Optimization of Blueberry Wine Fermentation Process

ZHENG Zhi-hong, QU Zhao-xia*, HE Da-jiang, MENG Xin, WEI Mian, ZENG Jing-lang

1. College of Biological and Food Engineering, Key Laboratory of Hunan Province for Study and Utilization of Ethnic Medicinal Plant Resources, Huaihua University, Huaihua 418008, PRC;

2. College of Electrical and Information Engineering, Huaihua University, Huaihua 418008, PRC

Abstract Blueberry was used as material for the optimization of fermentation process of fruit wine through single factor and orthogonal experiments with the contents of alcohol, total sugar, total acid and anthocyanin as indicators. The best recipe was concluded as follows: in combination with 19°Bx initial sugar level, 0.35% yeast innoculation and 55 mg/L sodium metabisulfte, main fermentation was performed at room temperature for 8 d in summer, the alcohol content of the obtained blueberry fruit wine was 13% (volume fraction), the total sugar content was 2.54%, the total acid was 0.15 mol/L, the final anthocyanin content was 145.62 mg/L after its gradual decrease with the extension of brewing time; post-fermentation was carried out at 20℃ for 20 d. Finally, sensory evaluation showed that the blueberry wine is clear and transparent in bright purple-red color, and enjoyable for its rich aroma, full mouthfeel, moderate sweet and sour taste.

Key words Blueberry; Fruit wine; Process recipe

1. Introduction

Bluberry, a plant in the Ericaceae family andVacciniumgenus, has a cultivation history of over 100 years, including more than 450 varieties[1]. In 1983, 15 cold-resistant varieties were introduced firstly and cultivated in Northeast China by HAO Rui, a professor from Jilin University. Then high-quality cold-resistant varieties were screened out. Sequently, highquality drought and waterlogging resistant varieties suitable for local climate and soil characteristics were cultivated in China[2]. Bluberry is rich in carbohydrates, proteins and amino acids, the contents of anthocyanin and superoxide dismutase (SOD) are several times higher than those of other fruits[3]. According to National Standard Substance Testing Center, blueberry fruit contains 8 essential amino acids, is widely praised as “King of Berries in the World”[4]. Due to high content of pectic substances, blueberries can effectively lower cholesterol, prevent atherosclerosis, reduce the incidence of cardiovascular disease and stroke. Abundant pigment glycoside can activate retina, improve and strengthen vision, relieve eyestrain. Anthocyanin, the most effective natural water-soluble free radical scavenger found at present, is found in blueberry with high content and many kinds, indicating that blueberry can effectively inhibit cell aging[5]. Blueberry also can improve the body immunity, enhance the constitution, prevent cancer etc. Blueberry wine is low in alcohol, suitable for people in all ages, and it is stronger than fruit in lowering cholesterol. At present, the methods of making blueberry wine mainly include thermovinification, rotating pot method, freezing concentration technique, carbon dioxide-impregnated fermentation, stationary yeast technique,etc. In this study, the thermovinification was used to make bluberry wine with blueberry from Huaihua as material, and single factor and orthogonal experiments was conducted to optimize the fermentation pocess of fruit wine by detecting the contents of contents of alcohol, total sugar, total acid and anthocyanin.

2. Materials and Methods

2.1. Materials

Bluberry was used as tested material.

2.2. Experiment methods

2.2.1. Process flow

The technical process of blueberry is as follows: raw blueberry fruit→crushing and making into fruit pupls→thermovinification→filtration→pectinase enzymolysis→filtration again→enzyme deactivation→ centrifugation at 4 000 r/min→clarifying blueberry juice→composition adjustment→primary fermentation→ post-fermentation[6].2.2.2. Operating tips

(1) Blueberry juice: the fruit was repeatedly squeezed with a juicer to improve the juice yield. (2) Enzymolysis: 0.25% pectinase was added to hydrolyze at 45℃ for 2 h in the water. (3) Composition adjustment: sucrose was added to adjust the initial sugar content of raw juice. (4) Activation of culture: purchased An'qi wine saccharomyces cerevisiae as strain was activated for 30 min at 37℃ in the proportional sterile water. (5) Fermentation: strain was cultured at 28℃ for 8 d at the stage of primary fermentation and at 20℃ for 20 d at the stage of post-fermentation. 2.2.3. Single factor experiment

Based on common fermentation process flow, initial sugar content, saccharomyces cerevisiae inoculum size and sodium pyrosulfite quantity were set as factors, 5 levels in each factor referring to initial sugar content: 14%, 17%, 20%, 23%, 26%; saccharomyces cerevisiae inoculum size: 0.2%, 0.3%, 0.4%, 0.5%, 0.6%; sodium metabisulfite quantity: 20, 35, 50, 65, 80 mg/L. Total sugar, total acid, anthocyanin and alcohol content were selected as detection indexes to explore their effects on the quality of blueberry wine.

