摆杆驱动式残膜回收机的设计与参数优化

谢建华,唐 炜,张学军,张凤贤,杨豫新,段威林

摆杆驱动式残膜回收机的设计与参数优化

谢建华,唐 炜,张学军,张凤贤,杨豫新,段威林

(新疆农业大学机电工程学院,乌鲁木齐 830052)

针对现有的杆齿式残膜回收机存在拾膜弹齿轴易卡顿、卸膜不可靠等问题,改进设计了摆杆驱动式残膜回收机。在原杆齿式残膜回收机的基础之上增加了起膜装置,改变了拾膜齿轴与支撑盘的连接方式,利用四杆机构将卸膜机构的回转运动转变为摆动往复运动。为确定机具作业时的最优参数组合,优化整机结构,以拾膜齿入土深度、土槽台车前进速度、拾膜齿线速度与土槽台车前进速度比(速比)为主要因素,拾膜率、卸膜率为评价指标,对拾膜机构和卸膜机构进行三因素三水平响应面试验。通过Design-Expert数据分析软件,建立各因素与拾膜率、卸膜率的二次回归模型,分析了各因素对拾膜率、卸膜率的显著性,结果表明各因素影响拾膜、卸膜率的大小顺序为:土槽台车前进速度、拾膜齿线速度与土槽台车前进速度比、拾膜齿入土深度。并对试验参数进行优化,确定了最佳工作参数组合为拾膜齿入土深度为65 mm,土槽台车前进速度为1.2 m/s,速比为1.0。根据优化结果进行验证试验,结果表明拾膜率为85.6%,卸膜率为86.7%,预测模型与试验结果相差较小,优化后的模型可靠。

机械化;优化;设计;残膜回收;摆杆驱动;响应面试验

0 引 言

地膜覆盖栽培技术给农业生产带来极大发展的同时,残留在田间的地膜也严重污染了土壤[1-5]。由于塑料地膜在自然条件下很难降解,残留在土壤中不仅阻碍作物根系的生长,还会阻止土壤中水分的渗透,使土壤含水率下降,作物吸水困难,并最终导致作物减产[6-9]。国外农业种植使用的地膜通常较厚,由于其强度高、耐风化的特点,一般采用结构简单、制造成本低的收卷式残膜回收装置回收残膜[10]。国内大部分地区使用厚度不超过0.01 mm的薄地膜,薄地膜力学性能差,残膜回收难度大。目前新疆等大面积覆膜种植区域主要采用机械化方式回收残膜[11-13]。残膜回收机根据农时的不同可分为苗期残膜回收机、播前残膜回收机和秋后残膜回收机[14-15]。王科杰等[16]设计了一种单组仿形功能的耙齿式残膜回收机,拾膜率达到86.5%,该机具只能将残膜收集堆卸在田间或地头,由后续液压打包机打包运出田间。王吉奎等[17]针对秋后棉田残膜回收,研制出结合棉杆粉碎的SMS-1500 型残膜回收机,该机拾膜率大于90%,但存在卸膜机构容易与残膜缠绕的问题。王旭峰等[18]设计了一种带自卸膜装置的抛膜链齿输送残膜回收机,但其结构复杂,机具可靠性不高。严伟等[19]针对铲筛式残膜回收机进行了优化试验,其清土效果好,残膜回收率高,但输膜性能较差。

现有残膜回收机主要分为杆齿式、链齿式、伸缩杆齿式及搂耙式等机型[20],其中,搂耙式和杆齿式使用较普遍。搂耙式残膜回收机作业效率高,结构简单,使用可靠,但功能单一,需要人工或其他机具配合捡拾,且回收的残膜含杂率较高。杆齿式残膜回收机具主要采用弹齿扎膜的方式回收地表残膜,机具结构较简单,可靠性较好,但卸膜困难,作业部件易缠绕地膜,残膜最终回收率不高[21-22]。本文根据新疆棉田地膜种植情况,综合杆齿式残膜回收机的结构特点[23],在对弹齿拾膜装置、刮板卸膜装置进行技术改进的基础上,设计了一种摆杆驱动式残膜回收机。并通过三因素三水平响应面试验和二次回归模型的优化获得机具最优工作参数,为后续物理样机的加工和制作提供理论与试验依据。

