纳米氧化锌改性LDPE食品包装薄膜中锌粒子的迁移规律

黄 皓,李 莉,秦 雨,罗自生,陈杭君,茹巧美

纳米氧化锌改性LDPE食品包装薄膜中锌粒子的迁移规律

黄 皓1,李 莉1,秦 雨1,罗自生1※,陈杭君2,茹巧美3

(1. 浙江大学生物系统工程与食品科学学院,杭州 310058;2. 浙江省农业科学院,杭州 310021;3. 杭州万向职业技术学院,杭州 310023)

为探究纳米氧化锌改性(low-density polyethylene, LDPE)薄膜中纳米锌粒子的迁移规律,依照欧盟法规(EU)No. 10/2011,分别采用蒸馏水、30 g/L乙酸溶液、体积分数10%的乙醇溶液、体积分数95%的乙醇溶液作为中性、酸性、脂肪性和酒精性食品模拟物,研究在不同温度条件下(40、70 ℃)纳米锌粒子的迁移情况,同时探究微波和紫外处理对迁移结果的影响。研究发现,纳米锌粒子在4种食品模拟物中的迁移量从高到低依次为:酸性食品模拟物、中性食品模拟物、酒精性食品模拟物和脂肪性食品模拟物,并且随温度的升高,纳米锌粒子的迁移量增大。此外,微波处理能促进纳米锌粒子的迁移,而紫外处理则没有促进效果。纳米锌粒子的迁移量范围为0.52~14.17 mg/kg。根据欧盟规定所允许的最大迁移量5 mg/kg,迁移试验表明纳米氧化锌改性LDPE薄膜还需要进一步开展减少纳米粒子迁移的研究工作,以确保其在食品包装中的安全使用。

包装;微波加热;紫外灯;LDPE;迁移;纳米氧化锌

0 引 言

低密度聚乙烯(low-density polyethylene, LDPE)膜是一种具有良好的强度和化学特性的包装材料,因此,被广泛应用于食品领域[1]。然而,由于LDPE膜的韧性、热稳定性、抗菌性的不足,它的应用受到了一定的限制。研究显示,运用纳米技术能够有效地克服普通LDPE膜的缺点[2-3]。马磊等[4-5]研究表明纳米SiO2与TiO2改性复合涂膜能够提高对松花蛋的保鲜效果。路洪艳等[6]证实纳米TiO2改性LDPE薄膜有利于保持山核桃贮藏品质。龙门等[7]在复合膜中添加纳米二氧化钛,延长了鸡蛋的保质期。研究发现利用纳米氧化锌改性包装膜能够分别延长苹果[8]和鲜切莲藕[9]的货架寿命。Li等[10]最新研究报道了采用纳米氧化锌改性LDPE薄膜包装的桃果实抗冷性优于普通LDPE薄膜。上述结果表明,纳米改性LDPE薄膜极具研究价值与应用前景。

然而,纳米粒子在加工或者贮藏过程中有可能迁移到食品中,产生食品安全问题[11]。Duncan[12]研究发现,纳米改性膜中的纳米粒子有一定概率从膜中迁移到产品和环境中。鉴于从纳米改性膜(NMFs)中迁移出的纳米粒子的潜在毒性,纳米粒子的迁移问题逐渐成为研究热点。Von-Goetz等[13]和Huang等[14]均对纳米银粒子在食品模拟物中的迁移情况进行了研究。Lin等[15]也报道了纳米二氧化钛聚乙烯膜中纳米钛粒子的迁移情况。欧洲食品安全局发布的标准(EU) No. 10/2011规定纳米改性包装材料在应用前必须进行一系列的迁移试验。

本研究将选取4种食品模拟物,采用(EU) No. 10/2011规定的方法进行迁移试验,探究不同食品模拟物及不同温度对纳米粒子迁移规律的影响,同时研究微波和紫外处理对迁移量的影响,旨在验证纳米氧化锌改性膜的安全性,为其应用提供一定的理论指导。

