Recent advances in film cooling enhancement:A review

Jingzhou ZHANG , Shengchang ZHANG, Chunhua WANG, Xiaoming TAN

Jiangsu Province Key Laboratory of Aerospace Power System, College of Energy and Power Engineering, Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China

KEYWORDS Active strategy;Cooling capacity;Discrete-hole film cooling;Film cooling enhancement;Jet-in-crossflow;Passive strategy

Abstract Film cooling is an indispensable scheme in the design of highly-efficient cooling configurations to satisfy the thermal protection requirement of turbine hot section components. During the last few decades, vast efforts have been paid on the discrete-hole film cooling enhancement.In this paper, some of the recent literatures related to the passive strategies (such as shaped film cooling holes, upstream ramps, shallow trenches, mesh-fed slots) and the active strategies (such as the use of pulsation modulating device or plasma actuator)for film cooling enhancement are surveyed, with the aim at presenting an updated overview about the state of the art in advanced film cooling.In addition,some challenging issues are also outlined to motivate further investigations in such a broad topic.

1. Introduction

In a common sense, the limitations of today’s gas turbines are tightly defined by the current cooling technologies as applied to the hot-section components.1As a result of pursuing high operational efficiency and high thrust-to-weight ratio, the turbine inlet temperature is continuously prompted in the advancement of aero-engines. For the next generation of aero-engines, the turbine inlet gas temperature is expected to beyond 2200 K,which is extremely higher than the limit operating temperature of most substrate materials without significant deterioration. Meanwhile, the coolant usage for the cooling purpose will be more limited.Thus,in the development of advanced aero-engines, the thermal protection of hot section components is one of the most critical challenges,without a shade of doubt.

Film cooling technique plays a major role in the thermal protection of turbine hot-section components (e.g. guide vane and blade,2-4turbine casing,5,6combustor liner,7-9exhaust nozzle,10-12etc.). As the cooling air used for film cooling purpose is extracted from the compressor stage, vast coolant consumption will undoubtedly lead to engine performance penalties. Therefore, the film cooling enhancement is a crucial necessity for satisfying the serious thermal protection requirement of hot-section components with a more limited cooling air usage. Thus, motivated by this quite challenging subject,from both scientific viewpoint(providing a deep understanding of the fundamental dynamic and heat transfer features) and technical viewpoint (achieving a highly-efficient film cooling scheme design in practical applications),vast efforts have been devoted during the past decades.13-15

Nomenclatures I momentum flux ratio M blowing ratio T temperature T∞ primary flow temperature Tc coolant flow temperature ρ∞ density of the primary flow ρc density of the coolant flow u∞ velocity of the primary flow uc velocity of the coolant flow Θ dimensionless temperature

It is well known that the two-dimensional slot film cooling is an ideal state of the art.Although it has been really applied in some hot-section components of the turbine engine,such as turbine endwalls and combustor liners,16,17in many situations the two-dimensional slot is generally restricted because it is hard to satisfy the thermal-mechanical constraints. For this cause, the use of discrete film holes is the primary focus in the practical applications.With regards to the film cooling of discrete holes,vast researches have revealed clearly that this cooling scheme generally produce a poor film coverage over the protected surface due to its native geometric feature. Therefore, vast researches are motivated on the exploration of effective strategies(both in passive and in active)for discrete-hole film cooling improvement during past decades. This challenging subject in the film cooling enhancement remains so far, with an ultimate goal to approach ideal film cooling.

In this paper, some of the recent literatures related to the film cooling enhancement are summarized and reviewed, with the aim at presenting an updated overview and illustrating further needs of research in such a broad topic. The current survey is outlined in the following sections:(A)fundamental flow dynamics of jet-in-crossflow; (B) passive strategies for film cooling enhancement; (C) active strategies for film cooling enhancement; (D) some challenges in future researches.

2. Fundamental flow dynamics of jet-in-crossflow

The art of film cooling concerns the flow dynamics of the jetin-crossflow. Vast investigations illustrate that the mutual interaction between the discrete jet and the mainstream result in complex coherent vortical structures, as displayed in Fig. 1. They are Windward Vortices (WV) at the leading edge of jet, Counter-rotating Vortex Pair (CVP) or kidney vortices in the jet, Horseshoe Vortices (HV) around the jet, and Leeward Vortices (LV) at the trailing edge of jet.

Fig. 1 Schematic diagram of vortical structures of jet-incrossflow.

