Status Analysis and Improvement of Heavy Material Logistics Robots

Xu Yifei

(School of Industrial Engineering,Southeastern University,Nanjing,Jiangsu 210096)

Abstract:Many heavy materials are now undergoing intelligent logistics and warehousing transformation.However,there are not many research materials on the intelligentization of heavy materials logistics,and most of the logistics of heavy materials are transported by special lines,which affects the efficiency of heavy materials logistics.The main factors are mainly concentrated in the two aspects of warehousing and distribution.In warehousing and distribution,the core of automation and intelligent implementation is AGV and RCS system for AGV scheduling.This paper will analyze the status quo of logistics robots through the status quo of power and water intelligent warehouses,and propose some improvement ideas.

Keywords:heavy materials;intelligent;robot;RCS system

I.Status Analysis of Hardware in Heavy Material Logistics Robots

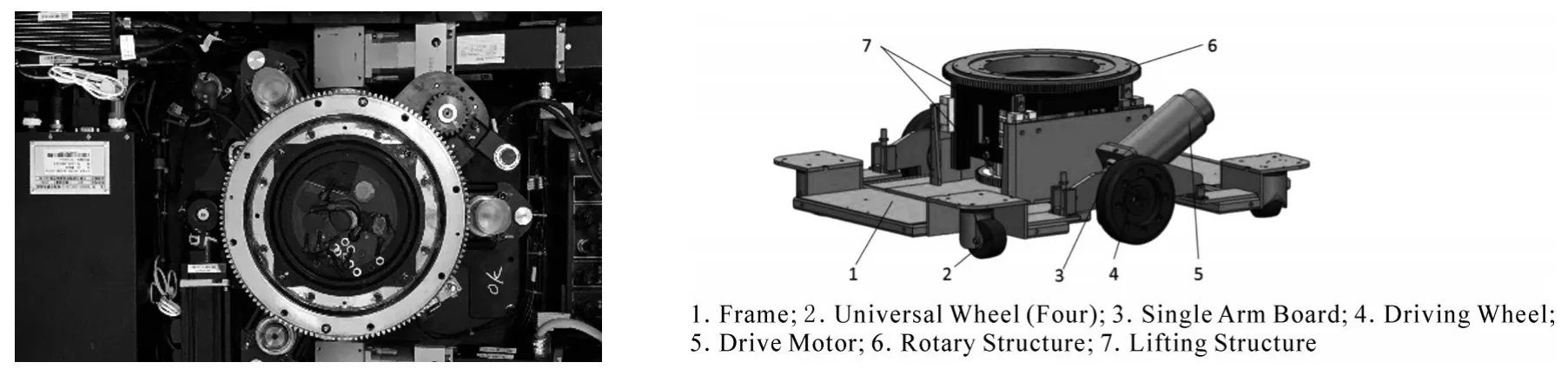

The main type of logistics robot is the automatic path finding vehicle,which is the AGV.The AGV mainly performs one operation,three actions,namely handling,moving,lifting and lowering three actions.After actually disassembling the robots of the two warehouses and reading the design specifications,the basic structure of the AGV was initially drawn:the main board,the power system,the steering system,the lifting system,the identification system,the power supply system,the communication system,and the alarm system.Many AGVs have many more advanced and complex features,but these eight parts are essential.Here mainly analyze two systems,one is the lifting system,and the other is the identification system.The main components of the AGV are shown below.

AGV Structure Diagram

There are three main types of lifting systems,namely rack-and-pinion,hydraulic,and motor.In essence,the lifting system is an automatic jack.The hydraulic type has been popular.However,due to the long-term lifting of heavy materials,the hydraulic lifting system is prone to oil leakage.Due to the relatively complicated structure and inconvenient maintenance,the oil is difficult to clean.The mainstream lifting systems are now both rack and motor.

The type of recognition system will change with the path.There are three mainstream types:optical path recognition,two-dimensional code path recognition,and stereo path recognition.Optical path recognition is essentially a path finding vehicle that finds paths by identifying lines with different colors on the ground,so the identification method is through optical sensors.The characteristic of this identification method is that the route is relatively fixed,so the operation hinder is less,but also because the route is fixed,the occupied area will become larger.Moreover,when there are too manymaterials,multipleAGVsoccupyingthe same channel will produce AGVs waiting to be stranded.

