大豆机收清选筛田间性能试验与分析

刘 鹏,金诚谦,,宁新杰,倪有亮,王廷恩,印 祥

大豆机收清选筛田间性能试验与分析

刘 鹏1,金诚谦1,2※,宁新杰1,倪有亮2,王廷恩1,印 祥1

(1. 山东理工大学农业工程与食品科学学院,淄博 255000;2. 农业农村部南京农业机械化研究所,南京 210000)

针对现阶段谷物联合收获机清选筛对大豆清选适用性较低以及大豆机收田间性能试验研究较少的现状,以久保田联合收获机PRO688D为试验机具,濉科20大豆为试验品种,以常规鱼鳞筛、加长鱼鳞筛、错位鱼眼筛、线性鱼眼筛和贝壳筛为上筛,网筛、圆孔筛和六棱孔筛为下筛,鱼鳞尾筛和栅格尾筛为尾筛,以清选损失率和含杂率为清选筛对大豆清选作业水平的评价指标,进行了大豆机收清选筛田间性能试验。利用模糊综合评价法对田间性能试验的数据进行了分析与评价,完成鱼鳞筛筛片开度、上筛、下筛、尾筛以及清选筛组合在大豆机收清选适用性方面的优化工作。清选作业水平评价结果表明,大豆机收清选适用性最佳的鱼鳞筛筛片开度是28 mm。进一步对不同尾筛、上筛、下筛和清选筛组合的清选作业水平进行评价,得出不同清选筛对大豆清选适用性情况为:栅格尾筛优于鱼鳞尾筛;贝壳筛和六棱孔筛是大豆机收清选适用性最好的上筛和下筛。大豆机收清选适用性最佳的上筛、下筛和尾筛组合为贝壳筛、六棱孔筛、鱼鳞尾筛,此时大豆机收田间性能试验的清选损失率为2.04%,含杂率为0.53%。试验结果表明,应用模糊综合评价法综合评价不同清选筛对大豆机收的清选损失率和含杂率,并进行清选作业水平的优选,可有效提高谷物联合收获机清选筛对大豆的清选适用性。该研究可为解决谷物联合收获机清选筛对大豆低适用性问题提供实际依据,对降低大豆联合收获机清选损失率和含杂率的田间试验研究起到推进作用,为研发适用于大豆收获的联合收获机清选装置提供参考。

农业机械;试验;收获机;清选筛;清选适用性;模糊综合评价法

0 引 言

清选筛是大豆联合收获机清选装置完成大豆籽粒与杂质分离以及大豆清洁的关键部件之一,是风筛式清选装置实现清选作业的必要结构,因此联合收获机清选筛对大豆的清选作业水平反映了清选筛对大豆作物的清选适用性,反之,提升清选筛对大豆作物的清选适用性对大豆联合收获机清选作业水平的精细化研究起到推进作用[1-4]。现阶段专用于大豆机收的清选筛类型较少,多数在谷物联合收获机清选筛基础上改变参数后直接用于大豆机收作业。因谷物联合收获机清选筛对大豆作物的清选适用性较低,造成大豆机收清选损失率和含杂率均较高,严重制约联合收获机清选装置的清选作业水平和整机作业性能[5-7]。

根据大豆作物的特性参数,优化清选筛的结构组合、创新清选筛形状以及优化清选筛结构参数,能有效提高清选筛对大豆作物的清选适用性[8-10]。科研人员为提高联合收获机清选筛对谷物的清选适用性已做了大量研究工作。王立军等[11-16]对比分析了贝壳筛和编织筛对玉米籽粒的筛分性能,研制了贝壳-圆孔组合孔筛体、双层不平行振动筛、正弦曲线编织筛、贯流风阶梯式贝壳筛和聚氨酯橡胶筛等多种新型清选筛,并对筛体结构参数进行了参数优化分析。程超等[17-18]进行了玉米收获机清选作业参数优化田间试验与最优组合分析,并对清选筛参数与水稻脱粒混合物的界面粘附特性进行了台架试验研究。李耀明等[19-20]设计了三维并联振动筛,对小麦脱粒混合物进行了台架试验与仿真分析,并构建了往复振动式清选筛质量检测系统。

目前,针对大豆机收清选适用性的清选筛优化研究还较少,金诚谦等[21]进行了大豆联合收获机整机作业质量的主要影响参数优化的田间试验,得出大豆联合收获机的最佳作业参数组合。已有研究多集中于小麦、玉米和水稻等作物,且研究的清选筛结构内容也较片面,主要是单一清选筛和清选筛部分结构的优化工作,对清选筛的上筛、下筛与尾筛组合优化研究较少,导致现阶段大豆机收清选损失率和含杂率均较高。本文从提高联合收获机清选筛对大豆的清选适用性出发,以久保田联合收获机机具为研究对象,以大豆机收的清选损失率和含杂率为评价指标,进行大豆机收清选筛田间性能试验。采用模糊综合评价法分析评价试验数据,以期得出大豆机收清选作业水平最佳的鱼鳞筛筛片开度,以及最佳的上筛、下筛和尾筛组合,为研制适用于大豆机收的清选筛提供实际参考。

