Three-dimensional numerical analysis on combustion performance and flow of hybrid rocket motor with multi-segmented grain

Hui TIAN, Yu DUAN, Hao ZHU,*

a School of Astronautics, Beihang University, Beijing 100083, China

b Key Laboratory of Spacecraft Design Optimization & Dynamic Simulation Technologies, Ministry of Education,Beihang University, Beijing 100083, China

KEYWORDS Combustion efficiency;Hybrid rocket motor;Multi-segmented grain;Regression rate;Rotation angle

Abstract This paper presents the combustion characteristics in hybrid rocket motors with multisegmented grain through three-dimensional numerical simulations. Multi-segmented grain is composed of several thin grains with two or more ports.The numerical model consists of Navier-Stokes equations with turbulence,solid fuel pyrolysis,chemical reactions,a fluid-solid coupling model and a regression rate model. The simulations adopt 90% Hydrogen Peroxide (HP) and PolyEthylene(PE) as the propellant combination. The effects of the rotation, port number, fuel grain segment number and mid-chamber length on the flow field and combustion performances are analyzed.The results indicate that the multi-segmented grain configuration can strengthen the flow field,and the regression rate and combustion efficiency are enhanced.Take the cases with two grain segments and three ports for example,the regression rate is increased by 32.4%-45.1%and the combustion efficiency increases by 6%-8.6% in different rotation angles.

1. Introduction

Hybrid Rocket Motors(HRMs)usually use solid propellant as the fuel and liquid propellant as the oxidizer.It has advantages such as safety, low cost, non-pollution and multiple restart capabilities.1-6Owing to this,HRMs are attractive propulsion systems suitable for a wide range of applications including sounding rockets, launch vehicles, spacecraft propulsion systems,7-9etc. However, due to the characteristic of nonpremixed diffusion combustion, HRMs have two obvious drawbacks: the inherent low regression rate and combustion efficiency.

Many researches have been conducted to solve these two problems. Cardoso10and Wu11et al. investigated the performances of HRMs using paraffin-based solid fuels, and the results show that the fuels can improve the regression rate.Ahn et al.12designed a multiport grain used in a hydrogen peroxide hybrid rocket motor,and the experimental result showed that the application of the simple cylindrical multiport design reduces the length-to-diameter ratio of the hybrid thruster and improves rocket combustion performance. Saito et al.13developed an axial-injection end-burning type fuel grains by high-accuracy three-dimensional printing, and results of 15 static firings tests show that fuel regression rate increases as the chamber pressure rises, and fuel regression rate decreases as the oxidizer port velocity increases. Nagata et al.14developed CAMUI (Cascaded Multistage Impinging-jet) type hybrid rockets in which the gas flow repeatedly collides with the solid fuel surface to accelerate the heat transfer to the fuel.Regression formulas for CAMUI type hybrid rockets as functions of local oxidizer to fuel ratio were also developed.15Kim et al.16found that the increase of port number positively shifts the oxidizer-to-fuel ratio to near its optimum value and the increase of regression rate is damped beyond three ports.Tian et al.5conducted numerical and experimental studies of the hybrid rocket motor with multi-port fuel grain. The results showed that the distribution of the fuel regression rate has a relationship with the flame location and fuel port profile.

Many of these studies show that the combustion performance can be improved by means of segmented grain configuration. Therefore, a former work17has been conducted to investigated the effect of segmented grain configuration on the combustion performances of HRMs. The numerical and experimental studies of HRMs with two segmented grains, in which the fore and after sections of the grains have different lengths,are performed and the results show that the segmented grain can obviously improve the combustion efficiency and regression rate. The numerical simulation method is also verified by comparing the results with the test ones. Based on the former work which only considering two segmented grains and the effect of their lengths, this paper is a further study to numerically investigate the flow field characteristics, local regression rate distribution and combustion performance of multi-segmented grains. Moreover, the effects of segmented grain number and rotation between them, port numbers of the segmented grains, and mid-chamber length on the performances are comprehensively analyzed based on the numerical simulation results. Steady flow field features and temperature distributions are studied to identify the mechanism of the grain configuration in improving the regression rate and combustion efficiency.