QR recognition can divide the entire AGV running area into points by two-dimensional code.For example,a two-dimensional code is set every 3m in the horizontal direction,then a 15m×15m area can be divided into 36 points because it is scanned by two.The dimension code is fixed,so the method of identification is through the camera.This identification method is characterized by accurate positioning and flexible change of route,but requires high recognition ability,and the efficiency will vary with path planning and program algorithms.

Stereo path recognition is a recognition method that relies on RFID technology.It is suitable for three-dimensional shelves with few layers(the stacker is generally used when there are many layers).The shelves themselves have tracks and elevators,and the tracks of AGV tracks and elevators.The horizontal and vertical and vertical continuous barcodes are attached,so the identification method is an RFID scanner.The identification method is mainly applied to the AGV of the fourway shuttle.The four-way shuttle can realize the orbital operation in different directions through two sets of mutually perpendicular wheels,so there is no steering system,but the direction change must be in the lateral track and the longitudinal track.The intersection point,so the method combines the characteristics of the first two methods to a certain extent,the route is relatively fixed,but it is also affected by the path planning and program algorithms.In addition,the track makes the method run more quickly and smoothly,and the three-dimensional shelf also greatly improves the space utilization.[1]

In the environment where the research object is heavy materials,the problem will be different.Firstly,the speed should be slow down,and the speed advantage on the track will not exist;secondly,because the running speed decreases,the waiting time will be longer;thirdly,when the steering occurs,the gear will be more loaded,reducing the service life of the gear;finally,when turning,it will rub against the identification mark on the ground or the identification mark such as the QR code.In the case of high load,it is easy to wear out the identification,affecting the accuracy of identification,or even causing AGV stagnation due to unidentification.

II.AnalysisoftheCurrentStatusof Heavy Material Logistics Robots

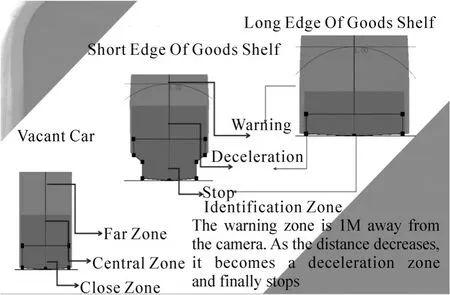

Heavy-duty logistics robots are affected by the working environment.First,the wheels are relatively small.One can limit the speed,and the second is more powerful.Secondly,the running surfaces such as the ground and the track are more demanded,because once the bumps occur,not only will the AGV be damaged.There will be great security risks,although there are studies on AGV in an unstable environment[2],but heavy material warehouses are not allowed to be built during construction;then some models of AGVs such as partial piggyback AGVs If the work is carried out on the shelf or the bottom of the pallet,then the area is smaller than the items being transported,and the observation and warning area can only exist directly in front,as shown in the following figure.

AGV Early Warning Area Identification Map

It can also be seen from the above figure that the warning area does not completely cover one side of the shelf.In the actual test,when the person places the hand or foot on the oblique upper side of the AGV,the AGV empty car will ignore the obstacles at a close distance and continue to advance.The AGV carrying the shelf did not know that the shelf hit the obstacle and moved on.Although automated warehouses generally do not allow personnel to enter the AGV operating area,there are potential safety hazards when some shelves are tilted or misplaced.

Then there is the route planning problem at runtime.Here,the AGV that uses the two-dimensional code identification path is more flexible for the route and the path planning is relatively high.First,when the warehousing or distribution task is issued,the AGV will bind the corresponding task,and the route will be planned together.Here we need to explain the characteristics of heavy materials.For heavy materials,such as electric power materials,based on the construction project,then there will be a high probability that a batch of materials corresponding to a project will be together,so these materials are stored.The locations are also grouped together.For example,there are two projects A and B.The material batches a corresponding to the A project are all stored in the area 1,and the material batches b corresponding to the B items are all stored in the area 2,corresponding to the areas a and b.The supplies are exactly the same,with Zone 1 inside and Zone 2 out.Due to the different scale and construction time of the project,the phenomenon of demanding materials at the same time for different projects is quite normal.However,according to the principle of first-in,first-out,after the two tasks are released,the system will automatically assign the route.The batch is a priority,so the priority is planned.However,because the material is in the inside,the b material must coincide with a on the shortest path.The system will re-route the AGV that transports the batch b.If the AGV of the batch b is two,then the two paths will have a considerable overlap.If the two meet,then the latter one The Taiwan will re-plan the route because of obstacles detected in the front,which will produce a phenomenon.The path distance has not changed,and the number of AGV turns has increased greatly.For the AGV with lower priority,the route cannot be in conflict with the previous AGV.The system will not be reallocated when the AGV fault in the forward position is temporarily unavailable.Secondly,for the same batch of AGV,because the path repeats more,the encounter is very normal.When the directions belong to the same direction,the latter AGV will be re-planned,and even two AGVs will be re-planned at the same time.Finally,when there are many tasks and the path cannot be planned without conflict,then there will be a case where one batch is completed first and then the next batch is executed.As shown below.

