Environmental load of solid wood floor production from larch grown at different planting densities based on a life cycle assessment

Siying Hu•Xin Guan•Minghui Guo•Jinman Wang

Abstract As one of the main structural units in a building,a solid wood floor has significant strategic research value for low-carbon energy saving.Taking the production line of a solid larch wood floor as a case study,we assessed the environmental load during production based upon a life cycle assessment.Using GaBi 6.0 software,we analyzed the associated carbon sequestration during floor production,with the initial planting density serving as the disturbance factor in a modular analysis.The results indicated that the cutting and finishing steps have relatively intense,negative influences on the environment,whereas transportation,ripping,and trimming do not.Additionally,recycling biomass waste has the potential to reduce greenhouse gas emissions.When the initial planting density was 3.0×3.0 m,carbon sequestration was relatively high.Although the emissions of freshwater pollutants,volatile organic compounds,and fine particulate matter(matter with a 2.5-μm diameter)were comparatively high,the reduction of greenhouse gas emissions was still excellent at this planting density.

Keywords Environmental effect·Larch ·Life cycle

Introduction

The atmospheric CO2concentration has increased from 280 μmol mol-1before the start of the Industrial Revolution in 1750 to 391 μmol mol-1in 2011(IPCC 2013).According to the CO2distribution in the atmosphere,countries north of the Equator are the main sources of carbon emissions,with fossil fuel burning and land utilization changes as the main contributors to anthropogenic CO2emissions(Begg et al.2001;Zhang et al.2005).In mid-and high-latitude regions,which are subject to high levels of nitrogen deposition,land-based ecosystems are the main intermediaries that absorb and sequester CO2via vegetation-mediated photosynthesis(Wu 2015).In natural systems,carbon storage is realized under different time dimensions,and it accumulates in carbon sinks in nature(Olson and Al-Kaisi 2015;Fredrik and Christian 2009;Post et al.1982).Vegetation accounts for approximately 20%of the carbon storage in land-based ecosystems,with tropical forests making the largest contribution,followed by northern-latitude forests.However,deforestation and forest degradation have converted natural carbon sinks into carbon sources(Li 2006;Houghton and Skole 2000).As a result,prolonging the lifetime of stored carbon and improving the environment via human intervention are of critical importance(Antonova and Stasova 1997).

As one of the component units in buildings,the floor is a very important factor to consider because its environmental effects are of great practical importance to optimizing building design.In a comparative analysis of the environmental effects of a wood floor at the University of Wisconsin,USA,a vinyl synthetic floor,and a nylon carpet,production of the wood floor resulted in lower air pollutant emissions and required less water and energy than for vinyl synthetic floor and nylon carpet(Nair et al.2013).Nebel et al.(2006)conducted a life cycle assessment(LCA)of 70%of the floor producers in Germany and found that floor production and utilization consume small amounts of energy.However,wood production has a significant influence on the environment from the perspectives of raw materials,manufacturing,and transportation,whereas harvesting and transportation have relatively insignificant effects(Puettmann and Wilson 2005).While scientific advances in forest cultivation reduce the detrimental environmental effects of wood production(He et al.2012;Ma et al.2010;Primo et al.2016),the effects of floor production,transportation,and the recycling of wood waste have rarely been studied.Based upon preliminary studies,we adopted an LCA to examine the influence of cultivated larch timber under different initial planting densities on resource consumption and environmental emissions during floor production.