1 机具的结构及工作原理

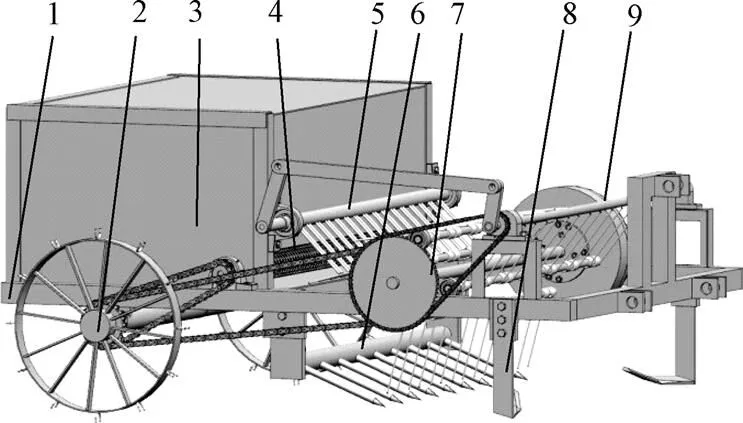

图1为摆杆驱动式残膜回收机的结构示意图,主要由行走轮、集膜箱、输膜辊、卸膜轴总成、拾膜机构、起膜装置、边膜铲、卸膜驱动装置组成。其中,边膜铲、起膜装置和拾膜机构实现残膜的捡拾;卸膜驱动装置、卸膜轴总成和输膜辊实现残膜的脱卸。

工作时机具由拖拉机牵引前进,边膜铲将地膜两边的板结覆膜土耕松,起膜装置将膜下土壤和地膜分离,并将地膜抬起一定高度。地轮前进的同时将动力传递给拾膜机构,拾膜机构在起膜装置和边膜铲的配合下将地表残膜挑起向卸膜位置输送。卸膜杆齿在卸膜驱动装置的带动下,在一定范围内摆动,将残膜从拾膜杆齿上捋下,并在输膜辊的带动下输入集膜箱后部。

1.机架 2.地轮 3.集膜箱 4.输膜辊 5.卸膜轴总成 6.起膜装置 7.拾膜机构 8.边膜铲 9.卸膜驱动装置

2 主要部件的设计与分析

2.1 拾膜机构

原杆齿式残膜回收机的拾膜齿轴直接穿在芯轴两端的支撑盘孔内(属于滑动连接),由于加工和制造精度的限制,拾膜机构在工作过程中存在的冲击、振动及卡顿现象,影响拾膜效果。在优化滑道轨迹的基础上,采用单耳带座轴承将拾膜齿轴与固定盘连接,将原来的滑动连接变为滚动连接,使机构运动平稳性得到提高。

拾膜机构如图2所示,主要包括支撑盘、主轴、拾膜齿、拾膜齿轴、防护罩、曲柄、滑道、滚子等。拾膜齿固定在拾膜齿轴上,拾膜齿轴通过单耳带座轴承与左、右支撑盘联接,左、右支撑盘固定在主轴上。拾膜齿轴的一端固接曲柄,曲柄与滚子铰接,滚子在滑道内滚动。拾膜齿在拾膜齿轴、曲柄、滚子和滑道的作用下,由前下方低头入土向后方挑膜,在起膜装置的辅助下将残地膜挑起,再平移、后退、反转,实现捡拾、升运、卸膜和回程4个工作步骤。为保证捡拾残膜的连续性,拾膜机构均匀布置四组拾膜齿轴,根据新疆一膜四行机采棉种植模式,拾膜齿轴上匀布7个拾膜齿。

1.主轴 2.左支撑盘 3.单耳带座轴承 4.拾膜齿 5.拾膜齿轴 6.右支撑盘 7.滚子 8.滑道 9.曲柄 10.防护罩

拾膜齿在拾膜齿轴上的排列间距的大小对拾膜效果有直接影响。排列间距小,可以提高机具的拾膜率,但易造成田间杂物壅堵,影响机具正常工作;排列间距过大,单个拾膜齿负责回收的区域增大,容易造成残膜漏捡,或在捡拾运送的过程中脱落。根据新疆一膜四行机采棉种植模式和前期的性能试验,拾膜齿轴上相邻两拾膜齿的中心距设置为165 mm。

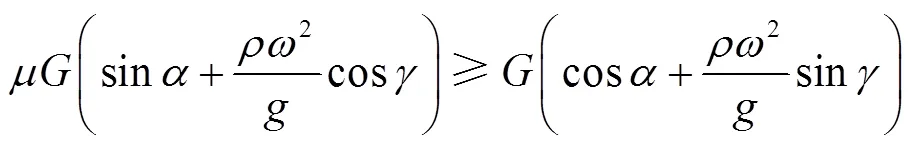

机具在工作时,拾膜机构转速的大小影响机具的拾膜效果。转速过快,拾膜杆齿向卸膜位置输送残膜时容易将残膜拉断;转速过小,被挑起的残膜会从拾膜杆齿上滑落。拾膜齿在拾膜过程中,拾膜主轴以的角速度转动时,被拾膜齿挑起残膜的受力情况如图3所示。

注:ω为拾膜主轴转速,rad·s-1;G为残膜自身重力,N;G1为残膜自身重力沿杆齿方向上的分力,Ν;G2为残膜自身重力垂直杆齿方向上的分力,Ν;Fg为残膜所受的惯性力,Ν;α为拾膜齿与垂直方向的夹角,(°);γ为惯性力与支持力间的夹角,(°)。

