福特公司工人住宅,科隆,德国

建筑设计:Archplan有限公司

Architect: Archplan GmbH

福特公司工人住宅,科隆,德国

建筑设计:Archplan有限公司

Architect: Archplan GmbH

"Fordsiedlung" der LEG, Cologne, Germany, 2010

1 鸟瞰/Aerial view

2 改造前/Before renovation

3 改造后/After renovation

4 外景/Exterior view

这片居民区在1950年代早期建成,是距该地3km远的福特工厂的工人住宅。住宅区南邻科隆市中心,位于一片发展完善的城市地段内。社区附近遍布古树的开放空间为居民提供了良好的活动场所。除了1970年代时建筑的木制窗框被更换为PVC窗框外,该住宅区自1950年代以来未经历过任何现代化改造。

整个社区由11个1950年代建成的公寓街块组成,总居住面积为14,211m2包含:300套平均47m2的公寓,每套公寓靠单个燃煤锅炉进行供暖;少数公寓有单独的微型阳台;卫生和电力系统都已经接近报废。要继续使用,这片住宅区必须接受全面更新或者被拆毁重建。

再开发项目的目的是将这片老旧住宅改造为一个现代化的、高度节能的居住小区。主要的目标包括:通过联通2~3套公寓来扩大目前过于局促的户型面积;为每套公寓提供阳台;减少公寓内的隔断;更新基础设施,包括所有卫生间;借助厨房花园、小活动场和聚会空间来营造更好的公共空间。

因为科隆无法为福特住宅内的居民提供300套临时居所,所以改造工程必须在不完全迁移居民的情况下开展。然而,每户居民都需要搬一次家,从旧房搬入一个改造后的新房。为了提高住房的市场价值,设计必须尽量增加住房的容积率。因此,所有房屋在3层的基础上被加盖为了4层(部分还被加建到了5层)。

这样一来,福特住宅区就在原来的300套住宅的基础上多出了6300m2的居住面积(81套新公寓),达到了20,500m2的总居住面积。新的产权持有者们获得了新的可灵活布置的居住公寓、宽敞的阳台和落地窗。

从节能的角度看,该项目也达到了相当可观的效果:高效的外墙、地下室和屋顶隔热;新装的吸热玻璃门窗;能量流失控制措施;每户加装了换气系统,顶层还加装了热回收系统;由冷凝式燃气技术和太阳能提供的暖气和热水,其中,真空太阳能板被安装在南向的屋顶上(1150m2); 45,000L储量的地板下能源中央存储池;供暖能耗减少85%;CO2排放量减少94%。