1 清选筛结构与风筛式清选系统工作原理

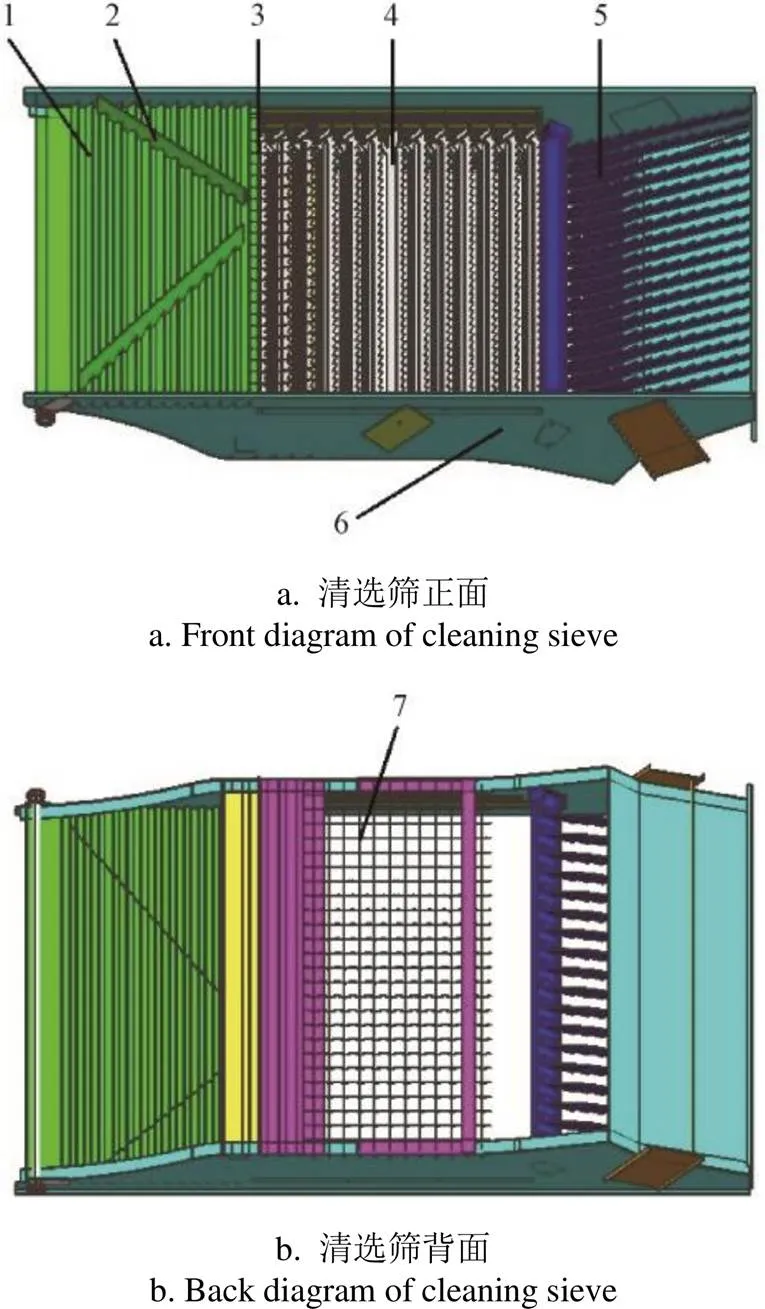

试验选用久保田联合收获机PRO688D原装清选筛,其结构为常见的双层平行式结构,由上层筛、下层筛和筛框组成。上层筛包括抖动板、导流条、指杆筛、上筛和尾筛;下层筛为下筛;筛框连接并固定双层筛,上筛面与筛框上沿平行,结构如图1所示。

1.抖动板 2.导流条 3.指杆筛 4.上筛 5.尾筛 6.筛框 7.下筛

风筛式清选系统作业时,清选筛整体在曲柄连杆机构的带动下进行往复运动,先由抖动板1承接脱粒装置脱粒后形成的大豆脱粒混合物,通过抖动板1和导流条2对脱粒混合物进行均匀分摊,经指杆筛3输送到上筛4,在风机形成的气流场和上筛4往复运动的共同作用下,大豆籽粒透过上筛4经过下筛7落入集粮搅龙进行籽粒输送,细秸草和碎颖壳等轻杂质则被风吹到机器外面,完成大豆脱粒混合物在上筛4和下筛7处的分离清选工作,而接近大豆籽粒物料特性的杂质在风机形成的气流场和清选筛往复运动的双重作用下通过尾筛5完成筛分,长碎秸秆被排出清选室外,未脱净豆荚则透过尾筛5落入复脱搅龙,由复脱搅龙输送到脱粒装置,与新的大豆脱粒混合物一同进行脱粒清选作业[8-9]。

