品种及含水率对谷子籽粒力学性质的影响

邱述金,原向阳,郭玉明,崔清亮,武新慧,张志勇

品种及含水率对谷子籽粒力学性质的影响

邱述金1,原向阳2,郭玉明1,崔清亮1※,武新慧1,张志勇1

(1. 山西农业大学工学院,太谷 030801;2. 山西农业大学农学院,太谷 030801)

谷子籽粒群是具有黏弹性性质的生物材料,谷子加工储藏和机械收获等作业环节需考虑其黏弹性,该文研究了不同品种、不同含水率对谷子籽粒群黏弹性力学指标的影响。该试验以不同品种、不同含水率为试验因素,以谷子籽粒群的瞬时弹性模量、迟滞弹性模量、松弛时间和黏度系数为试验指标进行蠕变试验,并对试验结果进行方差分析。结果表明:谷子籽粒群的蠕变特性可由四元件Burgers模型描述,不同含水率、不同品种谷子籽粒群的蠕变参数各异。品种对谷子籽粒群的迟滞弹性模量影响显著,晋谷21号谷子籽粒群的迟滞弹性模量均值为0.609 3 MPa,显著高于张杂10号的0.522 2 MPa。含水率对谷子籽粒群的瞬时弹性模量、迟滞弹性模量和黏度系数影响均显著,均呈随含水率升高而降低的趋势,含水率为12.10%的谷子籽粒群的瞬时弹性模量0.752 6 MPa显著高于含水率为16.05%的0.613 6 MPa和20.00%的0.569 7 MPa,含水率为12.10%、16.05%、20.00%的谷子籽粒群的迟滞弹性模量分别为0.706 4、0.583 5、0.407 5 MPa,含水率为12.10%的谷子籽粒群的黏度系数1 234.7 MPa·s显著高于20.00%的796.8 MPa·s,含水率对谷子籽粒群的松弛时间影响不显著。该文通过试验研究了不同品种和不同含水率的谷子籽粒群的蠕变特性,为谷子低损收获、加工储藏及参数优化提供了理论支持。

含水率;力学性能;模型;谷子籽粒群;蠕变特性;品种

0 引 言

谷子是中国丘陵山地有机旱作农业重要的杂粮作物之一[1],其机械收获与加工生产过程中持续受到复杂外力的作用,比如联合收获机搅龙输送过程中谷子籽粒群受持续推进力的作用,运输储藏环节中的随机碰撞等机械作用会导致谷子种子破裂、胚胎受损等问题[2]。谷子籽粒群的流变学特性是相关装备研发、工艺制定的理论基础,可为低损收获、低损加工、低损储藏等提供新的思路及参数优化。

目前,国内外学者对农业物料的流变学特性研究已经取得了较大进展。梁丽等[3]研究了小麦茎秆流变性质,建立了为小麦优种指标评价流变模型。Ma等[4]研究了麦麸膳食纤维对小麦面团的流变学指标影响,结果表明添加麦麸膳食纤维后降低了面团的黏弹性应变极限,但机械强度得到增强。宫泽奇[5]结合流变学参数研究了青贮玉米秸秆螺旋致密成型工艺,建立了2个经典Maxwell模型并联的应力松弛模型,获得螺旋致密成型物料应力松弛规律。盛韶阳[2]研究了不同含水率玉米籽粒的黏弹性,得到蠕变过程玉米籽粒的应变随含水率增加而增大,松弛过程玉米籽粒的应力随含水率增加而减小的结论。严平宇等[6]利用机械动态热分析仪对水稻种子进行了流变特性研究,建立了水稻种子的五元件开尔文模型和三元件麦克斯韦模型。还有其他学者研究了大豆[7]、豌豆等作物的流变学特性,获得了碰撞损伤及籽粒应力开裂的影响规律[8]。针对小籽粒谷物的流动特性[9]、摩擦特性运动学[10-11]、作物茎秆、种子及其加工产品面粉等的流变特性的研究较多[12-13]。程绪铎等[14]曾指出国内粮仓堆高大、储藏温度高、含水率大、时间久会使大豆弹性变小。马小愚等[15]通过应力松弛试验,得到不规则形状的大豆、小麦种子的挤压方程,提出了可识别松弛参数的Z变换法。张洪霞[16]对稻米及米饭籽粒进行了应力松弛试验,获得了应力松弛指标,建立了力学指标随影响因素变化的回归方程。还有学者应用有限元分析方法研究物料流变特性,如王芳等[17-18]利用有限元法仿真研究了西瓜的力学特性,验证了仿真数值解的可行性;藏楠[19]用ANSYS对马铃薯的力学特性进行仿真,仿真结果较好地反应马铃薯的蠕变特性。

