Ultrasound-assisted Enzymatic Extraction of SDF on Passion Fruit Seeds

YANG Cui-feng, TENG Zheng, WU Guan-ying, LIAO Shi-kong, HUANG Kun-lin

Agricultural and Food Engineering College, Baise College, Baise 533000, PRC

Abstract Ultrasound-assisted enzymatic extraction of soluble dietary fiber (SDF) from passion fruit seeds was carried out in order to shorten the extraction time and increase the yield of SDF. The effects of cellulase concentration, ultrasonic power, extraction temperature, solid-liquid ratio and water bath time on the SDF yield of passion fruit were studied by single factor analysis. And the orthogonal experiment was designed to optimize the extraction conditions. The results showed that the optimum conditions for the extraction of SDF from passion fruit by ultrasoundassisted enzymatic method were cellulase concentration 1.5%, ultrasonic power 120 W, solid-liquid ratio (g/mL) 1:15, extraction temperature 55 °C, and water bath time 160 min. The SDF extraction rate was determined to be 5.12%.

Key words Passion fruit seeds; Soluble dietary fiber; Ultrasound-assisted; Enzymatic extraction

1. Introduction

Passion fruit (scientific name:Passiflora edulia Sims) is one of the strongly recommended commercial crops for poverty-alleviation schemes. Passion fruit seeds, the by-product of passion fruit juice, are commonly discarded as wastes. In China, over 4 000 t of passion fruit seeds are thrown away each year, causing significant resource waste[1]. It is reported that passion fruit seeds not only contain fat and protein, but also are rich in dietary fiber[2]. Extracting dietary fiber from passion fruit seeds could effectively improve the comprehensive utilization of resources, producing better social benefits and higher economic revenue. Dietary fibers can be divided into soluble dietary fiber (SDF) and insoluble dietary fiber (IDF); SDF can be used to reduce blood sugar, diabetes, blood fat and cholesterol, and to prevent cardiovascular disease or tumor[3]. Research on dietary fibers is highly beneficial to the improvement of public health. Passion fruits are abundant in our country. Extraction of dietary fibers for further usage could greatly enhance the comprehensive usage value of passion fruits as well as the recycling of waste resources. Dietary fibers can be extracted by crude separation, chemical extraction, membrane separation, enzymatic extraction, and fermentation[4]. Enzymatic extraction is a mild, environmental, and easy-to-operate method for producing highly-purified, light-colored, and easyto-bleach dietary fibers[5-6].Therefore, it is widely used as a highly promising method. In recent years, researchers are focusing on the improvements of SDF extraction efficiency using ultrasound-assisted enzymatic extraction[7-9]. Ultrasound could cause violent vibration and strong cavitation in materials. On this basis, we extract SDF from passion fruit seeds by ultrasound-assisted enzymatic extraction to reduce the compactness among different tissues, to shorten the extraction time and to improve SDF yield.

2. Materials and Methods

2.1. Experimental materials and reagents

Purple passion fruits were picked from the fruit trees in Baise. Crude powder of passion fruit seeds was prepared as follows. The selected fruits should be similar in size, approximating maturity but not fully mature; the seeds were taken out and dried; the dried seeds were smashed into powder by a grinder; the powder was screened with a 40-mesh sieve; the powder was sealed in bags for storage. The reagents were analytically pure, mainly including 95% absolute ethyl alcohol, sodium hydroxide, hydrochloric acid, petroleum ether, and cellulase.

2.2. Extraction process

Passion fruit seeds→Drying→Grinding→Degreasing by petroleum ether→Screening→Ultrasound treatment→Water-bath heating→Enzyme deactiva- tion for 10 min→Centrifugal separation→Supernate→Suction filtration→Concentration→Ethanol precipit- ation→Filtration→Drying→Finished products

