Preliminary results of environmental monitoring of the natural gas hydrate production test in the South China Sea

Jin-ling Ye , Xu-wen Qin , Hi-jun Qiu , Qin-yong Ling , Yi-fei Dong , Jin-gong Wei ,Hi-long Lu, Jing-n Lu , Yo-hong Shi Cho Zhong , Zhen Xi

a Guangzhou Marine Geological Survey, China Geological Survey, Guangzhou 510075, China

b Gas Hydrate Engineering Technology Center, China Geological Survey, Guangzhou 510075, China

c College of Engineering, Peking University, Beijing 100871, China

ABSTRACT

Natural gas hydrate (NGH) is considered as one of the new clean energy sources of the 21st century with the highest potential. The environmental issues of NGH production have attracted the close attention of scientists in various countries. From May 10 to July 9, 2017, the first offshore NGH production test in the South China Sea (SCS) was conducted by the China Geological Survey. In addition, environmental security has also been effectively guaranteed via a comprehensive environmental monitoring system built during the NGH production test. The monitoring system considered sea-surface atmosphere methane and carbon dioxide concentrations, dissolved methane in the sea water column, and the seafloor physical oceanography and marine chemistry environment. The whole process was monitored via multiple means,in multiple layers, in all domains, and in real time. After the production test, an environmental investigation was promptly conducted to evaluate the environmental impact of the NGH production test.The monitoring results showed that the dissolved methane concentration in seawater and the near-seabed environment characteristics after the test were consistent with the background values, indicating that the NGH production test did not cause environmental problems such as methane leakage.

Keywords:

South China Sea

Natural gas hydrate

Production test

Methane leakage

Environmental monitoring

1. Introduction

The relationship between natural gas hydrates (NGH) and environmental changes is an important topic in gas hydrate research. Large-scale NGH dissociation could cause geohazards such as subsidence, landslides, earthquakes(Nisbet EG and Piper DJW, 1998), marine ecosystem change,and even global warming (Weissert H, 2000; IPCC, 2007).Conversely, global warming causes sea water temperature rise, which can further induce the NGH dissociation (Weissert H, 2000), and submarine geohazards (earthquakes, landslides,etc.) also represent a factor of the NGH dissociation on the seafloor (Nisbet EG and Piper DJW, 1998). Therefore, the NGH and the environment interact with each other. In general, the environmental impact of NGH is mainly reflected in the relationship between NGH and global climate change via contribution to the greenhouse effect, seafloor stability,and the destruction of the marine ecological environment.

Previous studies have indicated that, during geological history, some geological and environmental events may be related to the decomposition of NGH, such as the Early Toarcian Oceanic Anoxic Events (Early Toarcian OAE)during the Jurassic (Dickens GR et al., 1995; Hesselbo SP et al., 2000; Weissert H, 2000), Aptian Ocean Anoxic Events(Aptian OAE) during the Cretaceous (Jenkyns HC, 1999;Gröcke DR et al., 1999), Latest Paleocene Thermal Maximum events (Dickens GR et al., 1995, 1997), and global warming during Quaternary Interglacials (Lorius C et al., 1990;Chappellaz J et al., 1990; Brook EJ et al., 1996; Severinghaus JP et al., 1998; Kennett JP et al., 2000). Moreover, the seabed landslides caused by the dissociation of NGH are widely distributed worldwide, such as the Storegga slides offshore of Norway (Paull CK et al., 1991), the Beaufort Sea continental slope landslides off the northern Alaska of the United States(Kayen RE and Lee H, 1991), the Cape Fear slides on the South Carolina continental rise off of the east coast of the United States (Schmuck EA and Paull CK, 1993; Paull CK et al., 1996), the Amazon Fan off continental margin of northeastern Brazil (Clinton P, 1997), the Mega Turbidite of the Balearic basin in the western Mediterranean (Rothwell RG et al., 1998), and the Tuaheni landslide complex on the Hikurangi subduction margin, New Zealand (Lewis KB et al.,1998; Mountjoy JJ et al., 2014; Barnes PM et al., 2017).

Previous studies have shown that NGH development may cause landslides, subsidence and other geological disasters on the seabed. The simulation results of NGH exploitation in the Nankai Trough show that the seabed settlement caused by the short-term hydrate test was limited and had little impact on the environment (Rutqvist J et al., 2012; Yokoyama T et al.,2014). The numerical simulation results of submarine stability of the Shenhu NGH production test area in the SCS indicate that NGH production test will not cause geohazards such as landslides (Shi YH et al., 2018), and the seabed settlement caused by the production test is negligible (Liang QY et al.,2018). The engineering geological conditions of the production test area can meet the requirements of the wellhead and wall stability of the shallow deep-water unconsolidated NGH reservoir.

