Influences of characteristic parameters on starting-up process of an arcjet thruster

Yan SHEN, Yinggang TONG, Fuzhi WEI, Zhaopu YAO, Dawei HU

a School of Aerospace and Astronautics, Sun Yet-sen University, Guangzhou 510006, China

b Lab of Space Propulsion Technology, Beijing Institute of Control Engineering, Beijing 100094, China

KEYWORDS Arc root;Arcjet;Electric propulsion;Electrode ablation;Starting-up process

Abstract Arcjet thruster has been a widely used electrical propulsion technology on GEO satellites since 1993. In its long history of technical development and commercial application, lifetime verification of an arcjet thruster is always one of the most important and expensive tasks.Considering that the main life limitation of an arcjet thruster is electrode ablation and a significant share of the total ablation happens in its starting-up process,the starting-up process is studied with arc voltage signals.Through interpretation of arc voltage signals,the transfer process of the arc root on the anode surface is identified,and ΔT(the duration of the arc root transfer process)is suggested to be a characteristic parameter for fast evaluation of lifetime assessment and design optimization for an arcjet thruster. With this criterion, the influences of typical parameters on the starting-up process are established through comparison with a benchmark parameter.According to experimental results, an increase of the gas flow will obviously reduce ΔT, while a smaller swirl aperture and a longer throat channel do not have a remarkable correlation with ΔT. Moreover, with a sample of a smaller throat diameter to increase the flow velocity, a reduction of ΔT is achieved.Meanwhile, the modifications also affect the stability of arcjet thruster operation, which is also discussed.

1. Introduction

An arc-heated thruster, or arcjet thruster, heats propellant with an arc which connects the anode and the cathode crossover a narrow channel,as shown in Fig.1.As the temperature of an arc column is much higher than typical combustion temperature of chemical propellant,the specific impulse of an arcjet thruster is usually two or three times higher than that of a chemical thruster. Thanks to its characteristics of high performance,high reliability,and good compatibility with a chemical propulsion system, a lot of research work on arcjet thrusters has been carried out since 1960s. In 1993, the first in-space application of an arcjet thruster was realized by Aerojet Rocketdyne Company on GE-Astro (now Lockheed Martin Series 7000 spacecraft bus).1Since then, more than two hundreds of MR-508/509/510 series arcjet thrusters have been installed on more than 50 satellites for north-south station keeping and east-west station keeping missions,1-4and tremendous technological and commercial successes of this technology have been demonstrated.

Fig. 1 Fundamental principle of an arcjet thruster.

In its long history of technical development and commercial application, lifetime verification of an arcjet thruster is always one of the most important and expensive tasks. For example,the aforementioned MR508/509 and MR510 series arcjet thrusters have carried out many times of life verification programs in their technical development process, and more than 1700 h were accumulated for the longest one.1,5,6Even though there has been a lot of successful in-space validation, it is always necessary to carry out a long life-verification test in many subsequent important technical variations.7A similar situation happens at BICE (Beijing Institute of Control Engineering)in recent years,as shows in Fig.2.Since 2006,an engineering model of an arcjet thruster with hydrazine propellant has been successfully developed, and a life verification program of over 800 h has completed at BICE in 2016.8,9Subsequently, some optimization for the arcjet thruster is undertaking to fulfill mission constrains, which is quite common in many projects,and many experiments are undertaking for its life-time verification.

Fig. 2 Engineering prototype of a 2 kW arcjet thruster under testing.