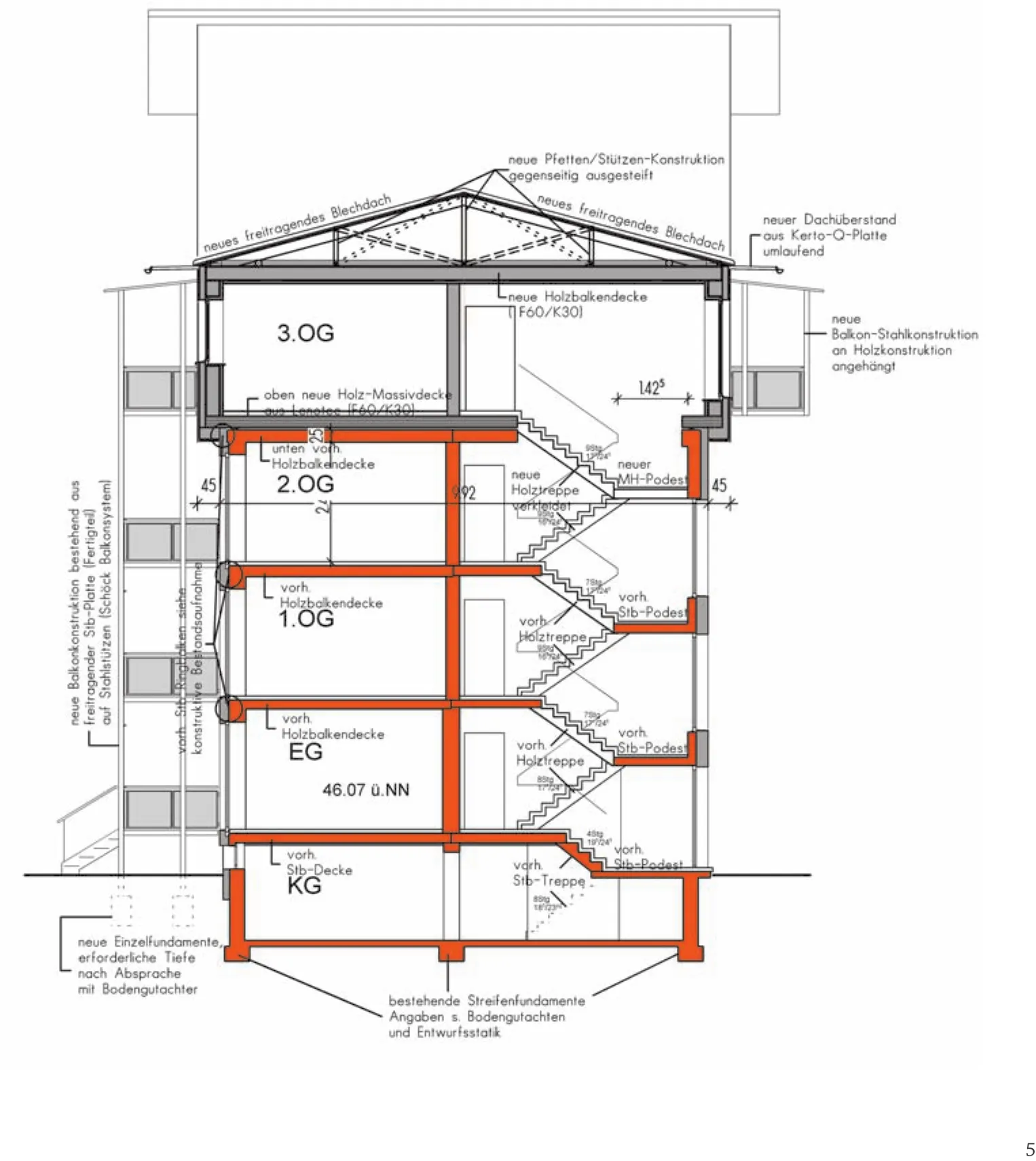

5 剖面/Section

对旧有建筑施工过程的调研发现,住宅楼的顶层屋顶无法承受额外的重量。因此,加建采用了交叉层接木结构方案。悬挑部分伸出原建筑屋顶45cm,不仅创造了一个1000m2的附加居住空间,还调和了新旧建筑之间的立面形式关系(其色彩设计受到了地中海风格的影响,为住宅区呈现出崭新的面貌)。预制的木结构框架在装配前就已经装有了窗户、室内饰面和两层室外抹灰。预制构件的最长边为12m。长80m的公寓街块用1周时间搭建完成,其间包含从拆除原有屋顶到完成木结构框架搭建的全部过程。

这样的施工方案还实现了旧有建筑改造与新加的四层体块加建的并行施工。在旧有建筑部分的施工结束之后,管道和基础设施才与加层部分相连接。因此,旧建筑的改造工程得以独立于加层的建造工程。

由于旧有建筑的顶层没有设置规则的楼梯交通,改造项目还为建筑加装了一个新的大型木制竖向交通系统。

除去室外设施的施工,11个街块的改造工程总共耗时18个月。□(张裕翔 译)

6 外景/Exterior view

7 五层平面渲染/Rendering flat 4th floor

8 建造中/Under construction

The settlement was built in the early fifties as workman's dwellings for the Ford factory which is only 3 km away. The estate is a grown urban quarter(in Cologne “Veedel”) at the northern gate to the city centre. The open space, with a number of old trees,provides space for activities of the neighbourhood residents. Since the 1950s nothing has been done or modernised except the replacement of wooden windows with PVC windows in the 70s.

The complex was made of 11 blocks of flats from the early 50s for 14,211m² of living area: in total 300 flats with an average of 47m² each, heated with single coal-burning stoves; only a few got mini balconies; the sanitary and the electric installations were obsolete. The complex had to be totally renovated or demolished and built anew.

The aim of developing the estate was to change the quarter into a modern, highly energy efficient housing estate. The main goals were: change very small flats into family flats by merging 3 to two flats; providing balconies; reduce barriers in the flats; renew the technical installations including all bathrooms; develop open space with kitchen gardens, playgrounds and meeting points.

As it was impossible in Cologne to find 300 alternate flats to move the residents, a renovation without moving the inhabitants totally to another area had been decided. The idea was that every resident had to move once, from the old flat to a renovated one. To increase the value of the object, the plot area had to be upgraded to a maximum of living space in proportion to the area of the property. The solution was the heightening of the 3-storey buildings by a 4th level (and a partial 5th floor).

So, more than 6300m² of living space (81 new flats) was added to the 300 existing flats, the total becomes more than 20,500m² area for habitation.New flexible flats for new stakeholders were created,as well as generous balconies and "French windows".

From the point of view of energy conservation,significance outputs have been achieved: highly efficient insulation of external walls, basement and top floor ceilings; new windows and doors with heat absorbing glass; reduction of energy loss; provision of air ventilation systems for each flat, with heat recovery in the top floor flats. Heating and warm water supply by gas condensing boiler technology and solar power comprised: installation of vacuum solar panels on south facing roofs (1150m²); central storage of energy of the solar panels in under floor tanks with 45,000L volume; reduction of heating energy demand by 85%;reduction of CO2emission by 94%.

As a result of the investigation of the construction of the existing buildings, it was found that the highest ceiling was not capable of withstanding additional load. The solution was a cross-laminated timber construction. Bridging the last ceiling with an overhang of 45cm. This overhang not only created 1,000m² additional living space, in relation to the level below, but also generated a solution for the changeover between the facade of the old and the new building parts(with colour design inspired by Mediterranean ambiance highlighting the new appearance of the estate). The prefabricated timber frame construction was delivered including the windows, the finished surface on the inside and the first two layers of plaster on the outside. It came to a maximum length of 12 metres. The whole construction for an 80m block of flats took about one week to erect, from the deconstruction of the roof to finishing the timber frame construction.

This construction method also allowed the renovation of the existing building without constant access to the fourth floor construction. Only when the renovation of the existing part of the building was finished, were the line sections (conduits)connected between the existing building and the new storey. So independent of the erection of the new storey, the renovation could be done.

As the last level of the existing building did not have a regular stairway, a new access in massive timber construction has been created.

The total construction time for all 11 blocks of flats took 18 months, excluding the outdoor facilities. □

项目信息/Credits and Data

业主/Client: LEG Wohnen NRW GmbH

建筑、结构工程、建筑工程物理、质量监管/Architects,Structural Engineering, Building Physics, Quality Assurance Management: Archplan有限公司/Archplan GmbH

建筑面积/Gross Floor Area: 25,600m²

造价/Cost: € 26,995,000

施工时间/Construction: 2008-2010

摄影/Photos: Archplan GmbH

9 施工图平面/The plan for detailed engineering