Although there is a close relationship between NGH and the environment, the environmental impact of hydrate production and development remains unclear. Canada, the United States, Japan, and China have carried out nine NGH production tests in the terrestrial or marine areas (Sloan ED and Koh CA, 2008; Li XS et al., 2016; Li JF et al., 2018), and have achieved a certain understanding; however, there are few public reports on the environmental monitoring results of NGH production tests. It has been suggested that, due to the limited influence of NGH production test on the reservoir or seabed stability, there will be no geohazards such as submarine landslides and subsidence associated with NGH production tests (Rutqvist J et al., 2012; Yokoyama T et al.,2014; Shi YH et al., 2018; Liang QY et al., 2018). In theory,the environmental impact of NGH production presents only a possibility of methane leakage. Based on the results of a study on the NGH environment in the SCS and the environmental monitoring results of the SCS NGH production test, this paper focuses on revealing the potential of methane leakage and the marine environmental change caused by the NGH production test.

2. Marine environment background of NGH production test areas

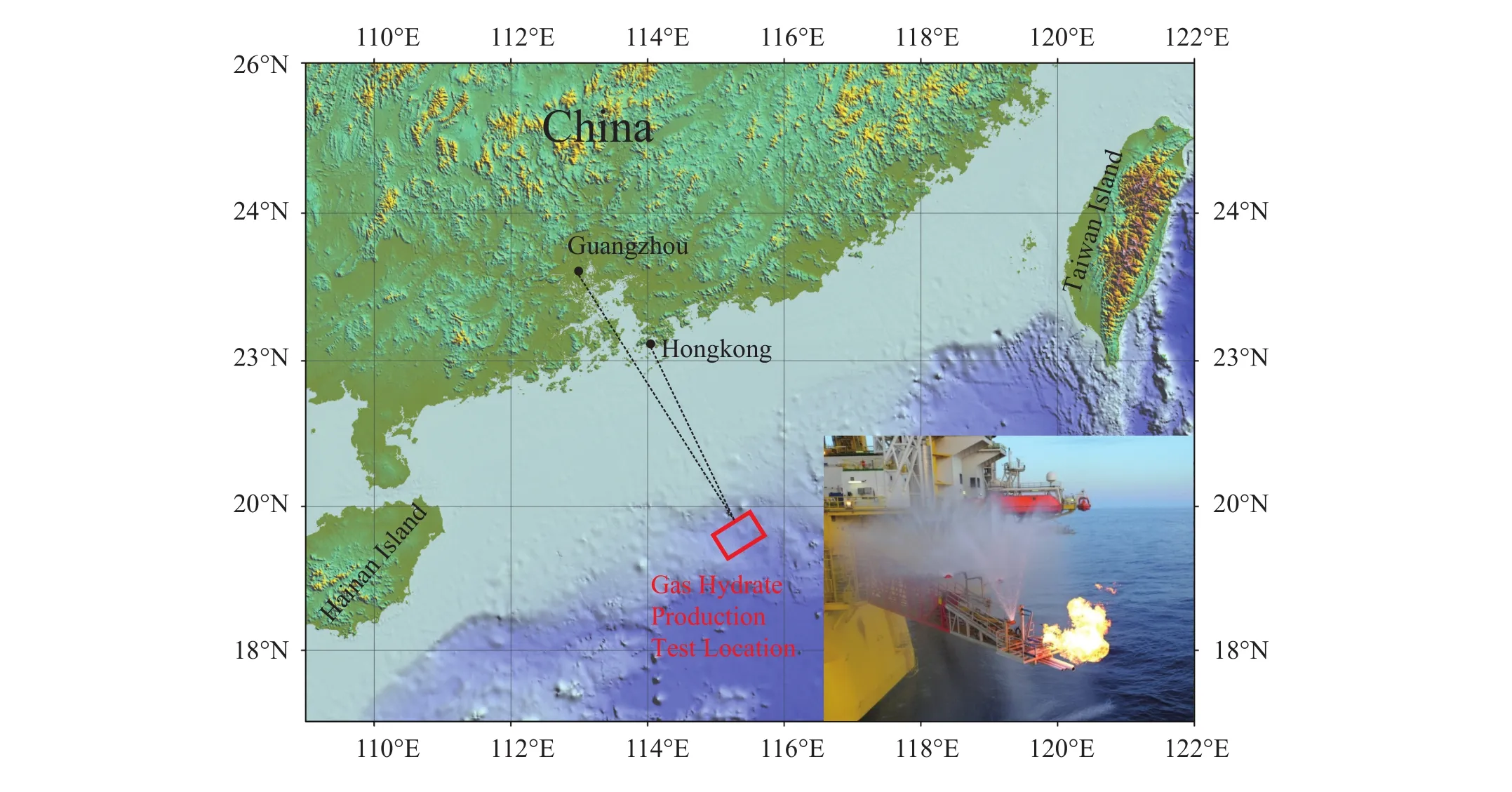

Since 2011, the China Geology Survey has conducted NGH environmental effect surveys in the NGH drilling area,and prospective areas in northern SCS (Fig. 1). Detailed investigations were conducted including sea-surface atmosphere methane and carbon dioxide concentration,marine physical oceanography and marine chemistry environment, and assessment of the marine biological environment and seabed geological environment. In addition,systematic study was performed on the possible causes of methane leakage, submarine landslides, subsidence, and marine ecological changes by marine NGH exploration and production tests.

