Purification of Starch from Cadmium-Contaminated Rice and Development of Functional Recombinant Rice

TAO Xiang-lin, PANG Min, GUO Jin-qi , WEI Ying-juan, WU Yue-hui, TANG Han-jun,3

1. Research Team of Crop Starch Chemistry and Metabonomics, Hunan Academy of Agricultural Sciences, Changsha 410125, PRC;

2. Hunan Institute of Agricultural Product Processing, Changsha 410125, PRC;

3. College of Longping, Graduate School of Hunan University, Changsha 410125, PRC

Abstract In order to provide a new utilization method for cadmium-contaminated rice, a preliminary study of the removal of rice starch cadmium by water, calcium hydroxide, sodium hydroxide and citric acid was conducted, the damage degree of starch was compared by SEM, and then the recombinant rice was obtained by a twin-screw extruder using the starch which met the safety standard. The physical and chemical properties of recombinant rice were analyzed by acid hydrolysis and texture analyzer. The results showed that citric acid was a good rice cadmium removal agent. The quality of recombinant rice prepared from cadmium-removed rice starch was improved; the acid resistance was increased. Heavy metal contaminated rice can be a staple food with better quality and higher value through processing.

Key words Cadmium removal; Rice starch; SEM; Texture; Acid resistance

1. Introduction

China is the largest country in the world in rice production and consumption, and the grain output of rice occupies more than 40% of total food production. More than 65% of the population lives on rice as a staple food[1]. However, the adsorption capacity of cadmium and other heavy metals in rice is stronger than other grain crops such as wheat and corn[2]. Unfortunately, in recent years, the improper use of pesticides and the rapid development of industry have led to serious environmental pollution in our country. The problem of cadmium pollution in rice has been a threat to food safety. Research showed that cadmium was mainly distributed in aleurone layer and the content in rice reduced gradually from outside to inside, meanwhile, cadmium mostly binded to proteins in the form of complexes and combined most often with gluten[3]. There were significant differences in cadmium content among different rice varieties[4-8]. The main component of rice was starch, accounting for approximately 90% of the dry weight of rice[9]. Therefore, the purification of starch from cadmium contaminated rice and its utilization as food were of great significance to the safety of the food supply.

Actually, the combination of rice starch and protein was very strong, and it was difficult to separate from the protein by physical methods[10]. In our previous research, when the contents of Cd in rice did not exceed 0.6 mg/kg, it could be reduced to below the safe value of 0.2 mg/kg by physical grinding technology, but when the contents of Cd exceeded 0.6 mg/kg, it was difficult to reduce it to below 0.2 mg/kg by grinding[11]. Acid methods of starch isolation are usually used in the industrial production of corn, potato starch,etc. Alkaline methods of starch isolation are the most commonly used method in laboratories[12]. Some organic acids, such as citric acid that contains carboxyl and hydroxyl groups, have been used as modifiers to remove cadmium from brown rice[13]. To date, no industrial production technology of rice starch has been established. Technology to purify starch from cadmium-polluted rice and the utilization method of rice starch are almost non-existent.

Therefore, this study used cadmiumcontaminated rice as the experimental material to compare the purity, damage degree and cadmium reduction efficiency of rice starch extracted by alkali and acid methods. The recombinant rice was prepared by screw extrusion technology with the rice starch in accordance with safety standards. The physical properties and acid digestibility of recombinant rice and raw rice were also evaluated. The extraction of rice starch from cadmium-polluted rice and the technical feasibility of food utilization were preliminarily established.

2. Materials and Methods

2.1. Materials

A total of 5 indica rice varieties were collected from Changsha in Hunan Province, China. The test numbers were V1 to V5. Rice grains were hulled using a husker to obtain brown rice. The samples were dried in a hot air oven (101-AB, Tianjin Taisite Instrument Co., Ltd., China) at 40℃ for 2 d; the cadmium content values by ICP-MS were 0.660, 0.173, 0.395, 0.984, and 0.999 mg/kg.

2.2. Starch isolatio n

Starch isolates were obtained according to the literature method with modification[14]. However, 4 different solutions were used: water (WS), calcium hydroxide solutions (CHS, 1 mg/mL), sodium hydroxide solutions (SHS, 1 mg/mL) and citric acid solutions (CAS, 1 mg/mL).