Many theoretical and numerical simulation works have been carried out to better understand the basic physical process of an arcjet thruster.10In some recent works, with a two-dimensional thermal and chemical nonequilibrium numerical model that incorporates the self-consistent effective binary diffusion coefficient approximation treatment of diffusion,species distributions in a low-power arcjet thruster have been well revealed, and the distributions of heavy-species temperature and velocity as well as some important chemical processes have been presented, which allow us to analyze the plasma flow features inside the thruster and their effects on the arcjet performance.11,12On the basis of the above theoretical works,experimental verification is still an indispensable means of life verification and prediction. Moreover, the effect of technical modification on the life time of an arcjet thruster could not be precisely estimated until failure happens or apparent performance degrades. That is because the main restriction mechanism of an arcjet thruster’s life is related to electrode ablation, while the inherent nature of electrode ablation for an arcjet thruster is designed to be a long-term process and difficult to quantify. In previous works, a quite firing test should be performed to evaluate the lifetime, and subsequently the ablation rate could be quantified either by weighing the electrode to get the mass loss or by the variation of the arc chamber pressure under the same operating condition.13In either way, the firing test should last a quite long duration, which is typically tens or hundreds of hours,to produce considerable ablation of the electrodes and provide a proper quantitative estimation.Although this method is effective,it is undoubtedly very expensive and time-consuming. Therefore, a cheaper and more convenient method is critically needed for life assessment and design optimization evaluation for arcjet thrusters.

Electrode ablation of an arcjet thruster happens in both the starting-up process and the steady-state operation process. In the steady-state operation process, the rate of electrode ablation is relatively stable and quantifiable, that is why many attentions focus on the starting-up process,which is often corresponding to relatively quick ablation.14Considering the starting-up process of an arcjet thruster, an arc is generated with a high-voltage discharge and develops rapidly driven by propellant flow, until the stable working state is established by a balance between the aerodynamic force and the electrodynamic force.In this paper,the correlation between the arc voltage signal and the starting-up process of an arc heated thruster is established, and the repeatability of the arc voltage signal is verified for the same thruster structure and operation parameters during the starting-up process. As the arc voltage during the starting-up process is the only signal concerned in the correlation,which is obtained in just several seconds,it is used as quick evaluation for life assessment and design optimization of the arcjet thruster.On this basis,by adjusting the characteristic parameters including flow rate,swirl aperture,throat diameter,and length of the throat channel,the influences of these parameters on the starting-up process are established, and suggestions for optimization are provided.

2. Theoretical basis and experimental design

Two modes exist in the arcjet thruster operation process,which are so called high-and low-voltage modes,and the position of the arc root attachment point on the anode determines in which mode the thruster is operating, as shown in Fig. 3.Under the high-voltage mode, the arc root is attached to the expansion section of the anode, where the gas flow is in the high-speed and low-pressure region, and the arc is dispersed at its adhesion region of the anode,which corresponds to a relatively lower heat flux density and a lower ablation rate.While under the low-voltage operation mode,the arc root is attached to the contraction section of the anode,where the gas flow is in the low-speed and high-pressure region, and the arc root is concentrated at the anode attachment point, corresponding to an extremely high heat flux density and a rapid ablation rate.15Ablation of the anode due to the concentration of heat flow is one of the most important life-constraining mechanisms of an arcjet thruster, which leads to a lot of previous works concerned on anode ablation.16-18

Therefore, all arcjet thrusters are designed to operate in a high-voltage mode during their steady-state operation process.Through proper thruster design, swirl flow stabilization, and power supply circuit and propellant feed system optimization,occurrence of a low-voltage mode for accidental disturbance during the steady-state operation process can be well limited.19-22

However, as an arcjet thruster is ignited with high-voltage Paschen breakdown,23,24an arc will firstly generate through the channel with a minimum gap and a minimum discharge potential energy. Therefore, the arc root always attaches to the contraction section of the anode, and the arcjet thruster always operate in a low-voltage, high-ablation mode at the igniting moment. Then, driven by the propellant gas flow,the arc root on the anode is pushed to the expansion section,and the arc voltage increases accordingly, until a highvoltage mode characteristic with stable running and low ablation is established.Similar processes exist in many linds of arc plasma sources.25As many experiments have verified that the anode ablates at a moderate rate under the high-voltage mode,the transition duration from the low-voltage mode to the highvoltage mode during the starting-up process has a decisive impact on the life time of an arcjet thruster.26,27According to the process described above, it is obvious that the arc root motion on the anode surface can be reasonably and adequately characterized by the arc voltage signal,as has been successfully verified and applied in previous research on an atmosphericpressure arc plasma jet.28,29