由图3可知,拾膜齿在输送残膜时对残膜的支持力为

残膜在拾膜齿的运送过程中不脱落的条件是残膜与拾膜齿间的摩擦力大于拾膜时对残膜的离心力,即

式中F为拾膜齿对残膜的支持力,N;为被挑起残膜的瞬时加速度,m/s2;为被挑起残膜中心的瞬时半径,m。

当拾膜齿末端线速度=1.2 m/s、拾膜齿挑膜半径=350 mm,可确定拾膜机构转速为=60/2π,约为33 r/min。

2.2 起膜装置

起膜装置如图4所示,主要由安装板、起膜齿轴、起膜齿组成。起膜齿固定在起膜齿轴上,安装板将起膜装置安装在机架上。起膜齿在起膜齿轴上排列时应当尽可能的避免与根茬触碰,为了避开棉花根茬,相邻两起膜齿的距离设置为110 mm。起膜齿的入土角不但影响起膜效果,而且与机具的工作阻力直接相关。根据起膜装置的部件试验,确定起膜齿入土角1为22°。

1.安装板 2.起膜齿轴 3.起膜齿

1.Assembling panel 2.Lifting film shaft 3.Lifting film tooth

注:1为起膜齿入土角,(°)。

Note:1is the penetration angle of film nail tooth, (°).

图4 起膜装置结构示意图

Fig.4 Structure diagram of lifting film device

2.3 摆杆驱动式卸膜机构

由于原杆齿式残膜回收机的旋转刮板式卸膜机构在工作时,若地膜破损不严重(呈长条状),地膜易缠绕在卸膜辊轴上。将原旋转刮板式卸膜机构改进为摆杆驱动式卸膜机构,利用四杆机构将卸膜机构的回转运动转变为摆动往复运动,减少了残膜缠绕情况。摆杆驱动式卸膜机构如图5所示,主要由卸膜驱动装置和卸膜轴总成组成,其中卸膜驱动装置包括摆杆、导杆和曲柄,卸膜轴总成由卸膜齿和卸膜轴组成。

1.机架 2.摆杆 3.卸膜轴总成 4.导杆 5.曲柄 6.曲柄转动轴

由于曲柄摇杆机构能将圆周运动转换为往复摆动,且制造简单、可靠性高,因此,选择曲柄摇杆机构作为机具的卸膜驱动装置。卸膜杆齿摆角的大小对摆杆驱动式残膜回收机的卸膜率起决定作用,摆角过大,会使卸膜驱动装置的整体尺寸加大,在工作时降低机具的动平衡性能,摆角过小会使卸膜杆齿不能将残膜刮入集膜箱,导致残膜挂在机具上或掉落田间,降低机具的卸膜率,通过卸膜机构的性能试验设定摆角为110°。

如图6所示,已知卸膜驱动机构的机架的长度l为710 mm,摆杆的长度l为190 mm,以点为圆心、l为半径做圆弧12,使摆角为110º,设导杆、曲柄的长度分别为l、l,则由曲柄存在条件

若导杆的长度l为680 mm,通过式(3)可得l=160 mm。

注:l为曲柄的长度,mm;l为导杆的长度,mm;l为摆杆的长度,mm;l为机架的长度,mm;为摆杆的摆角,(°);1、2为卸膜齿运动端点。

Note: lis the length of crank, mm;lis the length of guide rod, mm;lis the length of swing rod, mm;lis the length of frame, mm;is the swing angle of swing rod, (°);1and2are the moving end point of unloading film tooth.

图6 卸膜驱动机构结构参数分析

Fig.6 Analysis of structural parameters of film driving mechanism

3 试验条件及方法

为验证机构性能及确定后续样机结构参数和主要工作参数,对拾膜机构和卸膜机构进行试验。由于田间试验研究周期较长,且不易观察、测量,台架试验可以模拟田间工作环境[24-25]完成部件性能测试。本文通过台架土槽试验对改进的拾膜机构、摆杆驱动式卸膜机构的工作性能进行测试,分析土槽台车前进速度、拾膜杆齿线速度与土槽台车前进速度比、拾膜齿入土深度3个因素对机具拾膜、卸膜效果的影响,通过台架试验找出最优结构与工作参数组合,指导后续样机的制作。

3.1 台架试验条件

试验在牵引式土槽试验系统中进行,如图7所示,试验系统主要包括牵引式土槽台车、拾膜机构、摆杆驱动式卸膜机构、变频器、电动机和控制箱组成。试验时,拾膜、卸膜机构与地面的相对距离固定,采取改变土槽内的土壤厚度的方式来调整拾膜齿的入土深度。变频器与电动机连接,通过调节变频器频率的大小来控制电动机的转速,电动机通过链传动带动拾膜、卸膜机构工作,土槽台车中土壤表层覆膜,并在地膜两边插入棉杆来模拟实际工作环境。