Fig. 1. Gas hydrate environment effect survey areas and production test location in SCS.

2.1. Topographic features

The Shenhu area is in the mid-slope outside the Pearl River estuary, where the topography is mainly continental slope. The NGH production test area is located on the lower slope of southeastern Shenhu area, with a water depth from 800 m to 1600 m, and average slope value of 4.5°. The geomorphic features are generally characterized by four valleys, three ridges, and valley alternation with ridges. About three-quarters of the production test area, mainly in the north and west, belongs to the canyon wall, and the middle part of the production test area belongs to the canyon valley. The valley edge is steep, and its slope can be up to 6.8°, and the width between 1–5.7 km. The cutting depth is about 100–300 m,with strong slump. The topography of the ridges is the most rugged. The topography of the valley is flat, and some of the valley bottom topography shows clear undulation.

2.2. Submarine geological features

The sediments of the Shenhu NGH production test area are mainly composed of fine-grained sediments in the semideep sea. The shallow surface sediments (<4 m) mainly include four soil types: high liquid limit silt, high liquid limit clay, sand-containing high liquid limit clay, and sandcontaining high liquid limit silt, among which the high liquid limit silt is dominant. The hydrate reservoirs and overlying sediments are mainly silt and clay silt, and silt in some layers.The sediments below seafloor (0–6.5 m) are dominated by“very soft” to “soft” clay; the subsurface sediments (>6.5 m)are dominated by “very hard ” to “hard ” clay and silt.Compared with the overlying sediments, the silt content slightly increased, whereas the content of clay and sand decreased in the hydrate layer.

2.3. Submarine geohazard characteristics

Previous investigations have shown that there were many geological disasters such as landslides and landslides on the slopes of northern SCS (Wu SG et al., 2008; Ding WW et al.,2013; Wang L et al., 2014; Ma Y et al., 2014, 2017; He J et al., 2018). Based on high-accuracy multi-beam data, 3D seismic data, shallow profile, and Autonomous Underwater Vehicle survey data in the production test zone, the investigation results indicated that the disaster factors in the production test zone and the planned well locations included seabed disturbance traces, landslides, small slips, shallow gas,and the erosion surface (He J et al., 2018).

2.4. Characteristics of seawater dissolved methane in production test area

The dissolved methane content was 4.5±3.6 nmol/L in the Pearl River estuary area on the slope of northern SCS (Tseng HC et al., 2017). From May 2013 to March 2017, the background value of methane in the water column of the Shenhu NGH production test area ranged from 0 to 31.4 nmol/L with an average of 7.3 nmol/L, which was slightly higher than that during the year 2013–2015 with 6.7 nmol/L(Liang QY et al., 2017) and that of global seawater with an average of 0.5–2 nmol/L (IPCC, 2001). Previous investigations have shown that there was a relatively high methane flux at seafloor of Shenhu hydrate zone, where methane content was 4.25–10.64 nmol/L in the near-bottom seawater from the southwestern coast of Dongsha Islands (Yin XJ et al., 2008;Zhou HY et al., 2009). The dissolved methane content was 3.3–14.3 nmol/L at the benthic interface in the year 2015 before the NGH production test (Liang QY et al., 2017), and the measured value in 2016 was 1.0–27.8 nmol/L. Therefore,it was indicated that the background value of dissolved methane content was 1.0–27.8 nmol/L at the benthic interface of the Shenhu area.