AGV Path Map

If you take the route below,you only need to turn once,but the route above is the same length but needs to turn seven times.As mentioned above,the steering will cause two problems,one will reduce the gear life and the other will damage the identification mark.These two points are especially evident when handling heavy materials.

III.Improved Ideas for Heavy Materials Logistics Robots

The first is the hardware changes,here mainly to improve on two points,one is fixed measures,and the other is early warning system.Most AGVs do not have fixed measures,as do heavy-duty materials AGV,which further limits the speed of the AGV.However,one of the characteristics of heavy materials is that they have a large number of metal components,and because of the excessive quality,steel pallets and high-strength plastic pallets are generally not used for wooden pallets,and both steel pallets and high-strength plastic pallets must be There is a uniform standard so that the groove can be mounted on the lift panel of the AGV.For steel pallets with more steel originals,an electromagnetic switch can be installed on the lift panel.When the lift is in the lift state,the switch is energized,and the panel and the tray are fixed by magnetic force.By fixing,on the one hand,the AGV running speed can be appropriately increased,and on the other hand,when the obstacle described above is present but the AGV continues to advance,the damage can be reduced to some extent.In addition,there is the existence of a pallet-free AGV,but for heavy materials,too many moving parts can affect the service life,so it is not a priority.

For the early warning system,some AGVs have been improved,such as increasing the number of cameras.Here,one of them is listed by hand,as shown in the following figure.In addition to the camera,the sonar system is used for positioning to make obstacles.The detection range is more extensive.

AGV Identification System Schematic

However,for the field of view above the AGV,the AGV is always unavailable,especially when there are items on it,it is impossible to observe the above situation.It is very difficult for a single AGV to obtain an object with a larger area than its own lifting panel.Therefore,for an early warning system,when the AGV can share the vision to a certain extent,it will reduce the vision of the AGV.Blind areas,and blind spots will decrease as the number of AGVs operating simultaneously increases.

Finally,the changes to the AGV path algorithm.As mentioned above,heavy materials are linked to the project,and the project will naturally pass the process of bidding and bidding.Therefore,heavy-duty material manufacturers often do not produce or prepare large quantities of stock in advance,because heavy losses will result in large losses once the bid is unsuccessful.The warehousing and distribution will not be the same as the common consumer goods such as clothing,snacks,and washing supplies.Items arriving on the same day are of the same priority.In addition to the above-mentioned priority in time,there is sometimes a priority caused by the regional level,so the heavy material logistics AGV algorithm considers many more factors than the normal AGV,and there is a limitation that the system is updated and changed.The speed is very slow,and changes will occur.As mentioned above,these frameworks and priorities have not changed.Therefore,the path planning of the AGV cannot change the priority of the system.Therefore,with various limitations,many factors considered by algorithms such as heuristics need not be considered.Therefore,two ideas are proposed here,one is to change the priority object,and the other is to add a path.

The priority of the system cannot be changed,but the priority of the system is for materials,and the AGV has its own independent RCS system.Although the RCS system serves the WCS system,the RCS system can change the priority of the AGV.For example,there are 10 AGV numbers 0-9,the 0 machine has the highest priority,and the 9th machine has the lowest.When multiple tasks occur,the RCS system has a low priority AGV to perform the high priority task in the WCS system.The path of the low priority AGV will be planned first,but the high priority AGV can use the same path.According to the above examples of the A project and the B project,The low-priority AGV No.9 takes out one material from the area 1 in the relative inside position,while the high-priority AGV No.0 takes out one material from the area 2 in the relative outside position.Both vehicles need to return in the original road,then AGV No.0,who is operating in the outer region 2,will probably finish the operation and return first.AGV No.9 will not encounter obstacles when returning.Even if obstacles are encountered,it will be AGV No.9 that will carry out path planning again without the need for AGV No.0 to abandon the nearest route,as shown in the following figure.