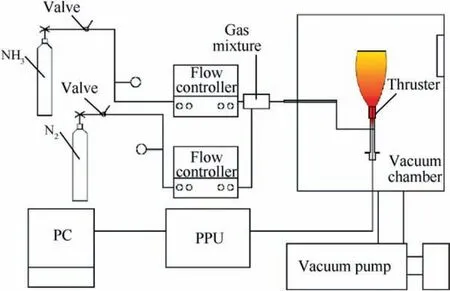

Based on these considerations, a experimental system is established as shown in Fig. 4. An arcjet thruster is operating in a vacuum chamber with 1.2 m in diameter and 1.5 m in length, which is driven by a pump assembly consisting of a mechanical pump, a Roots pump, and a thermal diffusion pump. Pressure in the vacuum chamber is sustained below 1 Pa for the operation flow rate,which is acceptable for an arcjet thruster.

In the experiment, mixture of ammonia and nitrogen in a ratio of 4:1 is used to simulate the catalytic decomposition products of hydrazine, which has been a common method in previous studies. An engineering prototype of a PPU (Power Processing Unit) is applied in the experiment. Its peak output voltage for ignition is about 6000 V, and a current-regulated output mode is adopted for its main circuit, whose no-load output voltage is 250 V.

Fig. 4 Experimental system layout for an arcjet thruster operation.

Considering that movement of the arc root attachment point from the contraction section to the expansion section of the anode is driven by the propellant gas flow, it is obvious that gas flow parameters and anode characteristic dimensions should have important influences on the transition duration from the low-voltage mode to the high-voltage mode. Therefore, through adjusting characteristic parameters related to the aerodynamic process, possible design modifications could be correlated with the mode transfer duration, thus a proper suggestion and a quick verification for the design optimization could be provided. An engineering prototype thruster is employed for the above consideration, on which an easily disassembled anode is installed, so that characteristic parameters related to the flow process, including the diameter of the swirl aperture Φs, the diameter of the anode throat Φt, and the length of the anode throat Lt,as shown in Fig.5,can be easily adjusted. The rest of the thruster is consistent with the engineering product.

3. Results and discussions

3.1. Typical arc voltage signal during starting-up process and related characteristics

Fig. 5 Characteristic parameters investigated with experimental arcjet thruster.

Fig. 6 Typical starting-up process of an arcjet thruster.

The typical starting-up process of an arcjet thruster is shown in Fig.6.At T0moment,the valve located upstream from the arcjet thruster is opened, and the simulated-hydrazine gas flow is fed to the thruster.After a few seconds at T1,as the gas flow is stabilized in the thruster, the main circuit voltage V0, which is about 250 V,is applied,and the upper limit of current is set to I1,which is about 10 A for the starting-up process.Obviously,the arcjet thruster will not be ignited until T2moment when the ignition pulse voltage VIof about 6000 V is applied. During the rising process of VI, discharge happens, and an arc generates and connects the anode and the cathode,while simultaneously the main power circuit is applied to the thruster. At this moment, the current of the thruster is regulated to I1=10 A as mentioned before,and the arc voltage V1is typically a little more than 100 V,depending on the thruster configuration and propellant flow rate.After the arc discharge maintains for several seconds and reaches a stable state,at T3moment,the PPU is switched to a 2000 W power-regulate mode,and the current rises to I2, which is about 18 A, while the voltage decreases slightly to V2. This is the so-called starting-up process of an arcjet thruster, and the time interval of typically less than 1 s from T2moment is especially concerned,as it is corresponding to the arc root transfer duration from the contraction region to the expansion region on the anode.

Fig. 7 Typical arcjet thruster starting-up process obtained in experiment.