Fig. 2 Difference of jet-in-crossflow structures at low and high blowing ratios.18

To present the detailed physical mechanisms involved in the film cooling, a significant amount of researches had been carried out early.18-23In particular as demonstrated in Fig.218the main flow features of a single jet in crossflow are tightly associated with the blowing ratio (M=(ρcuc)/(ρ∞u∞)) or the momentum flux ratio (I=(ρcu2c)/(ρ∞u2∞)). At a low blowing ratio (Fig. 2(a)) the mainstream covers the upstream part of the hole and lifts over the jet, helpful for pushing the jet towards the film-cooled wall. While at a high blowing ratio(Fig. 2(b)) the jet is only weakly affected by the mainstream and shows a strong penetration into the mainstream before it is bent over. In both instances, a complicated threedimensional separation region is identified immediately downstream of the jet,which promotes the core of the coolant jet far away from the surface and entrains the mainstream into the wake of jet. Due to the different behaviors of mutual interaction between the flows,three states of the coolant jets are identified, as shown in Fig. 321where D represents the film-hole diameter and the dimensionless temperature is defined as Θ=(T∞-T)/(T∞-Tc): namely, fully attached coolant jet at a low blowing ratio or momentum flux ratio (Fig. 3(a)),detached and reattached jet at a moderate blowing ratio or momentum flux ratio (Fig. 3(b)), and fully detached jet at a high blowing ratio or momentum flux ratio(Fig.3(c)).Clearly,whether or not the coolant jets are attached to the filmprotected surface strongly affects the cooling performance.As the coolant jets begin to detach from the protected surface the temperature of the mixed flow nearby the wall decreases because the core of the coolant jet travels above the surface and the hot primary flow invades beneath the coolant jet.Once a serious coolant jet detachment occurs, the surface is rarely protected by the film cooling layer.

Naturally, among these vortical structures, the Counterrotating Vortex Pair (CVP) is confirmed to be the dominant mechanism affecting discrete-hole film cooling. As seen in Fig. 4(a), the coolant jet is lifted to travels above the surface.Meanwhile, hot mainstream entrainment follows the CVP to make the temperature of the mixed flow nearby the wall increase. According to the fundamental flow structures of the jet-in-crossflow, the key mechanism of film cooling enhancement lies in the suppression of counter rotating vortices.24-27Of particular, if an additional anti-kidney vortex pair could be presented,the jet lift-off due to the mutual induction would be effectively reduced and the jet lateral coverage would be effectively increased, as illustrated in Fig. 4(b). Following this acceptance of the mechanism on improving film cooling effectiveness, a huge amount of investigations had been directed towards eliminating the adverse effect of the kidney vortices.

3. Passive strategies for film cooling enhancement

3.1. Shaped film cooling holes

Fig. 3 Dimensionless temperature profiles along film-hole centerline.21

Fig. 4 Schematic diagram of kidney and anti-kidney vortices.25

One of the most inspiring achievements in the discrete-hole film cooling enhancement is the use of shaped holes.28,29Early in 1970s, Goldstein et al.30first demonstrated and quantified that fan-shaped hole produces better film cooling performance when compared to the cylindrical hole. Further detailed flow visualization and measurements identify that the fan-shaped hole could lead to less penetration and wider lateral-coverage of the coolant jet due to its diffused exit.31,32Being a mostly common shaped hole, the fan-shaped hole achieves much attention during the past few decades.33-38These investigations provide deeper understandings on the comprehensive performances of fan-shaped hole film cooling.

When compared to the cylindrical hole,the fan-shaped hole involves more geometric parameters,such as forward diffusion angle, lateral diffusion angle, orientation positions corresponding to forward and lateral expansions, etc. Such a complicated multi-parameter influence presents an extreme complicity in the accurate correlations for predicting the adiabatic film cooling effectiveness of fan-shaped hole, even on a simply flat surface, making it still attractive to the researchers recently.39-41Of particular is the multi-parameter optimization of the fan-shaped hole by using optimization schemes, which could effectively bring out the latent potentiality of the existing fan-shaped holes by considering the film cooling performance and aerodynamic performance together.42-46For instances,Lee et al.43performed a multi-objective optimization investigation for a specific fan-shaped hole on a flat surface,as shown in Fig. 5(a), by taking the spatially averaged adiabatic film cooling effectiveness and the aerodynamic loss as the objective functions. Three typical varieties of the optimal solutions are deduced, in accordance with the option of the highest spatially-averaged adiabatic film cooling effectiveness (Opt-A at M=0.5 and Opt-D at M=2.0), the lowest aerodynamic loss(Opt-C at M=0.5 and Opt-F at M=2.0),and the compromise of both aspects (Opt-B at M=0.5 and Opt-E at M=2.0) respectively, as shown in Fig. 5(b). Huang et al.46performed a multi-objective optimization for the laidback fan-shaped hole on the suction surface of a turbine vane at M=1.5.Two independent objective functions that are simultaneously optimized are selected as the spatially-averaged adiabatic film cooling effectiveness (ηad,av) and the discharge coefficient (Cd). From the optimization, the Pareto front of optimal solutions is obtained(seen in Fig.646),which provides a variety of options for seeking the maximum spatiallyaveraged adiabatic film cooling effectiveness(Opt-A),the maximum discharge coefficient(Opt-B),or the compromise of both aspects(Opt-C).As displayed in Fig.746where s represents the streamwise distance along curved surface, the optimal fan shapes are very distinct under different optimal options. For Opt-A, the optimal fan-shaped hole is of a large inclination angle and a moderate forward expansion angle. The fanshaped hole in Opt-B needs a small inclination angle and a moderate forward expansion angle.While for seeking the compromise of both aspects, a small inclination angle and also a small forward expansion angle seem to be more favorable. In general, the improvement in film cooling effectiveness and the reduction in aerodynamic loss show a competing nature.How to balance them is a quite essential topic worthy of further assessment.In addition,as the optimal fan shape is tightly associated with the blowing ratio, the multi-objective optimization considering certain ranges of parameters is also very necessary.