1 材料与方法

1.1 材料与试剂

LDPE树脂,购于中国石化茂名分公司;纳米氧化锌颗粒(粒径(90±10)nm),购于上海阿拉丁生化科技股份有限公司;钛酸酯偶联剂,购于南京道宁化工有限公司;蒸馏水、冰醋酸、无水乙醇、优级纯浓硝酸、30%过氧化氢,购于国药集团化学试剂有限公司。

1.2 仪器与设备

HAAKE Polylab OS双螺杆挤出机,德国Thermo Electron GmbH 公司;KE19单螺杆挤出机,德国Brabender仪器公司;JEM-1200EX透射电子显微镜,日本JEOL公司;HH-2恒温水浴箱,浙江俊思仪器设备厂;Nexlon 300XX电感耦合等离子体质谱,美国PE公司;ETHOS ONE高压微波消解仪,中国milestone公司;UPW-I-60/90Z优普定量分析型超纯水机,西安优普仪器设备有限公司;WD800ASL23-3微波炉,广东格兰仕公司;30W/G30T8低压汞蒸气紫外放电杀菌灯,荷兰Philips公司;TAINA TN-2254手持式紫外线,台湾TAINA公司。

1.3 试验方法

1.3.1 纳米氧化锌改性LDPE膜的制备

本试验采用钛酸酯偶联剂改性纳米氧化锌,于高速混合机内加入LDPE树脂和改性纳米氧化锌,混合均匀。采用双螺杆挤出机进行造粒,进料速率1.5 kg/h,进料到模头的温度分别为180、190、200、210℃,螺杆转速300 r/min。所得造粒和LDPE树脂再次混合进行二次造粒。再利用单螺杆挤出机制备改性膜,进料到模头的温度分别为200、200、200、210℃,螺杆转速40 r/min。制备所得的纳米氧化锌改性LDPE膜厚度为(46±2)m。在预试验中,对比了纳米氧化锌添加量为0.5%、1.0%、1.5%和2.0%改性膜的力学性能、透气性、透湿性及透光率等性质,结果显示1%添加量的纳米氧化锌改性膜性能最好,因此采用添加量为1%的纳米氧化锌改性LDPE膜和普通LDPE膜进行后续的迁移试验,并参照欧洲标准检验。