我们团队前期对谷子单个籽粒的静态力学特性[20-21]、谷子茎秆力学特性[22-23]及谷子叶片摩擦特性[24-25]等方面进行了研究,在此基础上研究不同含水率的谷子籽粒群的蠕变特性,获取不同品种、不同含水率谷子籽粒群在联合收获机收获、输送及储藏等过程的蠕变参数,为谷子等杂粮作物的低损机械收获、加工、储藏及参数优化等提供理论依据。

1 试验材料和方法

1.1 试验材料

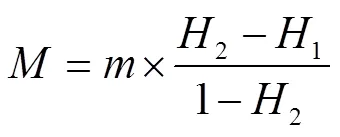

本试验所用谷子取自山西农业大学谷子试验田,品种为晋谷21号和张杂10号,这些品种大面种植于山西乃至全国,具有较强的代表性。考虑谷子贮藏、加工时的含水率为10%~13%,谷子收获时的含水率约为18%~20.00%,合理划分谷子的含水率,分别为12.10%、16.05%、20.00%。为配置不同含水率的谷子籽粒群,用精度为0.01g的分析天平对谷子籽粒群称质量。含水率为16.05%、20.00%的样品需要分2次进行,期间每隔两个小时需要均匀摇晃。配水的过程在塑封袋中完成,将处理好的样品密封,放入冷藏箱中备用,试验前将样品拿出恢复至室温。按式(1)配置含水率。

式中为所需配水的质量,g;为谷子籽粒群的质量, g;1为谷子籽粒群的初始含水率,%;2为需要调配后的含水率,%。

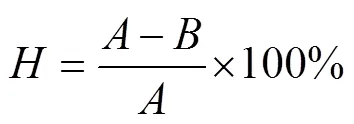

将谷粒试样称质量,准确至0.01 g,并将试样放入温度为105 ℃的干燥箱中干燥4.5 h,时间到后打开干燥箱将样品立即盖上盒盖,取出称质量,记录数据,再放入干燥箱中干燥0.5 h,时间到后重复上述操作,若质量差小于0.02 g,则认为谷子干燥完成。计算含水率,重复3次取其平均值。含水率按式(2)进行计算。

式中为含水率,%;为初始鲜质量,g;为最后干质量,g。

1.2 试验方法

试验采用CMT-6104型万能试验机,设计加工了用于谷子籽粒群流变特性试验的专用夹具,如图1所示,加载压头采用圆柱压头,压头直径为100 mm。试验前进行预试验以了解谷子籽粒群在保证不脱壳、不破壳的前提下所能承受的最大载荷。蠕变试验参数设置为:试验方向为压向,力控制40.0 N/s,目标力控制4 000 N,力保载900 s,试验结束后不自动返车,测定应变与时间关系。

图1 谷子籽粒群蠕变试验夹具

1.3 理论基础

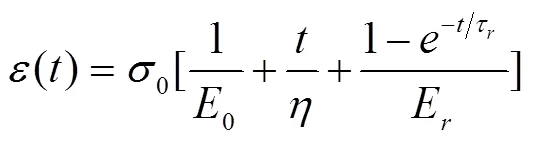

杨明韶等[26-28]认为,农业物料中的大多数是黏弹性体,可分为线性黏弹性体和非线性黏弹性体,目前尚未有成熟的研究支持用非线性黏弹性理论解释农业物料的流变特性,为简化模型,本文拟采用四元件Burgers模型研究谷子籽粒群的蠕变特性,如式(3)所示。