20 g brown rice samples were soaked overnight with each solution (0.25 g/mL, 25℃). The mixture was then grounded, passed through a 120 mesh sieve and centrifuged at 5 000×g for 10 min (25℃) with a centrifuge (TGL-20M, Changsha Pingfan Instrument and Meter Co., Ltd.). The precipitates were mixed with each solution (0.25 g/mL), stirred at room temperature for 2 h using a magnetic stirrer and then centrifuged at 5 000×g for 10 min at room temperature; this procedure was repeated twice. The precipitate was washed with deionized water and then adjusted to pH 6~7. Finally, the neutralized mixture was passed through a 400 mesh sieve and filtered with a glass filter. The wet starch was dried in a hot air oven at 40℃ for 2 d. The extraction rate of starch was calculated as follows:

Extraction rate= the mass of starch (g)/the mass of rice (g)×100%

2.3. Analysis of starch purity and ash content

The starch purity was determined according to the literature method with modification[15]. Approx- imately 0.5 g of each starch sample was accurately weighed, 30 mL H2SO4(1 mol/L) was added, and then clamped and oscillated at 95℃ in a constant temperature water bath oscillator (180 r/min) for 1 h. After cooling, the solution was transferred to a volumetric flask and the volume was set to 100 mL with the addition of deionized water. Finally, the soluble carbohydrates were measured using the phenol-sulfuric acid method. The ash content of the starch was determined according to the AOAC method[16].

2.4. Analysis of starch cadmium content

Approximately 0.5 g of each sample was accurately weighed, and the samples were dissolved completely with 9 mL concentrated nitric acid and 1 mL concentrated perchloric acid at 200℃. After cooling, the dissolved solution was transferred to a volumetric flask and the volume was set to 100 mL with the addition of deionized water. The solution was analyzed for the cadmium content by ICP-MS (7700X, Agilent Technologies, Inc.). The removal efficiency of cadmium was calculated as follows:

whereZwas the removal efficiency of Cd (%),M0was the amount of cadmium in brown rice, andMwas the amount of cadmium in starch.

2.5. Analysis of apparent amylose (AM) content

The apparent AM content of starch was determined according to the method of TANG Het al[17]. Briefly, 0.1 g starch was dissolved in 3 mL DMSO, and the solution was mixed with 30 mL absolute ethanol to precipitate the starch, and then, it was centrifuged (5 000×g, 10 min) . This step was repeated twice. The precipitated starch was washed twice with ethanol and dried at 40℃. Approximately 10 mg defatted starch was accurately weighed, 1 mL deionized water was added, the dispersed starch was incubated for 15 min in boiling water, cooled to room temperature, and then 1 mL NaOH (1 mol/L) was added to dissolve it completely. After it was adjusted to pH 6~7 with HCl (1 mol/L), the solution was transferred to a volumetric flask and the volume was set to 10 mL with the addition of deionized water. The 0.2 mL starch solution and 0.2 mL iodine solution (2 mg/mL I2and 20 mg/mL KI) were mixed in a test tube, and then 4.6 mL deionized water was added. Finally, the sample was settled in darkness for 20 min, and scanned at 680 nm using an ultraviolet spectrophotometer (Sp-756, Shanghai spectrum instruments Co., Ltd.) to obtain blue value (BV).

AM content = [BV(starch)/1.2] ×100%

2.6. Scanning electron microscopy (SEM) of starch granules

Starch granules were obtained using an SEM (A02100301, Carl Zeiss AG) at an accelerating voltage of 15 KV. The samples were mounted on aluminium stubs using double sided adhesive tape to which the samples were fixed and afterwards were coated with a thin layer of gold.

2.7. Preparation of recombinant rice

The starch extracted by CAS in VI and rice protein (Nutribiotic, USA) were mixed in a ratio of 9.3 : 0.7 through a 100 mesh sieve. The recombinant rice was prepared by a twin-screw extruder. The preparation parameters were temperature 90℃, water 25%, and screw speed 180 r/min. Finally, the extruded rice was dried until the moisture content was below 14% at 40℃.

2.8. Morphological observation of rice

Morphological observation of rice was performed using an SLR camera with a short-focus lens.