1.变频器 2.电动机 3.拾膜、卸膜机构 4.牵引式土槽台车 5.控制箱

试验时选用厚度为0.01 mm、覆膜天数约为180 d的旧地膜,按照(660+100) mm的机采棉种植模式铺膜,两边覆土厚度为35~45 mm,土壤含水率为10%~20%。由于该机具作业对象为棉杆已经被粉碎的棉田,因此,在残膜上插入露出土壤表面高度为50~70 mm的棉花根茬。试验过程中动力由路阳红404型拖拉机提供,选用天马FA1004型电子天秤测量残膜质量。

3.2 试验指标

根据NYT1227-2006残膜回收机作业质量标准选择拾膜率和卸膜率作为试验指标。将试验收集的残膜清洗干净并晾干,用电子天平称质量,计算机具的拾膜率、卸膜率,表达式为

式中1为拾膜率,%;2为卸膜率,%;M为被刮入膜箱中残膜的质量,g;M为未被挑起的残膜的质量,g;M为被挑起但未被刮入膜箱的残膜的质量,g。

3.3 试验设计

选取拾膜齿入土深度1、土槽台车前进速度2、拾膜齿线速度与土槽台车前进速度比33个因素,并根据机具的结构以及设计参数确定拾膜齿入土深度分别取30、60、90 mm,土槽台车前进速度分别取慢Ⅲ档(0.6 m/s)、慢Ⅳ档(0.9 m/s)、快Ⅰ档(1.2 m/s),拾膜齿线速度与土槽台车前进速度比分别取0.8、1.0和1.2。

本试验采用三因素三水平响应面分析试验,表1为试验因素水平编码表,表2为试验设计与试验结果,利用Design-Expert软件设计试验,共进行17组试验,对每组试验重复3次,并求得拾膜率、卸膜率的平均值为试验结果。

表1 试验因素水平编码Table 1 Horizontal coding of test factors

注:速比为拾膜齿线速度与土槽台车前进速度比。

Note: Speed ratio is the ratio of linear speed of the picking-up tooth to forward speed of soil bin trolley.

4 试验结果及分析

4.1 试验回归分析

表2 试验方案及结果

表3 回归模型方差分析

注:<0.05(显著*);<0.01(极其显著**)

Note:<0.05(significant,*);<0.01(highly significant, **)

4.2 试验因素对拾膜率、卸膜率的影响分析

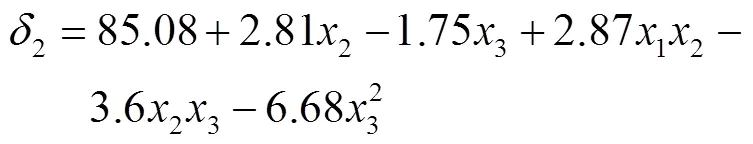

利用Design-Expert中数据分析功能对表2中的试验结果进行多元回归拟合[29-31],得到以拾膜齿入土深度、土槽台车前进速度及速比对拾膜率1、卸膜率2影响的回归方程为

为了直观反映不同交互因素对指标影响的强弱[32-33],根据二次回归模型(6)和(7)作出各交互因素对拾膜率、卸膜率影响的响应面图,如图8所示。

注:响应面试验因素和水平见表1,响应值见表2。

由图8a可以看出,当土槽台车前进速度在零水平,拾膜齿入土深度固定在低水平(30 mm)时,拾膜齿线速度与土槽台车前进速度比从0.8增加至1.0,拾膜率先增加,但增加到一定程度时,速比对拾膜率的影响趋于稳定,主要是因为当拾膜齿入土挑膜并将残膜向卸膜机构输送时,速比较低,拾膜机构转速低,挑起的残膜由于自身重力的原因,从拾膜齿上滑落,速比增大,拾膜机构转速增大,减小了残膜从拾膜齿上滑落的可能。

由图8b可以看出,拾膜齿入土深度在零水平,速比保持在低水平(0.8)时,土槽台车前进速度从0.6 m/s增加至1.2 m/s,拾膜率呈现增大的趋势,从总体来看,当土槽台车前进速度和速比同时增加时,拾膜率呈现先增大后减小的趋势,主要因为土槽台车前进速度和速比都增大时,拾膜机构转速也增大,但转速过快时,拾膜齿向卸膜位置输送残膜时会将残膜拉断,影响收膜时的连续性。