式中()为蠕变过程中时刻的应变,为蠕变时间,s,0为施加的恒定应力,MPa;0为瞬时弹性模量,MPa;E为迟滞弹性模量,MPa;为黏滞系数,MPa·s,τ为延迟时间,s。

2 结论与分析

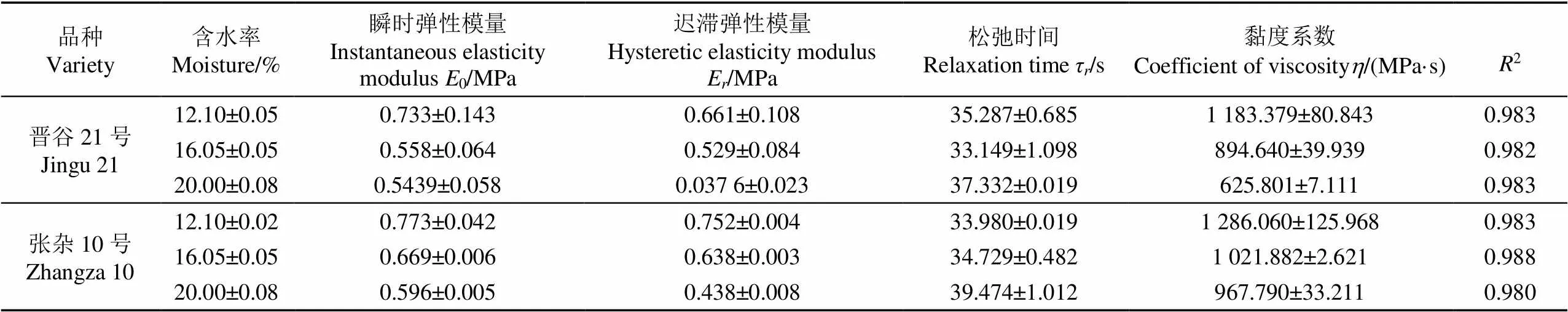

试验获得了应力保持为0.127 MPa下的谷子籽粒群的蠕变特性曲线,根据公式(3),采用本质非线性回归方法计算蠕变参数,用SAS软件拟合不同品种、不同含水率的谷子籽粒群Burgers蠕变模型[29-30],结果如表1所示。

表1 Burgers蠕变模型拟合参数

注:数据采用3次重复取平均值±标准偏差的形式。

Note: Data were averaged in the form of triplicates ± standard deviation.

2.1 品种对蠕变参数的影响

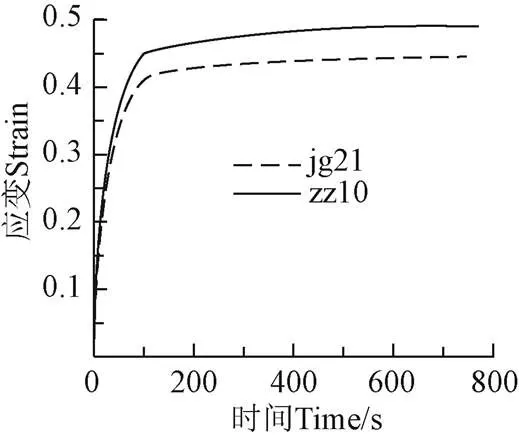

晋谷21号、张杂10号蠕变试验的应变-时间关系曲线如图2所示。

谷子籽粒群蠕变曲线表明,在试验开始至设定载荷过程中,谷子籽粒群的应变随载荷的增加呈线性增长的趋势,在应力保持阶段谷子籽粒群的应变随时间的增加缓慢增大,不同品种的谷子籽粒群蠕变曲线有差异。