2.2.4. Orthogonal experiment

Based on the single factor experiment, in order to further optimize the fermentation process, the influence of all factors on the quality of blueberry wine was investigated by L9(33) orthogonal test. The factor level was shown in Table 1.

Table 1 Orthogonal experiment design for blueberry wine fermentation process

2.3. Indexes determination and methods

Anthocyanin: colorimeter method[7-9]; total sugar: 3,5-dinitrosalicylic acid colorimetry; total acid: acid-alkali titration; sugar content and alcohol content: use saccharimeter and alcohol meter to detect; sensory evaluation: evaluate the color, winey, taste and typicality of blueberry wine with a assessment team of 10 people according to the method researched by LIU B[10], then calculate average score, finally calculate the total score using weighting method with color weighting efficient of 0.2, winey weighting efficient of 0.3, taste weighting efficient of 0.3 and typicality weighting efficient of 0.2.

3. Results and Analysis

3.1. Effect of saccharomyces inoculum size on the quality of blueberry wine

Inoculum quantity had certain influence on the fermentation of blueberry wine. Usually, if inoculum size is too small, fermentation will be slow, fermentation time will be greatly prolonged, and easy to be contaminated by miscellaneous bacteria; while if inoculum size is too large, the saccharomyces reproduction speed will be too fast, the fermentation will be fast, resulting in fast sugar consumption and difficult alcohol accumulation[11]. Under the same fermentation condition, 0.2%, 0.3%, 0.4%, 0.5% and 0.6% saccharomyces were inoculated into blueberry juice for fermentation. After fermentation for 4 d, the results showed that the soluble solid content of blueberry wine with 0.2% saccharomyces decreased slowly; while the soluble solid content of blueberry wine with 0.5% and 0.6% saccharomyces decreased fast, but that would produce peculiar smell, affecting taste. After fermentation for 8 d, the total sugar content was the same, indicating that fermentation had been completed. Therefore, the optimal inoculum size was 0.4%, because the fermentation was basically completed, no odor, and the alcohol content was up to the standard.

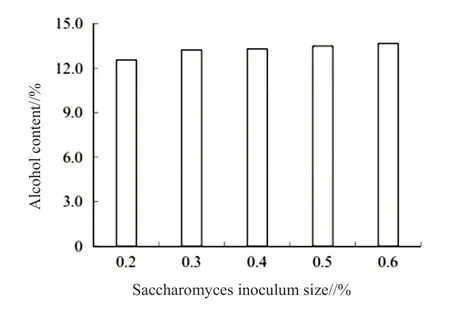

3.1.1. Effect of saccharomyces inoculum size on the alcohol content of blueberry wine

It can be seen from Fig. 1 that the alcohol content increased with the increase of saccharomyces inoculum size, but when the inoculum size exceeded 0.3%, the increase in alcohol content was not obvious. This is because at the early stage of fermentation, the total sugar content was high, the saccharomyces would speed up the sugar conversion rate and make the alcohol content rise. With the continuous increase of alcohol concentration, the normal reproduction and growth of saccharomyces were inhibited, resulting in the slow rise of the alcohol content at the later stage of fermentation. When the inoculum size was 0.2%, the substrate was not completely degraded, the alcohol content was low and the sensitivity of yeast and bacteria was high, hence the fruit wine was easy to be contaminated by miscellaneous bacteria. When the inoculum size was 0.5% and 0.6%, the growth and reproduction rate of saccharomyces was fast, the substrate was completely converted into alcohol, and the required fermentation time was also greatly reduced. However, the saccharomyces residue would occur, leading to the yeast odor in blueberry wine, which would affect the quality and taste of fruit wine. When the inoculum size was 0.4%, the alcohol content was higher, the saccharomyces residue was less, and both the flavor and quality of fruit wine were good.