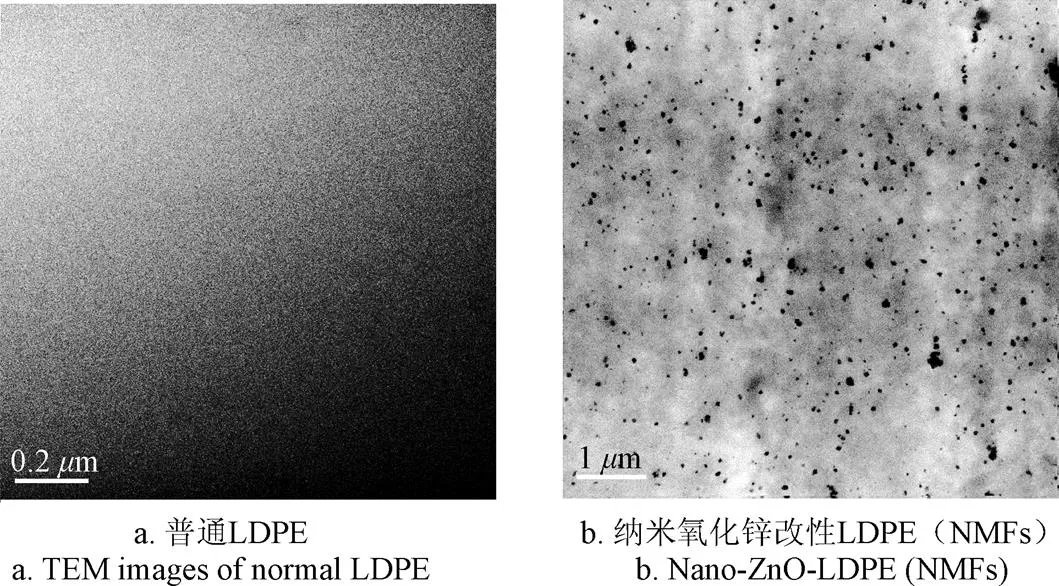

1.3.2 纳米氧化锌改性膜内部纳米粒子分散性表征

采用透射式电子显微镜对纳米粒子分散性进行表征。将样品膜放置于碳包覆铜网格上,在75 kV的加速电压下进行透射电子显微观测[16]。

1.3.3 样品的消解

参考余优军等[17]的方法,将纳米氧化锌改性LDPE膜和普通LDPE膜剪成1 cm×1 cm的碎片。于聚四氟乙烯微波消解罐中放入0.1 g样品碎片,同时加入6 mL浓HNO3和2 mL H2O2,置于微波消解仪中进行消解。消解功率设置为1 000 W,压力设置为3.5 MPa。消解温度在10 min内上升至150℃后,又在10 min内上升至210℃,保持10 min。消解完毕后冷却,再次加热以除去残余的酸。最后将消解液加入100 mL比色管中定容。采用ICP-MS测定锌的初始浓度[18]。使用带有微量雾化器的喷射器将消解液加入ICP-MS仪器中,喷雾室冷至2 ℃。运载气体为氦气。采用带有样品溶液的蠕动泵加入1g/mL的内部标准液钪。ICP-MS参数设置:射频功率为1 100 W,等离子体气体流动速率为16.0 L/min,雾化器流速0.91 L/min,测量模式为KED模式,测定同位素为Zn66。

ICP-MS测得锌浓度的标准曲线为。

(g/L)=905.11+ 6 751.36(2=0.997 6) (1)

式中为锌浓度,g/L;为检测强度。

这表明检测强度与锌浓度呈正相关关系。采用换算公式如下。

式中为换算后锌浓度,mg/kg,将锌浓度的单位由g/L转换为mg/kg。最终纳米锌粒子的迁移结果全部采用mg/kg表示。

1.3.4 迁移试验

依据欧盟标准(EU)NO. 10/2011,采用蒸馏水、30 g/L乙酸溶液、体积分数10%的乙醇溶液、体积分数95%的乙醇溶液分别作为中性、酸性、脂肪性和酒精性食品模拟物。先将样品膜洗净,剪成3.5 cm×3.5 cm的碎片。各取0.1 g样品碎片分别放入装有50 mL食品模拟物的玻璃瓶后,置于恒温水浴锅中进行的迁移反应。温度和时间设置如下:在40 ℃下分别进行2 h,1、4、7 d的迁移试验,在70℃下进行2 h的迁移试验。反应结束后将样品膜取出,采用ICP-MS测定食品模拟物中的锌浓度。

1.3.5 微波处理对纳米锌粒子迁移的影响

将样品膜剪成3.5 cm×3.5 cm的碎片。分别取0.1 g样品碎片,放入装有50 mL中性和酸性食品模拟物的容器中,单面接触。采用250和600 W的微波功率处理6 min。反应结束后,取出样品膜,利用ICP-MS测定食品模拟物中的锌浓度。

1.3.6 紫外处理对纳米锌粒子迁移的影响

采用低压蒸汽紫外杀菌灯(灯管直径2.4 cm,长度89 cm,功率30 W,波长254 nm)作为紫外光源。将样品膜剪成3.5 cm×3.5 cm的碎片。分别取0.1 g样品碎片置于紫外强度6 W/m2的紫外光源下,于40 ℃分别反应0、8、40 h。紫外处理结束后,将样品置于酸性模拟物中在40 ℃下迁移1 d,最后将样品膜取出,利用ICP-MS测定食品模拟物中的锌浓度。

1.4 数据分析

数据统计分析采用SPSS 20软件进行,各指标测定均重复3次,所得试验数据均以平均值±标准方差来表示,以 Duncan’s进行显著性差异比较。运用Origin 9.0软件进行作图。