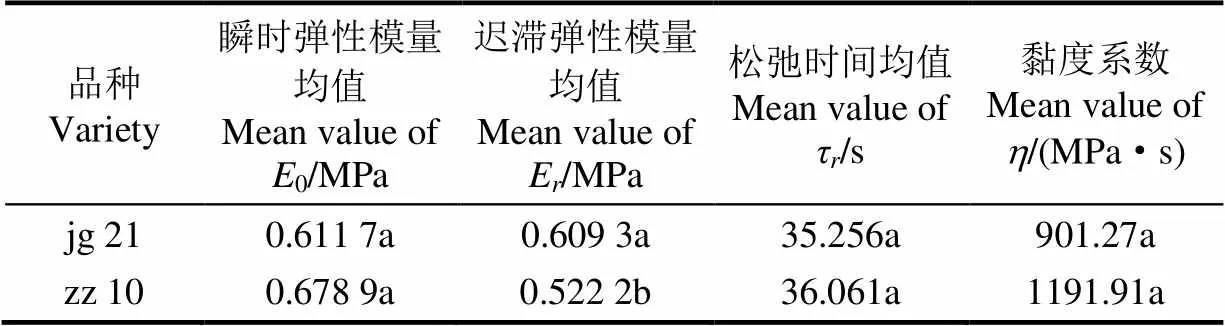

为研究品种对蠕变特性参数的影响,本文选取0.05作为显著性检验标准[26],对试验数据进行方式分析,结果如表2所示。

注:图中jg21代表晋谷21号,zz10代表张杂10号,下同。

表2 不同品种谷子籽粒群蠕变参数的比较

注:同一列数据后不同字母表示数据间有显著差别(<0.05),下同。

Notes: Values in the column with different superscripts were significantly different (<0.05) , the same below.

不同品种的谷子籽粒群的方差分析结果表明:品种对于谷子籽粒群迟滞弹性模量的影响显著,显著性值为0.023 3,晋谷21号谷子籽粒群的迟滞弹性模量均值为0.609 3 MPa,显著高于张杂10号的0.522 2 MPa。迟滞弹性模量表征了谷子籽粒群的硬度,即晋谷21号谷子籽粒群的硬度高于张杂10号,决定系数为0.994 6,分析结论可靠;品种对谷子籽粒群的瞬时弹性模量、松弛时间和黏度系数影响不显著。