Fig. 1 Effect of saccharomyces inoculum size on the alcohol content of blueberry wine

3.1.2. Effect of saccharomyces inoculum size on the total sugar content of blueberry wine

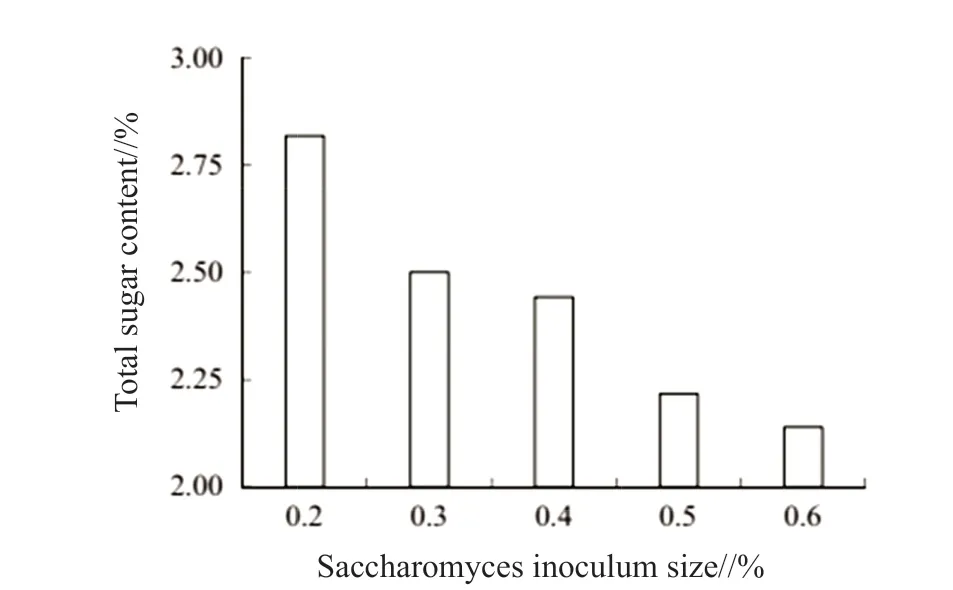

It can be seen from Fig. 2, with the increase of inoculum size, the decrease rate of total sugar content in blueberry juice reduced, and finally the decrease was not obvious. At the early stage of fermentation, the growth and reproduction rate of saccharomyces was very fast. After that, the fermentation rate decreased greatly. Because sugar was the carbon source for saccharomyce growth and reproduction. When the inoculum size was 0.2% and 0.3%, there were more carbon sources to maintain the normal growth and reproduction of saccharomyces. With the extension of fermentation time, the total sugar content in fruit wine decreased slowly. Starting from 0.4% inoculum size, the total sugar content decreased slowly. The reason was that the high alcohol content in the early stage inhibited the metabolic activities of saccharomyces and reduced the utilization rate of saccharomyces to sugar, so the total sugar content decreased slowly.

Fig. 2 Effect of saccharomyces inoculum size on the total sugar content of blueberry wine

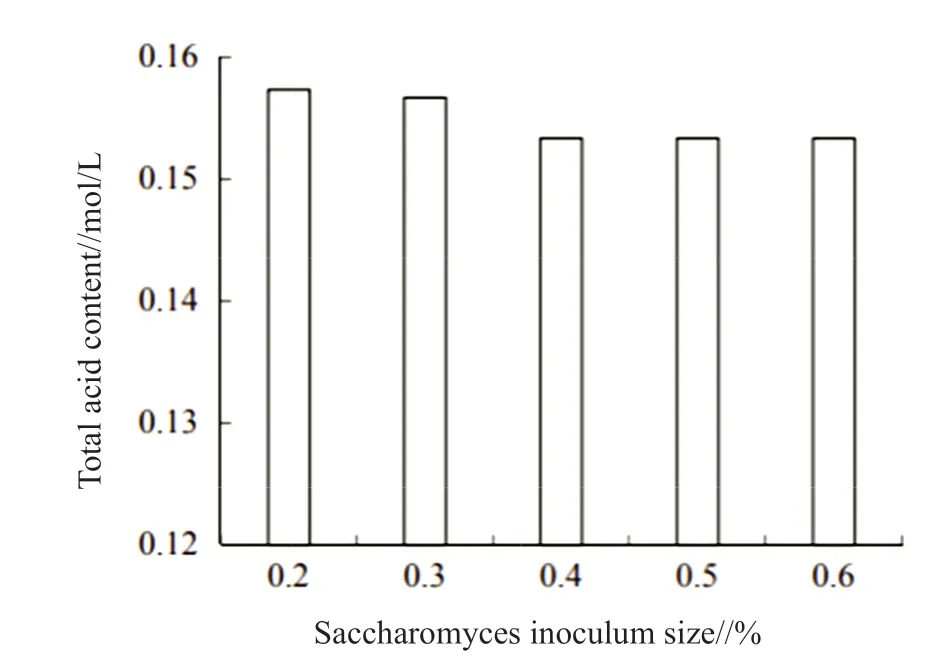

3.1.3. Effect of saccharomyces inoculum size on the total acid content of blueberry wine

It can be seen from Fig. 3, total acid content of blueberry juice decreased with the increase of inoculum size. Because at the moment alcohol fermentation had been almost completed, a malolactic fermentation process started to produce acid. However, the alcohol content of blueberry wine had exceeded 10%, and the alcohol had become the inhibitory factor of malolactic fermentation. Moreover, the higher the saccharomyces content, the higher the alcohol content, the greater the inhibition of malolactic fermentation, resulting in the lower total acid content.3.1.4. Effect of saccharomyces inoculum size on the anthocyanin content of blueberry wine