Fig. 5 Fan-shaped hole geometric optimization.43

Fig. 6 Pareto front of optimal solutions.46

Fig. 7 Adiabatic film cooling effectiveness distributions.46

Recently, the newly innovative shaped film cooling holes are continually proposed. A partial catalogue of the exploration relating to the typical shaped-hole film cooling holes is presented in Table 1.47-89Evidently,this list is not complete,because the shaped-hole film cooling is a board topic over the last decade. However, such a partial catalogue does constitute the majority of the advanced shaped holes.

Most of the novel shaped holes are evolved from the original fan-shaped and Double-Jet Film Cooling (DJFC) concepts. Naturally, the DJFC is a simple ant-vortex configuration, by using the secondary injection jet to establish the anti-rotating vortices with respect to the primary injection one.90Although the DJFC configuration is simple, the additional cylindrical holes are generally conjectured to be detrimental to the mechanical strength of the cooling structure.By an appropriate merging of the two holes, a NEKOMIMItype hole is evolved while maintaining the geometric features of DJFC configuration, as shown in Fig. 867. Fig. 9 shows a comparison of the local flow fields between a NEKOMIMItype hole and a fan-shaped hole, which is derived from Kusterer et al.69It is confirmed that the NEKOMIMI-type hole is more advantageous for the formation of the anti-vortex structure. Due to the anti-vortex pair, the coolant jet shows a distinctly less penetration in the normal direction but wider coverage in the spanwise direction, when compared to the fan-shaped hole. As seen in Fig. 1069, an appropriate NEKOMIMI design is capable of achieving more pronounced film cooling enhancement than that of fan-shaped hole. However,the geometry of NEKOMIMI hole is more complex when compared to the fan-shaped hole.Evidently,its geometric optimization needs further concerns.

Cratered hole is regarded as a realistic configuration because the crater depressions could be realistically fabricated by the thermal barrier coating. By embedding the film cooling hole within a crater chamber, the coolant jet could spread inside such a crater chamber in advance before it is directly affected by the oncoming mainstream. It is interesting that acontoured crater design proposed by Kalghatgi and Acharya74,75is able to generate strong anti-CVP vortices, as displayed in Fig. 11.74Therefore, the near-hole film cooling effectiveness could be significantly improved. However, due to the increased turbulence levels and flow separation within the crater chamber,additional pressure losses is also identified to generate in the cooling jet with respect to the baseline case of a cylindrical hole,which is tightly associated with the carter depth, as shown in Fig. 12.75Kim JH and Kim KY79performed a single-objective optimization investigation of the cratered hole to enhance film cooling effectiveness under a low blowing ratio of M=0.5,considering three geometric parameters of the crater (major axis length, minor axis length and depth). Interestingly, as displayed in Fig. 13.79The optimized crater alters the relationship of major axis and minor axis in the reference case. Feng et al.89also performed a singleobjective optimization on the cratered hole film cooling.Under

a low blowing ratio, the optimized crater is same as that of Kim JH and Kim KY.79But under a high blowing ratio, the optimized crater remains the relationship of major axis and minor axis in the reference case. In such a cratered-hole film cooling scheme, the crater depth and contour need further optimized.

Table 1 A brief survey of recent literatures on shaped holes47-89.

Fig. 8 Evolution of NEKOMIMI-type hole.67

Fig. 9 Temperature distribution and flow vectors at sectional planes under M=1.5.69

Fig. 10 Laterally-averaged adiabatic film cooling effectiveness for several holes at M=1.5.69