从图8c中可以看出,当速比持续增加时,机具的卸膜率先增大后减小,这是由于当速比过小时,残膜会从卸膜齿上滑落,当速比过大时,卸膜机构往复周期过小,同时,由于残膜的连续性遭到破坏,再加之破坏后的地膜更容易受到空气阻力的影响,导致卸膜杆齿将后抛未落下的残膜回带,影响机具的卸膜率。从图8d中可以看出,当速比在零水平时,拾膜齿入土深度固定在一定水平时,卸膜率总体上随土槽前进速度的增大而增大,但增大到一定程度后,卸膜率也会有下降的趋势,这是由于加快土槽台车前进速度时,要保证速比不变,就得加大拾膜、卸膜机构的转速,与上同理,也会使卸膜率降低。

4.3 参数优化与验证试验

借助拾膜率、卸膜率的回归方程模型式(6)和(7),以增大拾膜率和卸膜率为优化目标,应用Design-Expert软件中的优化模块,对拾膜、卸膜率的回归方程模型进行优化求解,得到最优工作参数为:拾膜齿入土深度为65 mm,土槽台车前进速度为1.2 m/s,速比为1.0,此时拾膜率为87.8%,卸膜率为87.9%。

为了验证优化后模型的可行性,按照优化后得到的参数进行验证试验,设定拾膜齿入土深度为65 mm,土槽台车前进速度为1.2 m/s,速比为1.0,试验共进行3次并对得到的数值求平均值,试验结果为拾膜率为85.6%,与预测值相差2.2%,与原杆齿式残膜回收机相比提升4.71%;卸膜率为86.7%,与预测值相差1.2%,与原杆齿式残膜回收机相比提升3.42%。试验值与理论优化值的相对误差均小于3%,优化模型可靠,优化后机构的性能得到改善。

5 结 论

1)针对现有的杆齿式残膜回收机存在拾膜弹齿轴易卡顿、卸膜不可靠等问题,设计了摆杆驱动式残膜回收机,确定了拾膜机构、起膜机构、摆杆驱动式卸膜机构的设计参数。

2)以拾膜齿入土深度、土槽台车前进速度、拾膜齿线速度与土槽台车前进速度比为影响因素进行试验,并通过Design-Expert软件对试验结果进行响应面分析,结果表明,各因素影响拾膜、卸膜率的大小顺序为:土槽台车前进速度、拾膜齿线速度与土槽台车前进速度比、拾膜齿入土深度。

3)利用Design-Expert软件的数据优化功能,以提高拾膜率、卸膜率为优化目标,确定最佳工作参数为:拾膜齿入土深度为65 mm,土槽台车前进速度为1.2 m/s,拾膜齿线速度与土槽台车前进速度比为1.0。对优化后的各因素进行验证试验,试验结果表明,拾膜率为85.6%,卸膜率为86.7%,优化后的参数可作为机具作业的最佳依据。

[1] 吕江南,王朝云,易永健. 农用薄膜应用现状及可降解农膜研究进展[J]. 中国麻业科学,2007,29(3):150-157.

Lü Jiangnan, Wang Chaoyun, Yi Yongjian. The development status of agricultural plastics mulching film and progress on degradable mulching films[J]. Plant Fiber Sciences in China, 2007, 29(3): 150-157. (in Chinese with English abstract)

[2] 王频. 残膜污染治理的对策和措施[J]. 农业工程学报,1998,14(3):190-193.

Wang Pin. Measures to reduce the pollution of residual of mulching plastic film in farmland[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 1998, 14(3): 190-193. (in Chinese with English abstract)

[3] 严昌荣,刘恩科,舒帆,等. 我国地膜覆盖和残留污染特点与防控技术[J]. 农业资源与环境学报,2014,31(2):95-102.

Yan Changrong, Liu Enke, Shu Fan, et al. Review of agricultural plastic mulching and its residual pollution and prevention measures in China[J]. Journal of Agricultural Resources and Environment, 2014, 31(2): 95-102. (in Chinese with English abstract)

[4] 严昌荣,梅旭荣,何文清,等. 农用地膜残留污染的现状与防治[J]. 农业工程学报,2006,22(11):269-272.

Yan Changrong, Mei Xurong, He Wenqing, et al. Present situation of residue pollution of mulching plastic film and controlling measures[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2006, 22(11): 269-272. (in Chinese with English abstract)

[5] 何文清,严昌荣,刘爽,等. 典型棉区地膜应用及污染现状的研究[J]. 农业环境科学学报,2009,28(8):1618-1622.

He Wenqing, Yan Changrong, Liu Shuang, et al. The use of plastic mulch film in typical cotton planting regions and the associated environmental pollution[J]. Journal of Agro-Environment Science, 2009, 28(8): 1618-1622. (in Chinese with English abstract)

[6] 毕继业,王秀芬,朱道林. 地膜覆盖对农作物产量的影响[J]. 农业工程学报,2008,24(11):172-175.