Fig. 3 Effect of saccharomyces inoculum size on the total acid content of blueberry wine

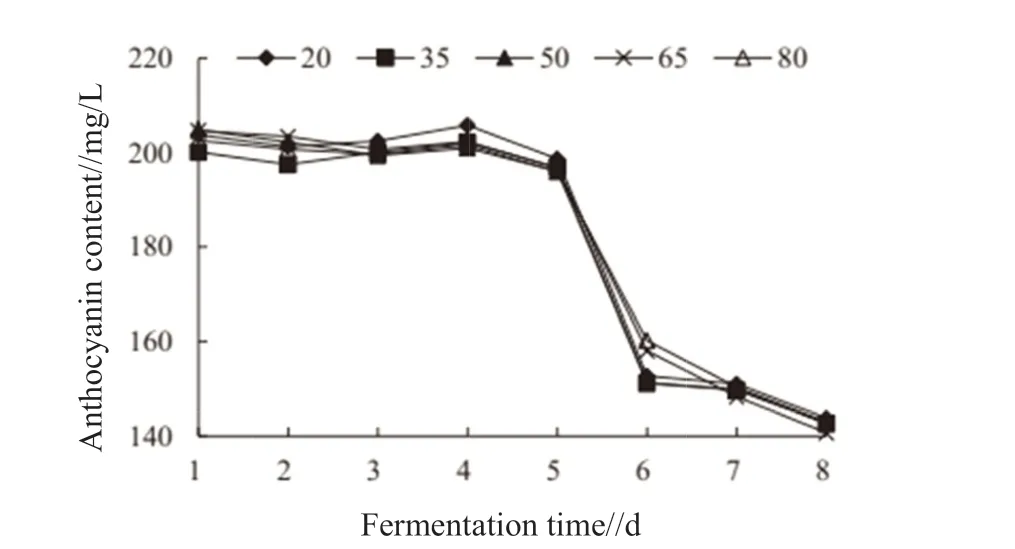

As can be seen from Fig. 4, the anthocyanin content decreased slowly, then rapidly, and finally steadily, but the overall value decreased. In the first 3 d of fermentation, due to a large number of saccharomyces proliferation, the need for more oxygen, so that the oxygen content of blueberry wine decreased, the oxidation was weakened, leading to the decrease of anthocyanin content. On the 4thday, the saccharomyces growth rate slowed down, and the accumulation of alcohol made part of the anthocyanins impregnated, and the anthocyanin content increased to the peak. With the saccharomyces died and aged, the anthocyanin content decreased slowly.

Due to the slow fermentation with 0.2% saccharomyces inoculum size, it required less oxygen for fermentation, resulting in the higher oxygen content in blueberry and stronger oxidation. Therefore, blueberry wine inoculated with 0.2% saccharomyces had high anthocyanin content compared to that inoculated with 0.4% and 0.5% saccharomyces. It can be seen from Fig. 4, the saccharomyces inoculum size had significant effect on anthocyanin content. Obviously, the more the inoculum size, the faster the fermentation rate, the more oxygen the fermentation required and the faster the anthocyanin is oxidized.

Fig. 4 Effect of saccharomyces inoculum size on the anthocyanin content of blueberry wine

3.2. Effect of initial sugar content on the quality of blueberry wine

Sugar, as carbon source of saccharomyces growth and reproduction, played an important role in the fermentation of fruit wine[12]. If initial sugar content was too low, the fermentation would end early and could not reach the fruit wine standar[13]; if the initial sugar content was too high, the osmotic pressure in the wine would increase, resulting in the death of saccharomyces and affecting the fermentation. In addition, the residual sugar concentration and acidity would also increase, affecting the taste of the wine. Sucrose was added to blueberry juice under the same fermentation conditions, the initial sugar content was adjusted to 14, 17, 20, 23, 26°Bx. After fermentation for 4 d, the results showed that when the initial sugar content was 19 and 20°Bx, the reproductive and metabolic rates of saccharomyces were fast; but when the initial sugar content was 19°Bx, the alcohol content was only 8.2%. With the initial sugar content increased, the alcohol content was increased. When the initial sugar content was 21°Bx, the reproductive and metabolic rates of saccharomyces slowed down, and even stopped when the initial sugar content exceeded a certain range. Therefore, the optimal initial sugar content was 20°Bx.