Materials and methods

Sample collection

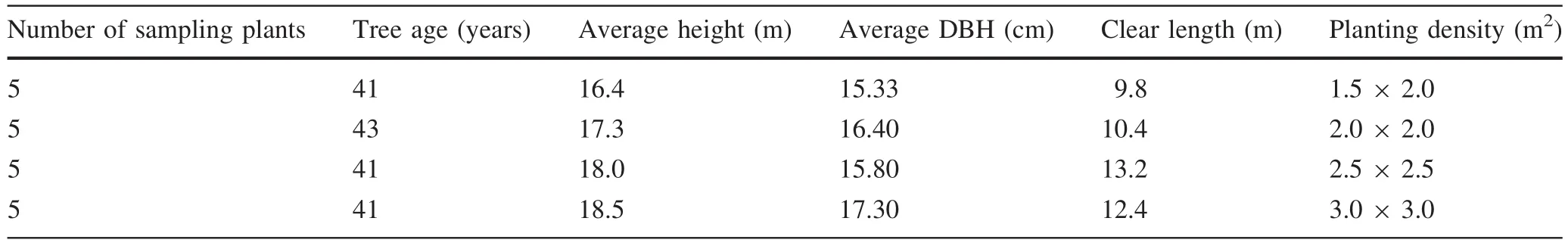

Samples were collected in stands of cultivated larch on the experimental forestry farm near Mount Maoer of the Northeast Forestry University.The samples were taken in stands with different initial planting densities,in accordance with the method of sample tree collection for physical and mechanical tests of wood(GB1927-91).Five samples were collected from each standard plot,and 25-and 50-mm-thick disks were excised from the trees at breast height,marked,and taken back to the laboratory.The characteristics of the collected wood samples are given in Table 1.

Assessment of the carbon storage volume

The carbon storage of the cultivated larch was calculated via the equation below:

whereMcis the carbon storage volume of lumber;ris the cell wall percentage,an important index for carbon storage research that is determined using the method of Guo(1996);Vis the volume of timber,derived from the sectional measurement of the felled timber;andnis the transformation factor for conversion of density and cell wall percentage.

Method for assessing environmental effects

The Divine Arctic Wood Co.,Ltd.was used as a case study.To analyze the environmental effects of floor production and transportation using larch as the raw material,we studied the production line of a solid cultivated larch floor,whose dimensions were 15×105×910 mm.The solid larch floor is a highly industrialized product processed according to a standardized work flow,whereas the planting,harvesting,and paint preparation steps are upstream processes during floor preparation;in this study,we focused on the former.The energy consumption and environmental effects were analyzed and assessed during processing of the solid larch floor comprising the following stages: timber→cutting→ripping→planing→trimming→milling→sanding→repairing→priming→drying→ finishing→drying→inspecting→packing.The steps from repairing to drying are part of lacquering process.

The data presented in this study were derived from the operation of the aforementioned enterprise and its database.The planting,production,and transportation phases of floor production(larch,processing equipment,workshop establishment,packing film,etc.)and the subsequent use of the solid floor were not included in the system boundary.According to the 5%principle,the environmental variables for the minor material flow during processing,such as theglue used during repairing,and the water that evaporated during film drying,were not considered.

Table 1 Characteristics of the tree and wood samples at different planting densities

Inventory analysis

Taking the non-uniqueness of the system function into account,we determined the system function using objects and system boundaries,with functional units serving as quantitative measures of data output and input.During the actual floor production,quality of the solid larch floor was assessed based on its physical and mechanical properties,rather than on the properties of the product.Thus,a unit of mass(kg)could not be used as an elementary unit.Furthermore,the fact that the product’s sale is evaluated based on its volume,1 m3volume of the solid larch floor was selected as the functional unit.Hence,data inputs of the material flow and energy flow during each phase of production were calculated based on the required quantity of the solid larch wood floor(1 m3)demanded.