Bi Jiye, Wang Xiufen, Zhu Daolin. Effect of plastic-film mulch on crop yield[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008, 24(11): 172-175. (in Chinese with English abstract)

[7] 肖军,赵景波. 农田塑料地膜污染及防治[J]. 四川环境,2005,24(1):102-105.

Xiao Jun, Zhao Jingbo. Farmland plastic film pollution and its counter measures[J]. Sichuan Environment, 2005, 24(1): 102-105. (in Chinese with English abstract)

[8] 马少辉,张学军. 废膜收获机的研究现状和发展趋势[J]. 农机化研究,2006(5):37-38.

Ma Shaohui, Zhang Xuejun. The rudimental plastic harvesting machinery’s present condition and developing trend[J]. Journal of Agricultural Mechanization Research, 2006(5): 37-38. (in Chinese with English abstract)

[9] 张东兴. 农用残膜的回收问题[J]. 中国农业大学学报,1998,3(6):103-106.

Zhang Dongxing. Study on collection of used plastic film in fields[J]. Journal of China Agricultural University, 1998, 3(6): 103-106. (in Chinese with English abstract)

[10] 刘旋峰,石鑫,郭兆峰,等. 滚筒式残膜回收机的性能试验研究[J]. 农业工程学报,2017,33(16):26-31.

Liu Xuanfeng, Shi Xin, Guo Zhaofeng, et al. Performance test on roller type residual film recycling machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(16): 26-31. (in Chinese with English abstract)

[11] 靳伟,张学军,鄢金山,等. 曲轴式棉田地表残膜回收机捡膜特性分析及工作参数优化[J]. 农业工程学报,2018,34(16):10-18.

Jin Wei, Zhang Xuejun, Yan Jinshan, et al. Characteristic analysis and working parameter optimization of crankshaft type cotton field surface residual film collecting machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(16): 10-18. (in Chinese with English abstract)

[12] 张佳喜,杨程,郭俊先,等. 滚刀式青贮玉米起茬及残膜回收联合作业机的设计与试验[J]. 农业工程学报,2018,34(6):25-34.

Zhang Jiaxi, Yang Cheng, Guo Junxian, et al. Design and experiment of hob-type joint operation machine for silage corn root stubble plucking and residual plastic film collecting[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(6): 25-34. (in Chinese with English abstract)

[13] 郭文松,简建明,散鋆龙,等. 4CML-1000 型链耙式地膜回收机设计与试验优化[J]. 农业机械学报,2018,49(2):66-73.

Guo Wensong, Jian Jianming, San Yunlong, et al. Design and experimental optimization of 4CML-1000 type chain rake film recycling machine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(2): 66-73. (in Chinese with English abstract)

[14] 张学军,吴成武,王伟,等. 齿形刮板式残膜与残茬输送装置设计与试验[J]. 农业机械学报,2008,39(9):49-51.

Zhang Xuejun, Wu Chengwu, Wang Wei, et al. Design and experiment on the zigzag scraper transportation device for remnant plastic film and stubble[J]. Transactions of the Chinese Society for Agricultural Machinery, 2008, 39(9): 49-51. (in Chinese with English abstract)

[15] 赵岩,陈学庚,温浩军,等. 农田残膜污染治理技术研究现状与展望[J]. 农业机械学报,2017,48(6):1-14.

Zhao Yan, Chen Xuegeng, Wen Haojun, et al. Research status and prospect of control technology for residual plastic film pollution in farmland[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(6): 1-14. (in Chinese with English abstract)

[16] 王科杰,胡斌,罗昕,等. 残膜回收机单组仿形搂膜机构的设计与试验[J]. 农业工程学报,2017,33(8):12-20.

Wang Kejie, Hu Bin, Luo Xin, et al. Design and experiment of monomer profiling raking-film mechanism of residue plastic film collector[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(8): 12-20. (in Chinese with English abstract)

[17] 王吉奎,付威,王卫兵,等. SMS-1500型秸秆粉碎与残膜回收机的设计[J]. 农业工程学报,2011,27(7):168-172.

Wang Jikui, Fu Wei, Wang Weibing, et al. Design of SMS-1500 type straw chopping and plastic film residue collecting machine[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(7): 168-172. (in Chinese with English abstract)

[18] 王旭峰,胡灿,鲁兵,等. 抛膜链齿输送式残膜回收机设计与试验[J]. 农业机械学报,2018,49(3):122-129. Wang Xufeng, Hu Can, Lu Bing, et al. Design and experiment of sprocket conveying residual film recycling machine of casting film[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(3): 122-129. (in Chinese with English abstract)

[19] 严伟,胡志超,吴努,等. 铲筛式残膜回收机输膜机构参数优化与试验[J]. 农业工程学报,2017,33(1):17-24.