2.3. Optimization of technological conditions

2.3.1. Single-factor experiment design

(1) Investigation into the effects of cellulase mass concentration on SDF yield of passion fruit seeds: fix the extraction temperature at 55 ℃, solid-liquid ratio (g/mL) at 1 : 20, water bath time at 180 min, and ultrasonic power at 100 W; set the mass concentration of cellulase to 1.0%, 1.5%, 2.0%, 2.5% and 3.0%. (2) Investigation into the effects of ultrasonic power on SDF yield of passion fruit seeds: fix the mass concen- tration of cellulase at 2.0%, solid-liquid ratio (g/mL) at 1 : 20, water bath time at 180 min, and extraction temperature at 55℃; set ultrasonic power to 80, 100, 120, 140, and 160 W. (3) Investigation into the effects of extraction temperature on SDF yield of passion fruit seeds: fix the mass concentration of cellulase at 2.0%, solid-liquid ratio (g/mL) at 1 : 20, water bath time at 180 min, and ultrasonic power at 100 W; set the extraction temperature to 35, 45, 55, 65, and 75℃. (4) Investigation into the effects of solid-liquid ratio on SDF yield of passion fruit seeds: fix the mass concentration of cellulase at 2.0%, extraction temper- ature at 55℃, water bath time at 180 min, and ultrasonic power at 100 W; set the solid-liquid ratio (g/mL) to 1:10, 1:15, 1:20, 1:25, and 1:30. (5) Investigation into the effects of extraction time on SDF yield of passion fruit seeds: fix the mass concentration of cellulase at 2.0%, solid-liquid ratio (g/mL) at 1 : 20, extraction temperature at 55℃, and ultrasonic power at 100 W; set the extraction time to 120, 140, 160, 180, and 200 min.2.3.2. Orthogonal experiment design

According to the results of single-factor experiment, highly influential factors, including solidliquid ratio, extraction temperature, ultrasonic power, cellulase mass concentration, and extraction time, were selected for orthogonal experiment to optimize the extraction conditions.

2.4. Calculation of SDF yield

The yield of passion fruit seeds' SDF is calculated by the following equation:

SDF yield (%) = mass of SDF (g)/mass of passion fruit seeds (g) × 100

3. Results

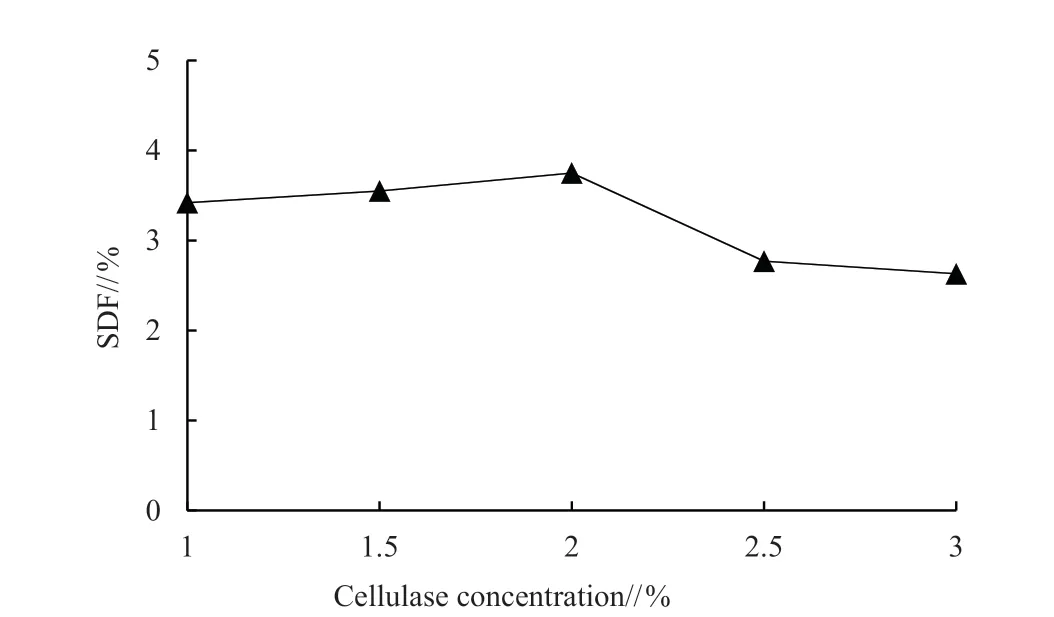

3.1. Effects of cellulase mass concentration on SDF yield

As shown in Fig. 1, the SDF yield of passion fruit seeds first mounted and then declined with the increase of cellulase; the SDF yield dropped sharply as cellulase went beyond 2.0%. The SDF yield increased possibly because of the effects of cellulase on IDF macromolecular component bonds. More specifically, part of the IDF was degraded into micromolecules with higher solubility, which means some IDF was transformed into SDF, and therefore the resulting SDF yield was improved. In contrast, the decline in SDF yield could be caused by the continuous effects of cellulase on SDF: excessive cellulase could decompose SDF into oligosaccharides or monosaccharides with small molecular weights and low convergence, which are easily dissolved in ethyl alcohol instead of precipitating at the bottom of the liquid. In this case, further addition of cellulase would inhibit the reaction velocity and suppress SDF yields[10]. It is recommended to fix the mass concentration of cellulase at 2.0% in consideration of economic factors.

Fig. 1 Effects of cellulase mass concentration on SDF yield of passion fruit seeds

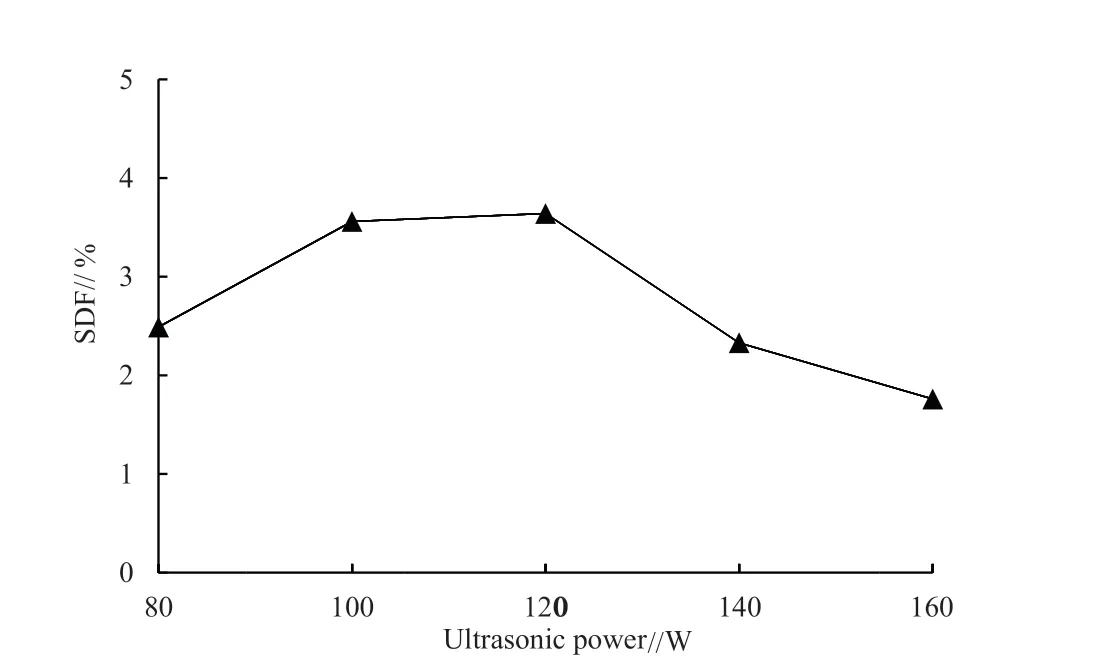

3.2. Effects of ultrasonic power on SDF yield

The SDF yield of passion fruit seeds, as shown in Fig. 2, first mounted and then declined with the increase of ultrasonic power; it reached the peak value at the ultrasonic power of 120 W. There were violent vibrations and strong cavitation inside the materials under ultrasonic treatment, which would reduce the compactness among different components. The cell wall of passion fruit seeds would break easily with the enhancement of ultrasonic power due to increased cavatition. Consequently, there would be higher SDF yields[11]. If the power of ultrasound surpassed 120 W, the SDF yield would begin to decrease with the decomposition of some dietary fibers. The optimal ultrasonic power should be 120 W.