2 结果与分析

2.1 纳米改性膜中纳米粒子的分布

如图1b所示,在改性膜中纳米氧化锌粒子分散良好,未发生团聚现象。而图1a显示,普通LDPE膜中没有颗粒状物质存在。在透射式电子显微镜下观测到的纳米氧化锌粒子的粒径约为100 nm。该结果表明纳米氧化锌在加入LDPE膜后仍然保持纳米尺寸。钛酸酯偶联剂的改性使得纳米氧化锌粒子由亲水性变为疏水性,使其能在非极性的LDPE膜中充分分散,保持原有的纳米尺寸[19]。

图1 普通LDPE(15 000倍)和纳米氧化锌改性LDPE(15 000倍)膜的透射电镜图

2.2 40℃下纳米锌粒子的迁移情况

测得普通LDPE膜和纳米氧化锌改性LDPE膜中初始的锌浓度分别为45.53 mg/kg和8254.40 mg/kg。如图2所示,在4种食品模拟物中,改性LDPE膜中锌的迁移量均高于普通LDPE膜。这表明较高的锌迁移量是源自用于改性的纳米氧化锌。有相关研究表明纳米复合材料中纳米粒子的迁移量随所加入纳米粒子量的增加而增加[20]。

图2 40℃下,普通LDPE膜和纳米改性LDPE膜在脂肪性,酸性,酒精性和中性食品模拟物中迁移1、4、7 d锌的迁移量

由图2a可见,在中性食品模拟物中,40℃下迁移7 d的锌迁移量要比迁移1 d的高10 %(<0.05)。如图2b所示,40℃下,纳米改性膜在酸性食品模拟物中迁移7 d,锌迁移量为14.17 mg/kg,比40℃下迁移1 d升高了31%(<0.05)。图2c和图2d所示,在酒精性和脂肪性食品模拟物中,迁移7 d的迁移量比迁移1 d的迁移量分别高4%与9%(<0.05)。这表明随着迁移时间的增加,纳米锌粒子的迁移量增大。Hannon等[21]研究了纳米银粒子的迁移情况,结果与本研究类似。总体而言,纳米锌粒子迁移至食品模拟物中的量为膜中初始量的6.2×10-3%~1.7×10-1%,这表明大部分的纳米粒子仍然留在膜中。但纳米锌粒子的迁移量范围为0.52~14.17 mg/kg,该范围已经超出欧盟规定所允许的最大迁移量5 mg/kg,因此纳米锌改性LDPE薄膜存在一定的安全隐患。

图2所示,4种食品模拟物中锌的迁移量由高到低分别为:酸性食品模拟物、中性食品模拟物、酒精性食品模拟物和脂肪性食品模拟物。该结果说明食品模拟物酸性的升高和极性的增大能够促进纳米锌粒子的迁移。Garde等[22]研究证实酸性溶液能够渗透进入膜中,增大膜分子间的空隙,进而提高纳米粒子的迁移率。Bott等[23]研究表明纳米粒子的迁移率随溶液酸性和极性的增加而增大。同时,有相关研究报道,纳米银在酸性模拟物中的迁移量高于中性和酒精性模拟物[24-25]。Addo等[26]研究发现在脂肪性食品模拟物中,纳米银改性包装材料中纳米银粒子迁移量极低。上述研究结果,与本研究结果相近。

2.3 70℃下纳米锌粒子的迁移情况

图3所示,在4种食品模拟物中,70 ℃下迁移2 h,纳米锌的迁移量高于40 ℃下迁移2 h。在中性模拟物中,70℃下迁移2 h的迁移量比40 ℃迁移2 h提高了1 245%(<0.05)。酸性模拟物中,70 ℃下迁移2 h的迁移量比40℃下迁移2 h提高了1047%(<0.05)。而脂肪性和酒精性食品模拟物中,70 ℃下迁移2 h比40℃下迁移2 h分别提高了902%与1 524%(<0.05)。而且,在70℃下迁移2 h的迁移量已经能够达到40 ℃下迁移1 d的迁移水平。而70℃下迁移1 d的迁移量和迁移2 h的迁移量接近,说明70℃下迁移2 h,迁移量已达到饱和。上述结果表明温度的升高能够促进纳米锌粒子的迁移。Lin等[27]研究不同温度下纳米二氧化钛改性聚乙烯膜中钛粒子的迁移,结果表明随温度的升高,纳米钛的迁移量增大,与本研究结果一致。