2.9. Texture analysis of cooked rice

The rice was cooked in an electric pressure cooker with a working pressure and cooking time of 40 KPa and 15 min, respectively. The solid (g) to solvent (mL) ratio of the raw rice and extruded rice was 1:1.2 and 1:0.6, respectively. The texture of the cooked rice was determined by a texture analyzer (CT3-4500, Brookfield Co., Ltd.) modifying to the method of MESTRES Cet al.[18]. The operating conditions of the instrument were: probe at TA39, a measured distance of 1 mm, a trigger force of 1 g, a test speed of 0.5 mm/s and a test type of compression.

2.10. Acid resistance of cooked rice

Approximately 5 g of each type of cooked rice was accurately weighed, 50 mL HCl was added, and then clamped and oscillated at 37℃ in the constant temperature water bath oscillator (180 r/min) for 5 h. Deionized water was added in the blank experiments at the same time. 1 mL digestive solution was taken every 1 h and centrifuged at 8 000×g for 10 min. The supernatant was obtained and analyzed for total carbohydrate by the phenol-sulfuric acid method. Three parallel tests for each sample and calculated the mean value.

2.11. Statistical analysis

An analysis of the variance of data was carried out using SPSS 17.0 to compare the significant differences (P<0.05) among the results. Other calculations were performed by Microsoft Excel 2007.

3. Results and Discussion

3.1. Characteristics of isolated starches

The characteristics of starch isolated from 5 rice varieties by different solutions were shown in Table 1. The extraction rates of starch with WS, CHS, SHS and CAS ranged from 66.9% to 71.3%, 69.4% to 75.3%, 75.0% to 79.5% and 59.1% to 65.1%, respectively. There were significant differences (P<0.05) in the extraction rates of starch with the different solutions among the same varieties. The SHS method had the highest extraction rates, and the CAS method had the lowest rate.

The purity of isolated starch with WS, CHS, SHS and CAS ranged from 80.5% to 91.0%, 86.8% to 95.6%, 93.8% to 96.8% and 95.6% to 97.9%, respec- tively. There were significant differences (P<0.05) between the different extraction methods or among the varieties. The CAS method had the highest purity, and the purity with the WS method was the lowest.

The ash content of isolated starch with WS, CHS, SHS and CAS ranged from 0.2% to 0.7%, 0.4% to 1.2%, 0.2% to 0.6% and 0.1% to 0.2%, respectively. There were significant differences (P<0.05) among the different extraction methods and among the varieties. These results indicated that the removal efficiencyof metal elements by water extraction was poor, and alkali extraction had alkali metal element residue. The CAS method was the best method from the perspective of removal efficiency and did not cause any metal element residue.

Table 1 Characteristics of starch isolated by different methods

The removal efficiency of cadmium with WS, CHS, SHS and CAS ranged from 28.3% to 79.8%, 66.8 % to 82.0%, 73.4% to 89.7% and 79.7% to 98.8%, respectively. There were significant differences (P<0.05) among the different extraction methods and among the varieties. The trend of starch purity was consistent with the trend of cadmium removal efficiency. The removal efficiency of cadmium with SHS and CAS was similar to the reports of TIAN Yet al.[19]and WU Y Net al.[13]. The highest cadmium removal efficiency was achieved by using citric acid and the contents of Cd in CAS treated samples were below the safety standard of 0.2 mg/kg.

The apparent AM content values of isolated starch with WS, CHS, SHS and CAS were 29.1%, 28.8%, 29.8% and 26.7% in V1, and 30.5%, 27.6%, 31.7% and 27.7% in V2, and 33.5%, 31.5%, 31.2% and 29.2% in V3, and 24.0%, 22.9%, 24.1% and 23.7% in V4, and 30.9%, 31.0%, 30.9% and 28.4% in V5, respectively. There was no significant difference in apparent AM content of V4 and V5 resulting from the different extraction methods. However, the apparent AM content of V1, V2 and V3 decreased significantly with the citric acid method; the citric acid might have caused damage to the starch granules. This result showed that the resistance of different varieties of starch granules to citric acid is different.