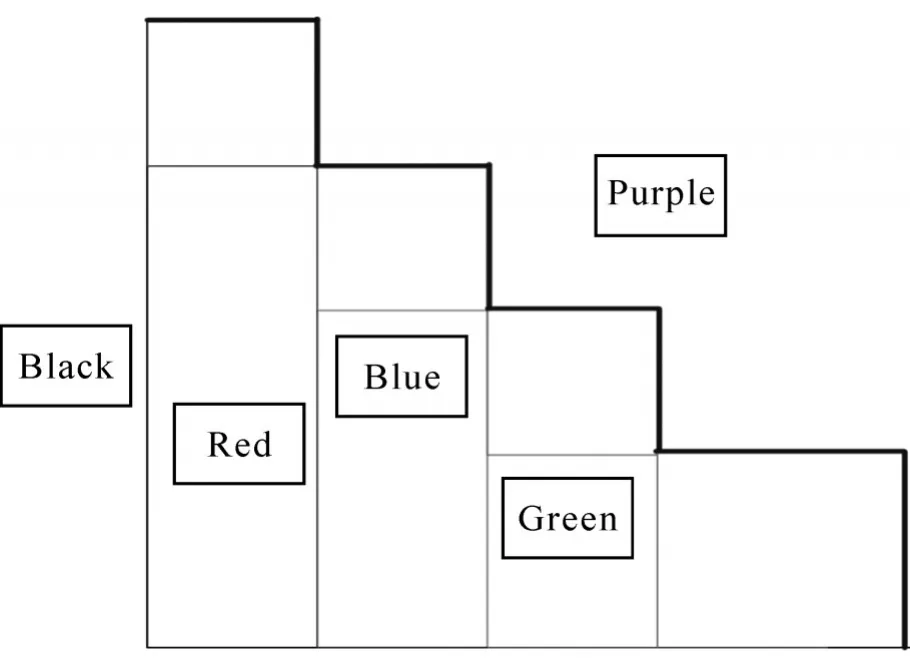

AGV Path Map after Changing RCS Priority

In the figure,the black,red,blue,and green colors are the AGV path maps whose priority is successively decreased,and the purple color is the route taken by the AGV using the black route when the priority is not changed.It can be found here that as the priority of the AGV in the RCS system increases,the number of steerings in the AGV route will decrease.Here,it is shown that each low-priority AGV will collide with the high-priority AGV,that is,the worst.In the case,the ideal situation is that all AGVs do not conflict(all low-priority AGVs do not encounter high-priority AGVs that are in the process of returning),so for the above figure,all AGVs can Work on a black route.However,according to the current algorithm,all AGVs have the same priority,and the path plan is based on the priority in the WCS system.Then the black route will turn into a purple route,and the parts covered by the color will all change and turn.The number of times has increased greatly,and when the line cannot be duplicated,the storage and distribution of some items will be suspended.[3]

The method of adding a path is actually similar to the emergency stop on the highway,adding a path as an emergency stop.The emergency stop path is not in the path planning of the system,so the system can ignore the duplicate path when planning the path.When the two AGVs have a path conflict,the AGV with the lower priority of the task batch trans-lates directly to the side to the emergency stop path.The AGV with the higher priority of the task can continue to work after returning to the original path.

IV.Conclusion

For the current situation of heavy-duty logistics robots,overall,low-efficiency automation can be achieved.As an example of the top three national networks of the world's top 500,its automated warehouses have first-class equipment but the actual efficiency is not high.More often,the forklift is skilled in the work,because it takes about 3 to 5 minutes for a forklift worker to fork a material from the warehouse to the truck,and 10 to 15 minutes for an AGV to work,so a phenomenon occurs.The outbound delivery business uses forklifts in order not to wait for the trucks of the project.The AGV,including the forklift model AGV,is only used to transport the reserved materials to the turnover area and the waiting area,and to transport the materials to be accessed to the flat area or the shelves.Therefore,the part of the automatic operation is mainly reflected in 24 hours.The materials to be stored are intermittently transported to the storage area.Therefore,if the operating efficiency of the AGV can be doubled,the full automation and intelligence of the heavy material logistics is reliable,and the main reason that affects the efficiency of the AGV is not the AGV hardware but the operating restrictions of the system on the AGV.