Fig. 2 Effects of ultrasonic power on SDF yield of passion fruit seeds

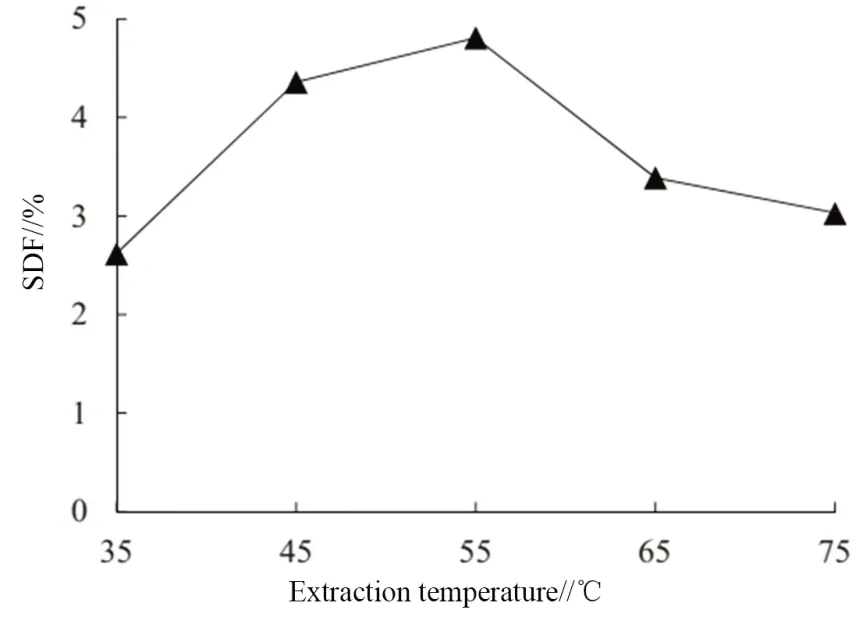

3.3. Effects of extraction temperature on SDF yield

According to Fig. 3, the yield of SDF first increased and then declined with the rise in extraction temperature; the peak value was observed at 55°C. Enzymes were gradually deactivated with the continuous increase in temperature, resulting in limited reaction velocity. Besides, high temperatures could gasify the solvents and destroy their effective components, causing insufficient contact between the carrier and the solvents. This would further affect the molecular bonding of effective components[12]. Therefore, the best extraction temperature was 55°C.

Fig. 3 Effects of extraction temperature on SDF yield of passion fruit seeds

3.4. Effects of solid-liquid ratio on SDF yield

When the solid-liquid ratio (g/mL) ranged from 1 : 10 to 1 : 15, the SDF yield had a tendency to increase with the dosage of extract (Fig. 4). Under the condition of fixed enzyme concentration and low substrate concentration, the acceleration of reaction velocity was in positive proportion to the increase of substrate concentration. SDF yield peaked at a solid-liquid ratio of 1 : 15 and gradually went down as the solid-liquid ratio ranged from 1 : 15~1 : 30. As the concentration of substrate increased to a certain amount, the reaction velocity would reach its peak value and stop increasing, even if the substrate concentration continued to rise. Taking the extraction yield and economic factors into consideration, the optimal solid-liquid ratio would be 1:15.

Fig. 4 Effects of solid-liquid ratio on SDF yield of passion fruit seeds

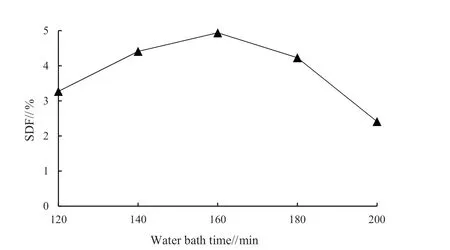

3.5. Effects of water bath time on SDF yield

The SDF yield of passion fruit seeds first increased and then declined with the extension of water bath time (Fig. 5); it reached the peak at 160 min. With the extension of enzymolysis on substrates, it became very hard for some SDF to aggregate and to precipitate by ethyl alcohol. SDF yield started to decrease as the water bath time reached 160 min. Therefore, the best water bath time would be 160 min.