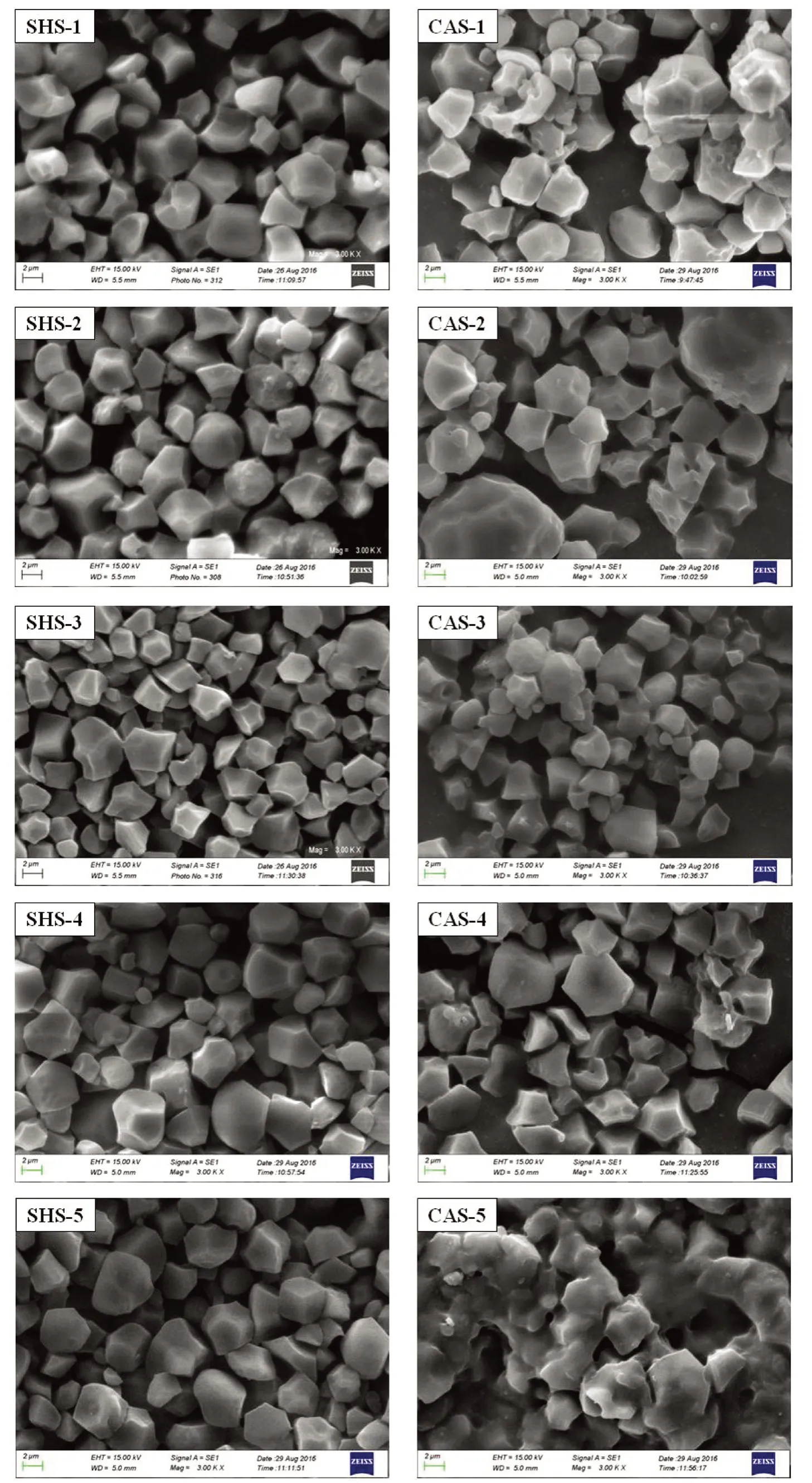

3.2. SEM of starch granules

The SEM observation of starch granules was shown in Fig. 1. The 5 rice varieties starch samples isolated by SHS maintained the original morphology of rice starch granules, similar to that described in previous reports[20-23]. It indicated that the starch granules isolated by SHS were basically undamaged. However, 5 kinds of starch granules isolated by CAS could be observed to varying degrees of injury. In particular, the CAS-5 starch granules showed a significant melting phenomenon, and no complete granules were found. These results indicated that citric acid gave rise to the highest removal efficiency for heavy metals such as cadmium whereas the most obvious damage to rice starch granules. For different rice varieties, suitable solvents and technologies should be selected for the removal of heavy metals such as cadmium.