2.2 含水率对蠕变参数的影响

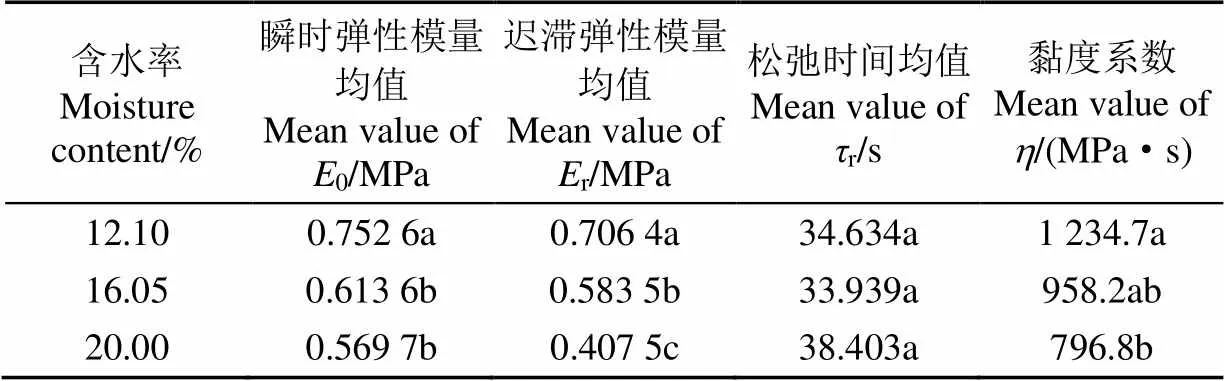

含水率分别为12.10%、16.05%、20.00%的谷子籽粒群蠕变试验的应变-时间关系曲线如图3所示。

为研究含水率对蠕变特性参数的影响,本文选取0.05作为显著性检验标准[26],对试验数据进行方式分析,结果如表3所示。

不同含水率的谷子籽粒群的方差分析表明:含水率对瞬时弹性模量影响显著,显著性值达0.047 3,瞬时弹性模量随含水率升高而减小,在0.05水平上,含水率为12.10%的谷子籽粒群的瞬时弹性模量0.752 6 MPa显著高于含水率为16.05%的0.613 6 MPa和20.00%的0.569 7 MPa,决定系数为0.968 2,说明分析结论可靠;含水率对迟滞弹性模量影响显著,显著性值为0.006 1,随含水率升高,迟滞弹性模量降低,含水率为12.10%、16.05%、20.00%的谷子籽粒群的迟滞弹性模量分别为0.706 4、0.583 5、0.407 5 MPa,决定系数为0.994 6;含水率对谷子籽粒群的黏度系数影响较显著,含水率为12.10%的谷子籽粒群的黏度系数1 234.7 MPa·s显著高于20.00%的796.8 MPa·s,随含水率升高,黏度系数降低,决定系数为0.935 3;含水率对谷子籽粒群的松弛时间影响不显著。

图3 不同含水率的谷子籽粒群蠕变曲线图

表3 不同含水率谷子籽粒群蠕变参数比较

瞬时弹性模量和迟滞弹性模量分别表征谷子籽粒群的弹性和硬度,随谷子籽粒群含水率的升高,其瞬时弹性模量和迟滞弹性模量降低,导致蠕变曲线高度增加,籽粒群的应变随之增加。

3 结 论

本文通过试验研究了不同品种、不同含水率的谷子籽粒群的流变特性,结果表明:

1)对晋谷21号和张杂10号2个品种的谷子籽粒群进行了蠕变试验,拟合获得蠕变模型参数,并以四元件Burgers模型描述了谷子籽粒群的蠕变行为。

2)不同品种、不同含水率的谷子籽粒群均可采用Burgers研究其蠕变特性,但其流变学参数各异。品种对谷子籽粒群的迟滞弹性模量影响显著,晋谷21号谷子籽粒群的迟滞弹性模量高于张杂10号。含水率对谷子籽粒群的瞬时弹性模量、迟滞弹性模量和黏度系数影响均显著,均呈随含水率升高而降低的趋势。

本研究为谷子等农业松散物料的储藏、加工、收获及运输等提供重要的理论依据,影响农业物料流变性能的因素较多,除含水率和品种的影响外,还与温度、物料的内部分子结构及化学成分组成等众多因素相关,农业松散物料的流变特性还需要结合生命科学原理进一步深入研究。

[1]李顺国,刘斐,刘猛,等. 新时期中国谷子产业发展技术需求与展望[J]. 农学学报,2018,8(6):96-100.

[2]盛韶阳. 玉米干燥特性及黏弹性研究[D]. 北京:中国农业大学,2016. Sheng Shaoyang. Study on Drying Characteristics and Viscoelastic Behaviors of Maize Kernels[D]. Beijing: China Agricultural University, 2016. (in Chinese with English abstract)

[3]梁莉,李玉萍,郭玉明. 小麦茎秆黏弹性力学性质试验研究[J]. 农机化研究,2011,33(5):174-177,185. Liang Li, Li Yuping, Guo Yuming. Experimental research on the viscoelastic mechanical properties of winter wheat stalks[J]. Journal of Agricultural Mechanization Research, 2011, 33(5): 174-177, 185. (in Chinese with English abstract)

[4]Ma Senhan, Wen Lili, Wang Xiaoxi. Small and large strain rheology of gluten and gluten-starch doughs containing wheat bran dietary fiber[J]. Journal of the Science of Food and Agriculture, 2019, 100(1): 400-409.