A typical arc voltage signal during the thruster starting-up process is shown in Fig.7(a),with an engineering arcjet thruster and liquid hydrazine propellant, which is consistent with that in Fig.6.In Fig.7(a),it can be clearly identified that point A corresponds to T2in Fig.6,and point B corresponds to T3in Fig. 6. By further expansion of the data near point A at T2moment, as shown in Fig. 7(b), the arc root transfer process in the arcjet thruster is clearly revealed,where the arcjet thruster is broken down with a high-voltage pulse, which instantaneously drops from a high-voltage peak of several thousand volts to tens of volts. At this moment, the attachment point of the arc root on the anode locates at the contraction section of the anode. Furthermore, driven by an aerodynamic force,the arc root moves downstream to the anode throat or the expansion section, and the voltage rises simultaneously to above 100 V,which will happen in a time interval ΔT from tens of milliseconds to several seconds, depending on the thruster configuration and operating parameters, which is correlated in the next section.

3.2. Preliminary experiments, improvements, and signal repeatability

Different from anticipated, the arc voltage obtained with the NH3and N2mixture propellant is not always regular and repeatable as shown in Fig.7,but quite possibly accompanied by irregular oscillations in some cases,as shown in Fig.8.This phenomenon means that the movement of the arc root on the anode surface during the starting-up process is not a monotonous downstream process, but accompanied by a random jump including an upstream direction in the contraction section or throat channel, that is, the process of internal rebreakdown. The mechanism of its occurrence is related to the state of electrode surface and pressure equilibrium establishment process for a thruster from cold gas flow to thermal arc flow during starting-up.

Fig.8 Arc voltage and current with irregular oscillations during starting-up process.

Therefore, we reviewed the differences between the simulated experiments setup and engineering prototype verification tests with liquid hydrazine propellants. During the starting-up process of an arcjet thruster, the pressure in the discharge chamber of the thruster increases due to the heating effect of the arc,which is alike for both simulated experiments and engineering prototype operations.However,for engineering prototype operations, incompressible liquid propellant is fed in the pipeline, and therefore the initial pressure equilibrium establishment process is only related with the volume of the gas generator and the thruster, whereas in simulation experiments,compressible cold gas mixture of N2and NH3is fed and controlled by a flow controller in the pipeline, which means that the initial pressure equilibrium establishment process is related with all of the volume downstream from the flow controller.Therefore, the initial pressure equilibrium establishment process takes a longer duration in simulation experiments, which introduces unwanted uncertainties.

According to the above consideration, a throttle orifice of about φ0.4 mm is installed at the inlet connecter of the thruster to increase the pressure of the gas pipeline and suppress irregular arc voltage oscillations,which is closer to engineering prototype operation conditions and functions quite well in the following experiments. In the following discussions, all results are obtained with the throttle orifice if not being specified.

Moreover,even though the throttle orifice is installed,irregular arc voltage oscillations still occur in a few cases during the starting-up process. While acknowledging the difference between simulated experiments and engineering prototype operations,we believe that the occurrence of irregular arc voltage oscillations means lower arc stability for its corresponding feature structure.

