Construction Analysis of Urban Underground Comprehensive Pipe Corridor Structure

Wang Zhen

(Hunan Sixth Engineering Co.,LTD,Changsha,Hunan 410015)

Abstract:With the development of social economy,the scale of cities has been expanding and various infrastructures are increasing.In order to beautify the city and save limited urban space,many cities have transferred the underground lines to the underground,but the various lines are increasing day by day,and the structure of the underground pipe network is becoming more and more complicated,which has created great difficulties to the construction of underground tunnel.This paper briefly describes the structural characteristics of urban underground integrated pipe gallery,and analyzes its construction points with examples to provide reference for relevant workers.

Keywords:city;underground integrated pipe gallery;construction key points

In recent years,with the growth of the national economic strength,the urban population is increasing,and the scale of the city is growing.As the infrastructure of the city and the construction of municipal roads,we should pay attention to the construction of road pipelines,further improve the comprehensive utilization rate of urban land,promote mutual cooperation between different industries,and achieve higher social benefits.Therefore,it is of great practical significance to study and analyze the installation and construction points of communication pipelines in municipal road construction.

I.Overview of Urban Underground Integrated Pipe Gallery

(i) Underground Integrated Pipe Gallery Structure

Figure 1 Schematic Diagram of Section Structure of Comprehensive Pipe Gallery in a City

1.The body of the pipe gallery.The urban underground integrated pipe gallery is essentially an underground reinforced concrete structure,which is constructed by on-site pouring or prefabrication.Its main function is to carry the various developments required by the city and the daily needs of the residents.

2.Pipeline.The urban underground integrated pipe gallery not only includes the comprehensive pipelines of electricity,gas,water supply and drainage required by urban residents,but also various pipelines that may be needed in the future development of cities such as communications and networks.

3.Monitoring system.The monitoring system mainly monitors the environment in the underground integrated pipe gallery,collects the environmental parameter information such as temperature,humidity and gas concentration of the underground integrated pipe gallery,and feeds back to the relevant management personnel to provide a basis for judging whether the pipe gallery has potential safety hazards.

4.Ventilation system.In order to ensure the life safety of the relevant construction personnel and improve the service life of the pipelines during the laying of urban underground integrated pipe corridors,mechanical ventilation measures are often used to ensure the air flow in the pipe corridor.

5.Drainage system.The urban underground integrated pipe gallery is located in the underground of the city.The environment is relatively complex.It may be affected by rainwater,groundwater,etc.,and water seepage problems occur.In order to avoid the accumulation of water in the underground integrated pipe gallery,all kinds of pipelines may fail,and perfect drainage system should be established.[1]

(ii) Advantages of Urban Underground Integrated Pipe Gallery

1.Saving urban space.Through the construction of the underground integrated pipe gallery,the comprehensive arrangement of various types of infrastructure pipelines required for urban development and daily life of the residents has been realized,which not only effectively reduced the construction of urban ground space cables,telephone poles and other facilities,but also improved the urban land.Comprehensive utilization,and avoiding repeated road excavation construction,reducing the impact on urban ground transportation and beautifying the urban environment.

2.Effectively protect all types of pipelines.The underground comprehensive pipe gallery is used to realize the comprehensive arrangement of various pipelines,which effectively reduces the influence of external factors on the pipeline.Even if large-scale geological disasters such as earthquakes occur,the underground integrated pipe gallery can play a higher pipeline protection role.In addition,the construction of underground integrated pipe corridors has reduced the construction of ground structures such as ground electric poles and elevated towers,avoiding secondary personnel injuries and property losses caused by breakage and dumping.

II.Problems in the Construction of Urban Underground Integrated Pipe Gallery Structure

(i) Line Planning is Risky

For the city,the construction of underground integrated pipe gallery is a one-time construction project.Therefore,higher requirements are put forward for relevant designers.It is necessary to accurately predict the development of the city's scale,economy and population based on the long-term development of the city.Ensuring sufficient space to meet the future development needs of the city and avoiding waste of resources caused by repeated construction.In addition,in the construction process of underground integrated pipe gallery,it may affect the original buildings and pipelines of the city,and it is necessary to minimize this impact through reasonable design and construction organization.[2]

(ii)Requiring a lot of Money Investment

In order to make better use of the role of urban underground integrated pipe corridors,it is necessary to realize the network coverage of underground integrated pipe corridors,which is inseparable from the investment of a large amount of funds.As one of the urban infrastructures,most of the underground integrated pipe corridors rely on the government's financial support or other financing policies.It is easy to have funding problems during the construction phase and affect the smooth progress of the construction.

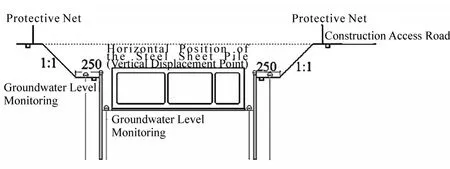

Figure 2 Schematic Diagram of the Foundation Pit Monitoring of the Underground Integrated Pipe Gallery

(iii) Construction Quality Requirements are High

The underground integrated pipe gallery belongs to the whole underground structure mode.The environment is very susceptible to groundwater,rainwater,etc.For example,communication,fiber optics and other pipelines have higher requirements for waterproofing and moisture protection.This requires the relevant construction units to pay attention to the on-site construction supervision and management during the construction phase,and adopt effective waterproof and moisture-proof measures to improve the construction quality and extend the service life of the underground comprehensive management.