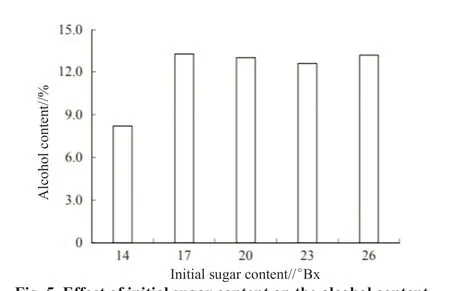

3.2.1. Effect of initial sugar content on the alcohol content of blueberry wine

As shown in Fig. 5, in the range of 14~20°Bx, the higher the initial sugar content, the higher the alcohol content of blueberry wine. Because the higher the initial sugar content, the more the material for fermentation, the faster the reproduction of saccharomyces and the more the alcohol produced. However, when the initital sugar content exceeded the optimal content, the fermentation was inhibited. Hence, it produced more alcohol at an initial sugar content of 20% than at an initial sugar content of 17%. When the initial sugar content was 14%, saccharomyces needed to consume a small amount of sugar for its growth and reproduction, resulting in the decrease in the total sugar required for fermentation to produce alcohol, so the alcohol content was low.

Fig. 5 Effect of initial sugar content on the alcohol content of blueberry wine

3.2.2. Effect of initial sugar content on the total sugar content of blueberry wine

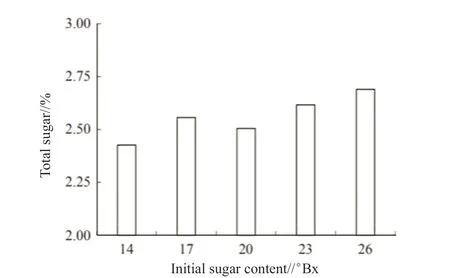

As shown in Fig. 6, in the range of 14~26°Bx, the higher the initial sugar content, the higher the total sugar content of blueberry wine. When the initial sugar content were 14% and 17%, sugar was consumed for saccharomyces proliferation and fermentation into alcohol, resulting in a low residual sugar content; when the initial sugar content were 23% and 26%, the high sugar content inhibited the saccharomyces proliferation and made fermentation slow, resulting in a high residual sugar content.

Fig. 6 Effect of initial sugar content on the total sugar content of blueberry wine

3.2.3. Effect of initial sugar content on the total acid content of blueberry wine

As shown in Fig. 7, in the range of 14~26°Bx, the higher the initial sugar content, the higher the total acid content of blueberry wine. There was a negative correlation between total acid content and alcohol content, as reflected by the increase in initial sugar content and alcohol content, resulting in an greater inhibition to malolactic fermentation and less total acid. Total acid content also had a negative correlation to residual sugar content. The total acid content increased with the decrease of residual sugar content, resulting in the imbalance between sweetness and acidity in blueberry wine, and seriously affecting taste.3.2.4. Effect of initial sugar content on the anthocyanin content of blueberry wine

Fig. 7 Effect of initial sugar content on the total acid content of blueberry wine