图3 不同食品模拟物中40和70 ℃下迁移2 h与1 d的纳米锌迁移量

2.4 微波处理对纳米锌粒子迁移的影响

如图4所示,在酸性食品模拟物中,与对照相比,250和600 W的微波处理使纳米锌的迁移量分别提高了约27 %和77%(<0.05)。而在中性食品模拟物中,250和600 W的微波处理则分别使迁移量提高了约22%和53%(<0.05)。

图4 微波处理下,在中性和酸性食品模拟物中40℃迁移1 d的纳米锌迁移量

这表明微波处理能够促进纳米锌粒子的迁移,而且微波功率越大,促进作用越强。这是由于微波处理能够使溶液和薄膜之间发生更加强烈相互作用,加速膜的降解,从而提高纳米粒子的迁移量[28]。Echegoyen等[25]报道了在用700和1 000 W微波处理后,纳米银粒子在中性和酸性食品模拟物中的迁移量增加,与本试验的结果相符。

2.5 紫外处理对纳米锌粒子迁移的影响

如图5所示,在酸性模拟物中,紫外处理对纳米锌的迁移影响并不显著(>0.05)。Funk等[29]报道紫外处理能够增加塑料膜的组成成分在食品模拟物中的迁移量,这是紫外处理加速塑料膜降解的结果。但是,有关紫外处理对纳米粒子迁移的影响还未见报道。本研究结果显示紫外处理并未促进纳米锌的迁移。这是由于纳米氧化锌具有吸收和散射紫外线的能力[30],使得紫外处理对于纳米氧化锌改性薄膜的降解作用较弱,无法促进纳米粒子在食品模拟物中的迁移。因此,紫外处理对于纳米氧化锌改性LDPE膜的纳米锌粒子迁移影响较小。

图5 紫外处理下,在酸性食品模拟物中40 ℃迁移1 d的纳米锌迁移量

3 结论与讨论

本文以纳米氧化锌改性LDPE膜为研究对象,探究了纳米氧化锌改性LDPE膜中纳米锌粒子的迁移规律。采用四种食品模拟物,在不同温度以及紫外或微波辅助处理下进行迁移试验,结果表明,4种食品模拟物中纳米锌迁移量从高到低依次为:酸性食品模拟物、中性食品模拟物、酒精性食品模拟物和脂肪性食品模拟物。温度的升高对纳米锌的迁移有促进作用,微波处理也能够促进纳米锌的迁移,但紫外处理对迁移没有显著的影响。纳米锌粒子的迁移范围为0.52~14.17 mg/kg,有可能超过标准(EU)No. 10/2011所规定的5 mg/kg。因此,纳米氧化锌改性LDPE薄膜存在一定的安全隐患,不能够直接作为食品包装膜使用,仍需要进一步的研究加以改进。

[1] 宋慕波,方方,罗自生,等. 纳米二氧化硅改性LDPE膜对贡柑贮藏品质的影响[J]. 食品与机械,2017,33(1):114-118.

Song Mubo, Fang Fang, Luo Zisheng, et al. Effect of nano-SiO2modified LDPE film on postharvest quality of Gonggan[J]. Food and Machinery, 2017, 33(1): 114-118. (in Chinese with English abstract)

[2] Chaudhry Q, Scotter M, Blackburn J, et al. Applications and implications of nanotechnologies for the food sector[J]. Food Additives and Contaminants, 2008, 25(3): 241-258.

[3] Xing Y, Li X, Zhang L, et al. Effect of TiO2nanoparticles on the antibacterial and physical properties of polyethylene-based film[J]. Progress in Organic Coatings, 2012, 73(2): 219-224.