III.Case Analysis—Main Points of Construction of Urban Underground Integrated Pipe Gallery Structure

The first phase of the underground comprehensive pipe gallery project of a city,with a total length of 5,500 m,the underground integrated pipe gallery has a structural size of 14 m×4.3 m and a covered soil thickness of 2.5 m.From the left to the right,the underground integrated pipe gallery is a heating cabin,a water supply tank and a power communication warehouse.The engineering ventilation section is 200 meters and the mechanical ventilation mode is used.[3]

(i) Foundation Pit Excavation

Combined with the actual situation of the project,the foundation pit excavation construction was carried out by means of construction methods of precipitation and grading excavation,and a reverse circulation drilling rig with a well depth of 14 m and a spacing of 5 m was installed on both sides of the foundation pit to draw a water well.During the earth excavation process,the excavation is carried out in a layered and segmented manner.With the entry of the excavation depth,effective support measures are taken to ensure the stability of the slope.The excavation of the project is too deep,and the foundation pit is excavated with a 1:2 and 1:1.25 grading plus step(three and grading),and the mechanical excavation is manually matched and leveled.The reserved working width on both sides of the base groove shall not be less than 100cm.The excavation soil layer of this project is backfilled,and at the same time,in order to protect the base,the mechanical work is excavated to 20cm on the base to stop,and the 20cm thick is manually flattened.

During the excavation of the foundation pit,a complete monitoring system is also needed to ensure the safety of the foundation pit excavation construction.The specific monitoring is shown in Figure 2.

(ii) Steel Processing and Installation

According to the design drawings of the underground integrated pipe gallery structure,the various types of steel bars required are processed.The fin-ished steel bars are installed before construction.Since the protective layer of the steel bars is related to the durability of the entire integrated pipe gallery structure,the installation and welding should be carried out in the order from bottom to top,and the plum-shaped concrete high-strength blocks are used.Protect the steel bars.

(iii) Template Processing and Installation

In combination with the actual situation of the project,the qualitative steel template system of 9015,6015 and 3015 is used for template installation and construction.During the template installation process,the following points should be noted.

1.Double-sided adhesive should be used for uniform bonding at the interface of the template flange to avoid the problem of slurry leakage;

2.The inside of the whole steel mold needs to be evenly coated with the release agent so as to release the mold later,and avoid affecting the pouring quality of the concrete.

(iv) Concrete Pouring

This project uses commercial concrete for layered pouring construction,and the height of each layer is 30cm.In the pouring process,combined with the thickness of the underground integrated pipe gallery structure,the bottom plate is poured three times.When the concrete is poured to the structural center line,the water stop belt needs to be lifted at a 45-degree angle,and fully vibrated and compacted,and then loosened.Use a water hose and tap gently with a wooden hammer.Finally,the pouring of the concrete above the floor is completed.After the pouring construction,cover the geotextile and sprinkle water for at least 14 days.

(v) Foundation Pit Backfill

For the gap between the outer side of the underground integrated pipe gallery and the retaining mechanism,the top of the main structure is backfilled with white ash soil.During the backfilling of the foundation pit,it should be ensured that no stones,gravel or organic matter are contained in the backfill.For some narrow gaps,manual backfilling can be used.The entire backfilling construction is treated by layered tamping,and the thickness of each layer is not more than 30cm.

(vi) Waterproof Construction

Since the underground integrated pipe gallery of the project is underground and the depth is more than 2.5m,effective waterproof measures should be taken to extend the service life of the underground integrated pipe gallery.

1.Choice of waterproof materials.In order to improve the waterproof performance of the overall structure,the three-section water-stopping rod material model external wall template tie rod is adopted,and the waterproof coiled material adopts selfadhesive polymer modified asphalt waterproofing membrane with high strength and high stability.

2.Grassroots processing.The base layer needs to be cleaned before waterproof construction to ensure that the surface is smooth,flat and free of foreign matter.Then,according to the structural outline of the underground integrated pipe gallery,the waterproof coiled material is laid,and the paving is affixed with a single side,and the overlapping width is 10 cm.

3.Node enhancement processing.For areas with broken joints,a layer of 100cm wide reinforcement is added to improve the waterproof performance.

4.Construction of water stop steel plate.The lower edge of the water-stopping steel plate is fixed on the three-section water-stopping rod,and the two ends are fixed by the standing steel bars,one at a distance of 1 m to avoid displacement when pouring concrete.

5.During the construction process,the steel edge waterstop should pay attention to the temperature control.If the steel plate mold is opened,there is a phenomenon of warping in some places,and the glue should be used for bonding when the temperature drops;if there is a large area of warping Or if the welding is not in place,the raw material at the joint is cleaned and re-docked.

6.In order to improve the waterproof effect,the two-component polysulfide sealant is used to seal the outer wall water-stopping rod,which is itself a flexible material and does not cause damage to the outer wall waterproofing membrane.

IV.Conclusion

In summary,with the rapid development of the city,various types of pipelines are increasing,which brings convenience to people's lives,and also causes the city to be surrounded by various types of pipelines,seriously affecting the beauty of the city.The construction of the underground integrated pipe gallery has effectively solved this problem and realized the comprehensive arrangement of various types of pipelines.Therefore,relevant workers must pay attention to the research on underground integrated pipe gallery construction technology,actively introduce new technologies and new materials,improve the management and maintenance efficiency of underground integrated pipe corridors,extend the service life of various pipelines,and further promote the modernization of the city.