Fig. 11 Near-hole flow structures in contoured crater case.74

Fig. 12 Contours of pressure loss coefficient.75

Fig. 13 Development of streamlines and vectors.79

Of particular, Sargison et al.47,48presented a novel shaped hole, namely, CONSOLE (CONverging Slot-hOLE). This shaped hole has a conventional round inlet but a narrow exit,mostly close to the ideal 2-D slot configuration among the current shaped film cooling holes.As the CONSOLE remains the geometric feature of discrete hole,it overcomes the main drawbacks or the thermal-mechanical constraints of 2-D slot in the real applications. Preliminary experimental studies performed by Sargison et al.47,48illustrate that the CONSOLE could achieve a good lateral uniformity of adiabatic film cooling effectiveness, approaching the 2-D slot film cooling. The fanshaped holes produce lower laterally-averaged heat transfer coefficient than the CONSOLE, thus maybe provide a higher Net-Heat-Flux-Reduction (NHFR). With respect to the fanshaped holes,the CONSOLE is confirmed to have some specific advantages with greater laterally-averaged film cooling effectiveness and lower aerodynamic loss. Further investigations reveal that the CONSOLE changes the inherent kidney-vortices structure in cylindrical film cooling.52,62,71Due to the strongly lateral divergence of CONSOLE during the transition from an initially round inlet to a finally slot outlet, the coolant jet is forced to flow laterally inside the film cooling hole, towards both lateral edges of the slot. As a consequence, the lateral coverage of coolant jet on the surface is tremendously improved. Moreover, the strong lateral flow of the coolant jet is attributed for generating anti-CVP vortices at both edges of slot, as displayed in Fig. 14.62This mutual interaction of jet-in-crossflow is completely different from that in the conventional hole, which is of great potential for suppressing the normal penetration of coolant jet into mainstream and also preventing the lateral incursion of mainstream into the wake of coolant jet. Yao et al.72carried out a numerical study on the film cooling performance of a single row CONSOLEs at the blade suction side in an engine-simulated environment. Their results confirm that the CONSOLE provides a significant enhancement of film cooling effectiveness, as displayed in Fig. 15.72With regard to the aerodynamic loss, as shown in Fig. 16,72the enthalpy loss coefficient due to CONSOLE film cooling is less than the cylindrical-hole film cooling when the film holes are located upstream of the cascade throat.While when the film holes are located downstream of the cascade throat,the situation is the opposite.As we know,the total aerodynamic loss involved in film cooling comes from two aspects, loss in the internal cooling passages and loss in the mixing process between coolant jet and primary flow.Although the CONSOLE could minimize the mixing loss due to a good film layer attachment on the surface, the loss in the internal cooling passage would be more serious due to its complicated geometry. Therefore, the CONSOLE shows its advantage in the aerodynamic loss reduction when the active role is dominated.

Fig. 14 Temperature and velocity distribution on a normal plane downstream of film-hole.62

Fig. 15 Adiabatic film cooling effectiveness distributions.72

Fig. 16 Enthalpy loss coefficients in a turbine cascade.72

Liu et al.56,61performed some experimental tests to study the effect of console geometry variants on the film cooling performance.Their results show that properly changing the geometry parameters of the console could improve the film cooling performance. Generally, consoles with smaller exit-entry area ratio produce higher cooling effectiveness but smaller discharge coefficients. Because of a totally converging geometric feature, a greater pressure drop of coolant jet is paid for the CONSOLE. More recently, Zhang et al.85extended the concept of CONSOLE to RTSH (Round-To-Slot Hole). Huang et al.86performed a numerical investigation to illustrate the geometric effects of RTSH on the film cooling over a flat surface, aiming at achieving the maximum adiabatic film cooling effectiveness through a single-objective optimization. In general, a converging round-to-slot hole is more favorable at low blowing ratios but a diffusing round-to-slot hole seems more favorable at high blowing ratios. Zhu et al.87conducted a numerical study on the geometric effects of RTSH in the multiple-row film cooling of a turbine guide vane under engine-representative conditions (as schematically shown in Fig. 17), by taking five film cooling holes (Cylindrical Hole,CH; Fan-shaped Hole, FH; converging RTSH, RTSH-1;equivalent-area RTSH, RTSH-2; diffusing RTSH, RTSH-3)into consideration, given the same coolant feeding total pressure().In their study,only the alteration of film-hole shape at Suction Side(SS)and Pressure Side(PS)is concerned while the showerhead film cooling holes at the Leading Edge (LE)remain cylindrical or baseline shape.As the converging RTSH(RTSH-1)has a smallest discharge coefficient of coolant injection, it reduces the coolant massflow rate while the diffusing film hole (FH and RTSH-3) increases the coolant massflow rate in comparison with the baseline case under the same bleeding pressure of coolant flow. In the viewing of individual single-row situation, as seen in Fig. 18(a) where s represents the streamwise distance from the leading edge of turbine blade,all shaped holes are demonstrated to improve the adiabatic film cooling effectiveness immediately downstream of respective row location. However, as seen in Fig. 18(b), converging RTSH is found to achieve weaker overall film cooling effectiveness than the baseline case because it has the smallest coolant usage.At the same time,the converging RTSH leads to the smallest enthalpy loss coefficient, as seen in Fig. 18(c). With regard to the diffusing RTSH, it indeed provides the highest cooling effectiveness. But it also produces the largest coolant usage and cascade enthalpy loss coefficient. Therefore, it is suggested that the equivalent-area transition round-to-slot hole(RTSH-2)should be the most compromised shape for balancing the active effect of RTSH on film cooling enhancement and the adverse effect of RTSH on coolant usage and enthalpy loss.

Fig. 17 Effect of film-hole shape on coolant flow usage for a multi-row film-cooled guide vane.87

Fig. 18 Effect of film-hole shape on cooling performance of a multiple-row film-cooled guide vane.87

3.2. Upstream ramps

It is commonly known that the approaching boundary-layer flow across a backward-facing step will separate to form a recirculation region immediately behind the rear face of ramp,as shown in Fig. 19. Due to this flow pattern, the upstream ramp is also an effective flow-control means for the jet-incross-flow. As the oncoming mainstream deflects upwards by the presence of an upstream ramp, its impact on the coolant jet injection is weakened, which is helpful for modifying the coolant flow inside the film cooling hole. As demonstrated in Fig. 20,91the jetting effect inside the film cooling hole caused by the separation and flow turning at the inlet is alleviated.Because of this cause, the pressure drop of coolant jet across the film cooling hole is reduced by the presence of an upstream ramp. Besides, as the upstream ramp forms a local low static pressure zone immediately ahead the film-hole exit, the lateral spreading of cooling jet is thus increased.According to Na and Shih,91the laterally-averaged adiabatic film cooling effectiveness in presence of the upstream ramp can be two or three times higher than the baseline case.

