Discussion on Construction Quality Problems and Control of Sewage Disposal Plant

Fan Tengfei

(The Second Engineering Co.,LTD of China Railway First Engineering Group,Tangshan,Hebei 063004)

Abstract:This paper takes the construction quality control of Changchun north suburb sewage treatment plant as an example,and analyzes and summarizes the quality control of hydraulic structure seepage prevention,unbonded prestress concrete water tank,and heterogeneous hydraulic structure construction,hoping to provide experience for the same type of project construction.

Keywords:quality control;seepage prevention;prestress;special-shaped

Changchun north suburb sewage treatment plant is the largest sewage treatment project in northeast China.After completion,the project will treat 780,000 tons of domestic sewage per day,and the sewage treatment and discharge standard will be the highest in China(level A).The hydraulic structures in this project have high requirements for construction process design and control,and their spatial location,reserved holes and embedded parts have high requirements for accuracy.By analyzing the key points and difficulties in the civil construction of this project,the corresponding measures are taken for the key links prone to quality defects to ensure the excellence of the project.

I.The Quality Problems should be Critically Controlled in the Construction of Sewage Treatment Plant

(i) Leakage Phenomenon of Concrete Hydraulic Structures

The reasons that appears leakage phenomenon basically are as follows:cracks in the pool cause seepage;improper treatment of settlement,deformation,construction and other problems cause seepage;faulty installation or fracture at water stop cause seepage;seepage at the interface of embedded casing;water seepage at the pull bolt through the wall;steel reinforcement protection work is not in place resulting to the steel corrosion,and the concrete cracking cause seepage.

(ii) Loss of Unbonded Prestress

The reasonsfor the loss of unbonded prestress are:uneven laying of prestressed steel strand;the location of steel strand is not firm,displacement and deformation appear when casting concrete;the tensioning operation is not standard and the prestress calculation is not adjusted in time.

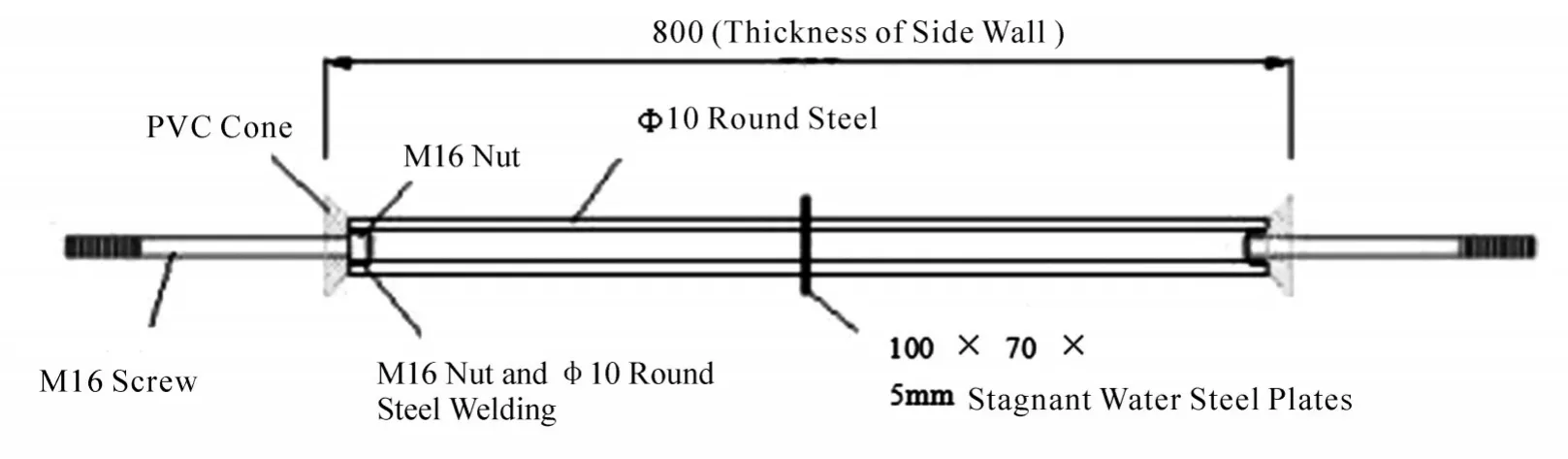

Figure 1 Schematic Diagram of Water Stop Pull Rod

II.Construction Quality Control Points of Sewage Treatment Plant

(i) Quality Control Points of Seepage Prevention Construction

1.Reasonably deal with the cracks in deformation and construction.Properly handle deformation joints and construction joints.The horizontal construction joints of the pool wall are made of steel plate water stop belt as waterproof structure,which is set on the construction seam of the horizontal pool wall 0.5 meters above the bottom plate,ensuring that the water stop belt is in the middle,and weld firmly,no leakage and penetration of welding,and ensure that the welding seam is impervious to water.Before the pouring of new concrete,the strength of the old concrete should not be less than 2.5 Mpa,and the surface should be chiseled,cleaned and wetted,and it is advisable to lay a layer of 20 mm thick cement mortar with the same proportion,to ensure that the concrete poured twice is tightly combined to achieve the purpose of impermeability[1].