3. Environmental investigation and monitoring methods

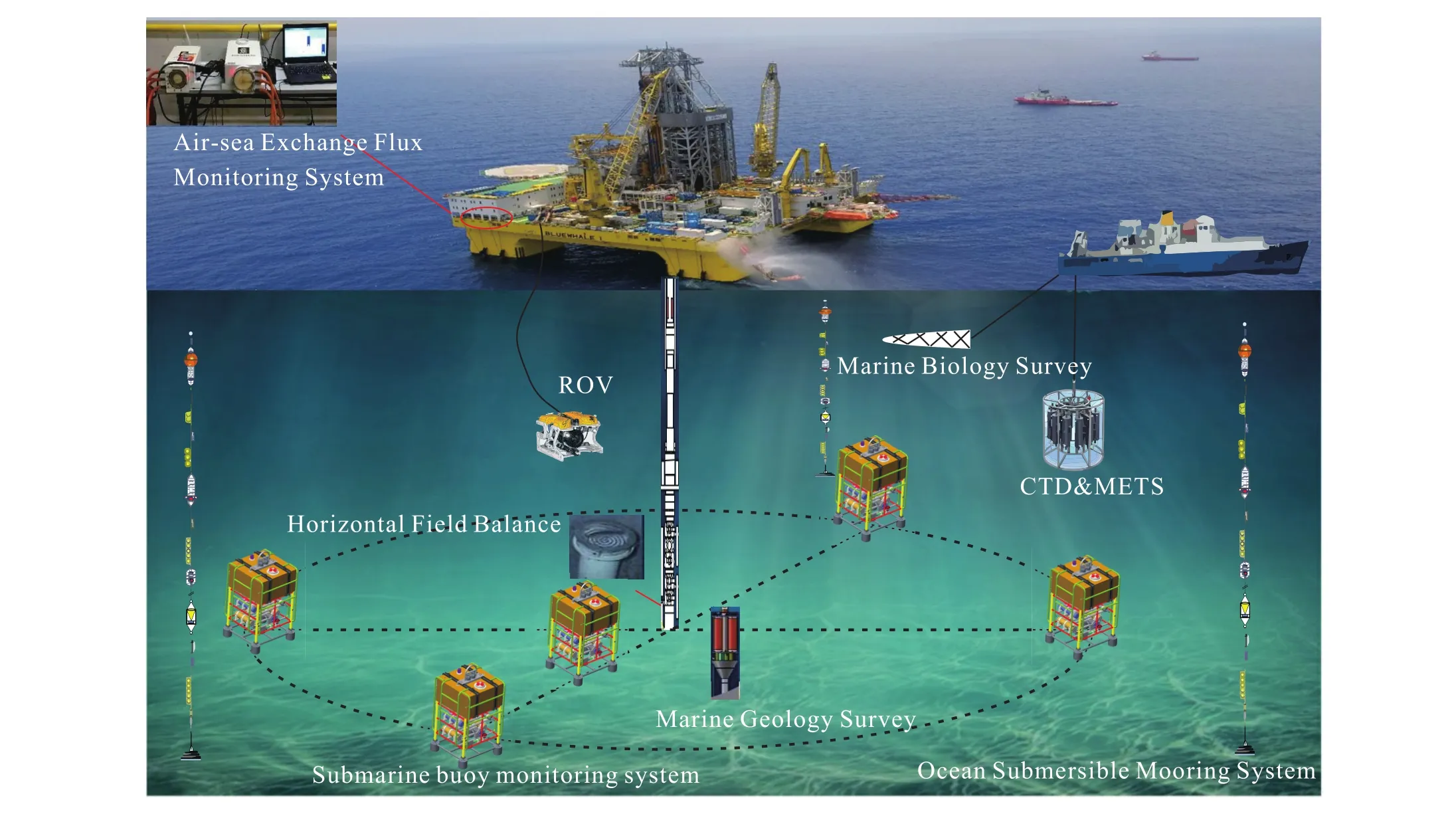

From June 2011 to March 2017, we conducted 13 marine environmental survey voyages in the NGH production area.During the production test, an environmental monitoring system of "four in one" in atmosphere, sea water, seabed, and underground (Li JF et al., 2018; Fig. 2) was established around Bluewhale I platform. The possible methane leakage and marine environmental changes that may be caused by the NGH production test process could be monitored in all directions with this system. After the production test, a comprehensive marine environment survey was carried out.This article focuses on the possibility of methane leakage and the marine environment change which may be caused by the NGH production test, and only introduces the monitoring methods and results of seabed environment and sea water investigation.

3.1. Dissolved methane measurement

Before and after the NGH production test, the dissolved methane content of the water column was measured by improved METS (Franatech Inc., Germany; measurement range from 10 nmol/L to 500 nmol/L, and with a sensitivity of 1 nmol/L) combined with SBE 917plus CTD, which provided power supply and data collection (Liang QY et al., 2017).

During the production test, a METS equipped with an RBR (RBR Ltd, Canada) data collector, was used to monitor the methane leakage on the seabed by Remote Operated Vehicle during the test.

3.2. Submarine methane leakage monitoring during the production test

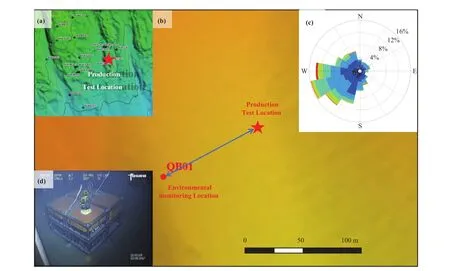

According to the underflow direction and gradient, the submersible buoyant system was positioned 87 m downhill,southwest of the test wellhead (Fig. 3) with the “HY IV” ship.The methane content in the bottom seawater near the wellhead was monitored by the submersible buoyant system during the whole process of production. The methane data were collected for 40 min per 12 h, with a sample interval of 5 s.