Fig.19 Schematic diagram of flow field over an upstream ramp.

Although the presence of upstream ramp is helpful for reducing the flow loss inside the film cooling hole, the total aerodynamic loss involved in film cooling is prompted as a consequence of the flow separation of oncoming boundary layer flow.92,93Evidently, the ramp angle is an important factor affecting the film cooling performance. Referring Chen et al.94a larger ramp angle is more pronounced to the film cooling enhancement at a high blowing ratio. In accordance to Fig. 19, the relationship of coolant injection position with respect to the rear edge of ramp is also an important factor.95As demonstrated in Fig.2195(where durepresents the distance of backward facing step from leading edge of film cooling hole and h represents the height of upstream step), when the upstream step is located far ahead the film cooling hole, such that the coolant injection is just located at the reattachment zone of the separated shear layer, a negative impact may occurs in the film cooling effectiveness. Generally, positioning the ramp immediately upstream of the holes yields significant enhancement of the adiabatic film cooling effectiveness.

More recently, the shape of upstream ramp receives much attention. A partial catalogue of the exploration relating to the shaped ramps is presented in Table 2.96-104By utilizing shaped ramps, the approaching boundary layer flow is modified, and subsequently the mutual interaction between coolant jet and mainstream.The most inspiring advantage of the use of shaped ramps is that a good compromise between the film cooling effectiveness and the aerodynamic loss could be realized.

Fig. 21 Schematic diagram of effect of upstream ramp position on coolant injection.95

Table 2 A brief survey of recent literatures on shaped ramps.

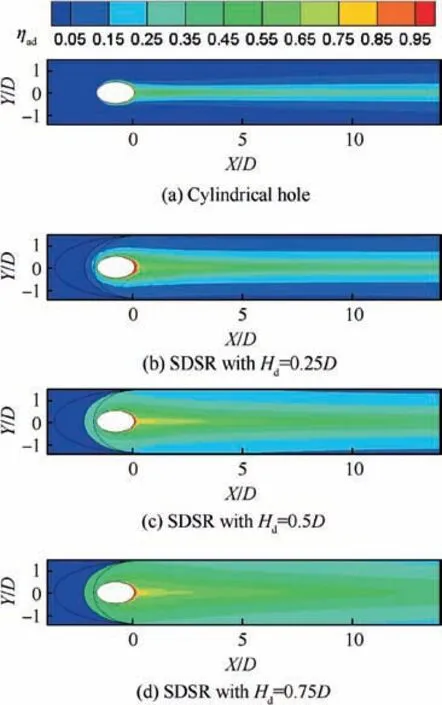

Among various upstream ramps,of particular interest is the novel Sand-Dune-Shaped Ramp(SDSR),which is of a favourable aerodynamic contour with respect to the oncoming airflow. Fig. 22 shows the tested instantaneous vorticity distributions (taken from Zhou and Hu101) and the computed local streamlines(taken from Zhang et al.104)behind upstream ramp. It is found that an additional pair of vortices is generated in the presence of upstream sand-dune-shaped ramp,named as anti-Counter-Rotating-Vortex (Anti-CRV), with respect to the conventional CRV. Evidently, this additional pair of anti-kidney vortices is resulted from the mixed flow shedding from the sand-dune-shaped ramp horns. As a consequence,the sand-dune-shaped ramp show pronounced roles on film cooling enhancement over the entire surface, as demonstrated in Fig. 23.104The upstream SDSR remains large volume of coolant concentrating in the near-field of film-hole and enlarges the lateral coverage of coolant jet. The improvement of adiabatic film cooling effectiveness with respect to the cylindrical hole seems to be more pronounced at a larger ramp height (Hd). However, it is conjectured that a larger ramp height generally attributed to a higher aerodynamic loss. To our knowledge, the researches on the effects of contoured upstream ramp are really insufficient. Especially, most of the previous investigations relating to the upstream ramp mainly concern the adiabatic film cooling effectiveness.The additional flow losses and the Net-Heat-Flux-Reduction (NHFR) are rarely concerned. Further investigations for addressing more comprehensive insights into the roles of shaped ramps on film cooling performance are necessary.

Fig. 22 Near-hole flow fields for sand-dune-shaped ramp.