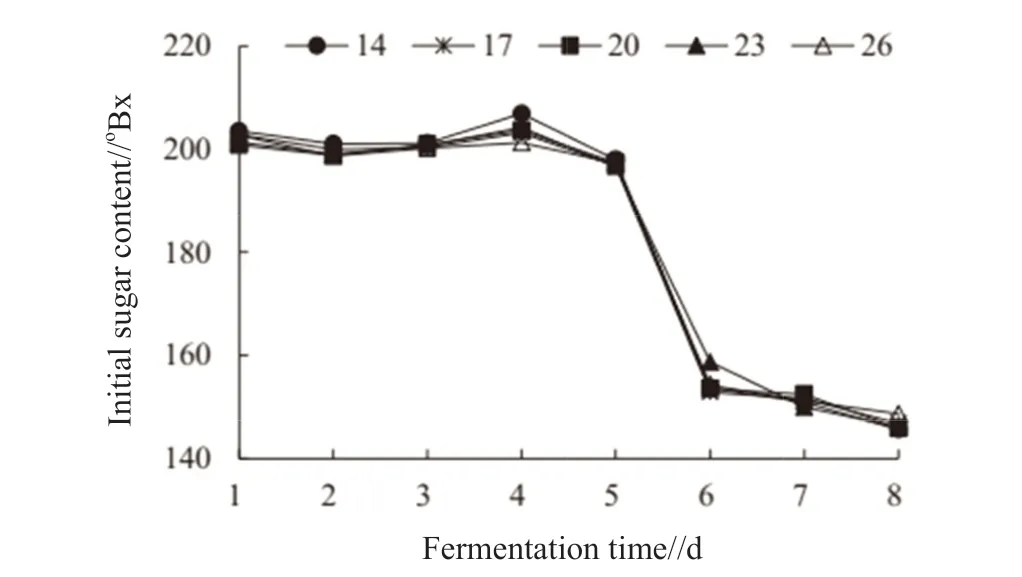

As shown in Fig. 8, the anthocyanin content peaked on the 4thday, which was consistent with the effect of saccharomyces inoculum size on the anthocyanin content. Of which, when the initial sugar content was 20%, the anthocyanin content was the highest. The reason is that a part of sugar was consumed for saccharomyces proliferation, making fermentation raw material decreased. By the 3rdday, fermentation was completed and saccharomyces stopped growing and reproducing. Therefore, blueberry wine fermented with initial sugar content of 20% had more oxygen content than that of the other two groups, allowing more anthocyanins to soak out.

Fig. 8 Effect of initial sugar content on the anthocyanin content of blueberry wine

3.3. Effect of sodium pyrosulfite on the quality of blueberry wine

Sodium pyrosulfite could be hydrolyzed into SO2, which had bactericidal, antiseptic, antioxidant and clarifying effects on blueberry wine while decreasing pH value. Although the growth and fermentation of saccharomyces were the best in slightly acidic environments, too low pH would not only affect saccharomyces fermentation, but also promote the hydrolysis of acetate, seriously affecting taste[14]. Under the same fermentation condition, 20, 35, 50, 65 and 80 mg/L sodium pyrosulfite were added into blueberry juice for fermentation, respectively. After fermentation for 4 d, the results showed that 20 and 35 mg/L sodium sulfite were not enough to inhibit bacteria, resulting in the contamination of bacteria. The 50 mg/L sodium pyrosulfite could play a good antioxidant effect, the anthocyanin content in blueberry wine decreased slowly, and the color and aroma of the wine were very good. Although 80 mg/L sodium pyrosulfite could better inhibit the growth of miscellaneous bacteria, it also inhibited the fermentation of saccharomyces, resulting in fermentation ended in advance, bad color and taste. Therefore, 65 mg/L sodium pyrosulfite was the optimal.

3.3.1. Effect of sodium pyrosulfite on the alcohol content of blueberry wine

As shown in Fig. 9, the alcohol content decreased with the increase of sodium pyrosulfite concentration within the range of 20~50 mg/L. Because sodium pyrosulfite could be hydrolyzed to SO2, resulting in the decrease in pH value. However, too low pH value could affect saccharomyces proliferation and fermentation, and decrease alcohol content.