2. Numerical simulation method

The propellant combination used in this paper are 90%Hydrogen Peroxide(HP)and PolyEthylene(PE).The working process in a HRM is a combination of complex physical and chemical reactions including turbulence, oxidizer injection,atomization, fuel pyrolysis, gasification and burning.4HP is considered to be completely decomposed to simplify the working process. Radiation is neglected because there are no metal energetic particles contained in the fuel.

The numerical model consists of governing equations, a turbulence model, a chemical reaction model, a coupled gas/-solid phase model and a regression rate model. The main simulation process is solved by the ANSYS Fluent solver, while the coupled gas/solid phase model and the regression rate model are calculated by User-Defined Functions (UDFs).

The energy balance equation is as follows4:

where λgis the coefficient of thermal conductivity of gas,(∂T/∂x) represents the temperature gradient, subscript ‘‘g”means gas phase, ρfis the fuel density, ˙r is the regression rate,H represents enthalpy, Tsis the temperature of the solid fuel grain surface and T0is the initial temperature of the solid fuel grain surface.

The pyrolysis performance of PE is affected by the temperature of the fuel grain. The regression rate of PE can be described by the Arrhenius equation

where A is the pre-exponential factor, Eais the activation energy, and R is molar gas constant. The value of A is 2678.1 m/s and the value of Eais 125604.0 J/mol.

Eqs. (1) and (2) are coupled to calculate the fuel surface temperature Tsand the fuel regression rate ˙r in the iterations.After this, the source terms of mass, momentum, energy and species are generated and then added to the fluid zone by UDFs.

To validate the numerical model, the experimental regression rate obtained by Tian et al.17is compared with the simulation data. The experiment adopts 90% HP and PE as propellants. The oxidizer mass fluxof the three experiments is 114.4, 128.4 and 140.7 kg/(m2·s) respectively. In Fig. 1, the experimental data represents the regression rate in the experiment. The curve of the simulation data obtained by the numerical model agrees well with the experimental data.It is demonstrated that the numerical model in this paper is reasonable and feasible to predict the performance of the HRM.

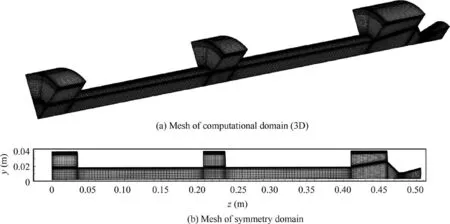

Fig.2 shows the structured hexahedral meshes of the motor with two segments and one port. The whole model contains about 307 thousand cells and 328 thousand nodes.

To validate sensitivity of the mesh above, the height of the first layer near the fuel surfaces and walls is refined to 0.005 mm. The whole model contains about 720 thousand cells. The gas temperature along the axis (z direction) of the motor in the high-density and low-density grid model is compared in Fig. 3.

Fig. 1 Comparison of simulation data and experimental data.

Fig. 2 Mesh of computational domain with two segments and one port.

Fig. 3 Gas temperature of high-density and low-density grid model.

As can be seen from Fig.3,the temperature distribution of the two meshes are almost the same.This shows that the mesh density of the original model and the height of the first layer can accurately describe the performance and characteristics of the engine.

3. Structure and geometry model of HRM

The motor with multi-segmented grain used in this paper consists of a catalyst bed, a pre-chamber, multi-segmented grains and the mid-chambers between them, a post-chamber and a nozzle.The detailed structure is illustrated in Fig.4.The catalyst bed is set to ignite and decompose HP into gaseous oxygen(O2) and water vapor (H2O) to continuously supply oxidizers.The fuel grain consists of two or more segments(number is Ng)with multi ports. Mid-chambers are set between fuel segments to fix grain positions and enhance the mixing of the propellants. Fig. 5 defines the rotation angle θ of the grains.