Fig. 23 Adiabatic film cooling effectiveness at M=1.0104

3.3. Film cooling holes embedded in trenches

Holes-in-slot geometry is a possible solution roughly close to 2-D slot.Jia et al.105presented a mixing-slot concept,as shown in Fig. 24(a). This mixing slot recesses the discrete jets into a narrow chamber, allowing them to premix inside this narrow chamber and then merging together to form a slot-like jet at the exit. By replacing the mixing slot with an overlying transverse trench, as shown in Fig. 24(b)106trenched film cooling configuration is achieved. As the transverse shallow trench could be realistically fabricated by the thermal barrier coating,therefore, this kind slot-like film cooling configuration is regarded to be more practical in the engineering applications,for breaking the limits of diffusion shaped holes.106-108

Straight transverse trench is a common configuration. The trench width and depth are the two main geometric parameters tightly associated with the straight transverse trench.Inside the trenched cavity,lateral flow of the coolant jet is induced due to the front blockage. Therefore, the coolant distribution along the spanwise direction could be modified. Earlier investigations indicates that a narrow and shallow trench performed better than deeper and wider trenches.109-113Recently, Oguntade et al.114conducted a numerical investigation on the improved-trench film cooling by shaping the trench outlets.Two modified outlet shapes,namely beveled and filleted trench outlet shapes,are suggested to be more pronounced to remain the cooling air attachment to the downstream wall surface,due to the more effective suppression of vertical jet momentum and the Coanda effect. Kross and Pfitzner115proposed a novel trench configuration by placing tetrahedral elements upstream of the trench. It is illustrated that upstream tetrahedral elements modify the approaching flow filed near the trench,leading to a less mixing but a stronger lateral spreading of the coolant jet within the trench. When compared to the original trench configuration, the adiabatic film cooling effectiveness is effectively enhanced. Of particular interest is the novel contoured trench, such as the swept-shaped trench116and the wave-shaped trench.117-119As shown in Fig. 25,114the swept shape of the trench yields an obvious film cooling improvement with respect to the conventional straight trench. Due to the angled trench layout,the coolant could be directed to flow into this region between adjacent holes, the vortices structures are different from those observed in the straight trench case,as illustrated in Fig. 26.118For the conventional trench, the kidney-vortex pair is still dominant in the downstream flow field. While for the contoured trench, the anti-counterrotating vortices could be formed. Therefore, the contoured trench behaves more pronouncedly on enhancing the adiabatic film cooling effectiveness.

Fig. 24 Schematic diagram of holes-in-slot geometry.

Fig. 25 Local adiabatic film cooling effectiveness.114

3.4. Mesh-fed slot

Davidson120and Bruce-Black121et al. proposed an improved slot-like film cooling configuration by the incorporation of internal impinging jets to the angled slot. The coolant jets are fed through discrete impinging holes and then merged together inside the angled slot. In comparison with the trenched-slot geometry,this slot-based interior-feeding cooling scheme ensures a longer mixing slot before the coolant jet is ejected into the mainstream and integrates the role of internal jet impingement.Lee and Bunker122proposed a novel integrating film cooling configuration, namely the mesh-fed slot. As shown in Fig. 27,122the mesh-fed slot uses in-wall mesh network to fit into a 2-D narrow channel.At least two advantages are involved in this particular film cooling configuration,in the view of cooling performance. Firstly, the internal convective cooling could be enhanced inside the film cooling hole,caused by a fairly dense array of pedestals.Secondly,the mesh-fed slot is mostly close to a 2-D slot,thus nearly perfect film cooling is achieved. Referring Bunker,123although it is still unable to proving the idealistic cooling level like a 2-D slot, the meshfed slot does realize a more significant benefit when compared to the other shaped holes.Besides,as the compact in-wall mesh network helps the structural-integrity,the application of meshfed slot film cooling is feasible.

Fig. 26 Temperature and velocity distributions.118

Fig. 27 Mesh-fed film cooled turbine airfoils.122

Fig. 28 Temperature and velocity vector for mesh-fed slot cooling at M=2.0125

Actually,the in-wall mesh network is the key in such a film cooling configuration.Firstly,it affects the flow and convective cooling inside the coolant-fed channel and consequently the overall cooling effectiveness. Secondly, it also affects the coolant distribution uniformity at the slot exit and consequently the mutual interaction between coolant jet and mainstream.Recently, Wei et al.124experimentally investigated the influence of in-wall pin-fin arrangement on the mesh-fed slot film cooling.The in-line pin-fin arrangement is found to form more uniform film cooling adiabatic film cooling effectiveness distribution than the staggered pin-fin arrangement. Tan et al.125paid their concerns on the effects of in-wall pin-fin shapes.Their results illustrate that in the mesh-fed slot film cooling the kidney vortices also appear, as displayed in Fig. 28125(where swrepresents the slot width and znrepresents the spanwise pitch of pin-fin array), although the jet-off is effectively suppressed. It is also noted that a pair of anti-kidney vortices is generated in the mesh-fed slot film cooling, providing a favorable coolant coverage on the surface. The formation of kidney vortices is attributed to the ‘‘jetting” effect of coolant jet injection near the mesh-fed slot exit. In comparison with idealistic 2-D slot, the in-wall mesh destroys uniformity of the coolant distribution at the slot exit evidently. By using an elliptical or drop-like pin-fin shape, the ‘‘jetting” effect of coolant flow is alleviated a little,which is helpful for improving the film cooling effectiveness downstream the mesh-fed slot outlet,125as seen in Fig. 29.