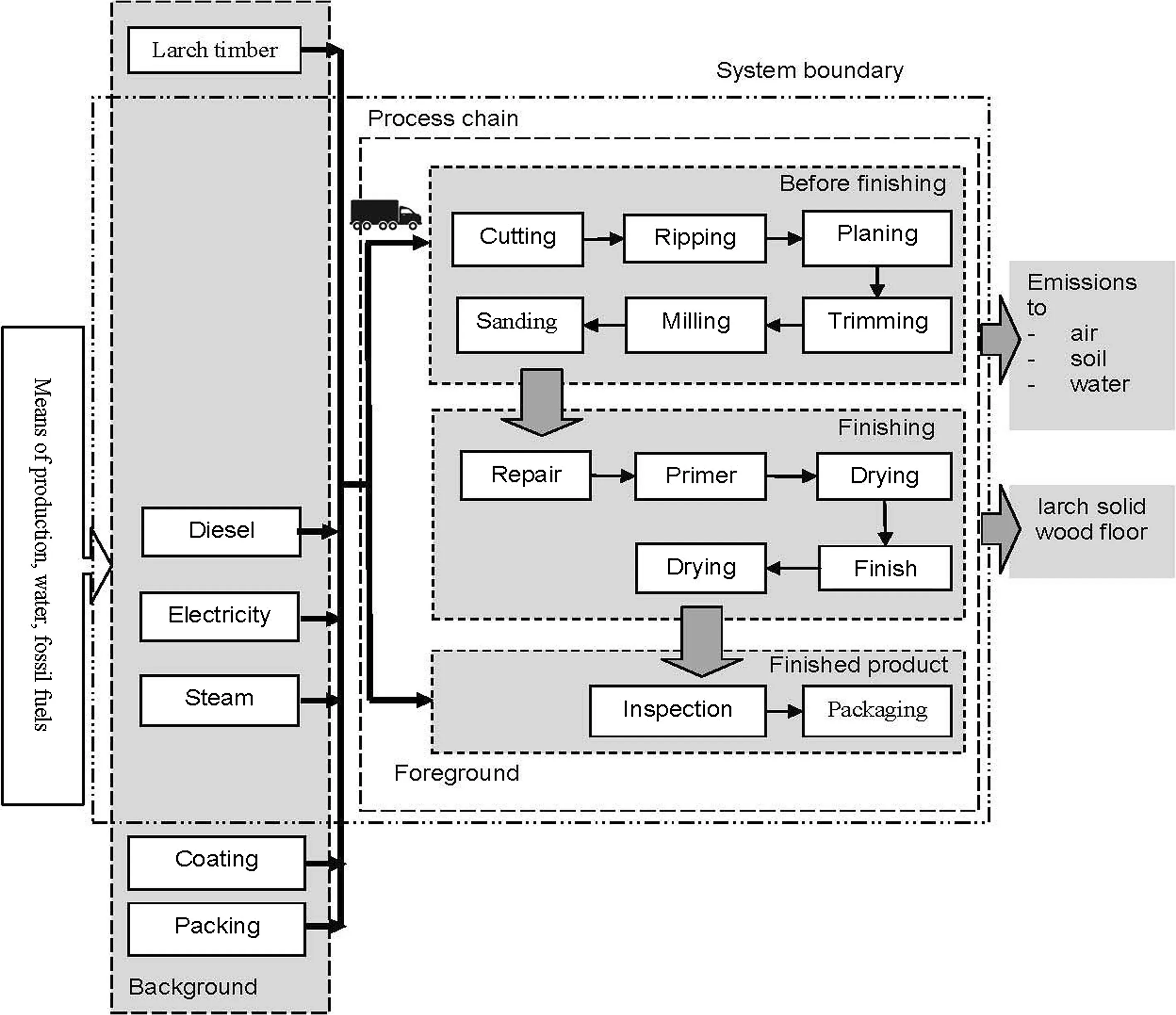

An LCA inventory analysis can generate quantitative statistics regarding the input and output data of resource consumption,energy consumption,wastewater emissions,and solid waste emissions during processing.The scope,inputs and outputs of the system are presented in Fig.1.

The environmental load during the processing of a solid larch wood floor includes(1)the consumption of renewable resources,namely,the wood-based biomass waste produced during cutting,ripping,trimming,planing,and milling,which will be recycled as biomass fuel.The production of 1 m3of a solid larch wood floor consumes 534.048 kg of these recyclable materials,which during the model calculation,was equivalently converted into the electricity generated from the burning of fossil fuels.It also includes(2)the consumption of nonrenewable resources,which refers to the diesel consumed during the transportation of sawn timber.The sawn timber of larch in this study was transported via a 38-tonne truck.According to the actual situation,the highway,road,and backroad coefficients were set as 0.37,0.62,and 0.01,respectively.Additionally,the consumption also includes 500.95 kW of electricity used during the processing of 1 m3of the solid larch wood floor.

Life cycle impact assessment

From the information in the GaBi 6.0 software and relevant databases such as Ecoinvent and an extensional database of building materials,as well as manufacturing,energy,and terminal treatments,we estimated the environmental impacts on the emissions within the system boundary.To restrict in determinant factors,we established a quantitative model via CML2011(Guinée 2002)and included the following items in the assessment indexes:abiotic depletion(ADP), acidification potential (AP), eutrophicationpotential(EP),global warming potential(GWP),ozone layer depletion potential(ODP),and photochemical ozone creation potential(POCP).

Fig.1 Life cycle assessment of the solid larch wood floor

Nondeterminacy analysis

Some factors,such as the difference in the carbon content of the sawn timber due to climate factors or genetic differences among trees,or differences in biomass waste due to growth or manufacturing deficiencies,are uncertain during the LCA of a solid larch wood floor.Thus,taking the random error of the measurements and the approximity of modeling,we adopted a Monte Carlo simulation to analyze the uncertain factors in the model.