3.6. Orthogonal experiment

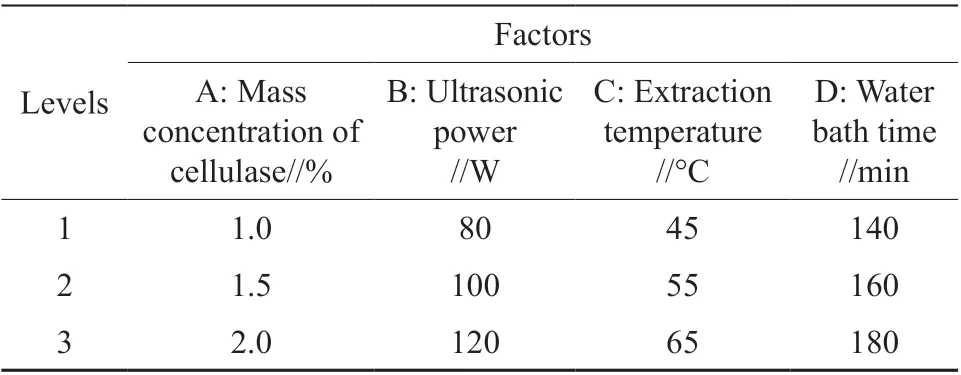

The above results of single-factor experiments indicated that solid-liquid ratio had little effect on the yield of SDF. Therefore, only four of the above factors were selected for orthogonal experiment (four factors and three levels, Table 1), which were cellulase concentration (A), ultrasonic power (B), extraction temperature (C), and water bath time (D).

Fig. 5 Effects of water bath time on SDF yield of passion fruit seeds

Table 1 Factors and levels for orthogonal experiment

Table 2 Orthogonal experiment design and results

The figures of “Range R” in Table 2 presented a result of B>C>D>A. Then, the factors can be listed in order of priority as ultrasonic power> temperature>extraction time>cellulase concentration. From k2A>k1A>k3A we can infer that the “Excellent” level of Factor A would be A2. Likewise, we consider B3as the “Excellent” level of Factor B based on k3B>k1B>k2B, C2as the “Excellent” level of Factor C from k2C>k1C>k3C, and D2as the “Excellent” level of Factor D from k2D>k3D>k1D. Consequently, the optimal combination should be A2B3C2D2, namely, a cellulase concentration of 1.5%, an ultrasonic power of 120 W, an extraction temperature of 55°C, and an extraction time of 160 min. This combination has been proved to be the optimal one by the highest SDF yield of 5.12%.

4. Discussion and Conclusion

In this research, ultrasound-assisted enzymatic extraction was used to extract soluble dietary fibers from passion fruit seeds. A single-factor experiment was designed to assess the effects of cellulase concentration, ultrasonic power, extraction temperature, solid-liquid ratio, and water bath time on SDF yield. The results recommend a combination of 2.0% cellulase concentration, 120 W ultrasonic power, 55°C extraction temperature, 1:15 solid-liquid ratio (g/mL) and 160 min water bath time; the solidliquid ratio was fixed to 1:15 because of its relatively insignificant effects on SDF yield. On this basis, a fourfactors and three levels orthogonal experiment was designed: cellulase concentration 2.0% (A), ultrasonic power 120 W (B), extraction temperature 55℃ (C), and water bath time 160 min (D). According to the findings, the optimal combination would be: 1.5% cellulase mass concentration, 120 W ultrasonic power, 55°C extraction temperature, and 160 min water bath time. This combination provided an SDF yield of up to 5.12%. These technological parameters and findings were highly instructional and offered great potential in practical applications.

Agricultural Science & Technology2020年1期

Agricultural Science & Technology2020年1期

- Agricultural Science & Technology的其它文章

- Effects of Growth Regulator MeJA on Nitrogen Metabolism in Rice under Cadmium Stress

- Purification of Starch from Cadmium-Contaminated Rice and Development of Functional Recombinant Rice

- Soil Heavy Metal Absorption Performance of the New Sorghum Combination Dunuo 201

- Optimization of Blueberry Wine Fermentation Process

- Study on the Effects of Reducing Blood Lipid by Flavonoids from Ampelopsis grossedentata on Hyperlipidemia Rats

- Isolation, Identification and Phosphate Solubilizing Capacity of Organophosphorus Solubilizing Bacteria in Rhizosphere Soil of Camellia oleifera