Fig. 29 Tested adiabatic film cooling effectiveness distribution for mesh-fed slot configurations at M=1.0.125

4. Active strategies for film cooling enhancement

4.1. Pulsed film cooling

Active film cooling enhancement strategies mostly comprise jet pulsation. As the coolant flow conditions have a strong influence on mutual interaction between coolant jet and mainstream, consequently, the fluidic actuation applied to the coolant injection is feasible for the active control of jet-incrossflow.126-128Due to its highly-unsteady feature,the pulsed film cooling is very complex,affected by many operational pulsation parameters (e.g. frequency (f) or Strouhal number (Sr),amplitude (AN), Duty Cycle (DC), etc.). Furthermore, the effects of pulsation parameters are tightly coupled with the other factors(such as blowing ratio,momentum flux ratio,turbulence, injection scheme, etc.), making the multi-parameters influencing roles extremely complicated. For instances, the coolant pulsation is found helpful to improve film cooling effectiveness in the cases where obvious jet-detachment occurs(e.g.,at high blowing ratios).While in the cases where the coolant jet fully attaches the surface (e.g., at low blowing ratios),the pulsation decreases the film cooling effectiveness.129-134In general, pulsation at high frequency helps to improve film cooling effectiveness in some but pulsation at low frequency has the opposite effect. Because the pulsation causes periodic oscillation in the boundary layer flow, the convective heat transfer is enhanced with the increase of frequency and duty cycle, which is generally detrimental to the Net-Heat-Flux-Reduction (NHFR) with some exception. For instance, Rutledge et al.135evaluated experimentally the influence of pulsation on the NHFR of film cooling, over a semi-cylindrical convex surface.Their results show that the pulsed film cooling yields worse NHFR than the steady film cooling at moderate blowing ratios. However, at high average blowing ratios beyond the optimum blowing ratio in the steady film cooling,the pulsed film cooling is found more favorable on reducing the net heat flux. Ke and Wang136,137numerically investigated the pulsed film cooling on a turbine guide vane.It is concluded that the pulsation shows distinct roles at different regions,such as the leading edge, the pressure surface and the suction surface.At the suction side,the time-averaged adiabatic film cooling effectiveness is found to be increased with the increase of blowing ratio or Strouhal number. But the convective heat transfer is also increased. As a consequence, the pulsed film cooling is suggested not suitable for application at the suction surface at higher blowing ratios. At the pressure surface, the pulsed film cooling leads to a less heat transfer when compared to the steady film cooling. It is suggested more suitable to be used on the pressure surface.

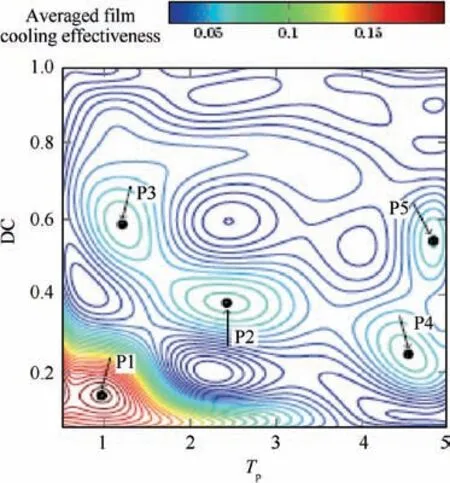

Babaee et al.138presented an optimization strategy in the pulsed film cooling. By constructing a response surface of the spatially-averaged film cooling effectiveness as a function of the main operational pulsation parameters, such as Duty Cycle (DC) and pulsation frequency or pulsation period(Tp), as demonstrated in Fig. 30,138both the global optimum point (such as P1) and local optimum points (P2-P5) are accordingly obtained.

4.2. Use of plasma actuators

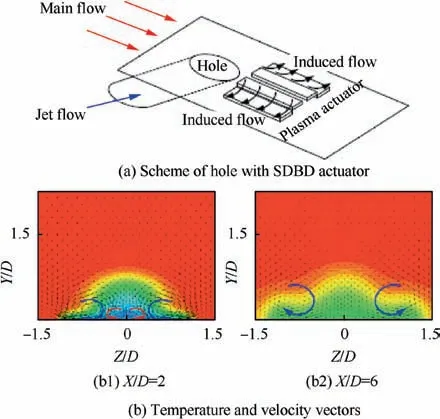

The beneficial effects of the synthetic jet actuators have been well demonstrated in active flow control. Wang and Roy139-142performed a series of numerical investigations to evaluate the use of plasma actuator on film cooling, as schematically shown in Fig. 31.140The dominant structures of the coolant could be effectively controlled to attach the film-protected surface. As a consequence, the film cooling effectiveness is significantly improved.