2 试验参数与方法

2.1 大豆特性参数

参照GB/T5262-2008《农业机械试验条件测定方法的一般规定》[22],试验基地大豆品种为濉科20,其特性参数如表1所示。

表1 濉科20大豆特性参数

2.2 试验机具主要作业参数

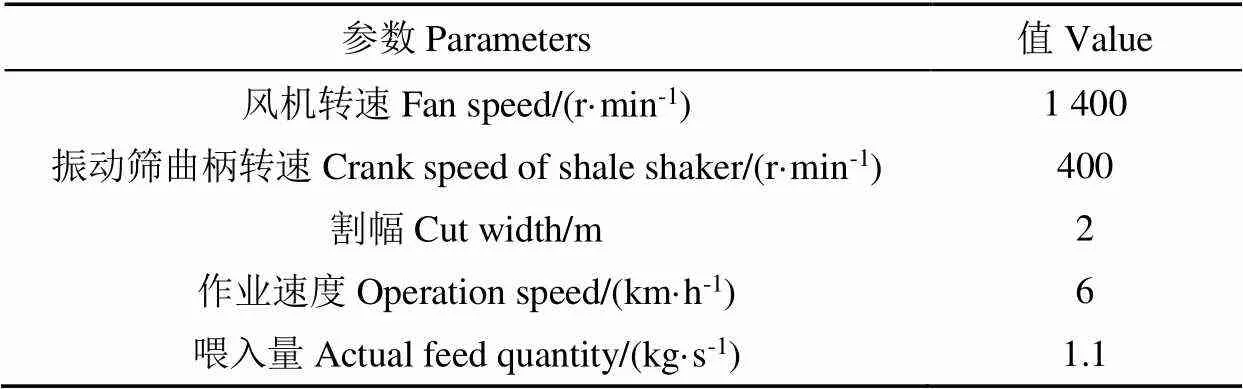

根据前期研究文献[21]和文献[23]确定久保田PRO688D联合收获机主要作业参数如表2所示。

表2 PRO688D机具主要作业参数

2.3 清选筛种类与参数

本次试验选用常见的上筛、下筛和尾筛,鱼鳞筛筛片开度均可调节,且上筛、下筛与尾筛均可更换,满足大豆机收清选筛田间性能试验中清选筛作业参数与部件可调可更换的功能要求。因国内大豆机收清选筛研究内容较少,可参考资料也较少,因此以前期大豆机收田间试验和田间实际收获经验为主要依据,结合已有研究[21-31],确定试验用清选筛种类与参数,如表3所示。

2.4 清选损失率与含杂率计算

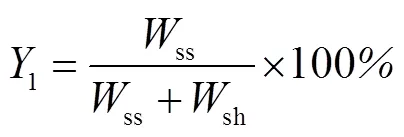

参照行业标准JB/T11912—2014《大豆联合收割机》[32],清选损失率与含杂率分别按式(1)、(2)计算。对每组试验清选损失样本清除杂质后称量籽粒质量,用每组试验大豆清选损失量除以收获面积,求出每组试验的单位面积大豆清选损失量ss。从每组试验含杂样本中随机取出部分样本,将样本中杂质清除后称量得到杂质清除后样本质量zq。

式中1为清选损失率,%;ss为单位面积大豆清选损失量,g/m2;sh为单位面积大豆收获量,g/m2;2为含杂率,%;zz为样本质量,g;zq为杂质清除后样本质量,g。

表3 清选筛种类与参数

3 大豆机收清选筛田间性能试验与分析

3.1 田间试验

本次试验地点是安徽省淮北市濉溪县大豆试验基地,试验时间是2018年10月6日—13日,试验现场如图 2。先完成鱼鳞筛不同筛片开度清选作业水平评价后,再进行尾筛、上筛、下筛和清选筛组合的清选作业水平评价。本次试验目的是研究谷物联合收获机清选筛对大豆作物的清选适用性,因此脱粒装置、割台、输送器、作业速度和清选装置其余部件等作业参数需维持不变。试验进行时,天气状况良好,已尽量排除其他因素的干扰,在大豆适收期内完成大豆机收清选筛田间性能试验,最大程度降低试验误差。

图2 试验现场

3.2 鱼鳞筛不同筛片开度的清选作业水平评价

3.2.1 筛片开度组合设计

为突出田间性能试验的代表性和实用性,选择市面上常见的常规鱼鳞筛为大豆机收鱼鳞筛筛片开度优化试验的上筛,搭配鱼鳞尾筛,由于鱼鳞筛筛片均互相平行,相邻两个平行筛片的垂直间距即为筛片开度(图3),参考相关文献资料和实际田间机收经验[29-31],将筛片开度的3个水平定为26、28和30 mm。用3个筛片开度下的鱼鳞筛上筛分别与网筛、圆孔筛和六棱孔筛的下筛组合,搭配鱼鳞尾筛,设计鱼鳞筛筛片开度与下筛的9种组合(表4)。

图3 筛片开度示意图

3.2.2 试验数据分析与清选作业水平评价

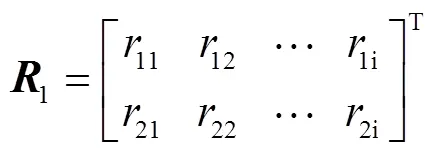

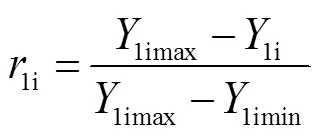

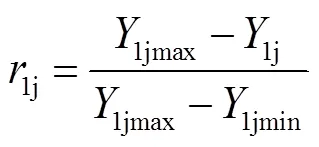

采用模糊综合评价法对试验数据进行分析与评价[33-35],将模糊综合评价值作为鱼鳞筛筛片开度田间试验的清选作业水平。设定清选损失率1和含杂率2为评价指标集,以3种下筛在不同筛片开度的9组试验数据(表4)为评价对象集。因为大豆机收作业要求清选损失率1和含杂率2越小越好[1-4],因此评价指标1和2均为偏小型指标,隶属函数矩阵为