The main parameters of the motor are shown in Table 1.The total length of the chamber Lpis sum of all of the grain length Lgand the mid-chamber length Lm. It is set as 375 mm for all the simulation cases. The port diameter of the segmented grain Dpvaries with the port number Npto keep the total cross-sectional area of grain ports Agunchanged.

The meshes are generated by ANSYS ICEM CFD. To accurately simulate the fluid in the low Reynolds number region adjacent to the fuel wall, the enhanced wall treatment is adopted and the height of the first layer near the fuel surfaces and walls is refined to 0.02 mm to make sure that y+is about one.

Fig. 4 Schematic diagram of lab-scale motor.

Fig. 5 Rotation angle θ of grains.

Table 1 Main parameters of lab-scale motor.

Fig.6 shows the structured hexahedral meshes of the motor with four segments and three ports.Several parts of the meshes are combined by interfaces. The whole model contains 423713 cells and 459187 nodes.

The oxidizer inlet is set as a mass flow rate inlet and the mass flow rate ranges from 50 to 200 g/s in different working conditions. The mass fraction of O2and H2O are 0.42353 and 0.57647 respectively.The inlet temperature of the oxidizers is 1028 K and the initial pressure is 2.5 MPa.

The initial temperature of the fuel is 298.16 K. The boundary condition of the fuel surface is defined as an interface where the regression rate and the temperature are determined by the fluid-solid coupling model and the Arrhenius equation.The mass, momentum, energy and species source terms are added into the fluid zone by UDFs. The boundary conditions of other solid surfaces are defined as non-slip, adiabatic and non-pressure gradient.

The nozzle outlet is defined as pressure outlet,the equations of which can be extrapolated from the inner domain because of the supersonic condition.

The convergence criterion are as follows. The difference between the inlet mass flow rate and the outlet mass flow rate is less than 10-6kg/s.The residuals are smaller than 10-3.The variation of the results between iterations is less than 0.1%.

4. Simulation results and discussion

Many cases are calculated in this paper.The results and discussion focus on the following effects on the performance: rotation angle, port number, fuel grain segment number and the mid-chamber length.

4.1. Effect of rotation angle

The combustion flow field, temperature, chamber pressure,regression rate and combustion efficiency of HRMs with two-segmented grains which have three ports are simulated.The effects of the rotation angles of the two grains, ranging from 0°to 60°,are investigated.Table 2 describes the details of the cases.

Fig. 6 Computational meshes of motor with four segments and three ports.

Observing the directions of the gas flow in Fig.7(a),streamlines in the inner port area are not influenced by the structure,instead, the gas flows directly forwards through the midchamber.Streamlines in Figs.7(b) and(c) clearly show vortex zones in the mid-chamber where the collision between the fluid flow and the fuel surface occurs. The gas movement direction is not parallel to the axis due to the rotation of the second grain. The barricade of the front-end face of the second grain can enhance the disturbing effect and benefit the mixture of propellant species. Besides, the residence time of the gas flow and the combustion efficiency are enhanced.

The temperature distributions of the fluid field of the Cases A1, A3 and A5 are illustrated in Figs. 8(a)-(c) respectively.The temperature of the combustion chamber increases along the axis and peaks in the post-chamber. The area-weighted average temperature of the cross-sectional area in front of the nozzle inlet is 1821.34, 1978.44 and 1961.44 K respectively in these three cases. Comparing these cases, the temperature distributions of the first grain are similar while the distributions of the second grain are different. The temperature distributions of the middle cross-sections of the second grain(360 mm apart from the chamber inlet) are shown in Fig. 9.It is clearly seen that the temperature of the Cases A3 and A5 are much higher than that of Case A1. The rotation ofthe second grain produces a barricade to the axial flow of gas, causing the reaction proceed to completion. The gas temperature has increased and the high temperature flame zone gets closer to the fuel surface wall.