Fig. 2. "Four-in-one" environmental monitoring system employed during the production test (from Li JF et al., 2018).

Fig. 3. Schematic diagram of submarine environmental monitoring arrangement in the production test area (a. Gas hydrate production test location; b. Submarine topography and geomorphy map of production test station; c. Rose diagram of production test area; d. Submersible buoyant system in seabed during test production).

4. Results and discussion

4.1. Effect of hydrate test production on dissolved methane content in seawater

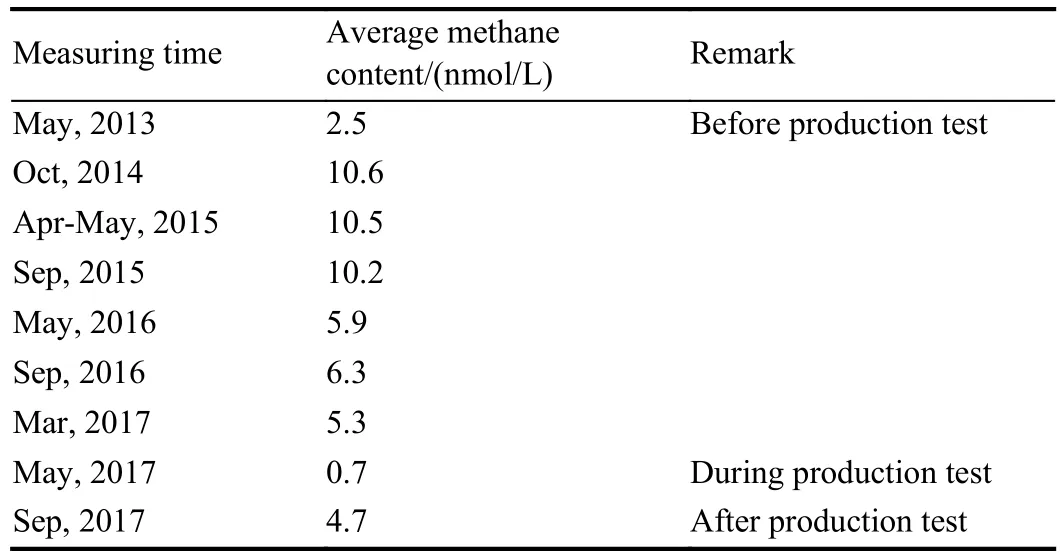

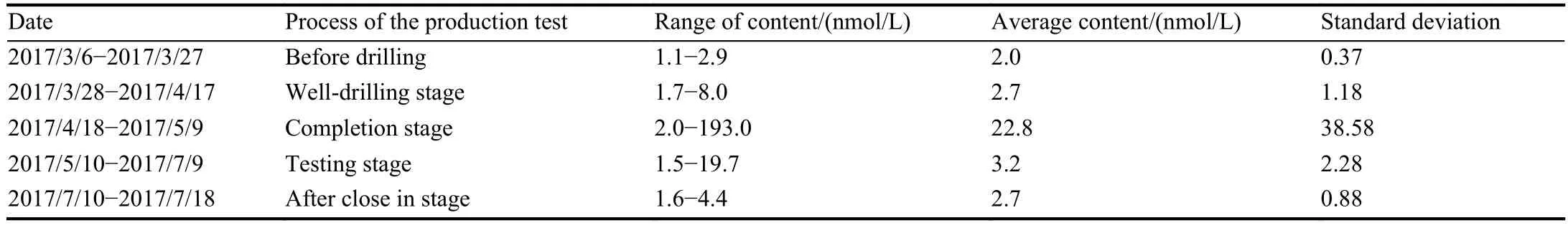

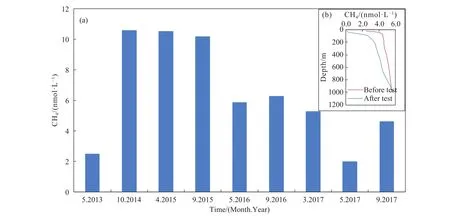

Table 1 shows the average dissolved methane content in seawater from May 2013 to Sep 2017 in the Shenhu area. The seawater dissolved methane content was 2.5 nmol/L in May 2013, 10.6 nmol/L in Oct 2014, 10.5 nmol/L from Apr to May 2015, 10.2 nmol/L in Sep 2015, 5.9 in May 2016, 6.3 nmol/L in Sep 2016, 5.3 nmol/L in Mar 2017, and 4.7 nmol/L in September 2017. Comparison of the pre-test with post-test dissolved methane profile (Fig. 4) indicated no increase in the methane content, suggesting that the NGH production test did not induce methane leakage on the seabed.

Table 1. The profile of seawater dissolved methane content in Shenhu hydrate production test area of SCS.