Yan Wei, Hu Zhichao, Wu Nu, et al. Parameter optimization and experiment for plastic film transport mechanism of shovel screen type plastic film residue collector[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(1): 17-24. (in Chinese with English abstract)

[20] 侯书林,胡三媛,孔建铭,等. 国内残膜回收机研究的现状[J]. 农业工程学报,2002,18(3):186-190.

Hou Shulin, Hu Sanyuan, Kong Jianming, et al. Present situation of research on plastic film residue collector in China[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2002, 18(3): 186-190. (in Chinese with English abstract)

[21] 刘鸿智. 杆齿式拾膜机构的设计及试验研究[D]. 乌鲁木齐:新疆农业大学,2015.

Liu Hongzhi. Design and Experiment Study of Pole Teeth Collecting Plastic Film Machine[D]. Urumqi: Xinjiang Agricultural University, 2015. (in Chinese with English abstract)

[22] 孙超伟. 杆齿式残膜回收机的设计及试验研究[D]. 乌鲁木齐:新疆农业大学,2016.

Sun Chaowei. Design and Experiment Study of Pole-tooth Mulching Plastic Film Collector[D]. Urumqi: Xinjiang Agricultural University, 2016. (in Chinese with English abstract)

[23] 谢建华,陈学庚,孙超伟. 杆齿式残膜回收机卸膜过程分析及高速摄像试验[J]. 农业工程学报,2017,33(10):17-24.

Xie Jianhua, Chen Xuegeng, Sun Chaowei. Unloading film process analysis and high-speed photography experiment of pole-tooth residual plastic film collector[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(10): 17-24. (in Chinese with English abstract)

[24] 谢建华,侯书林,付宇,等. 残膜回收机弹齿式拾膜机构运动分析与试验[J]. 农业机械学报,2013,44(增刊1):94-99.

Xie Jianhua, Hou Shulin, Fu Yu, et al. Motion analysis and experiment on spring-tooth mulching plastic film collector[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(Supp.1): 94-99. (in Chinese with English abstract)

[25] 程修沛,贾晓东,陈美舟,等. 上拉茎掰穗式玉米收获台架试验与分析[J]. 农业工程学报,2016,32(22):50-55.

Chen Xiupei, Jia Xiaodong, Chen Meizhou, et al. Experiment and analysis on test device of corn ear picking by pulling stalk upwards[J].Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(22): 50-55. (in Chinese with English abstract)

[26] 戴飞,郭笑欢,赵武云,等. 帆布带式马铃薯挖掘-残膜回收联合作业机设计与试验[J]. 农业机械学报,2018,49(3):104-113.

Dai Fei, Guo Xiaohuan, Zhao Wuyun, et al. Design and experiment of canvas belt combined operation machine for potato digging and plastic film collecting[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(3): 104-113. (in Chinese with English abstract)

[27] 赵武云,戴飞,杨杰,等. 玉米全膜双垄沟直插式精量穴播机设计与试验[J]. 农业机械学报,2013,44(11):91-97.

Zhao Wuyun, Dai Fei, Yang Jie, et al. Design and experiment of direct insert precision hill-seeder with corn whole plastic-film mulching on double ridges[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(11): 91-97. (in Chinese with English abstract)

[28] 赖庆辉,马文鹏,刘素,等. 气吸圆盘式微型薯排种器充种性能模拟与试验[J]. 农业机械学报,2017,48(5):44-53.

Lai Qinghui, Gao Youjun, Zhang Zhihong, et al. Simulation and experiment on seed-filling performance of pneumatic disc seed-metering device for mini-tuber[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(5): 44-53. (in Chinese with English abstract)

[29] 吕金庆,孙贺,兑瀚,等. 粘重土壤下马铃薯挖掘机分离输送装置改进设计与试验[J]. 农业机械学报,2017,48(11):146-155.

Lü Jinqing, Sun He, Dui Han, et al. Design and experiment on conveyor separation device of potato digger under heavy soil condition[J]. Transactions of the Chinese Society for Agricultural Machinery. 2017, 48(11): 146-155. (in Chinese with English abstract)

[30] 刘彩玲,王超,宋建农,等. 振动供种型孔轮式非圆种子精密排种器设计与试验[J]. 农业机械学报,2018,49(5):108-115.

Liu Cailing, Wang Chao, Song Jiannong, et al. Design and seed-filling test of cell-type precision seed-metering device with vibration technology[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(5): 108-115. (in Chinese with English abstract)

[31] 曹引,冶运涛,赵红莉,等. 基于离散粒子群和偏最小二乘的水源地浊度高光谱反演[J]. 农业机械学报,2018,49(1):173-182.

Cao Yin, Ye Yuntao, Zhao Hongli, et al. Satellite hyper spectral retrieval of turbidity for water source based on discrete particle swarm and partial least squares[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(1): 173-182. (in Chinese with English abstract)

[32] 高筱钧,周金华,赖庆辉. 中草药三七气吸滚筒式精密排种器的设计与试验[J]. 农业工程学报,2016,32(2):20-28.