Response assessment of planting density

To further assess the influence of the carbon storage of larch at different initial planting densities on the environmental load of the solid wood floors within the boundary,we conducted a comparative analysis on the input and output streams via the situational model in GaBi 6.0.

Results and discussion

Analysis of environmental influences

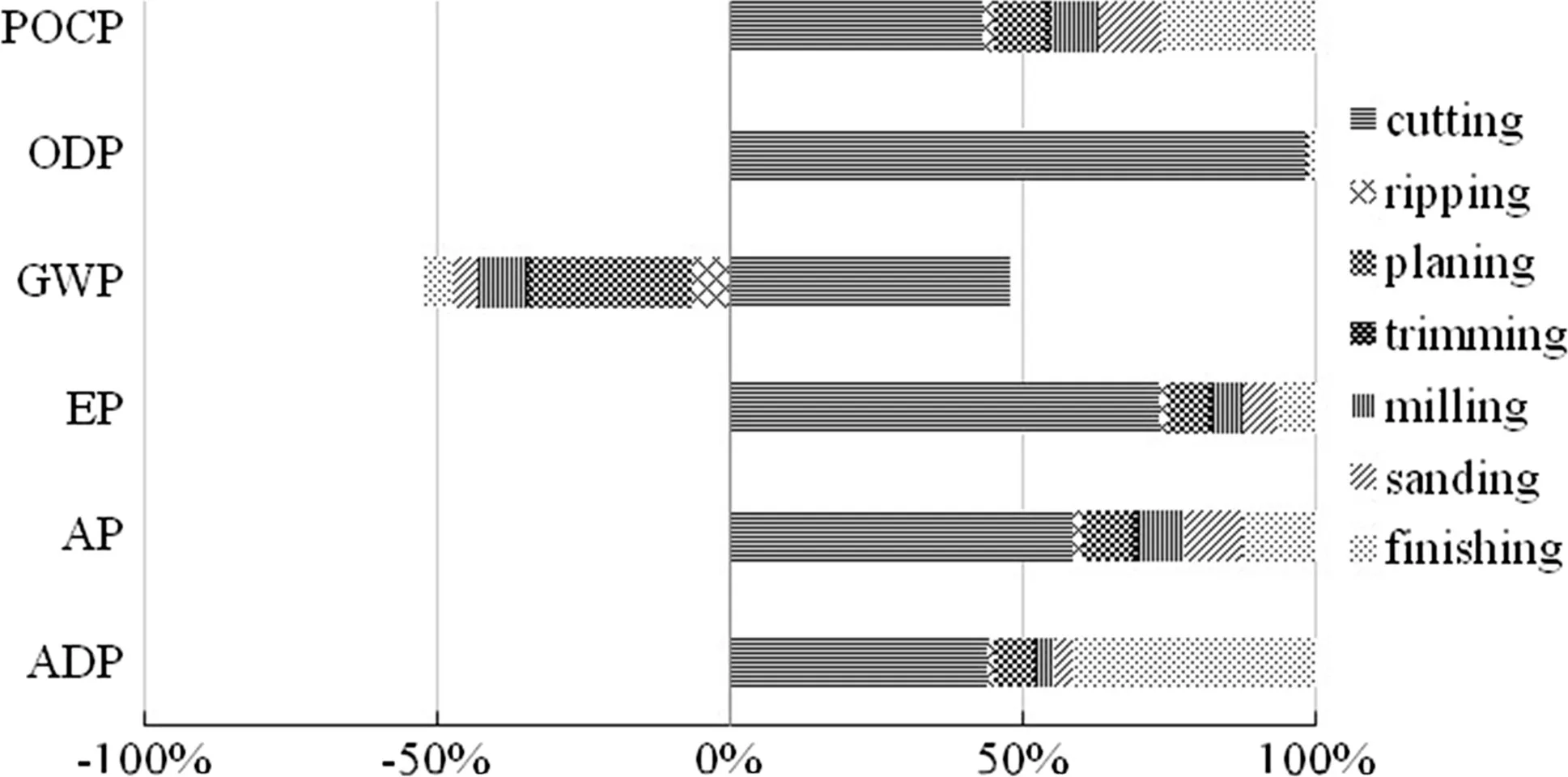

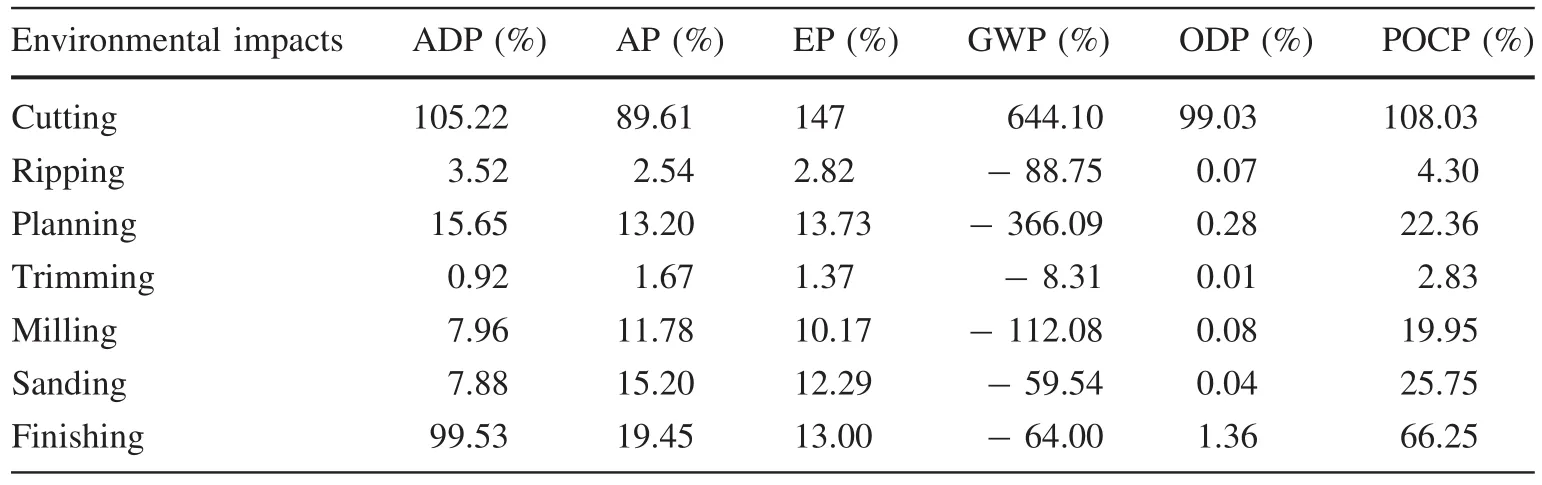

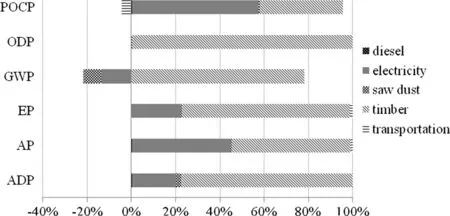

The normalized results of the influences of the solid larch wood floor production processes on the environment are shown in Fig.2 and Table 2.

Fig.2 Relative contributions of the different processes to various environmental impacts.Impacts:ADP abiotic depletion,AP acidification potential,EP eutrophication potential,GWP global warming potential,ODP ozone layer depletion potential,POCP photochemical ozone creation potential

