Progress of Geophysical Exploration in Karatungk Mine in Northern Xinjiang,China1

- Quick Phase Identification for Dense Seismic Array with Aidfrom Long Term Phase Records of Co-located Sparse Permanent Stations1

- Application of Machine Learning Methods in Arrival Time Picking of P Waves from Reservoir Earthquakes1

- Application on Anomaly Detection of Geoelectric Field Based on Deep Learning1

- Simulation of Silty Clay Compressibility Parameters Based on Improved BP Neural Network Using Bayesian Regularization1

- Study on the Criterion of the Correlation between Deformation Precursors and Earthquakes1