2.Do a good job of filling polysulfide sealant,steel welding fixed,pull bolt installation and other construction details control.Before filling in the polysulfide sealant,ensure that both sides of the seam are clean,flat and no water seepage,and apply base course treating compound,etc.At the same time,pay attention to control the vulcanizing time and vulcanizing degree.As for the two-component polysulfide sealant,it should be used with stirring,the environmental temperature has a great influence on its solidification.The higher the temperature,the shorter the applicable period,and the lower the temperature,the slower the solidification speed.The construction temperature should be 5~35℃,and no construction on rainy days;By using split screw with split bolt combined welding square water stop ring to achieve the seepage effect.Loosen the nuts immediately after the final setting of concrete,but do not touch the water-stop pull rod with force.At the end of concrete preservation,remove the formwork after ensuring the effective combination of concrete,and use epoxy mortar to seal the hole of the pull rod left by compacting(as shown in figure 1).

3.Do a good job of seepage prevention on embedded parts and embedded casing installation the surface decontamination and cleaning work of embedded parts and embedded casing should be done in advance to avoid weak bonding and leakage.In order to improve its strength,ensure the quality of concrete components,and ensure the compactness to meet the requirements,the water stop ring should be set on the embedded casing,and the vibration and compaction of the lower casing should be done well.

4.Do a good job in concrete curing.Concrete maintenance time and frequency should be in-creased,after the final setting of the concrete,it is suggested that the bolt should be slightly loose while do not remove the formwork,and take water spraying maintenance for more than 14 days;for projects with long construction period,the full water maintenance method(5~10 cm full water at the bottom of the pool)should be adopted before putting into operation.

5.Treatment measures for leakage.For the leakage between the deformation joint and the old and new structure,measures such as using grouting to stop water,inserting the water stop rod(contact with water produces an expansion reaction)can be used;when the embedded parts have the leakage,the water should be stopped with rapid plugging materials first,and then fill the embedded seal with coating brush waterproof materials,and finally use cement mortar and waterproof coating to strengthen the work of leakage prevention.

(ii) Construction Quality Control Points of UnbondedPrestressed Concrete Water Tank

This project is a radial flow secondary sedimentation tank,a circular thin-walled unbonded prestressed concrete structure with a diameter of 42 m.The quality control points of unbonded prestressed concrete construction mainly include:

1.The laying of prestressed steel strand should be kept parallel and no twisting is allowed.Especially,the installation and protection of end anchors should be done well.

2.Radial flow secondary sedimentation tank adopts segmental-tensioning technology of ring-direction unbonded prestressed steel strand.6 anchoring ribs with a width of 790 mm are arranged equalspaced on the wall of the tank.18 rings of unbonded prestressed steel strand with special anticorrosive coating and outer covering layer are arranged in circular varying pitch,with a nominal diameter of 15.2 mm.In the tensioning of prestressed steel bars,several sections of prestressed steel bars in the same ring should be simultaneously and synchronously tensioned at both ends,so as to reduce the loss of prestress in batch tensioning.

(iii) Construction Quality Control Points of Heterogeneous Concrete Construction

The secondary sedimentation tank and distribution well of this project are circular and elliptic respectively,and their complicated structure and high technical content are the key points of the project and the difficulties of construction.The construction quality controlling points of heterogeneous,such as elliptic,are as follows:

1.Detailed formwork and scaffold construction plan.Formwork engineering and scaffold engineering are the difficulties in the construction of specialshaped concrete structures.In order to meet the requirements of structure and building shape,it is necessary to design a reasonable and effective formwork system,and carefully formulate the construction plan.The installation,verification and demolition of formwork should have a detailed operational plan,so as to ensure that the structural dimensions of concrete structures meet the design requirements.