式中1为隶属函数矩阵;1i为清选损失率隶属度;2i为含杂率隶属度;1i为清选损失率;1max为9组试验清选损失率的最大值;1imin为9组试验清选损失率的最小值;2i为含杂率;2imax为9组试验含杂率的最大值;2imin为9组试验含杂率的最小值。

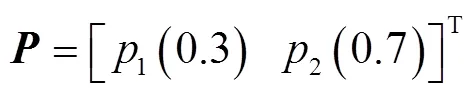

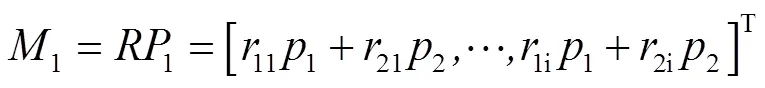

由文献[1]和[33]可知,含杂率为整机三大收获性能指标之一,而清选损失率仅为整机损失率4个分量指标之一,因此在分析试验数据选定清选损失率与含杂率的比重时,设定清选损失率比重约为含杂率的0.5倍。设定评价指标1与2的权重分配集矩阵为,大豆机收鱼鳞筛筛片开度优化试验数据的模糊综合评价值为

式中为评价指标1与2的权重分配集矩阵;1为模糊综合评价值;1为清选损失率比例;2为含杂率比例;1i为清选损失率隶属度;2i为含杂率隶属度。

大豆机收鱼鳞筛筛片开度优化试验的清选损失率1、含杂率2、评价指标隶属度与模糊综合评价值如表4所示。评价指标1和2均为偏小型指标,因此模糊综合评价值越大,得出清选作业水平更高,表示大豆机收清选适用性越好,以此作为清选作业水平的评价方法[33-35]。

表4 3种下筛在不同筛片开度的模糊综合评价分析

根据表4,筛片开度26、28、30 mm分别对应的3种下筛模糊综合评价值的平均值分别为0.533、0.578和0.407。按清选作业水平评价方法,筛片开度28 mm对应模糊综合评价值平均值最大,因此大豆机收清选作业水平最佳的鱼鳞筛筛片开度为28 mm。

3.3 不同尾筛、上筛、下筛和清选筛组合的清选作业水平评价

3.3.1 清选筛组合设计

选取表4中最佳鱼鳞筛筛片开度为28 mm时,常规鱼鳞筛搭配栅格尾筛,在3种不同下筛条件下的3种清选筛组合。用加长鱼鳞筛和常规鱼鳞筛分别搭配栅格尾筛,用线性鱼眼筛、错位鱼眼筛和贝壳筛分别搭配鱼鳞尾筛,在3种不同下筛条件下,设计12种清选筛组合。汇总18种清选筛组合及试验数据,如表5所示。

3.3.2 试验数据分析

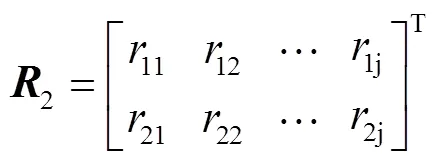

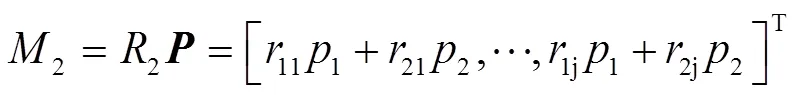

用模糊综合评价法处理试验数据,设定清选损失率1和含杂率2作为评价指标集,表5中18组试验数据为评价对象集,评价指标1和2均为偏小型指标。

表5 清选筛组合数据模糊综合评价分析

式中2为隶属函数矩阵;1j为清选损失率隶属度;2j为含杂率隶属度。

设定清选损失率比例约为含杂率的0.5倍,确定评价指标1与2的权重分配集矩阵同式(6),计算模糊综合评价值为

式中2为模糊综合评价值;1j为清选损失率隶属度;2j为含杂率隶属度。

不同尾筛、上筛、下筛和清选筛组合的清选损失率1、含杂率2、评价指标隶属度与模糊综合评价值如表5所示。

3.3.3 尾筛、上筛、下筛和清选筛组合的分析评价

根据表5评价数据,对不同尾筛、上筛、下筛和清选筛组合的大豆机收清选筛田间性能试验的清选作业水平进行分析评价。相同上筛和下筛时,分析不同尾筛的大豆机收清选作业水平;相同下筛与尾筛时,分析不同上筛的大豆机收清选作业水平;相同上筛与尾筛时,分析不同下筛的大豆机收清选作业水平;最后,对18种清选筛组合的大豆机收清选作业水平进行综合分析与评价。

1)鱼鳞尾筛与栅格尾筛分析评价

根据表5中序号1~3、7~9的评价数据可知,此6组试验上筛均为常规鱼鳞筛且筛片开度均为28 mm,1~3组为鱼鳞尾筛,7~9组为栅格尾筛,鱼鳞尾筛和栅格尾筛分别对应3种不同下筛的模糊综合评价值平均值分别为0.483和0.758,栅格尾筛对应模糊综合评价值平均值大于鱼鳞尾筛。按清选作业水平评价方法,得到大豆机收清选作业水平较高的尾筛是栅格尾筛,即栅格尾筛对大豆的清选适用性优于鱼鳞尾筛。