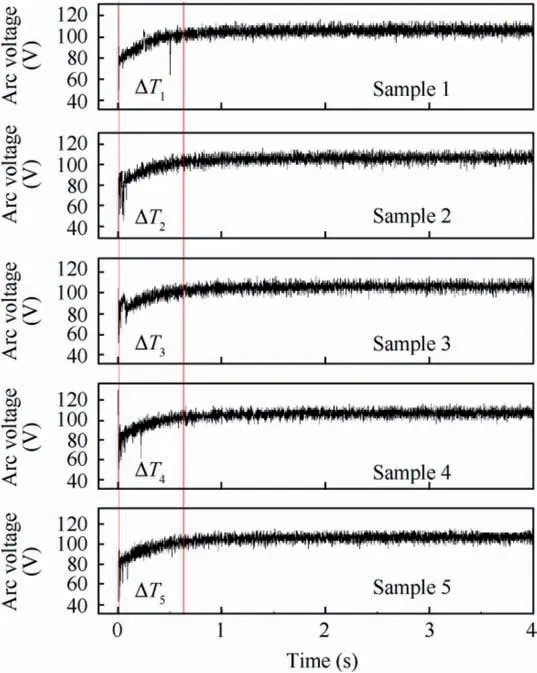

Another factor that should be considered is the signal repeatability,for the characteristics of the random distribution of arc root attachment points on the surface of the anode at the ignition moment. At least 10 ignitions under each condition is performed in the following experiments to verify the possible effects of the random distribution of arc attachment points on the anode surface. Fig. 9 shows five randomly selected ignition processes under definite operating parameters and structural configurations. Generally, the transfer time of an arc at an anode attachment point is highly consistent under a definite condition,that is to say,the randomness of the initial position of the arc attachment point has very little impact on the transfer time,and we simply ignore this impact of the random initial distribution of the arc root in the following discussion.

Fig. 9 Randomly selected ignition processes under a typical operation condition.

3.3. Characteristic transfer time under different structure parameters

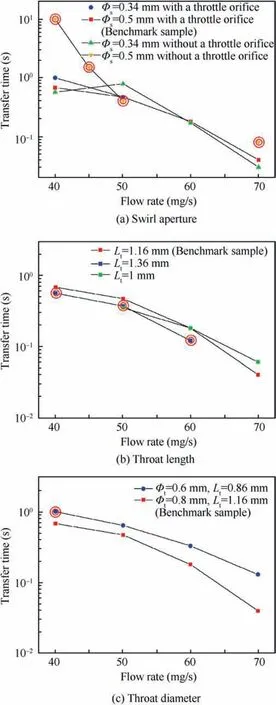

Since the transfer duration of the arc root in the starting-up process is mainly related to the aerodynamic process,it is natural that the gas feeding parameter and the characteristic structure of the anode, including flow rate, swirl aperture,throat channel diameter, and length are introduced as the experimental variables. For convenience of comparison, a thruster with a throat diameter Φtof 0.8 mm, a throat length Ltof 1.16 mm, and a swirl aperture Φsof 0.5 mm is selected as the benchmark,and in all the experimental results,we label a symbol ‘‘◎” for cases with irregular arc voltage oscillations happening.

The first factor is obviously the gas flow rate,and therefore tests with a flowrate range from 40 mg to 70 mg and an interval of 10 mg are performed for all the structural dimensions mentioned below, and typical results are shown in Fig. 10.From Fig. 10, we can find that the arc root transfer duration decreases rapidly with an increase of the flow rate,while a voltage oscillation in the starting-up process is more likely to occur at a low flow rate. This is obvious and easy to understand: a longer arc root transfer duration at a low flow rate should subject to an insufficient aerodynamic force for an arc root motion,whereas a higher flow rate will lead to a higher restrike energy potential, which leads to better arc stability.

Fig. 10 Arc root transfer time under different structure parameters.

The next characteristic considered is the swirl aperture.Experimental results of the same thruster with swirl apertures of Φs=0.34 mm and Φs=0.5 mm installed, respectively, are shown in Fig.10(a),from which we can find that the variant of swirl aperture dimension has a poor influence on the arc root transfer duration,whereas a smaller aperture seems to be helpful to restrain voltage oscillations.This phenomenon should be attribute to the higher inlet pressure and swirl intensity achieved with the smaller swirl aperture.

The next characteristic considered is the throat length Ltof the anode,and a sample with Lt=1.36 mm is compared with the benchmark product, as shown in Fig. 10(b). Logically, a longer throat channel means a longer arc root transfer distance, which should prolong the arc root transfer duration.On the other hand, a higher arc voltage is expected to achieve a better efficiency and a steady-state ablation rate of electrodes for the steady operation process with a relatively lower arc current at the same input power, which could be achieved by increasing Lt. Therefore, if the arc root transfer duration is not affected obviously, the throat length should be increased as long as possible. However, from Fig. 10(b), we find that although the arc root transfer duration is not obviously increased with an increase of the throat length,the initial voltage oscillation is increasing, which is obviously not a positive phenomenon for the stability of the thruster. The increasing initial voltage oscillation can be attributed to higher arc voltages caused by a prolonged channel which will be beneficial for overcoming the arc restrike potential.