Table 2 Parameters of two-segmented cases with different rotation angles.

Fig. 7 Streamlines of Cases A1, A3 and A5.

Fig. 8 Temperature distributions of fluid field of Cases A1, A3 and A5.

The regression rate distributions of Cases A1 to A5 are illustrated in Fig.10.It can be seen that the regression rate distributions of the first grain are almost not related to the rotation angle. With the axial location increasing, the fuel regression rates decrease rapidly first and then increase smoothly. The regression rate of the second grain is higher compared to that of the first grain.The rotation of the second grain can significantly increase the regression rate, which reaches maximum when the rotation angle is 30°.The increase of the regression rate can be explained by the fact that the barricade of the second grain leads to radial and tangential movement of the gas. The eddy generated by the structure can enhance the fluid flow in the mid-chamber and the downstream area, boosting the heat feedback transferred to the grain surface. As a result, the pyrolysis rate and the reaction rate are accelerated.

The combustion efficiency ηC*can be obtained by the characteristic velocity C* calculated from the simulation and the theoretical characteristic velocityacquired by thermochemical calculation.The combustion performances of Cases A1 to A5 is shown in Table 3,where Pcis chamber pressure, ˙m is outlet mass flow, and O/F ratio means the mass ratio of oxidizer and fuel. The ηC*of Case A1 is 91.36% while the ηC*of other cases can increase by up to 8%.The improvement of combustion efficiency is mainly attributed to the disturbing effect of the fore-end face of the second grain on the incoming gas flow.As shown in Table 3,when the average temperature at the inlet section of the nozzle Tavergets higher, the combustion efficiency is improved.

Fig. 9 Temperature distributions of middle cross-sections of second grain.

Fig. 10 Regression rate distributions of Cases A1 to A5.

Fig.11 shows the regression rate,combustion efficiency and O/F ratio in Cases A1 to A5.The curve shows that the regression rate increases more and more slowly. The regression rate reaches the maximum value when the rotation angle reaches 30°. Subsequently, the regression rate decreases smoothly,and the decrease rate was much lower than the increase rate.The variation trend of combustion efficiency is generally similar to that of the regression rate.As the oxidizer mass flow rate is constant, the O/F ratio is inversely proportional to the regression rate. The regression rate and combustion efficiency of HRM are obviously enhanced by the rotation of the second grain.This effect is most significant when the rotation angle is 30°.

4.2. Effect of port number

Table 4 describes the parameters of cases with different port number Np. In order to distinguish the influence of the port number and rotation angles,cases with the same Ngand different θ are also conducted.

Fig. 11 Regression rate, combustion efficiency and O/F ratio in Cases A1 to A5.

The regression rate distributions are shown in Fig. 12 and the mass flow rate is 200 g/s.As for the first grain,the variation trends of regression rates along the axis are almost the same.As the port number increases, the regression rate of the first grain improves gradually with the increasing rate getting slower. This phenomenon coincides with the conclusions drawn from Kim et al.16As for the second grain, comparing the zero-angle cases, the regression rate increases as the port number increases from one to three, while the regression rates of the 3-port grain and 4-port grain are almost the same.Regarding the nonzero-angle cases, the regression rate of the grain is improved as the port number increases from one to three. The improvement of the regression rate can be attribu-ted to two factors:the decrease of port size and the rotation of the second grain.Nevertheless,the regression rate of the 4-port grain is much lower than that of the 3-port grain due to the weakened disturbing effect caused by more ports.

Table 3 Performance parameters of Cases A1 to A5.

Table 4 Parameters of two-segmented cases with different port numbers.

Fig. 12 Regression rate distributions of Cases B1 to B7.

Fig. 13 Regression rate curves of Cases B1, B3, B5, B7 and experiment.