2)上筛优化分析与评价

① 鱼鳞筛分析评价

根据表5中序号4~9的评价数据可知,此6组试验尾筛均为栅格尾筛,4~6组上筛为加长鱼鳞筛,7~9组上筛为常规鱼鳞筛,筛片开度均为28 mm,计算加长鱼鳞筛和常规鱼鳞筛分别对应3种不同下筛的模糊综合评价值平均值为0.617和0.758,常规鱼鳞筛对应模糊综合评价值平均值大于加长鱼鳞筛。按清选作业水平评价方法,得到大豆机收清选作业水平较高的鱼鳞筛是常规鱼鳞筛,即常规鱼鳞筛对大豆的清选适用性优于加长鱼鳞筛。

② 线性鱼眼筛与错位鱼眼筛分析评价

根据表5序号10~15的评价数据可知,此6组试验尾筛均为鱼鳞尾筛,10~12组上筛为线性鱼眼筛,13~15组上筛为错位鱼眼筛,线性鱼眼筛和错位鱼眼筛分别对应3种不同下筛的模糊综合评价值平均值分别为0.662和0.727,错位鱼眼筛对应模糊综合评价值平均值大于线性鱼眼筛。按清选作业水平评价方法,得到大豆机收清选作业水平较高的鱼眼筛是错位鱼眼筛,即错位鱼眼筛对大豆的清选适用性优于线性鱼眼筛。

③ 3种上筛分析评价

根据表5中序号1~3、13~18的评价数据可知,此6组试验尾筛均为鱼鳞尾筛,1~3组上筛为常规鱼鳞筛,13~15组上筛为错位鱼眼筛,16~18组上筛为贝壳筛,常规鱼鳞筛、错位鱼眼筛和贝壳筛分别对应3种不同下筛的模糊综合评价值平均值分别为0.483、0.727和0.843,贝壳筛对应的模糊综合评价值平均值最大。按清选作业水平评价方法,得到大豆机收清选作业水平最高的上筛是贝壳筛,即贝壳筛对大豆的清选适用性优于常规鱼鳞筛和错位鱼眼筛。

3)下筛优化分析与评价

根据表5中筛型组合可知,3种不同的下筛为网筛、圆孔筛与六棱孔筛,分别对应相同的6组上筛与尾筛组合,分别是常规鱼鳞筛与鱼鳞尾筛组合、加长鱼鳞筛与栅格尾筛组合、常规鱼鳞筛与栅格尾筛组合、线性鱼眼筛与鱼鳞尾筛组合、错位鱼眼筛与鱼鳞尾筛组合以及贝壳筛与鱼鳞尾筛组合。网筛、圆孔筛与六棱孔筛分别对应6组上筛与尾筛组合的模糊综合评价值平均值分别为0.610、0.702和0.734,六棱孔筛对应模糊综合评价值平均值最大。按清选作业水平评价方法,得到大豆机收清选作业水平最高的下筛是六棱孔筛,即六棱孔筛对大豆的清选适用性优于网筛和圆孔筛。

综合1)、2)和3)中的分析与评价情况,得出不同清选筛对大豆清选适用性最佳的尾筛、上筛和下筛分别为栅格尾筛、贝壳筛和六棱孔筛。

4)清选筛组合优化数据的对比分析

通过对比表5中的18组试验数据的模糊综合评价值的大小,可知序号为18的清选筛组合的模糊综合评价值最大,按清选作业水平评价方法,该清选筛组合的大豆清选作业水平最高,即序号为18的清选筛组合对大豆的清选适用性优于其余组合。根据表5中序号为18的筛型组合,得出大豆机收清选适用性最佳的清选筛组合为上筛是贝壳筛,下筛是六棱孔筛,尾筛是鱼鳞尾筛,此时的大豆机收清选损失率为2.04%,含杂率为0.53%。

4 结 论

本文采用模糊综合评价法对大豆机收清选筛田间性能试验的清选损失率和含杂率进行了分析与评价,最后得出试验结论。

1)鱼鳞筛不同筛片开度的清选作业水平评价表明,鱼鳞筛筛片开度为28 mm时,鱼鳞筛对大豆的清选作业水平最高,即筛片开度为28 mm时鱼鳞筛对大豆的清选适用性最好。

2)通过评价不同尾筛、上筛、下筛和清选筛组合的清选作业水平,得出不同清选筛对大豆的清选适用性情况为:栅格尾筛优于鱼鳞尾筛;常规鱼鳞筛优于加长鱼鳞筛;错位鱼眼筛优于线性鱼眼筛;贝壳筛和六棱孔筛是大豆机收清选适用性最好的上筛和下筛;大豆机收清选适用性最佳的清选筛组合为上筛是贝壳筛,下筛是六棱孔筛,尾筛是鱼鳞尾筛,此时大豆机收田间性能试验的清选损失率为2.04%,含杂率为0.53%,提高了谷物联合收获机清选筛对大豆的清选适用性。试验结果可为研发适用于大豆机收的联合收获机清选筛提供实际经验。

[1] 刘基,金诚谦,梁苏宁,等. 大豆机械收获损失的研究现状[J]. 农机化研究,2017,39(7):1-9,15. Liu Ji, Jin Chengqian, Liang Suning, et al. Research status of soybean mechanical harvest loss[J]. Journal of Agricultural Mechanization Research, 2017, 39(7): 1-9,15. (in Chinese with English abstract)