[5]宫泽奇. 青贮玉米秸秆螺旋致密成型工艺及压缩过程流变学试验研究[D]. 中国农业大学,2017. Gong Zeqi. The Experimental Study on Rheology of Silage-corn Stalk in the Mechanized Spiral Dense Forming Process[D]. Beijing: China Agricultural University, 2017. (in Chinese with English abstract)

[6]严平宇,李栋,毛志怀,等. 水稻种子热力学及流变特性测定与数学模拟分析[J]. 农业机械学报,2015,46(7):245-250. Yan Pingyu, Li Dong, Mao Zhihuai, et al. Mathematical simulation analysis of rice seeds on thermal dynamical and rheological properties[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(7): 245-250. (in Chinese with English abstract)

[7]王扬,吕凤妍,徐天月,等. 大豆籽粒形状和尺寸分析及其建模[J]. 吉林大学学报(工学版),2018,48(2):507-517. Wang Yang, Lv Fengyan, Xu Tianyue, et al. Shape and size analysis of soybean kernel and modeling[J]. Journal of Jinlin University (Engineering and Technology Edition), 2018, 48(2): 507-517. (in Chinese with English abstract)

[8]张涛. 谷物力学特性与理化指标及其关联性研究[D]. 兰州:甘肃农业大学,2015. Zhang Tao. Related Study on Mechanical Characteristic And Physicochemical Property of Corn[D]. Lanzhou: Gansu Agricultural University, 2015. (in Chinese with English abstract)

[9]赵晓根. 谷物颗粒流动特性的试验研究[D]. 呼和浩特:内蒙古农业大学,2007. Zhao Xiaogen. Experimental Research on Flow Characteristics of Grain[D]. Hohhot: Inner Mongolia Agricultural University, 2007. (in Chinese with English abstract)

[10]张烨,李长友,李建民,等. 稻谷摩擦特性研究[J]. 广东农业科学,2011,38(13):15-17. Zhang Ye, Li Changyou, Li Jianmin, et al. Experimental study on frictional characteristic of Grain[J]. Guangdong Agricultural Sciences, 2011, 38(13): 15-17. (in Chinese with English abstract)

[11]刘晓. 小籽粒谷物散体力学性质研究及应用[D]. 太谷:山西农业大学,2015. Liu Xiao. Study and Application Agricultural Material Mechanics[D]. Taigu: Shanxi Agricultural University, 2015. (in Chinese with English abstract)

[12]Nuttinee T, Rungtiwa W, Manop S. Physicochemical and rheological properties of flour and starch from Thai pigmented rice cultivars[J]. International Journal of Biological Macromolecules, 2019, 137: 666-675.

[13]Ning Liu, Sen Ma, Li Li, et al. Study on the effect of wheat bran dietary fiber on the rheological properties of dough[J]. Grain & Oil Science and Technology, 2019, 2(1): 1-5.

[14]程绪铎,严晓婕,黄之斌. 储藏条件对大豆籽粒力学特性的影响[J]. 中国粮油学报,2014,29(2):67-71. Cheng Xuduo, Yan Xiaojie, Huang Zhibin. Effects of storage conditions on mechanical properties of soybean[J]. Journal of the Chinese Cereals and Oils Association, 2014, 29(2): 67-71. (in Chinese with English abstract)

[15]马小愚,雷得天,赵淑红,等. 东北地区大豆与小麦籽粒的力学—流变学性质研究[J]. 农业工程学报,1999,15(3):70-75. Ma Xiaoyu, Lei Detian, Zhao Shuhong, et al. Study on the mechanical-rheological properties of soybean and wheat grain grown in northeast China[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 1999, 15(3): 70-75. (in Chinese with English abstract)

[16]张洪霞. 稻米及米饭的力学流变学特性的研究及其应用探讨[D]. 哈尔滨:东北农业大学,2004. Zhang Hongxia. Studies on the Mechanical and Rheological Properties of Brown Rice and Cooked Rice and Discuss of Application[D]. Harbin: Northeast Agricultural University, 2004. (in Chinese with English abstract)

[17]王芳. 西瓜压缩及蠕变特性的研究[D]. 呼和浩特:内蒙古农业大学,2008. Wang Fang. Study on Compressive and Creep Characteristics of Watermelon[D]. Hohhot: Inner Mongolia Agricultural University, 2008. (in Chinese with English abstract)