[4] 马磊,严文静,赵见营,等. 纳米SiO2及TiO2改性复合涂膜提高松花蛋的保鲜效果[J]. 农业工程学报,2015,31(18):269-280.

Ma Lei, Yan Wenjing, Zhao Jianying, et al. Preserved effect of nano-SiO2and nano-TiO2modified composite coating materials on pidan[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(18): 269-280. (in Chinese with English abstract)

[5] 尹月玲,刘瑶,章建浩,等. 纳米SiO2复合涂膜材料包装松花蛋的保鲜效果[J]. 农业工程学报,2012,28(增刊1):281-287.

Yin Yueling, Liu Yao, Zhang Jianhao, et al. Effect of composite conting with nano-silicon dioxide on fresh-keeping of preserved eggs[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(Supp.1): 281-287. (in Chinese with English abstract)

[6] 路洪艳,李莉,罗自生. 纳米TiO2改性低密度聚乙烯包装保持山核桃贮藏品质[J]. 农业工程学报,2017,33(3):288-293.

Lu Hongyan, Li Li, Luo Zisheng. Nano-TiO2modified low-density polyethylene packaging preserving storage quality of Chinese hickory (.)[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(3): 288-293. (in Chinese with English abstract)

[7] 龙门,马磊,宋野,等. 纳米Fe3+/TiO2改性聚乙烯醇基紫胶复合膜对鸡蛋的保鲜效果[J]. 农业工程学报,2014,30(20):313-324.

Long Men, Ma Lei, Song Ye, et al. Preserved effect of nano-Fe3+/TiO2modified PVA-based composite preservation coating for eggs[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(20): 313-324. (in Chinese with English abstract)

[8] Li X, Li W, Jiang Y, et al. Effect of nano-ZnO-coated active packaging on quality of fresh-cut ‘Fuji’apple[J]. International Journal of Food Science and Technology, 2011, 46(9): 1947-1955.

[9] Ding Y, Yun J, Li X, et al. Evaluation of nano-packing on the shelf life of fresh-cut lotus root (NelumbonuciferaGaerth)[J]. Advances in Technology and Management, 2012, 165: 775-780.

[10] Li D, Li L, Luo Z, et al. Effect of nano-ZnO-packaging on chilling tolerance and pectin metabolism of peaches during cold storage[J]. Scientia Horticulturae, 2017, 225(18): 128-133.

[11] Lagaron J M, Cabedo L, Cava D, et al. Improving packaged food quality and safety. Part 2: Nanocomposites[J]. Food Additives and Contaminants, 2005, 22(10): 994-998.

[12] Duncan T V. Applications of nanotechnology in food packaging and food safety: Barrier materials, antimicrobials and sensors[J]. Journal of Colloid and Interface Science, 2011, 363(1): 1-24.

[13] Von-Goetz N, Fabricius L, Glaus R, et al. Migration of silver from commercial plastic food containers and implications for consumer exposure assessment[J]. Food Additives and Contaminants: Part A, 2013, 30(3): 612-620.

[14] Huang Y, Chen S, Bing X, et al. Nanosilver migrated into food-simulating solutions from commercially available food fresh containers[J]. Packaging Technology and Science, 2011, 24(5): 291-297.

[15] Lin Q B, Li B, Song H, et al. Determination of silver in nano- plastic food packaging by microwave digestion coupled with inductively coupled plasma atomic emission spectrometry or inductively coupled plasma mass spectrometry[J]. Food Additives and Contaminants: Part A, 2011, 28(8): 1123-1128.

[16] 陈珊珊, 陶宏江, 王亚静,等. 葵花籽壳纳米纤维素制备工艺优化及其表征[J]. 农业工程学报, 2015, 31(15):302-308.

Chen Shanshan, Tao Hongjiang, Wang Yajing, et al. Process optimization of nanocrystalline cellulose from sunflower seed hull and its characterization[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(15): 302-308. (in Chinese with English abstract)

[17] 余优军,吕飞,杨培玉,等. 微波消解ICP-MS法同时测定凉茶中的六种重金属元素[J]. 现代食品科技,2012(11):1603-1605.