[2] 宫云涛. 大豆收获机发展研究[J]. 农业科技与装备,2013(2):61-62. Gong Yuntao. Research on soybean harvester development[J]. Agricultural Science & Technology and Equipment, 2013(2): 61-62. (in Chinese with English abstract)

[3] 陈伟,张美艺,韩嫣,等. 大豆机械收获环节损失调查:以黑龙江、内蒙古为例[J]. 中国农业文摘-农业工程,2017,29(3):16-20. Chen Wei, Zhang Meiyi, Han Yan, et al. Investigation on loss of soybean machinery harvesting links - Taking Heilongjiang and Inner Mongolia as examples[J]. Agricultural Science and Engineering in China, 2017, 29(3): 16-20. (in Chinese with English abstract)

[4] 刘英,李铭. 大豆机械化收获技术要点[J]. 山东农机化,2019(4):35.

[5] 梁苏宁,沐森林,金诚谦,等. 黄淮海地区大豆生产机械化现状与发展趋势[J]. 农机化研究,2015,37(1):261-264,268. Liang Suning, Mu Senlin, Jin Chengqian, et al. Current situation and development trend of soybean production mechanization in Huang Huai Hai area[J]. Journal of Agricultural Mechanization Research, 2015, 37(1): 261-264,268. (in Chinese with English abstract)

[6] 刘立晶,尹素珍. 黄淮海地区夏大豆生产机械化现状及发展趋势[J]. 现代农业研究,2016(1):16-19. Liu Lijing, Yin Suzhen. Current situation and development trend of mechanization of summer soybean production in Huang Huai Hai area[J]. Modern Agriculture Research, 2016(1): 16-19. (in Chinese with English abstract)

[7] 陈海霞. 大豆联合收获机械的研究[J]. 农村牧区机械化,2009(2):4-5.

[8] 刘鹏,金诚谦,印祥,等. 大豆联合收获机清选装置与关键技术研究进展[J]. 浙江农业学报,2019,31(10):1758- 1766. Liu Peng, Jin Chengqian, Yin Xiang, et al. Research progress on cleaning device and key technology of soybean combine harvester[J]. Acta Agriculturae Zhejiangensis, 2019, 31(10): 1758-1766. (in Chinese with English abstract)

[9] 徐立章,李洋,李耀明,等. 谷物联合收获机清选技术与装置研究进展[J]. 农业机械学报,2019,50(10):1-16. Xu Lizhang, Li Yang, Li Yaoming, et al. Research progress on cleaning technology and equipment of grain combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(10): 1-16. (in Chinese with English abstract)

[10] 乔金友,张晓丹,王奕娇,等. 规模化大豆产区大豆联合收获机综合评价与优选[J]. 东北农业大学学报,2014,45(8):124-128. Qiao Jinyou, Zhang Xiaodan, Wang Yijiao, et al. Comprehensive evaluation and optimization of soybean combine harvester in large-scale soybean production area[J]. Journal of Northeast Agricultural University, 2014, 45(8): 124-128. (in Chinese with English abstract)

[11] 王立军,冯鑫,郑招辉,等. 玉米清选组合孔筛体设计与试验[J]. 农业机械学报,2019,50(5):104-113. Wang Lijun, Feng Xin, Zheng Zhaohui, et al. Design and test of corn cleaning combined sieve[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(5): 104-113. (in Chinese with English abstract)

[12] 王立军,李瑞,于泳涛,等. 玉米籽粒收获机双层不平行振动筛设计与试验[J]. 农业机械学报,2019,50(7):130-139. Wang Lijun, Li Rui, Yu Yongtao, et al. Design and test of double layer non parallel vibrating screen for corn harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(7): 130-139. (in Chinese with English abstract)

[13] 王立军,武振超,冯鑫,等. 玉米收获机清选曲面筛设计与试验[J]. 农业机械学报,2019,50(2):90-101. Wang Lijun, Wu Zhenchao, Feng Xin, et al. Design and test of cleaning curved screen of corn harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(2): 90-101. (in Chinese with English abstract)

[14] 王立军,冯鑫,武振超,等. 玉米联合收获机贯流风阶梯式振动筛设计与试验[J]. 农业机械学报,2018,49(10):115-123. Wang Lijun, Feng Xin, Wu Zhenchao, et al. Design and test of cross flow stepped vibrating screen for corn combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(10): 115-123. (in Chinese with English abstract)

[15] 王立军,彭博,宋慧强. 玉米收获机聚氨酯橡胶筛筛分性能仿真与试验[J]. 农业机械学报,2018,49(7):90-96. Wang Lijun, Peng Bo, Song Huiqiang. Simulation and test of screening performance of polyurethane rubber screen for corn harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(7): 90-96. (in Chinese with English abstract)

[16] 王立军,张传根,丁振军. 玉米收获机清选筛体结构优化[J]. 农业机械学报,2016,47(9):108-114. Wang Lijun, Zhang Chuangen, Ding Zhenjun. Structure optimization of corn harvester cleaning screen[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(9): 108-114. (in Chinese with English abstract)