[18]王芳,王春光,杨晓清. 西瓜的力学特性及其有限元分析[J]. 农业工程学报,2008,24(11):118-121. Wang Fang, Wang Chunguang, Yang Xiaoqing. Mechanics characteristics and finite element analysis of watermelon[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008, 24(11): 118-121. (in Chinese with English abstract)

[19]藏楠. 马铃薯蠕变特性的研究与仿真[D]. 呼和浩特:内蒙古农业大学,2006. Zang Nan. Study and Simulation on Potato Creep Behavior[D]. Hohhot: Inner Mongolia Agricultural University, 2006. (in Chinese with English abstract)

[20]杨作梅,孙静鑫,郭玉明. 不同含水率对谷子籽粒压缩力学性质与摩擦特性的影响[J]. 农业工程学报,2015,31(23):253-260. Yang Zuomei, Sun Jingxin, Guo Yuming. Effect of moisture content on compression mechanical properties and frictional characteristics of millet grain[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(23): 253-260. (in Chinese with English abstract)

[21]孙静鑫,杨作梅,郭玉明,等. 谷子籽粒压缩力学性质及损伤裂纹形成机理[J]. 农业工程学报,2017,33(18):306-314. Sun Jingxin, Yang Zuomei, Guo Yuming, et al. Compression mechanical properties and crack formation law of millet grain[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(18): 306-314. (in Chinese with English abstract)

[22]武翠卿,李楠,张帅,等. 谷子秸秆生物力学性质试验研究[J]. 山西农业大学学报(自然科学版),2016,36(5):377-380. Wu Cuiqing, Li Nan, Zhang Shuai, et al. Experimental study on the biomechanical properties of millet stem[J]. Journal of Shanxi Agricultural University. (Natural Science Edition), 2016, 36(5): 377-380. (in Chinese with English abstract)

[23]梁莉,李玉萍,郭玉明. 小麦茎秆黏弹性力学性质试验研究[J]. 农机化研究,2011,33(5):174-177, 185. Liang Li, Li Yuping, Guo Yuming. Experimental research on the viscoelastic mechanical properties of winter wheat stalks[J]. Journal of Agricultural Mechanization Research, 2011, 33(5): 174-177, 185. (in Chinese with English abstract)

[24]杨作梅,郭玉明,崔清亮,等. 谷子摩擦特性试验及其影响因素分析[J]. 农业工程学报,2016,32(16):258-264. Yang Zuomei, Guo Yuming, Cui Qingliang, et al. Test and influence factors analysis of friction characteristics of millet[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(16): 258-264. (in Chinese with English abstract)

[25]张宁,李红波,张燕青,等. 收获期谷子叶片摩擦特性的试验研究[J]. 农机化研究,2019,41(6):154-161. Zhang Ning, Li Hongbo, Zhang Yanqing, et al. Experimental study on the friction characteristics of millet leaves at harvest time[J]. Journal of Agricultural Mechanization Research, 2019, 41(6): 154-161. (in Chinese with English abstract)

[26]杨明韶,马彦华. 农业流变学模型概念分析[M]. 北京:中国农业科学技术出版社,2017:31-56.

[27]李翰如,潘君拯. 农业流变学导论[M]. 北京:农业出版社,1990:51-54.

[28]周祖锷. 农业物料学[M]. 北京:农业出版社,1994:29-34.

[29]GB/T 4889—2008,数据的统计处理和解释正态分布均值和方差的估计与检验[S]. 中华人民共和国国家质量监督检验检疫总局;中国国家标准化管理委员会.

[30]王玉顺,武志明,李晓斌,等. 试验设计与统计分析SAS实践教程[M]. 西安:西安电子科技大学出版社,2012:166-167.