The increase of the regression rate gets slower as the port number increases. Cai et al.18consider that the regression rate is proportional to, andWhen Agis set to be constant,it is obtained that the regression rate is proportional to Np0.1. Therefore, the increase of the port number contributes less and less to the regression rate. With the increase of the port number, the gas’s turbulent motion is reduced, and the vortex and the mixing effect are weakened.When the port number increases to four, the positive effect of the port size is weaker than the negative effect of the weakened vortex, leading to the decrease of the regression rate.In Marxman and Gilbert’s theory, the average regression rate for one grain depends primarily on the mass flow rate of the oxidizer,19and it is given as

Fig. 14 illustrates the combustion efficiency of these cases.As for the zero-angle cases,the combustion efficiency increases with the increase of the port number.As for the nonzero-angle cases, the combustion efficiency increases as the port number increases from one to three while the combustion efficiency of the 4-port grain is a little lower than that of the 3-port grain.The change regulation of the combustion efficiency is similar to that of the regression rate.

The gas residence time represents the mixing and reaction time of the gas flow in the combustion chamber. A longer gas residence time is beneficial for the mixing and combustion of the propellants. The gas residence time can be estimated as the ratio of the gas mass to the total mass outflow rate from the combustion chamber, and it can be calculated as

where ˙m is the total flow rate of the propellant,Vefis the effective combustion volume and ρ-efis average density of the combustion gas.Fig.15 shows the gas residence time of these cases.The gas residence time increases by more than 1.5 ms due to the multi-port configuration.The residence time increases with the port number increasing from one to three while the residence time of the 4-port case is shorter than that of the 3-port case.

4.3. Effect of fuel grain segment number

Cases C1 to C3 are calculated to investigate the effect of the fuel grain segment number on the performance of the motor.Relative to the first grain,the rotation angles of the third grain are set to 0°while the rotation angles of the second and fourth grain are the same. Table 6 describes the parameters of threeport cases with different segments.

Table 5 Regression rate formulas of cases and experiments.

Fig. 14 Combustion efficiency of Cases B1 to B7.

Fig. 15 Gas residence time of Cases B1 to B7.

As shown in Fig.16,when the rotation angle is 30°in Case C2 and 45° in Case C3, the regression rate reaches the maximum. The combustion efficiencies of the nonzero-angle cases are almost the same, improved by 7%-12% comparing with the zero-angle cases. The O/F ratio is inversely proportional to the regression rate.

Fig. 16 Regression rate, combustion efficiency and O/F ratio in Cases C2 and C3.

Cases C1-0°, C1-30°, C2-0°, C2-30°, C3-0° and C3-45° are compared to research the distributions of the regression rate.As is shown in Fig. 17, the distributions of the regression rate of the first grains are almost the same, and the regression rate of the post grain is always greater than that of the front grain.For the zero-angle cases,the regression rate is kept unchanged with the increase of the segment number;and for the nonzero-angle cases, the regression rate increases with the increase of the segment number.

Table 6 Parameters of three-port cases with different segments.

Fig. 17 Regression rate distributions of Cases C1-0°, C1-30°,C2-0°, C2-30°, C3-0° and C3-45°.

Fig. 18 describes the regression rates of Cases C1 to C3. It can be seen that: (A) The regression rate increases with the increase of the segment number. (B) When the rotation angle is 0°, the regression rate scarcely increases. When the rotation angle is not 0°, the regression rate improves by up to 75%(comparing with 0°situation).This phenomenon indicates that the key of the multi-segmented grain configuration is the rotation between grains which can accelerate the heat transfer to the fuel and promote combustion. (C) The regression rate increases first and then decreases slowly,and the rotation angle corresponding to the maximum regression rate is 30°-45°when the segment number is 2, 3 and 4.

The mechanism of the improvement can be explained as follows. In general, the gas at the entrance area of each grain(except the first grain) has been fully mixed and the chemical reaction is better completed. When the rotation angle is not 0°, swirls with high temperature are generated in the midchambers because of the structure. Swirling motion applied to the gas flow reduces the boundary layer thickness and increases the intensities of transfer coefficients in the turbulent flow,due to the increase of the additional tangential and radial flow velocity near the fuel surface.21With the increase of the segment number,more swirls are generated, and the turbulent flow is strengthened.