Fig. 9 Effect of sodium pyrosulfite on the alcohol content of blueberry wine

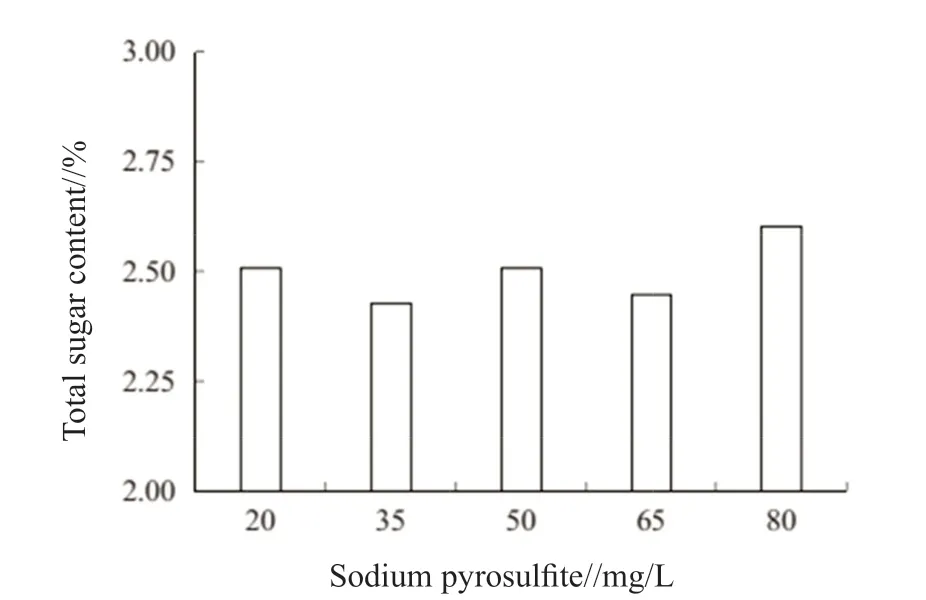

3.3.2. Effect of sodium pyrosulfite on the total sugar content of blueberry wine

As shown in Fig. 10, the total sugar content of blueberry wine with 20 and 80 mg/L sodium pyrosulfite was higher than that with 35 and 65 mg/L sodium pyrosulfite. The reason was that although sodium pyrosulfite could inhibit the growth of miscellaneous bacteria, it also inhibited the fermentation of saccharomyces, making fermentation terminated in advance. Therefore, 50 mg/L sodium pyrosulfite was the optimal.

Fig. 10 Effect of sodium pyrosulfite on the total sugar content of blueberry wine

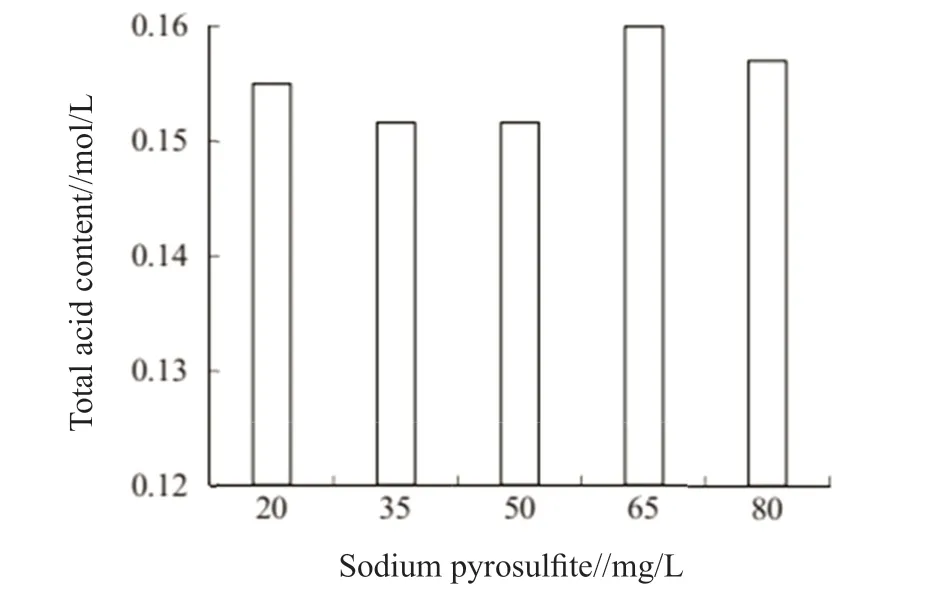

3.3.3. Effect of sodium pyrosulfite on the total acid content of blueberry wine

As shown in Fig. 11, the total acid content decreased with the increase of sodium pyrosulfite concentration within the range of 20~50 mg/L. The higher concentration of sodium pyrosulfite, the more SO2was released. High concentration of SO2could not only inhibit the proliferation and fermentation of saccharomyces, but also could inhibit the activity of bacteria using organic acids as the fermentation substrate, thus inhibiting malolactic fermentation and finally resulting in the decrease in total acid content. Corresponding to the above residual sugar content, the blueberry wine with low residual sugar had high content of total acid, which made the imbalance between sweetness and acidity, seriously affecting the taste of the wine. When the concentration of sodium pyrosulfite was 65 mg/L, the blueberry wine had the highest content of total acid and the optimal taste. While 80 mg/L sodium pyrosulfite led to incomplete fermentation and inhibited the reproduction of saccharomyces.

Fig. 11 Effect of sodium pyrosulfite on the total acid content of blueberry wine

3.3.4. Effect of sodium pyrosulfite on the anthocyanin content of blueberry wine

As shown in Fig. 12, the anthocyanin content decreased slowly, then rapidly, and finally steadily, but the overall value decreased. In the first 4 d, due to the accumulation of anthocyanin and soaking by alcohol, the anthocyanin content peaked, then decreased slowly with the death and aging of saccharomyces. The fermentation process was slow and required less oxygen when 80 mg/L sodium pyrosulfite was added, making less anthocyanin oxidized. Therefore, blueberry wine fermented with 80 mg/L sodium pyrosulfite had higher content of anthocyanin than that with 35 and 50 mg/L sodium pyrosulfite. It can also be seen from Fig. 12, the higher concentration of sodium pyrosulfite, the more SO2was released, indicating that sodium pyrosulfite had significant effect on the anthocyanin content. SO2could easily combine with the anthocyanin in blueberry wine to form colorless addition product, and it also could inhibit the formation of dark red anthocyanin-tannin polymeride. Therefore, too high concentration of sodium pyrosulfite could lead to the lighter color of blueberry wine.