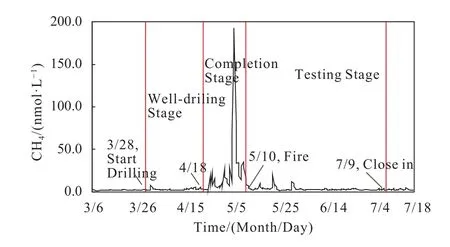

4.2. Effect of NGH production test on seabed methane leakage

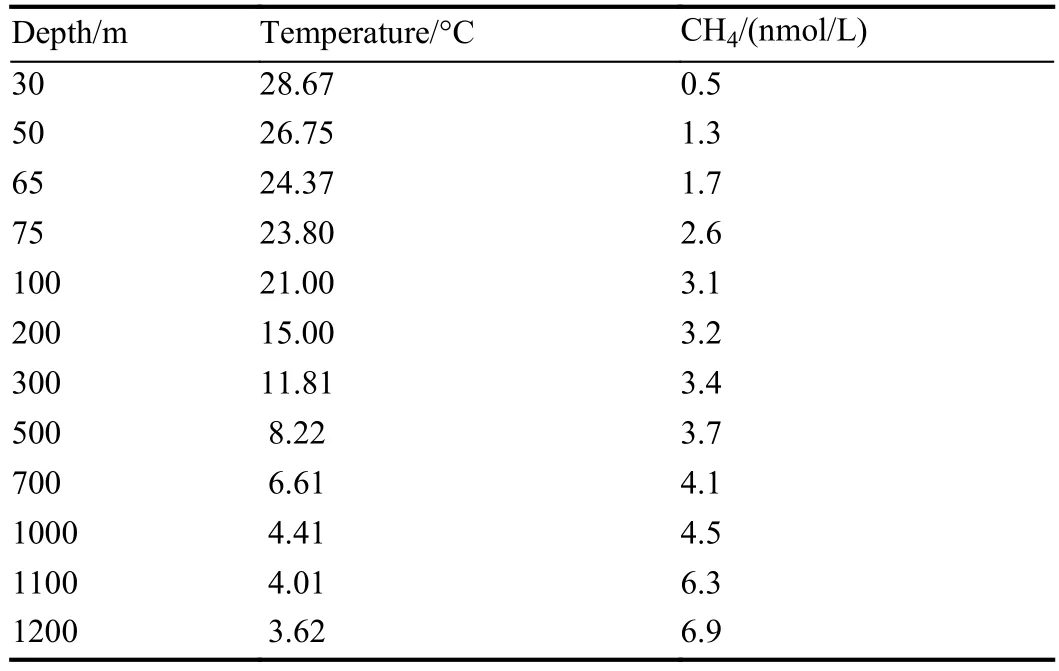

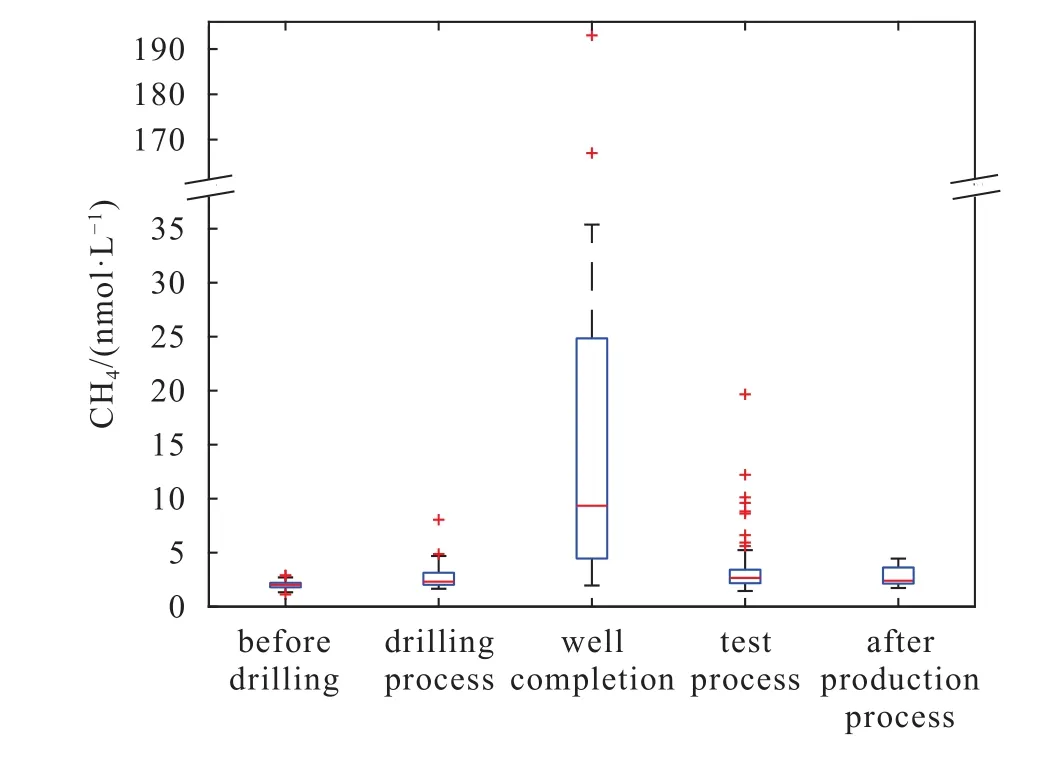

Table 2 shows the changes of dissolved methane content in bottom seawater near the wellhead before and after the production test (March 6 to July 18). From March 6th to March 27th, the methane content ranged from 1.1 nmol/L to 2.9 nmol/L, with an average of 2.0 nmol/L. It was within the background value of methane content in the production test area (Liang QY et al., 2017). During the drilling operation from March 28th to April 17th, the methane content ranged from 1.7 nmol/L to 8.0 nmol/L with an average value of 2.7 nmol/L. When the well was completed from April 18th to May 9th, there was a little methane overflow due to reservoir drilling. The methane content ranged from 2.0 nmol/L to 193.0 nmol/L with an average content of 22.8 nmol/L. After the well cementation, the methane overflow stopped.Subsequently, during the ignition test and abandoned well phase (Fig. 5), the seawater methane content remained at a normal background level (Liang QY et al., 2017).

Table 2. Changes of dissolved methane contents in bottom seawater near the wellhead before and after the production test.

Table 3. Temperature and dissolved methane concentration of water column at production test station.

Overall, from the beginning of drilling operation, methane content distribution in each stage was in a negative partial state, indicating that methane content was relatively low most of the time, except for the completion stage and the methane content distribution showed a