Yu Youjun, Lü Fei, Yang Peiyu, et al. Simultaneous determination of 6 heavy meta elements in herbal tea by ICP-MS with microwave digestion. Modern Food Science and Technology, 2012(11): 1603-1605. (in Chinese with English abstract)

[18] 杨海君,张海涛,刘亚宾,等. 不同修复方式下土壤-稻谷中重金属含量特征及其评价[J]. 农业工程学报,2017,33(23):164-171.

Yang Haijun, Zhang Haitao, Liu Yabin, et al. Characteristics and its assessment of heavy metal content in soil and rice with different repair methods[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(23): 164-171. (in Chinese with English abstract)

[19] 邢宏龙,徐国财,李爱元,等. 纳米粉体的分散及纳米复合材料的成型技术[J]. 材料导报,2001,15(9):62-64.

Xing Honglong, Xu Guocai Li Aiyuan, et al. Development in dispersion of nanoparticles and preparation of organic-inorganic nanocomposites[J]. Materials Review, 2001, 15(9): 62-64. (in Chinese with English abstract)

[20] Cushen M, Kerry J, Morris M, et al. Migration and exposure assessment of silver from a PVC nanocomposite[J]. Food Chemistry, 2013, 139(1): 389-397.

[21] Hannon J C, Kerry J P, Cruz-Romero M, et al. Assessment of the migration potential of nanosilver from nanoparticle- coated low-density polyethylene food packaging into food simulants[J]. Food Additives and Contaminants: Part A, 2016, 33(1): 167-178.

[22] Garde J A, Catala R, Gavara R. Global and specific migration of antioxidants from polypropylene films into food simulants[J]. Journal of Food Protection, 1998, 61(8): 1000-1006.

[23] Bott J, Störmer A, Franz R.Chemistry of Food, Food Supplements and Food Contact Materials from Production to Plate[M]. Washington, DC: American Chemical Society, 2014: 51-70.

[24] Busolo M A, Fernandez P, Ocio M J, et al. Novel silver-based nanoclay as an antimicrobial in polylactic acid food packaging coatings[J]. Food Additives and Contaminants, 2010, 27(11): 1617-1626.

[25] Echegoyen Y, Nerín C. Nanoparticle release from nano-silver antimicrobial food containers[J]. Food and Chemical Toxicology, 2013, 62: 16-22.

[26] Addo Ntim S, Thomas T A, Begley T H, et al. Characterisation and potential migration of silver nanoparticles from commercially available polymeric food contact materials[J]. Food Additives and Contaminants: Part A, 2015, 32(6): 1003-1011.

[27] Lin Q B, Li H, Zhong H N, et al. Migration of Ti from nano-TiO2-polyethylene composite packaging into food simulants[J]. Food Additives and Contaminants: Part A, 2014, 31(7): 1284-1290.

[28] Alin J, Hakkarainen M. Migration from polycarbonate packaging to food simulants during microwave heating[J]. Polymer Degradation and Stability, 2012, 97(8): 1387-1395.

[29] Funk M, Schlettwein D, Leist U. Migration characteristics under long-term storage and a combination of UV and heat exposure of poly (amide)/poly (ethylene) composite films for food packaging[J]. Packaging Technology and Science, 2016, 29(6): 289-302.

[30] Mahmoudifard M, Safi M. Novel study of carbon nanotubes as UV absorbers for the modification of cotton fabric[J]. Journal of the Textile Institute, 2012, 103(8): 893-899.