Fig. 12 Effect of sodium pyrosulfite on the anthocyanin content of blueberry wine

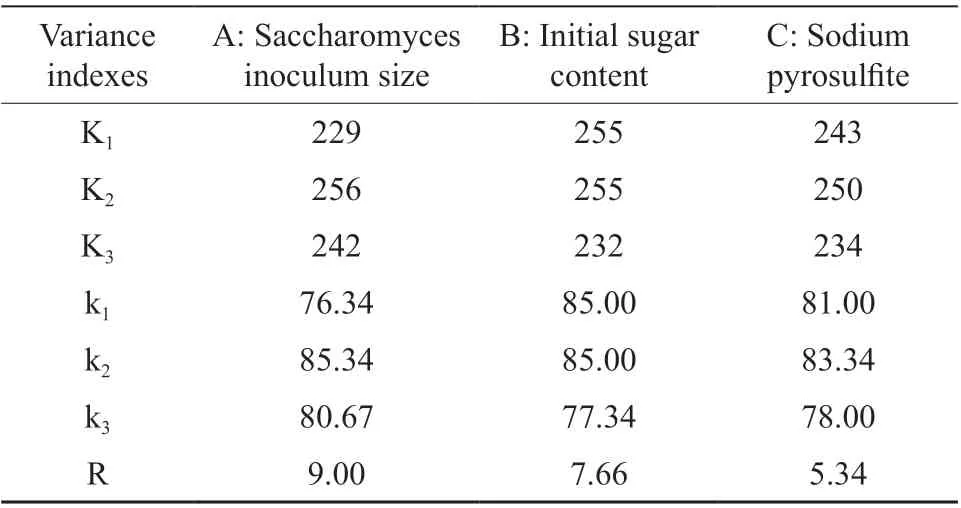

3.4. Orthogonal experiment results

In the sensory evaluation of the orthogonal experiment, the top 3 combinations were A2B1C2(90 points), A3B2C1(88 points), A2B2C3(86 points). According to the K value in Table 2, the factors affecting the quality of blueberry wine were in the order: A>B>C, that is, the primary factor was inoculum size and the secondary factor was initial sugar content. The K value in each level showed that the optimal combination was A2B1C1, in which, saccharomyces inoculum size was 0.35%, initial sugar content was 19°Bx, sodium pyrosulfite concentration was 55 mg/L.

Table 2 Orthogonal experiment results

4. Conclusion

The optimal fermentation process of blueberry wine was determined by single factor and orthogonal experiments as follows: saccharomyces inoculum size 0.35%, initial sugar content 19°Bx, sodium pyrosulfite 55 mg/L. The thermovinification and enzyme hydrolysis method were used to make blueberry juice. Because heating fruit pulp could destroy the microbial pathogens, effectively prevent the oxidation of the wine, and promote the extraction of pigment from fruit peel. The advantages of this experiment: fermentation with pure juice could save fermentation container and reduce labor; blueberry wine with high colority and low content of volatile acid ensured its quality and flavor, and avoided the loss of nutrients. Disadvantage: out of juice incompletely caused by physical squeeze resulted in too low juice yield and seriously wasting of raw materials; too long enzymatic hydrolysis time prolonged the fermentation cycle.

Agricultural Science & Technology2020年1期

Agricultural Science & Technology2020年1期

- Agricultural Science & Technology的其它文章

- Effects of Growth Regulator MeJA on Nitrogen Metabolism in Rice under Cadmium Stress

- Purification of Starch from Cadmium-Contaminated Rice and Development of Functional Recombinant Rice

- Soil Heavy Metal Absorption Performance of the New Sorghum Combination Dunuo 201

- Ultrasound-assisted Enzymatic Extraction of SDF on Passion Fruit Seeds

- Study on the Effects of Reducing Blood Lipid by Flavonoids from Ampelopsis grossedentata on Hyperlipidemia Rats

- Isolation, Identification and Phosphate Solubilizing Capacity of Organophosphorus Solubilizing Bacteria in Rhizosphere Soil of Camellia oleifera