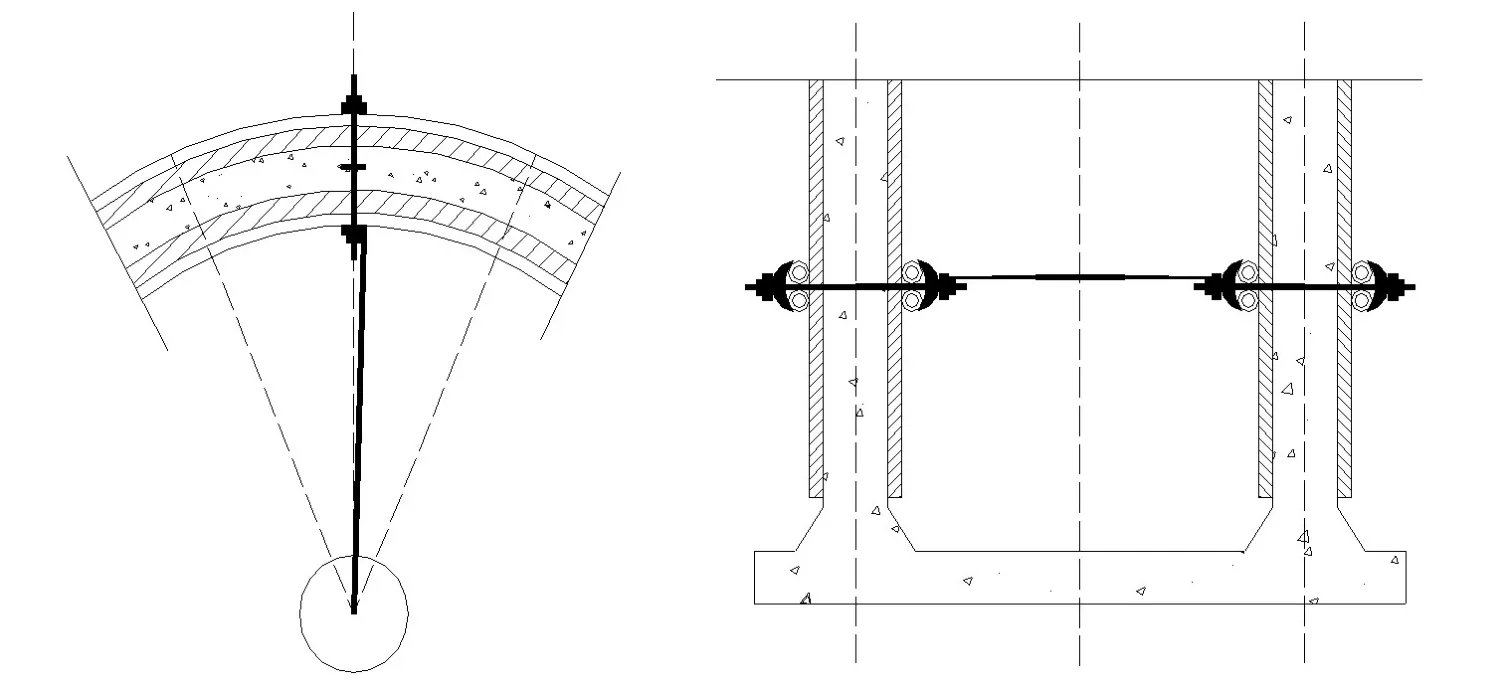

2.Carry out strict quality control for steel reinforcement engineering and concrete construction.Because the wall of the engineering project is a curved surface rather than a vertical plane,the prestressed tensioning hole reinforcement is often used,the concrete mixture vibration puddling is difficult,the compacting work,joint treatment and maintenance of concrete become more difficult.Therefore,in addition to laying and tensioning of prestressed reinforcement should be considered,concrete mix ratio designing,pouring and maintenance should also be taken into account during construction.In addition to meeting the requirement of seepage prevention of concrete itself,the complexity and details of heterogeneous concrete construction should also be studied(as shown in figure 2).

III.Conclusion

As an important part of construction project management,quality control determines the success or failure of the project.

Figure 2 Formwork Diagram of Strengthening the Siding of Heterogeneous Hydraulic Structures Radial Flow Secondary Sedimentation Tank

Due to quality problems,the poor construction project will definitely cause rework and maintenance problems in the later stage for various reasons,which will increase the cost,shrink the service life of the project,and even cause human safety problems and economic losses.Every link in the construction process should strictly and comprehensively implement the quality control measures,so as to ensure the construction quality and create a highquality project.The above content is an experience summary on the key points of construction quality control in the construction process of Changchun north suburb sewage treatment plant,hoping to provide experience for other similar projects.