Effects of variety and moisture content on mechanical properties of millet

Qiu Shujin1, Yuan Xiangyang2, Guo Yuming1, Cui Qingliang1※, Wu Xinhui1, Zhang Zhiyong1

(1.,,030801; 2.,,030801,)

In order to clarify the rheological mechanical properties of millet grain group during mechanical harvesting and processing, this paper studied the effects of different varieties and different moisture contents on the creep characteristics of millet grain group. In this experiment, different varieties (Jingu 21, Zhangza 10), and different moisture contents (12.10%, 16.05%, 20.00%) of millet grain group were selected as creep experimental factors. The creep characteristics (instantaneous elastic modulus, delayed elastic modulus, relaxation time and viscosity coefficient) of millet seed group were used as experimental indicators, and one-way analysis of variance and multi-factor analysis of variance were performed. Based on the original contents of millet seed group, the target moisture contents of the millet grain group were formulated to be 12.10%, 16.05%, 20.00%. The experiment was conducted on the CMT-6104 universal testing machine, and the special fixture for testing the creep characteristics of millet grain group was designed. Combining the Burgers model, nonlinear programming method was used to optimize search regression parameters, and creep parameters of millet grain group were obtained. The creep curve of millet grain group of different varieties showed that, as time going on, the amount of deformation caused by creep tended to be constant, which reaching the strain saturation. There were differences in the millet grain group creep characteristic curves of the different varieties. The significance test standard was 0.05, and the variance analysis was performed. The results showed that the creep characteristics of millet grain group could be described by the four-element Burgers model, and the creep parameters of millet grain group with different moisture content and different varieties were different. The variety had a significant effect on the delayed elastic modulus of the millet grain group. The delayed elastic modulus of the Jingu 21 millet grain group was higher than that of Zhangza 10. The moisture content had significant effects on the instantaneous elastic modulus, delayed elastic modulus and viscosity coefficient of the millet grain group, which was decreasing while the moisture increasing. The instantaneous elastic modulus of the millet grain group with the water content of 12.10% was significantly higher than the water content of 16.05% and 20.00%. The delayed elastic modulus of the millet grain group with the moisture content of 12.10% was significantly higher than the water content of 20.00%. The instantaneous elastic modulus and the delayed elastic modulus represented elasticity and hardness of the millet grain group, respectively. With the increasing of the moisture content of the millet grain group, the instantaneous elastic modulus and the delayed elastic modulus of millet grain group decreased, resulting in a high increasing of the creep curve. The strain in the screw conveyor of combine harvester was correspondingly larger. In this paper, the creep properties of millet grain group with different varieties and different moisture contents were studied experimentally, which provided theoretical support for low-loss harvesting, processing and storage and parameter optimization of millet. There are many factors affecting the mechanical properties of the material, in addition to the influence of moisture contents and varieties, it is also related to many factors such as temperature, internal molecular structure and chemical composition of the material, et al. The rheological properties of agricultural materials need to be further studied in conjunction with the principles of life sciences.

moisture content; mechanical properties; model; millet grain group; creep characteristics; variety

邱述金,原向阳,郭玉明,崔清亮,武新慧,张志勇. 品种及含水率对谷子籽粒力学性质的影响[J]. 农业工程学报,2019,35(24):322-326. doi:10.11975/j.issn.1002-6819.2019.24.038 http://www.tcsae.org

Qiu Shujin, Yuan Xiangyang, Guo Yuming, Cui Qingliang, Wu Xinhui, Zhang Zhiyong. Effects of variety and moisture content on mechanical properties of millet[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(24): 322-326. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2019.24.038 http://www.tcsae.org

2019-07-28

2019-11-27

“十三五”国家重点研发项目(2016YFD0701801);国家现代农业产业体系(CARS-06-13.5-A28);山西农业大学博士科研启动项目(2015YJ01);晋中市科技重点研发计划(Y182013)

邱述金,副教授,博士,主要从事农业物料机械特性与农业机械化装备研究。Email:sxauqsj@sina.com

崔清亮,教授,博士,主要从事农业物料机械特性与农业机械化装备研究。Email:qlcui@126.com

10.11975/j.issn.1002-6819.2019.24.038

S183

A

1002-6819(2019)-24-0322-05