Gao Xiaojun, Zhou Jinhua, LaiQinghui. Design and experiment of pneumatic cylinder precision seed-metering device for panax notoginseng[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(2): 20-28. (in Chinese with English abstract)

[33] 袁雪,祁力钧,王虎,等. 温室摇摆式变量弥雾机喷雾参数响应面法优化[J]. 农业机械学报,2012,43(4):45-50,54.

Yuan Xue, Qi Lijun, Wang Hu, et al. Spraying parameters optimization of swing, automatic variables and greenhouse mist sprayer with response surface method[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(4): 45-50,54. (in Chinese with English abstract)

Design and parameter optimization of swing rod driven residual plastic film collector

Xie Jianhua, Tang Wei, Zhang Xuejun, Zhang Fengxian, Yang Yuxin, Duan Weilin

(,,,830052,)

Although plastic sheet-covered cultivation technology has brought great development to agricultural production, the plastic film residual in the field has also seriously polluted the soil. Because plastic film is difficult to degrade under natural conditions, its residue in the soil will not only hinder the growth of crop roots, and make it difficult for crops to absorb water, but also prevent the infiltration of water in the soil, making the soil moisture content decline, and ultimately leading to crop yield reduction. The traditional pole-tooth residual plastic film collector mainly uses elastic tooth to recover the surface plastic film residue. The structure of the machine is simple, but it is difficult to unload the plastic film, and the working parts are easy to be wrapped by the film, which ultimately leads to the low recovery rate of the plastic film residue. According to the typical mulching planting situation in Xinjiang cotton field and the structural characteristics of the pole-tooth residual plastic film collector, the swing rod driven residual plastic film collector was improved and designed. In particular, the technology improvement of the spring-tooth picking device and the scraper discharging device was carried out, which solved the problems of easy jamming of the elastic tooth shaft and unreliable film unloading. Compared with the traditional pole-tooth residual plastic film collector, the swing rod driven residual plastic film collector mainly improved in the following aspects: the lifting film device was increased, and the effect of picking-up film was improved; the connection mode between the picking-up tooth shaft and the supporting plate was changed, and the operation of the picking-up residual plastic film mechanism was improved; four-bar linkage was used to change the gyratory motion of unloading film mechanism into swing reciprocating motion, so as to reduce residual film winding. In order to verify the performance of the mechanism, determine the optimal combination of parameters, and optimize the structure of the whole machine, the picking-up film mechanism and the unloading film mechanism were tested. Taking the penetration depth of the picking-up teeth, the forward speed of the trolley, the linear speed of the picking-up teeth and the forward speed ratio (the ratio of linear speed of the picking-up tooth to forward speed of soil bin trolley) of the trolley as the main factors, and the picking-up rate and the unloading rate as the testing indexes, the three-factor and three-level response tests of the picking-up mechanism and the unloading mechanism were carried out. The quadratic regression model between each factor and the picking-up film rate and unloading film rate were established by the software of Design-Expert. The significant influence of each factor on the picking-up film rate and unloading film rate were analyzed, and the test parameters were optimized. The results showed that the order of influencing factors on the picking-up film rate and the unloading film rate was as follows: the forward speed of soil bin trolley, the speed ratio, and the depth of picking-up teeth into soil. The optimum working parameters were determined as follows: the penetration depth of the picking teeth of 65 mm, 1.2 m/s of the forward speed of the soil bin trolley, and the speed ratio of 1.0. According to the optimization results, the validation test was carried out. The result showed that the picking-up film rate was 85.6%, the unloading film rate was 86.7%, which were less different from the prediction model, and the optimized model was reliable.

mechanization; optimization; design; plastic film residue-collecting; swing rod driven; response surface experiments

谢建华,唐 炜,张学军,张凤贤,杨豫新,段威林. 摆杆驱动式残膜回收机的设计与参数优化[J]. 农业工程学报,2019,35(4):56-63. doi:10.11975/j.issn.1002-6819.2019.04.007 http://www.tcsae.org

Xie Jianhua, Tang Wei, Zhang Xuejun, Zhang Fengxian, Yang Yuxin, Duan Weilin. Design and parameter optimization of swing rod driven residual plastic film collector[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(4): 56-63. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2019.04.007 http://www.tcsae.org

2018-09-10

2019-01-30

国家自然科学基金资助项目(51465057,51665057);“十三五”国家重点研发计划(2017YFD0701102-2);中国农大-新疆农大联合基金(2017TC009)

谢建华,副教授,博士,主要从事农业机械设计与研究。 Email:xjh199032@163.com

10.11975/j.issn.1002-6819.2019.04.007

S223.5

A

1002-6819(2019)-04-0056-08