low standard deviation,indicating no methane leakage (Fig. 6). In the completion stage, the high methane content showed a large standard deviation, revealing periodic methane leakage. In general, the results suggested that the NGH production test was safe and controllable and did not cause methane leakage.

Fig. 4. Comparison of average dissolved methane content in seawater of production test area (a. The average content of dissolved methane from May 2013 to Sep 2017; b. The profile of seawater methane content at production test location in March and September of 2017).

Fig. 5. Results of methane content in the seabed during production test.

Fig. 6. Methane content box line map at various stages of the production test process.

4.3. Discussion on the effect of NGH production test on the marine environment

Previous studies have shown that natural methane leakage from the seafloor has always existed and only 2%–4% of atmospheric methane comes from the ocean (Cicerone RJ and Oremland RS, 1988; IPCC, 2001; Dickens GR, 2003;Reeburgh WS, 2007). "The benthic filter for methane" in seafloor biota (Niemann H et al., 2006; Sommer S et al.,2006) influences the amount of methane emitted from the sea floor (Reeburgh WS, 2007; Valentine D, 2011). In continental slopes, the anaerobic oxidation of methane in sulphate permeable sedimentary strata by microbes removes almost all the methane formed in the underlying methane production area (Reeburgh WS, 2007; Regnier P et al., 2011). Due to the seawater barrier and microbial action, methane leakage from the seafloor only slightly affects the methane water–air flux of the ocean (Schmale O et al., 2011).