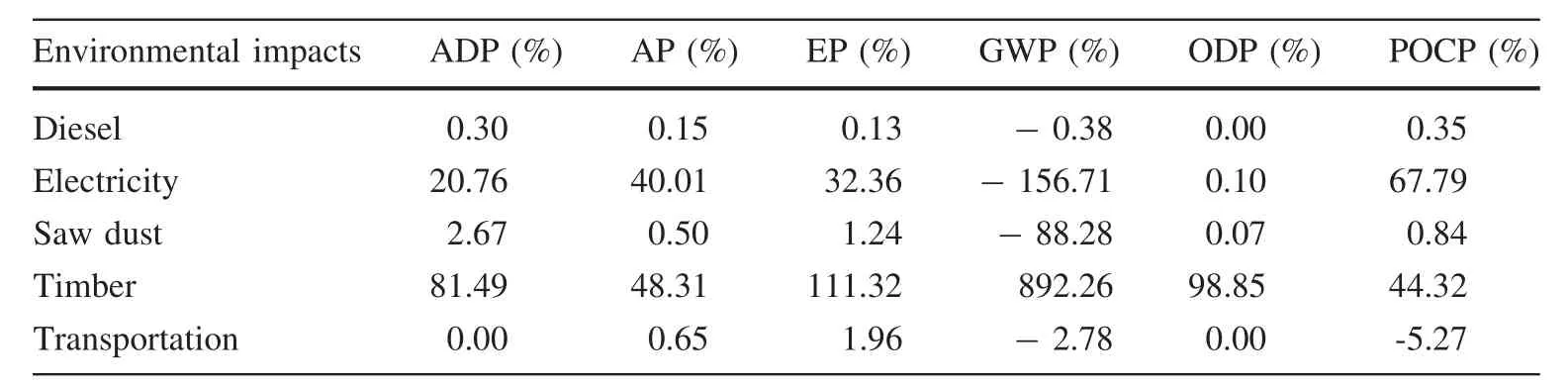

It can be seen that the overall environmental impact by both ripping and trimming was lower than that of the other processes.Thus,the influence of cutting,whose secondary subsystems include diesel,electricity,sawdust,transportation,and sawn larch timber,was generally the largest(Fig.3 and Table 3).The influence of sawn larch timber(moisture content,10.7%)included cultivation,harvesting,and drying,which were imported into the model calculation as baseline values.Additionally,the influence of electricity consumption on the environment was greater than that of transportation(Puettmann and Wilson 2005).The contribution of planing to GWP was greater than that of the other processes,because the amount of sawdust generated during the processing and production could offset greenhouse gas emissions due to fossil fuel burning.Additionally, finishing processes contributed greatly to ADP and POCP.According to the data analysis,oil finishing made the greatest contribution to ADP,whereas oil finishing and electricity consumption contributed the most to POCP.