Fig. 30 Contours of averaged film cooling effectiveness vs duty cycle and pulsation period.138

Fig. 31 Active flow control by plasma actuator.140

Fig. 32 Effect of SDBD on cylindrical-hole film cooling.143

Fig. 33 Distribution of mean velocity magnitude in central plane.146

The use of Surface Dielectric Barrier Discharge actuators(SDBD)on enhancing the film cooling effectiveness was examined numerically by Dai143and Xiao144et al., and experimentally by Audier et al.145,146Upon the impact of the body force excited by the SDBD plasma actuator, induced flows are generated due to the electro-dynamic mechanism. These induced flows help the formation of anti-kidney vortices, as demonstrated in Fig.32143,and also the attachment of coolant jet on the surface,as demonstrated in Fig.33146(where u and ujrepresent the velocity and the jet injection velocity respectively). Subsequently, the film cooling effectiveness is improved. Meanwhile, the use of SDBD plasma actuator shows little influence on the convective heat transfer in the film cooling.145,146Of course,as the use of SDBD plasma actuators increases the adiabatic film cooling effectiveness significantly but has nearly on influence on the convective heat transfer, it is surely positive for the reduction of net heat flux.‘‘transpiration-like” cooling. Evidently, for the micro film cooling, the most serious challenge is the hole plugging problem, resulted from fine-particles deposition, thermal barrier coating spallation and imperfect manufacturing.148-150The acceptable size in the micro cooling design needs deeply assessed.

6. Conclusions

5. Some challenges in future researches

The present survey attempts to identify recent advances on the film cooling enhancement.To authors’opinion,the key mechanism of film cooling enhancement is quite well understood.However, several issues remain deeply investigated.

Firstly, the mutual interaction between the discrete jet and the mainstream is extremely complicated due to the native coherent of jet-in-crossflow.Commonly,the roles of the above film cooling enhancement strategies are tightly affected by the effects of internal coolant crossflow, streamwise pressure gradient, free-stream turbulence, surface curvature, multi-row superposition, etc. Of particular, in a highly loaded transonic turbine cascade,the combined curvature and pressure gradient effects, together with the other complex flow structures (such as passage vortex, shock, wake, etc.), make this subject extremely challenging. Therefore, for the advanced film cooling enhancement schemes, further understanding is needed about the jet-in-crossflow dynamics and film cooling characteristics in the really practical situations.

Secondly,most of currently advanced film cooling enhancement schemes is evaluated mainly in the view of film cooling effectiveness. The heat transfer coefficient, overall cooling effectiveness, and additional flow loss are rarely concerned.In the real applications, the Net-Heat-Flux-Reduction(NHFR) is an important factor. In addition, the use of these advanced film cooling enhancement schemes will alter the thermo-mechanical performance. Therefore, conjugated heat transfer analysis as well as the thermal-mechanical coupling analysis under representative engine-simulated conditions is necessary to provide more comprehensive insights into the advanced film cooling enhancement schemes.

Thirdly, the improvement in film cooling effectiveness and the reduction in aerodynamic loss generally show a competing nature. The shaped holes indeed play significantly active roles on film cooling enhancement. However, whether they are of advantages over cylindrical holes on the aerodynamic loss reduction is not convinced.With respect to each advanced film cooling enhancement scheme, multi-objective optimization is an effective means to bring out its latent film-cooling enhancement potentiality with a compromise of aerodynamic loss.Furthermore, the integrated film cooling scheme, such as the integration of shaped hole and upstream ramp, shaped hole and shallow trench, the upstream ramp and shallow trench,need extensively explored to present possible cooling configuration, approaching to the ideal cooling capacity.

Another issue needed concerns in the advanced film cooling enhancement is the concept of moving from macro to micro cooling.147Two main goals by using micro cooling concept are outlined as the follows:providing better cooling uniformity and lesser thermal gradients, as well as bring the cooling air closer to the outer film-protected surface.Possible applications of micro film cooling are the laminated cooling and the

Film cooling enhancement is a crucial necessity in the advancement of aero-engines, to satisfy the serious thermal protection requirement of hot-section components with a more limited cooling air usage.Motivated by this quite challenging requirement, vast efforts have been paid on the exploration of film cooling enhancement strategies, either in passive or in active.Although these innovative means maybe have some drawbacks involved in the real applications (due to the fabrication, additional aerodynamic losses, integrity strength, etc.), they do provide possible technological routines for overcoming the critical challenge faced in the thermal protection of hot section components.

Evidently, the feasibility of the use of the above advanced film cooling enhancement schemes in the real applications needs further assessed. It is noted that the usage of the above advanced film cooling enhancement schemes faces to some special challenges,such as the fabrication and the feasibility,especially for the active strategies. Nevertheless some of the above advanced film cooling enhancement schemes will become viable as manufacturing methods progress further, which is certainly helpful for breaking the limits of current cooling technologies.

Acknowledgments

The authors gratefully acknowledge the financial support for this project from the National Natural Science Foundation of China(Nos.U1508212 and 51706097)and National Science and Technology Major Project, China (No. 2017-III-0011-0037).

CHINESE JOURNAL OF AERONAUTICS2020年4期

CHINESE JOURNAL OF AERONAUTICS2020年4期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- Reliability and reliability sensitivity analysis of structure by combining adaptive linked importance sampling and Kriging reliability method

- Aeroelastic dynamic response of elastic aircraft with consideration of two-dimensional discrete gust excitation

- Thermal damage analysis of aircraft composite laminate suffered from lightning swept stroke and arc propagation

- An aerospace bracket designed by thermo-elastic topology optimization and manufactured by additive manufacturing

- Applications of structural efficiency assessment method on structural-mechanical characteristics integrated design in aero-engines

- An energy-based coupling degradation propagation model and its application to aviation actuationsystem