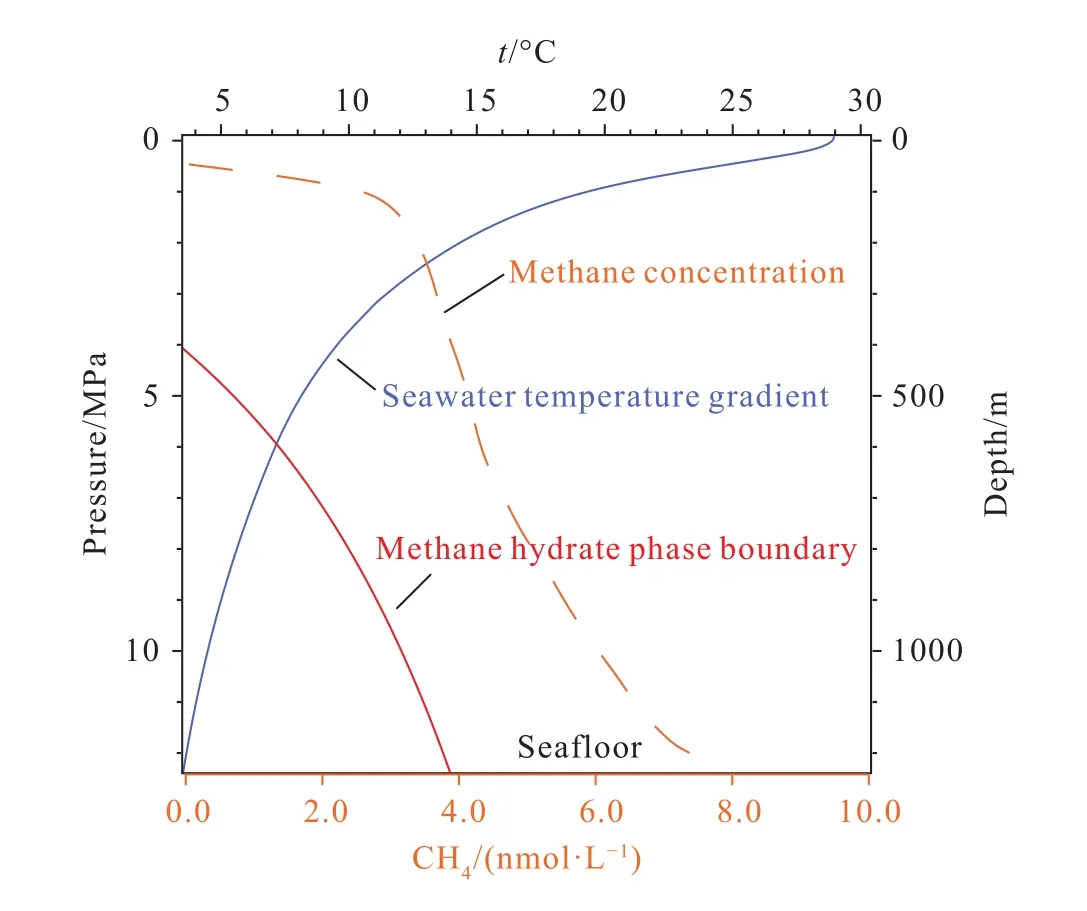

Methane microleakage has been observed on the seafloor of the Shenhu production test area, and the leaked methane does not reach the atmosphere (Liang QY et al., 2017). The equilibrium curve of NGHs in seawater (Fig. 7) indicates that methane leaking into seawater from seafloor firstly formed methane hydrates and then, at about 600 m depth (the upper stability limit of methane hydrates), methane hydrates completely decomposed, dissolved into water, and was consumed by microorganisms. The dissolved methane curve(Fig. 7) showed that the methane content decreased at shallower depths, and its content tended to 0 at about 50 m depth, with values lower than the detection limit of the methane sensor (1 nmol/L). This indicates that the methane leaking into seawater from the sediment hydrate zone is unlikely to reach the atmosphere.

Fig. 7. The phase diagram of NGH equilibrium in SCS (the solid green line indicated geothermal gradient in production test zone; the red solid line indicated the equilibrium line of methane hydrates in seawater; the blue solid line indicated the seawater temperature curve in production test zone; the red dotted line indicated the measured value of seawater dissolved methane content after production test,where specific values were shown in Table 3).

The hydrate formation conditions and reservoir pressure also determine that the NGH production test will not cause methane leakage on the seafloor. Unlike the shallow gas pressure, which is higher than the strata pressure in the seabed, the NGH formation pressure was basically consistent with hydrostatic pressure. After drilling and other artificial disturbances, the reservoir pressure recovered to the hydrostatic pressure in the formation. Thus, the NGH production test and drilling operation development will not cause disordered methane leakage.

5. Conclusions

During the NGH production test, the methane content in the downhole and overlying water layer surrounding the wellhead was equivalent to the background value. Only a small amount of methane overflowed when reservoir drilling was taking place during the completion stage, which indicates that most of the production test was safe and controllable without causing methane leakage.

The “four-in-one” monitoring system for atmosphere,seawater, seabed, and downhole was established to realize real-time monitoring and effective control of the entire process of the NGH production test. The integrated analysis of the data showed that the NGH production test was safe and controllable.

Given the limited environmental impact of the NGH production test, existing monitoring technologies may not be able to meet the needs of NGH development. The next step will be to increase the research and development of environmental monitoring equipment and technology, and to establish a real-time monitoring and early warning system to assist with providing advice and decisions for NGH exploitation.

Acknowledgments

The authors are grateful for the crew of all voyages on“HY IV” Ship and “HY VI” Ship for assistance in sampling and editor Hao ZG, Yang Y and anonymous reviewers for insightful comments on the manuscript. This work was financially supported by China National Project “Natural Gas Hydrate Exploration and Production Test” (Grant No.DD20160217), National Key R&D Project “Application of Environmental Monitoring Technology Demonstration” (No.2017YFC0307605) and Open Fund of Key Laboratory belong to Seabed Mineral Resources of Ministry of Land and Resources (No. KLMMR-2017-A-10).

- China Geology的其它文章

- Deep Continental Scientific Drilling Engineering Project in Songliao Basin: progress in Earth Science research

- Main technical innovations of Songke Well No.2 Drilling Project

- Episodic crustal growth in the Tanzania Craton: evidence from Nd isotope compositions

- Origin of natural sulfur-metal chimney in the Tangyin hydrothermal field, Okinawa Trough: constraints from rare earth element and sulfur isotopic compositions

- Exploration and research progress of shale gas in China

- Overview on hydrothermal and hot dry rock researches in China