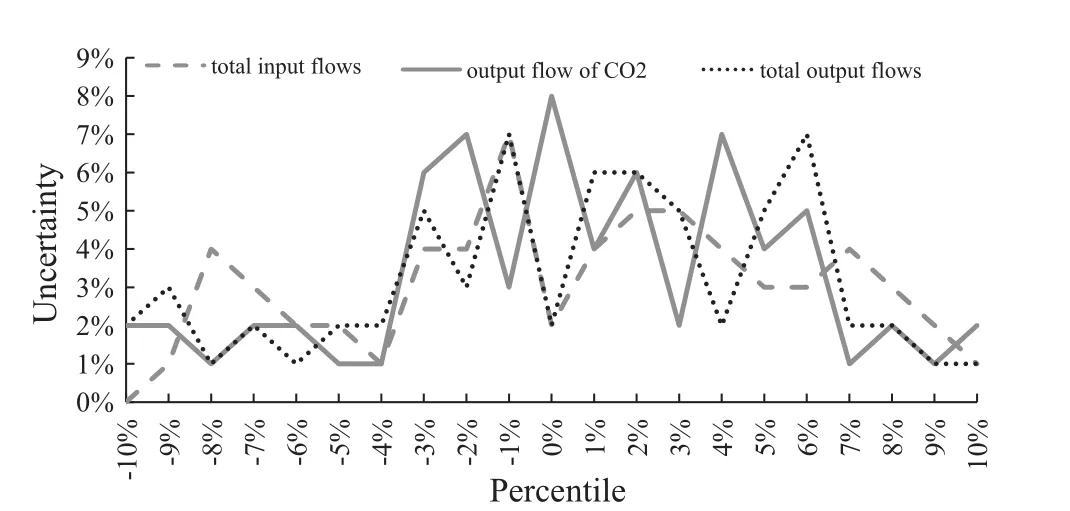

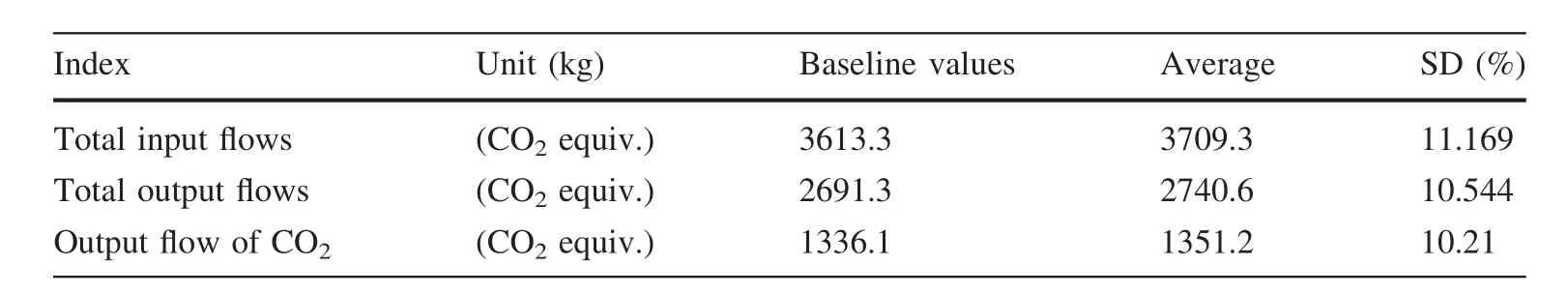

The nondeterminacy analysis

Using GaBi 6.0 software,we quantified the overall nondeterminacy of the data via the Monte Carlo method.The results showed that the output stream was mainly CO2,one of the main greenhouse gases.Therefore,we only conducted the nondeterminacy analysis on the total input/output streams and the CO2output stream(Table 4 and Fig.4).

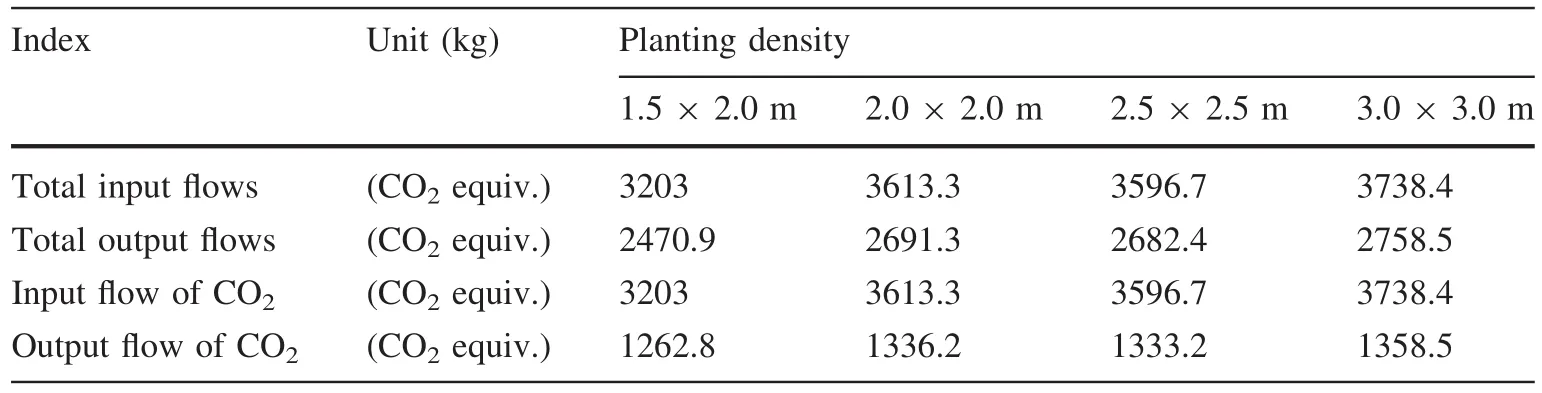

Response assessment of the planting density

We conducted a comparative analysis of CO2equivalents(Table 5)and found that the input/output streams under an initial planting density of 1.5 m×2.0 m were lower,whereas those under a 3.0 m×3.0 m were higher,and those under 0.0 m×2.0 m and 2.5 m×2.5 m densities were similar.Our calculations showed that the level of carbon sequestration under an initial planting density of 3.0 m×3.0 m was2379.9 kg,where as those under 2.0 m×2.0 m,2.5 m×2.5 m,and 1.5 m×2.0 m densities were 102.8,116.4,and 439.5 kg,respectively.Therefore,from the perspective of carbon sequestration,an initial planting density of 3.0 m×3.0 m is optimal for larch cultivation.