3.3. Morphological observation of rice

Using starch extracted by CAS in V1 as the main ingredient, the recombinant rice was prepared by twinscrew extrusion technology. The morphology of the recombinant rice and the raw rice was observed (Fig. 2). The recombinant rice was similar to the raw rice in morphology, but the surface of the rice grain was smoother and the organization was more transparent and more uniform. These results were similar to the broken rice reconstituted rice reported by WANG H R[24]and LIU J F[25]. After cooking, the color of the rice was almost the same between the recombinant rice and the original rice, but the morphological difference increased, i.e., the recombinant rice was relatively flat. The difference could be because the granulation of the cutting edge structure was not as smooth and tight as that of the other parts of the rice grain, and water swelling was not the same in the cooking process. The granulation technology must be further improved.

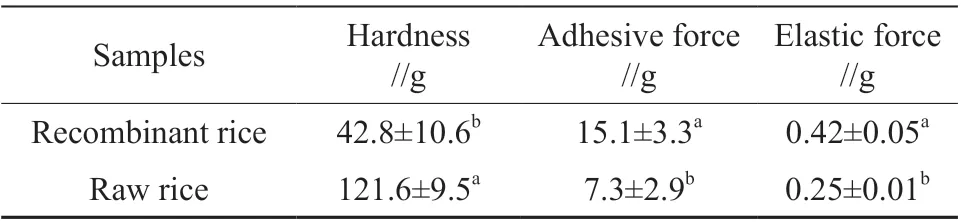

3.4. Texture analysis of cooked rice

The hardness, adhesive force and elastic force of recombinant rice and raw rice were determined by a texture analyzer (Table 2). The hardness of the recombinant rice was significantly lower than that of the raw rice, but the adhesive and elastic forces were significantly higher than that of the raw rice. This was in accordance with the results of WANG H R[24]and LIU J F[25]. These results indicated that the texture of the recombinant rice was better than that of the raw rice and thus will be more popular with consumers.

3.5. Acid resistance of cooked rice

Fig. 1 SEM of rice starch isolated by different solutions(SHS-1、SHS-2、SHS-3、SHS-4、SHS-5: The starch isolated by sodium hydroxide solution from V1、V2、V3、V4、V5; CAS-1、CAS-2、CAS-3、CAS-4、CAS-5: The starch isolated by citric acid solution from V1、V2、V3、V4、V5)

Fig. 2 Morphological observation of rice

Table 2 Texture result of cooked rice

The hydrolysis rate of hydrochloric acid from cooked rice was shown in Fig. 3. In the first 2 h, two samples were rapidly hydrolyzed; the raw rice was faster. After 2 h, the hydrolysis rate of the recomb- inant rice was approximately 53%, and the hydrolysis was basically stopped; the final hydrolysis rate was approximately 53%, while the hydrolysis rate of the raw rice was approximately 65%, the hydrolysis rate was still slow, and the hydrolysis rate was close to 75% after 4 h. The results showed that the recombinant rice had better acid resistance than the raw rice, and the proportion of resistant starch increased significantly. Therefore, the raw rice starch could not only improve the taste by extrusion molding technology but also increase the acid resistance. The recombinant rice was probably a kind of functional rice suitable for people with diabetes or obesity, nevertheless, this still required further experimental proof.

Fig. 3 Acid digestion of cooked rice in vitro

4. Conclusions

The effects of water, calcium hydroxide, sodium hydroxide and citric acid on the removal of cadmium from rice starch were preliminarily determined in this study. At the same level of treatment, the best removal efficiency of cadmium from rice starch was achieved by using citric acid, with the greatest purity of the obtained starches, but the starch damage of some rice was greater. Compared with that of the raw rice, the quality of the recombinant rice with cadmiumfree starch was significantly improved, while the acid resistance increased significantly. The recombinant rice was probably a functional staple food suitable for the people having diabetes or obesity. This study showed that rice with heavy metal presence can be greatly improved in quality and value through processing.

Agricultural Science & Technology2020年1期

Agricultural Science & Technology2020年1期

- Agricultural Science & Technology的其它文章

- Effects of Growth Regulator MeJA on Nitrogen Metabolism in Rice under Cadmium Stress

- Soil Heavy Metal Absorption Performance of the New Sorghum Combination Dunuo 201

- Optimization of Blueberry Wine Fermentation Process

- Ultrasound-assisted Enzymatic Extraction of SDF on Passion Fruit Seeds

- Study on the Effects of Reducing Blood Lipid by Flavonoids from Ampelopsis grossedentata on Hyperlipidemia Rats

- Isolation, Identification and Phosphate Solubilizing Capacity of Organophosphorus Solubilizing Bacteria in Rhizosphere Soil of Camellia oleifera