[17] 程超,付君,陈志,等. 玉米籽粒收获机清选装置参数优化试验[J]. 农业机械学报,2019,50(7):151-158. Cheng Chao, Fu Jun, Chen Zhi, et al. Parameter optimization test of cleaning device of corn grain harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2019, 50(7): 151-158. (in Chinese with English abstract)

[18] 程超,付君,陈志,等. 收获机振动筛振动参数影响不同湿度脱出物粘附特性[J]. 农业工程学报,2019,35(8):29-36. Cheng Chao, Fu Jun, Chen Zhi, et al. Effect of vibration parameters of vibrating screen of harvester on adhesion characteristics of different humidity effluents[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(8): 29-36. (in Chinese with English abstract)

[19] 李耀明,刘晓飞,马征,等. 不同支链初始相位的三维并联筛分性能研究[J]. 农业机械学报,2017,48(9):88-95. Li Yaoming, Liu Xiaofei, Ma Zheng, et al. Three dimensional parallel screening performance of different initial phases of branch chains[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(9): 88-95. (in Chinese with English abstract)

[20] 李耀明,庞靖,徐立章,等. 基于振动激励溯源的谷物联合收获机清选筛制造缺陷定位[J]. 农业工程学报,2019,35(5):10-17. Li Yaoming, Pang Jing, Xu Lizhang, et al. Defect location of cleaning screen manufacturing of grain combine harvester based on vibration excitation traceability[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(5): 10-17. (in Chinese with English abstract)

[21] 金诚谦,郭飞扬,徐金山,等. 大豆联合收获机作业参数优化[J]. 农业工程学报,2019,35(13):10-22. Jin Chengqian, Guo Feiyang, Xu Jinshan, et al. Operational parameters optimization of soybean combine harvester[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(13): 10-22. (in Chinese with English abstract)

[22] 郝文录,刘恒新,朱良,等. GB/T 5262-2008,农业机械试验条件测定方法的一般规定[S]. 北京:中国标准出版社.

[23] 金诚谦. 大豆收获机脱粒分离装置参数优化与试验[C]. 第十届全国大豆学术讨论会论文摘要集. 中国作物学会大豆专业委员会:中国作物学会,2017

[24] 樊晨龙,崔涛,张东兴,等. 纵轴流联合收获机双层异向清选装置设计与试验[J]. 农业机械学报,2018,49(S 1):239-248. Fan Chenlong, Cui Tao, Zhang Dongxing, et al. Design and test of double-deck heterotropic cleaning device for longitudinal-axial flow combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(Suppl.1): 239-248. (in Chinese with English abstract)

[25] 刘晓飞,李耀明,马征,等. 三自由度风筛清选试验研究[J]. 农机化研究,2018,40(6):139-144. Liu Xiaofei, Li Yaoming, Ma Zheng, et al. Three-degree-of-freedom air screening cleaning test[J]. Journal of Agricultural Mechanization Research, 2018, 40(6): 139-144. (in Chinese with English abstract)

[26] 李菊. 用于谷物清选的三维并联振动筛的研究[D]. 镇江:江苏大学,2013. Li Ju. Research on Three-dimensional Parallel Vibrating Screen For Grain Cleaning[D]. Zhenjiang: Jiangsu University, 2013. (in Chinese with English abstract)

[27] 司增永,李耀明,唐忠,等. 横置多滚筒联合收获机清选装置参数优化与试验[J]. 农机化研究,2018,40(7):185-189,205. Si Zengyong, Li Yaoming, Tang Zhong, et al. Parameter optimization and test of cleaning device of transverse multi-drum combine harvester[J]. Journal of Agricultural Mechanization Research, 2018, 40(7): 185-189, 205. (in Chinese with English abstract)

[28] 陈霓,刘正怀,夏劲松,等. 基于Petri网模型的收获机轴流式脱分选装置参数化设计[J]. 农业机械学报,2017,48(11):123-129. Chen Ni, Liu Zhenghuai, Xia Jinsong, et al. Parametric design of axial flow separator for harvester based on Petri net model[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(11): 123-129. (in Chinese with English abstract)

[29] 梁振伟,李耀明,马培培,等. 纵轴流联合收获机清选装置结构优化与试验[J]. 农机化研究,2018,40(5):170-174. Liang Zhenwei, Li Yaoming, Ma Peipei, et al. Structural optimization and test of cleaning device of longitudinal-axial flow combine harvester[J]. Journal of Agricultural Mechanization Research, 2018, 40(5): 170-174. (in Chinese with English abstract)

[30] 余波. 基于EDEM的小区收割机振动筛筛分性能研究与优化[D]. 成都:西华大学,2016. Yu Bo. Research and optimization of Vibration Screening Performance of District Harvester Based on EDEM[D]. Chengdu: Xihua University, 2016. (in Chinese with English abstract)

[31] 钟龙旺. 怎样用小麦联合收割机收获大豆[J]. 北京农业,2012(22):39-40. Zhong Longwang. How to harvest soybeans with wheat combine[J]. Beijing Agriculture, 2012(22): 39-40. (in Chinese with English abstract)

[32] 栗慧卿,王永建,柏玉霞,等. JB/T 11912-2014,大豆联合收割机[S]. 北京:中国标准出版社.