Migration rules of Zn from nano-ZnO modified LDPE food packaging films

Huang Hao1, Li Li1, Qin Yu1, Luo Zisheng1※, Chen Hangjun2, Ru Qiaomei3

(1.,,310058; 2.,310021,; 3.,310023,)

In order to study the migration of Zn from low-density polyethylene (LDPE) films modified with nano-ZnO, according to the EuropeanUnionregulation NO. 10/2011, distilled water, 30 g/L acetic acid, 95% ethanol (v/v) and 10% ethanol (v/v) were chosen as the neutral, acidic, fatty and alcoholic food simulants, respectively. Nanoparticle modified films (NMFs) were prepared by blending LDPE with nano-ZnO. Film characterization was conducted by transmission electron microscope (TEM) and the migration of Zn was measured by ICP-MS (inductively coupled plasma - mass spectrometry). Migration tests of Zn into 4 kinds of food simulants were performed under 40 ℃ for 2 h, 1 d, 4 d and 7 d, as well as 70 ℃ for 2 h. The effect of different temperatures on the migration was studied. Moreover, the influences of microwave and ultraviolet treatment were also studied. The size of nano-ZnO was observed to be about 100 nm in TEM image. This result indicated that particles in the NMFs still possessed nano size. It was obvious that NMFs had relatively higher content of Zn compared to the control in all kinds of food simulants. For NMFs in neutral simulant, the migration amount of Zn in 40 ℃ for 7 d was 10% higher than that in 40 ℃ for 1 d. While in acidic simulant, the migration amount of Zn in 40 ℃ for 7 d was 31% higher than that in 40 ℃ for 1 d. Migration amount of Zn in 40 ℃ for 7 d were 4% and 9% higher than that in 40 ℃ for 1 d, respectively, in alcoholic and fatty simulants (<0.05). Results showed that the highest migration amount of Zn was in acidic simulant, followed by neutral, fatty and alcoholic simulants. The amounts of migration rose with the increase of temperature. In neutral simulant, the migration amount of Zn in 70 ℃ for 2 h was 1 245% higher than that in 40 °C for 2 h. When in acidic simulant, the migration amount of Zn in 70 ℃ for 2 h was 1 047% higher than that in 40 °C for 2 h. Migration amounts of Zn in 70 ℃ for 2 h were 902% and 1 524% higher than that in 40 ℃ for 2 h in alcoholic and fatty simulants, respectively (<0.05). Microwave treatment could promote the migration. In neutral simulant, compared to the control, microwave treatment of 250 and 600 W increased the migration amount of Zn by 22% and 53%, respectively. While in acidic simulant, migration amount of Zn was enhanced by 22% and 53%, under microwave treatment of 250 and 600 W, respectively (<0.05). However, ultraviolet treatment could not promote the migration of Zn. The amounts of Zn migrated into food simulants ranged from 0.52 to 14.17 mg/kg. The highest migration amount of Zn was beyond the limitation of 5 mg/kg in the European Union regulation No.10/2011. The results of migration test indicated that LDPE films modified with nano-ZnO might not be a kind of safe food packaging film, and it still needs further investigation.

packing; microwave heating; ultraviolet lamps; LDPE; migration; nano-ZnO

10.11975/j.issn.1002-6819.2018.02.038

TS206.4

A

1002-6819(2018)-02-0278-06

2017-09-01

2017-12-26

国家科技重点研发计划项目(2017YFD0401304);国家科技支撑计划课题:生鲜农产品防腐保鲜新型物流包装材料安全评价与示范(2015BAD16B06);浙江省公益技术研究农业项目:新型纳米保鲜材料的开发与应用(2016C32001)

黄 皓,博士生,研究方法为食品科学。Email:qyhuanghao@zju.edu.cn

罗自生,教授,博士,研究方法为食品科学。 Email:luozisheng@zju.edu.cn

黄 皓,李 莉,秦 雨,罗自生,陈杭君,茹巧美. 纳米氧化锌改性LDPE食品包装薄膜中锌粒子的迁移规律[J]. 农业工程学报,2018,34(2):278-283. doi:10.11975/j.issn.1002-6819.2018.02.038 http://www.tcsae.org

Huang Hao, Li Li, Qin Yu, Luo Zisheng, Chen Hangjun, Ru Qiaomei. Migration rules of Zn from nano-ZnO modified LDPE food packaging films [J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(2): 278-283. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.02.038 http://www.tcsae.org