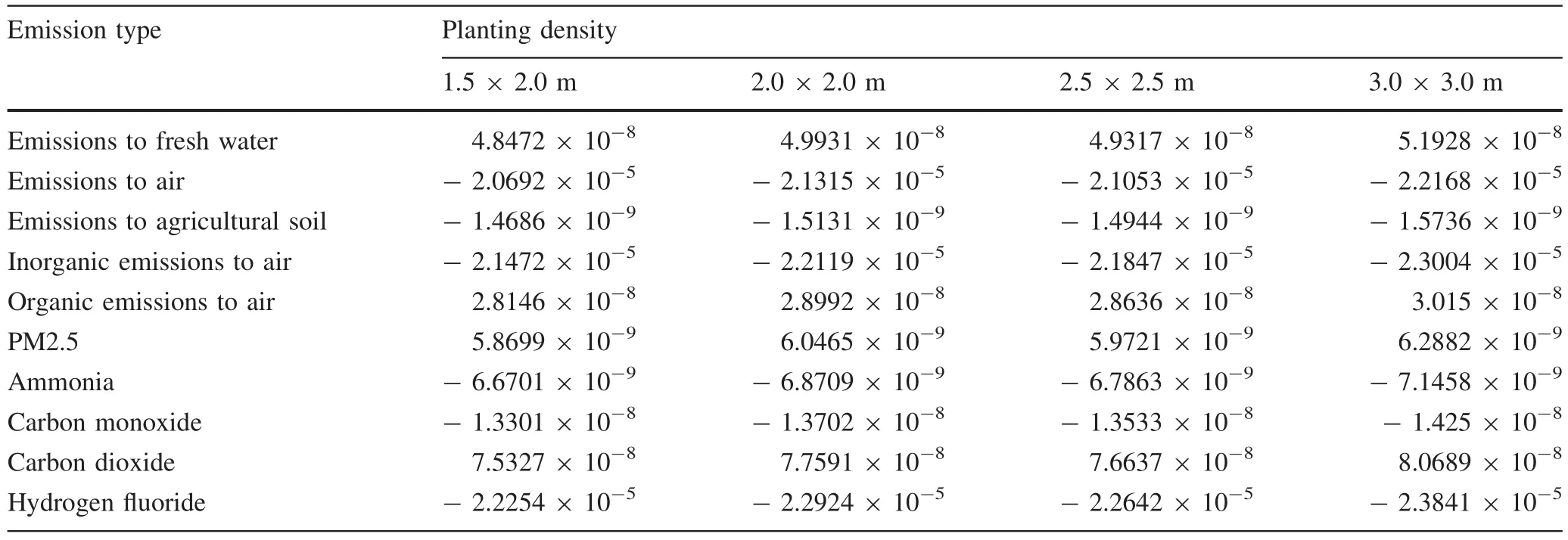

In addition to carbon sequestration,we also assessed emission reductions.The quantified environmental outputs are listed in Table 6.Here,negative values indicate positive influences on the environment,whereas positive values indicate the opposite.Generally,the values of the 10 indices for an initial planting density of 3.0×3.0 m were greater than those for the other planting densities,and freshwater pollutant emissions,volatile organic compounds,particulate matter 2.5(PM2.5),and CO2had the greatest negative influences on the environment.However,as seen from the above analysis,although the CO2emissions were high,it is still beneficial to carbon sequestration on the whole.Therefore,according to the values for the 10indices,the emission reductions at an initial planting density of 3.0×3.0 m were greater than those at all the other densities.

Table 2 Relative contributions of the different processes to various environmental impacts

Fig.3 Relative contributions of the secondary subsystems of the cutting process to the environmental impacts

Conclusions

Fig.4 The results of the uncertainty analysis

To trace the carbon footprint during the production of solid wood flooring from cultivated larch,we analyzed the associated environmental load based on an LCA,and we found that cutting and finishing had greater negative effects on the environment,compared with transportation,ripping,and trimming.Furthermore,the recycling of wood-based biomass material had a positive influence on the environment,especially in terms of a reduction of greenhouse gas emissions.Considering the effect of an artificial disturbance on the carbon storage of cultivated larch,we analyzed the effects of different initial planting densities on the carbon sequestration to produce solid wood flooring from cultivated larch.We found that an initial planting density of 3.0×3.0 m had the most beneficial effect on carbon sequestration and lowest emissions,while its negative influence was mainly reflected by the emission of freshwater pollutants,volatile organic compounds,and PM2.5.

Table 3 Relative contributions of the secondary subsystems of the cutting process to the environmental impacts

Table 4 The results of the uncertainty analysis

Table 5 The differences of input/output flows at different planting densities

Table 6 Different emissions to the environment at different larch planting densities

Journal of Forestry Research2018年5期

Journal of Forestry Research2018年5期

- Journal of Forestry Research的其它文章

- Variability in physical properties of plantation-grown progenies of Melia composita and determination of a kiln-drying schedule

- Optimization of CNC cutting parameters using design of experiment(DOE)and desirability function

- Reduction of electric field strength by two species of trees under power transmission lines

- Forest type identification by random forest classification combined with SPOT and multitemporal SAR data

- Forest mapping:a comparison between hyperspectral and multispectral images and technologies

- Genetic variation of height growth rhythm between clones of Larix kaempferi×L.gmelini based on logistic models