Fig. 18 Regression rates of 3-port cases with different segments and rotation angles.

Fig. 19 Combustion efficiencies of 3-port cases with different segments and rotation angles.

Fig.19 shows the combustion efficiency of these cases.It is obvious that the rotation between the grains can improve the combustion efficiency, while the increase of the segment number has little effect on the combustion efficiency. However,excessive segments will reduce volumetric loading fraction,chamber pressure and combustion efficiency.The grain should be long enough for the boundary layer to become fully developed and the stability of combustion during ignition should also be considered when determining the segment number.

4.4. Effect of mid-chamber length

Table 7 shows the detail parameters of the cases with different mid-chamber lengths. The regression rate and performance of the motor are shown in Table 8(˙r1and ˙r2are regression rates of the 1st grain and 2nd grain, respectively;is the average fuel regression rate) and Fig. 20. The regression rate of Case D2 is greater than that of Cases D1 and D3. With the increase of the mid-chamber length, the combustion efficiency decreases slightly due to the increase of the gas flow volume and the decrease of pressure and swirl intensity.

5. Conclusions

The multi-segmented grain configuration is investigated in this paper through three-dimensional numerical simulations.Many cases are calculated, and simulation results are compared by groups. The effects of rotation, port number, fuel grain segment number and mid-chamber length on the performance of the hybrid rocket motor are discussed. The conclusions obtained in this study can be drawn as follows:

(1) The key to multi-segmented grain configuration lies in the rotation between grains, which can impede the axial flow of gas and produce swirls in mid-chambers, thus accelerating the heat transfer to the fuel and promoting combustion.

(2) With the increase of rotation angles, the regression rate increases first and then decreases slowly in most cases.Take the cases with two grain segments and three ports for example, the regression rate increases by 32.4%-45.1% and the combustion efficiency increases by 6%-8.6%. The rotation angles of the cases with maximum regression rate are distributed between 30°to 45°,where additional tangential and radial flow velocity reaches the maximum.

Table 7 Parameters of three-port cases with different mid-chamber lengths.

Table 8 Performance parameters of Cases D1 to D3.

Fig. 20 Regression rate, combustion efficiency and O/F ratio in Cases D1 to D3.

(3) For the zero-angle cases, the increase of the regression rate and combustion efficiency winds down with the increase of the port number. For the nonzero-angle cases with two segments, the regression rate and combustion efficiency increase first and then decrease.When the port number is three, the regression rate and combustion efficiency reach the maximum, which are improved by 45.1% and 8.6% respectively. When the port number increases to four, the positive effect of the port size is weaker than the negative effect of the weakened vortex, and the performance gets worse accordingly.

(4) For the nonzero-angle cases with three ports,the regression rate increases by nearly 33% with the increase of the segment number while the combustion efficiency varies little. More swirls with high temperature are generated in more mid-chambers. Swirling motion applied to the gas flow can reduce the boundary layer thickness and increase the intensities of transfer coefficients in the turbulent flow.

(5) The mid-chamber length can influence the regression rate, but has little effect on the combustion efficiency.When the mid-chamber length is 30 mm, the regression rate reaches the maximum.

CHINESE JOURNAL OF AERONAUTICS2020年4期

CHINESE JOURNAL OF AERONAUTICS2020年4期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- Reliability and reliability sensitivity analysis of structure by combining adaptive linked importance sampling and Kriging reliability method

- Aeroelastic dynamic response of elastic aircraft with consideration of two-dimensional discrete gust excitation

- Thermal damage analysis of aircraft composite laminate suffered from lightning swept stroke and arc propagation

- An aerospace bracket designed by thermo-elastic topology optimization and manufactured by additive manufacturing

- Applications of structural efficiency assessment method on structural-mechanical characteristics integrated design in aero-engines

- An energy-based coupling degradation propagation model and its application to aviation actuationsystem