[33] 钟挺,胡志超,顾峰玮,等. 4LZ-1. 0Q型稻麦联合收获机脱粒清选部件试验与优化[J]. 农业机械学报,2012,43(10):76-81. Zhong Ting, Hu Zhichao, Gu Fengwei, et al. Experiment and optimization of threshing and cleaning components of 4LZ-1. 0Q rice-wheat combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(10): 76-81. (in Chinese with English abstract)

[34] 吴崇友,丁为民,张敏,等. 油菜分段收获脱粒清选试验[J]. 农业机械学报,2010,41(8):72-76. Wu Chongyou, Ding Weimin, Zhang Min, et al. Rapeseed threshing test by stages harvesting[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(8): 72-76. (in Chinese with English abstract)

[35] 杜金萍. 模糊正交法在GCr15钢切削用量优化中的应用[J]. 轴承,2007(3):26-28. Du Jinping. Application of fuzzy orthogonal method in optimizing cutting parameters of GCr15 steel[J]. Bearing, 2007(3): 26-28. (in Chinese with English abstract)

Field performance test and analysis of the cleaning sieve of soybean harvesters

Liu Peng1, Jin Chengqian1,2※, Ning Xinjie1, Ni Youliang2, Wang Ting’en1, Yin Xiang1

(1.,,255000,; 2.,,210000,)

In view of the current situation that the cleaning sieve of the grain combine harvester is less applicable to soybean cleaning and the field performance test of soybean mechanical harvest is less, field performance tests of cleaning sieve of soybean harvest were conducted. We selected PRO688D as the field performance test machine and suike 20 as the soybean test variety. According to the preliminary experiments, researches of soybean combine harvester, the types and parameters of cleaning sieve which included upper, lower and tail sieve were determined. Selected conventional fish scale sieve, lengthened fish scale sieve, misplaced fish eye sieve, linear fish eye sieve and shell sieve as upper sieve, mesh sieve, round hole sieve and hexagonal hole sieve as lower sieve, and fish scale tail sieve and grid tail sieve as tail sieve. The vertical distance between two adjacent parallel sieves in the fish scale sieve is taken as the sieve plate opening of the fish scale sieve, and they were set as 26 mm, 28 mm and 30 mm. The cleaning loss rate and impurity rate during the field operation of the soybean combine harvester were used as the evaluation indexes of the soybean cleaning operation. Then, the field performance tests of cleaning soybean were carried out, and the data of the field performance test were analyzed and evaluated with the fuzzy comprehensive evaluation method. The optimization of the combination of sieve plate opening of fish scale sieves, upper sieves, lower sieves, tail sieves and cleaning sieves in the applicability of soybean harvesting was completed. The evaluation of cleaning operation level of different sieve plate opening of fish scale sieve showed that the cleaning operation level of fish scale sieve to soybean was the highest when sieve plate opening was 28mm. That is to say, when sieve plate opening was 28mm, the cleaning applicability of fish scale sieve to soybean was the best. The evaluations of the cleaning operation level of different tail sieve, upper sieve, lower sieve and combinations of cleaning sieve were conducted, the results of the cleaning applicability of different cleaning sieve to soybean were as follows: grid tail sieve was better than fish scale tail sieve; shell sieve and hexagonal hole sieve were the upper sieve and lower sieve with the best applicability for soybean machine cleaning. The highest level of cleaning sieves combination was that upper, lower and tail sieve were shell sieve, hexagonal hole sieve and fish scale tail sieve respectively. Cleaning sieve combination has the best cleaning applicability to soybean under the combination of shell sieve, hexagonal hole sieve and fish scale tail sieve. At this time, the cleaning loss rate of field performance test was 2.04%, and the impact rate was 0.53%. The results showed that the application of fuzzy comprehensive evaluation method to comprehensive evaluation of cleaning loss rate and impurity rate of different cleaning sieves and optimization of cleaning operation level could effectively improve the cleaning applicability of grain combine harvester to soybean. This study can provide the practical basis for solving the problem of low applicability of cleaning sieve to soybean, promote the field test and research on reducing cleaning loss rate and impurity rate of soybean combine harvester, and supply references for the research and development of cleaning device for soybean combine harvester.

agricultural machinery; test; harvesters; cleaning screen; cleaning applicability; fuzzy comprehensive evaluation method

刘鹏,金诚谦,宁新杰,等. 大豆机收清选筛田间性能试验与分析[J]. 农业工程学报,2020,36(9):36-43.doi:10.11975/j.issn.1002-6819.2020.09.004 http://www.tcsae.org

Liu Peng, Jin Chengqian, Ning Xinjie, et al. Field performance test and analysis of the cleaning sieve of soybean harvesters[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(9): 36-43. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2020.09.004 http://www.tcsae.org

2019-11-25

2020-05-05

现代农业产业技术体系建设专项资金项目(CARS-04-PS26);山东省农机装备研发创新计划项目(2018YF006);山东省高等学校优势学科人才团队培育计划项目(2016—2020);中央引导地方科技发展专项基金项目;山东省科技创新基地专项(SDKL2019014)

刘鹏,博士生,主要从事机械化旱作农业技术体系及装备研究。Email:820016001@qq.com

金诚谦,教授,研究员,主要从事大田作物收获机械化与智能化技术研究。Email:412114402@qq.com

10.11975/j.issn.1002-6819.2020.09.004

S225.6

A

1002-6819(2020)-09-0036-08