The next feature considered is the throat diameter Φtof the anode,whose experimental results are shown in Fig.10(c).It is natural to think that a smaller throat diameter leads to a faster gas velocity in the throat channel, and therefore a shorter arc root transfer duration can be expected. The sample with a throat diameter of Φt=0.8 mm is chosen as the benchmark as previously mentioned and compared with an anode with a throat diameter of Φt=0.6 mm. Because of errors due to the mechanical process, the actual throat length of the Φt=0.6 mm sample is 1.23 mm. Experimental results show that with this structure, the initial voltage oscillation is much more remarkable. Therefore, the length of the throat channel is reduced to 0.86 mm for another sample of a Φt=0.6 mm throat channel, and results are shown in Fig. 10(c). Although a reduction of the transfer time is due to the coupling effects of the throat length and the throat diameter,we still think that a reduction of the throat diameter is conducive to a reduction of the transfer time through comparison with the results in Fig. 10(b). Moreover, in low-flowrate conditions, the arc voltage of the sample with Φt=0.6 mm tends to be accompanied by a more obvious initial voltage oscillation. We can attribute the increase of arc voltage oscillation to the fact that a smaller throat diameter leads to a higher arc chamber pressure, which results in a higher arc voltage and a higher possibility of arc restrike. In summary, the throat diameter is closely related to the arc root transfer time and initial voltage oscillation, and we should be very cautious to determine this dimension.

4. Conclusions

In the starting-up process of an arcjet thruster, the transition duration from a low-voltage mode to a high-voltage mode,which corresponds to the arc root movement on the anode surface,has an important impact on the anode ablation rate,and thereafter the thruster lifetime. In this paper, the following conclusions are obtained:

(1) A correlation between the arc voltage signal and the arc root movement on the anode surface during the startingup process of an arcjet thruster is established. Through interpretation of arc voltage signals, the transfer time of the arc root on the anode surface can be clearly identified.

(2) The transfer time of the arc root on the anode surface,or ΔT, is highly consistent under a definite condition,which makes it possible to be introduced as a parameter for fast evaluation of lifetime assessment and design optimization for an arcjet thruster.

(3) Using ΔT as a criterion,the influences of typical parameters on the starting-up process are established through comparison with a benchmark parameter. An increase of the gas flow will obviously reduce the arc root transfer duration in all experiments. A sample with a smaller swirl aperture does not have a remarkable correlation with ΔT. A longer throat channel tends to have a negative impact on the arcjet thruster operation stability,although a relatively lower arc current could be achieved with this configuration. Moreover, with a sample of a smaller throat diameter, a variation of the arc root transfer duration is observed,and a relatively lower stability is accompanied.

Acknowledgements

The authors are grateful to Prof. Jinsong GONG at Tsinghua University for his generous help in experimental establishment.This study was co-supported by the Defense Industrial Technology Development Program, China (No. JCKY2018203B029),and the National Natural Science Foundation of China (No.11702021).

CHINESE JOURNAL OF AERONAUTICS2020年12期

CHINESE JOURNAL OF AERONAUTICS2020年12期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- Design and experimental study of a new flapping wing rotor micro aerial vehicle

- CFD/CSD-based flutter prediction method for experimental models in a transonic wind tunnel with porous wall

- Prediction of pilot workload in helicopter landing after one engine failure

- Study of riblet drag reduction for an infinite span wing with different sweep angles

- Modulation of driving signals in flow control over an airfoil with synthetic jet

- Strong interactions of incident shock wave with boundary layer along compression corner